Promag Stargel HF 35 User guide

PROMAG

le macchine per il gelato

STARGEL HF 35

STARGEL HF 60

STARGEL HF 90

with R404A

USE AND MAINTENANCE

INSTRUCTION MANUAL FOR

WHIPPED-ICE-CREAM MACHINE

STARGEL

HF 60

STARGEL

HF 35 STARGEL

HF 90

09 - 2001

INSTRUCTIONS

FORTECHNICIAN-INSTALLER

STARGEL HF35/60/90 English TECHNICAN-INSTALLER

+

RESET

PROMAG

PROMAG

+

RESET

+

RESET

PROMAG

PROMAGSTARGEL HF 35 - HF 60 - HF 90

2

GB

The technical data for each machine model is

shown in the enclosed tables and on the data

plate located on the rear side of the machine.

This data is used as a reference when

performing inspections or checks.

Safemachineoperationisassuredbycorrectlyfollowingthe

instructionsgiveninthismanual.Therefore,wesuggestyoukeepthe

manual in a safe place where it can be readily consulted as required.

Manufacturer

This plate is an exact

copy of that located on

the rear side of the

machine, for this reason

the manual forms an

integral part of the

machine and must be

kept together with it.

PROMAG OTT

Via Emilia, 45/A

40011 Anzola Emilia

Bologna Italy

Tel. +39-051-6505358

Telefax +39-051-6505253

Bar code

A = air condensation

W = water condensation

PROMAG STARGEL HF 35 - HF 60 - HF 90

3

GB

A

page 7 / 46 INSTRUCTIONSFORUSER

B

INSTRUCTIONS FOR TECHNICIAN-INSTALLER

page 45/60

SPARE PARTS

page 61/71

PROMAGSTARGEL HF 35 - HF 60 - HF 90

4

GB

INTRODUCTION

This manual gives all assembly, operating and

maintenance instructions required for assuring

excellent operating results and a long machine

service life.

Before starting to use the machine,

read these instructions and follow them

very carefully.

Please do not hesitate to contact us for

any assistance you may require.

Failure to abide by the norms included in this

manual will invalidate the guarantee.

If the machine is sold or otherwise put

into another person's possession, ensure that the

manual accompanies the machine, therefore

allowing the new owner to correctly follow the

operating procedures and abide by the relative

precautions.

This machine is destined exclusively for the

pasteurization, maintenance and maturation of ice

cream mixtures.

Do not use this machine for any other use other

than that described above.

A similar use shall be considered improper.

This machine is designed to be used by adults.

Keep children away from the machine:

they should not be allowed to play with it.

Any attempt to modify this machine will not

only invalidate the guarantee but it will also be

extremely dangerous.

In order to assure efficient, correct machine

operation, carefully follow the manufacturer's

instructions and only allow professionally

qualified personnel to perform any necessary

maintenance.

Never try to repair the machine yourselves, as any

attempt to make repairs by non-competent

persons will not only be dangerous but may also

cause serious injuries.

In the case of a malfunction, contact the

distributor from whom the machine was bought.

He can give you the address of the Authorized

Service Centre closest to you.

Only use original spare parts for any necessary

replacements.

If you decide to no longer use the machine, we

advise you to cut the electrical cord so that it

cannot be used (after disconnecting the plug from

the power socket).

In addition:

- In no circumstances should the refrigerant

gas or compressor oil be allowed to escape and

thus contaminate the environment.

- See that the machine is disassembled and that

the parts are disposed of in accordance with the

national regulations in force.

This machine contains R404A. gas which could be

harmful to the environment in the case of incorrect

maintenance operations or disassembly.

Therefore, any such operations must be done in

accordance with the national regulations in force,

and must only be performed by authorized

maintenance personnel.

PROMAG reserves the right to make any and all

modifications it deems necessary in order to keep

the machine updated - technically or otherwise -

as well as to allow it to meet the requirements of

certain individual countries.

For any additional information or technical help

you may require, please contact your authorized

service centre.

PROMAG STARGEL HF 35 - HF 60 - HF 90

5

GB

This manual is made

up of three parts: Part B:

instructions and information for

the Technician - the Shipper

the Installer - the Maintenance Man the Repair Man

Part C:

electrical diagrams

and spare parts

Part A:

instructions and information for

the User and

the Technician-Installer

Copy of the conformity declaration found with the machine

The operating instructions form an integral part of the machine. - The machine user must not perform any of the operations described in

parts B and C; these must only be carried out by a qualified technician. - The user is therefore informed that if he attempts to do so he will

compromise the safety and health standards with which the machine is designed and built.

1) La ditta PROMAG, con la firma del suo delegato alla sicurezza del prodotto, dichiara sotto la propria esclusiva responsa-

bilità che la macchina:

2) The company PROMAG hereby declares under its own sole responsibility, through the signature of its product safety

manager, that the machine:

3) La société PROMAG, parla signature de son délégué à fa sécurité du produit, déclare sous sa propre et exclusive

responsabilité que la machine:

4) Die Firma PROMAG erklärt unter ihrer ausschließlichen Verantwortung mit der Unterschrift ihres Beauftragten für die

Produkt-Sicherheit, daß die Maschine:

5) Het bedrijf PROMAG verklaart hierbij uitsluitend op eigen verantwoordelijkheid, door middel van de handtekening van zijn

manager produktveiligheid, dat de machine:

6) La empresa PROMAG, mediante la firma de su encargado para la seguridad del producto, declara bajo su propia y

exclusiva responsabilidad que la máquina:

7) A firma PROMAG, com a assinatura do seu delegado para a segurança do produto, declara sob a própria e exclusiva

responsabilidade que a máquina:

8) Firmaet PROMAG erklærer hermed, gennem den produktsikkerhedsansvarliges underskrft og under eget ansvar, at

maskinen:

9) Yhtiö PROMAG vakuuttaa täten tuoteturvallisuudesta vastaavansa allekirjoittamana ja omalla vastuullaan, että kone:

10) Härmed intygar företaget PROMAG, genom underskrift av sin produktsäkerhetsansvarige och på eget ansvar,

att maskinen:

11) Firmaet PROMAG erklærer herved, ved den produktsikkerhetsansvarliges underskrift og under sitt eneansvar, at

maskinen:

STARGEL HF- 35/60/90 Matr..................

1) mantecatore orizzontale per la produzzione del gelato, è conforme ai requisiti essenziali previsti dalle Direttive CEE 89/

392, 91/368, 89/336, 73/23 e 93/68.

2) horizontal mixer for ice cream production, complies with the essential requirements indicated in EEC directive 89/392,

91/368, 89/336, 73/23 and 93/68.

3) machine horizontale pour le travail et pour la production de la glace, est conforme aux conditions requises essentielles

prévues par les directives CEE 89/392, 91/368, 89/336, 73/23 et 93/68.

4) Horizontal-Eismaschine für die Zubereitung von Speiseeis, den grundlegenden, von den EWG-Richtlinien 89/392, 91/

368, 89/336, 73/23 und 93/68 gestellten Anforderungen genügt.

5) horizontale mixer voor het bereiden van consumptieijs, voldoet aan de essentiële voorwaarden vervat in de EEG-

Richtlijnen 89/392, 91/368, 89/336, 73/23 en 93/68.

6) mantecador horizontal para la producción de helado, es conforme a los requisitos esenciales prevístos por las Directivas

CEE 89/392, 91/368, 89/336, 73/23y 93/68.

7) Batedeira horizontal para a produção de sorvete, é feita conforme os resuisitos principais previstos pelas Normas

CEE 89/392, 91/368, 89/336, 73/23 e 93/68.

8) horisontal mixer til is-fremstilling, overensstemmer med de væsentligste krav anført i EU direktiv 89/392, 91/368, 89/336,

73/23 og 93/68.

9) jäätelöntuotantoon käytettävä vaakasuora mikseri noudattaa EU direktiiveissä 89/392, 91/368, 89/336, 73/23 ja 93/68

ilmaistuja olennaisia vaatimuksia.

10) horisontal mixer för glassframställning uppfyller de väsentliga kraven i EU-direktiv 89/392, 91/368, 89/336, 73/23 och

93/68.

11) maskin for tilberedning og pasteurisering av deig-og iskremprodukter er i samsvar med de vesentligste krav angitt i EU-

direktiv 89/392, 91/368, 89/336, 73/23 og 93/68.

PROMAGSTARGEL HF 35 - HF 60 - HF 90

6

GB

INFORMATIONFORTHEUSERANDTECHNICIAN-INSTALLER

HELPFUL ADVICE

When manufacturing your products only use

the very best ingredients, in order to fully

satisfy even your most demanding customers.

Obtain all basic ingredients from well-established

firms that have a proven reliability.

When making your products follow the

instructions very carefully and do not try

to change the recipe in any way.

Always keep the machine spotlessly clean.

For all necessary repair work always contact one of PROMAG's assigned maintenance

firms.

If any of the operating, cleaning or maintenance instructions given in this manual are not

carefully followed, and an accident occurs, PROMAG cannot be held responsible.

General Information

Thank you for having chosen this machine.

Please read the instructions in this manual

carefully, they will assure long machine

service life.

We can guarantee that only the very best

materials have been used for this machine,

that it has been very carefully tested,

and that we are always ready to serve and

assist you in the best possible way.

IMPORTANT PRECAUTIONS

When the machine is being installed,

make sure that a disconnecting switch is

installed on the power supply line by a qualified

technician.

Always ensure that the plug is disconnected

from the mains before putting your hands inside

the machine or before performing cleaning or

maintenance operations.

(Contact a qualified technician whenever

maintenance is required).

Never clean the machine using a water jet

under pressure.

Always ensure that the plug is disconnected

from the mains before removing the housing,

side panels or any other protection in order to

carry out any operation within the inner part

of the machine.

(Such operations must only be performed by a

qualified technician)

Thanking you once again, we wish you all the best.

PROMAG STARGEL HF 35 - HF 60 - HF 90

7

GB

8

9

10

10

10

10

11

12

12/14

15

16

17

17/18

18/19

20

20

21

21

21

22/28

29/32

33

33

33/34

35

35

36

37/38

39

40

41

41/42

42

43

A 1

A 2

A 3

A 4

A 5

A 6

A 7

A 8

A 9

A 10

A 11

A 12

A 13

A 14

A 15

A 16

A 17

A 18

A 19

A 20

A 21

A 22

A 23

A 24

A 25

A 26

A 27

A 28

A 29

A 30

A 31

A 32

A 33

A 34

pag.

pag.

pag.

pag.

pag.

pag.

pag.

pag.

pag.

pag.

pag.

pag.

pag.

pag.

pag.

pag.

pag.

pag.

pag.

pag.

pag.

pag.

pag.

pag.

pag.

pag.

pag.

pag.

pag.

pag.

pag.

pag.

pag.

pag.

AINSTRUCTIONS FOR THE USER AND THE TECHNICIAN-INSTALLER

Environmental conditions

Machine description

Number of users and type of work

Production cycle

Operating modes

Precautions

Safety devices

Intended machine use

Description of external components

Description of internal components

Dangerous points on the machine

Protection measures for machine's dangerous points

Risk information

Special precautionary measures

Installation

Machine operation

Functioning

First method

Second method

First method

Second method

Ice cream consistency variation

Holding program

Programing of holding parameters

Grated-ice drink program

Grated-ice drink holding program

Parameter programing

Example of Grated-ice drink production

Stop modes and procedures

Important

Operations to be performed after use

Cleaning

Dismantling

Technical characteristics

PROMAGSTARGEL HF 35 - HF 60 - HF 90

8

GB

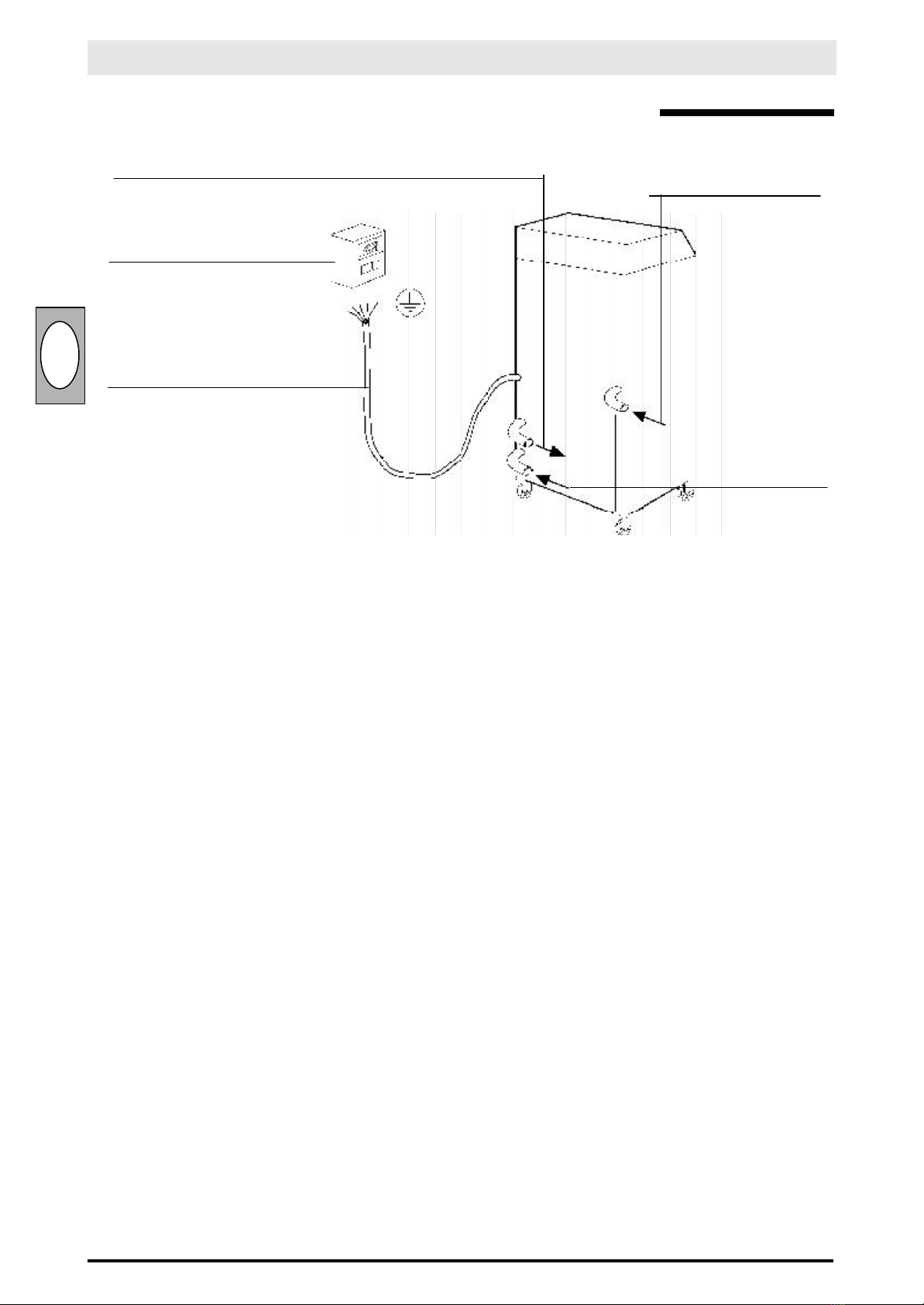

+

RESET

PROMAG

1 m.

50 cm

A 1.1

MACHINE OPERATING NOISE LEVELS

A 1 - ENVIRONMENTAL CONDITIONS

The machine must not be kept in a room where the temperature can drop below 0° C.

The machine is not designed for installation in atmospheres where there is a risk of explosion.

The acoustical pressure level produced by

the machine is shown on the enclosed

technical diagram.

Measyrements have been made as shown

in the drawing aside.

Instrument used: PHONOMETER BRUEL & KIAER

Kind: 2218 - 1613 N° 068110042

Total noise in the different functions

HF 35 Background (dBA)

Production (dBA)

Extraction (dBA)

Cleaning (dBA)

HF 60

HF 90

46

68

72

62

46

72

74

67,5

47

75

77

68

Background (dBA)

Production (dBA)

Extraction (dBA)

Cleaning (dBA)

Background (dBA)

Production (dBA)

Extraction (dBA)

Cleaning (dBA)

PROMAG STARGEL HF 35 - HF 60 - HF 90

9

GB

A 2 - MACHINE DESCRIPTION

Function:

MACHINE FOR MAKING WHIPPED ICE CREAM

See enclosure for machine technical data

Machine components

The machine has a main parallelepiped frame

made of stainless steel, the base of which is

provided with four wheels, one at each corner.

The machine's electrical motor, transmission

units, cooling circuit and whipped-ice-cream

cylinder are mounted inside the frame.

The whipped-ice-cream cylinder is mounted

horizontally and is provided with a cooling jacket

containing R404A refrigerant gas.

The outlet of the cylinder is located on the front of

the machine. The ice-cream whipping shaft ,

which is mounted horizontally inside the cylinder,

rotates by means of a worm reduction unit.

The cooling system consists of a piston

compressor, activated by an electric motor and

a water-cooled condenser.

As mentioned previously, the whipped-ice-cream

cylinder opening is located on the front of the

machine.

This opening has a hinged door (23) closure

which is provided with a mechanical lock.

A funnel (15), complete with cover, is located at

the top of the machine for feeding the mixture to

be whipped into the cylinder.

The door has a magnetic microswitch and an

opening which is closed by an element (17) which

permits ice-cream dispensing without having to

open the door.

On the front right of the machine there is a recess

which contains a small shower unit (25),

commanded by a tap (18), located on the left,

which can be used during machine washing

operations.

The electricalcabinet is also located inside

the main frame on the right-hand side of the

machine.

On the front of the machine, a stainless steel shelf

is located below the cylinder discharge nozzle for

holding the container being filled with ice cream.

The inlet water line connections for the cooling

system and cleaning shower are located on the

back of the machine.

PROMAGSTARGEL HF 35 - HF 60 - HF 90

10

GB

A 3 -NUMBER OF USERS AND TYPE OF WORK

The machine is designed for use by just one operator who loads the mixture to be whipped, sets the

production cycle and collects the produced ice cream.

A 6 - PRECAUTIONS

Danger points

The machine has certain danger points and areas

in which accidents can occur if the following

precautions are not observed.

- It is dangerous to access the machine's

whipped-ice-cream cylinder when it is turned

on and/or in motion.

- It is dangerous to carry out repairs on any

component or part of the machine, whether

mechanical or electrical, when the machine is

in operation.

Refer to the enclosures for the electrical and

hydraulic systems.

- Never leave the machine unattended while it

is operating.

- It is dangerous to put your hands or fingers or

any other object whatsoever between the vertical

bars in the cylinder or funnel cover opening.

- It is dangerous to try turning the machine on

or off at the wall switch with wet hands.

- Never, under any circumstances, access the

electrical box in any way.

- It is dangerous to bring magnetic material

of any kind close to the machine as this could

interfere with the magnetic safety microswitches

located on the upper front part of the machine.

(For the user only)

- It is dangerous to try doing any work on the

machine that should be done by a technician-

installer.

The removal of protective coverings, access to

the inner part of the machine, the carrying out of

any internal maintenance operations, repairs,

installation, shipping and unpacking

of the machine must only be done by qualified

personnel.

A5 - OPERATING MODES

The machine is designed so that once the

whipped-ice-cream button has been pressed the

machine operates uninterruptedly.

The machine stops automatically and the ten LED

come on together with an acoustic signal.

The machine can also be stopped by pressing the

normal stop button.

A 4 -PRODUCTION CYCLE

The user closes the cylinder discharge door and

pours the mixture to be whipped into the funnel.

The operator then puts the funnel cover in place,

sets the appropriate parameters and starts the

production cycle.

When the cycle has been completed, the operator

opens the door covering the cylinder outlet port

and presses the appropriate button to make the

whipping shaft turn at high speed and dispense

the ice cream.

If necessary, after the ice cream has been

dispensed, the cylinder should be cleaned before

proceeding with the subsequent production

cycles.

PROMAG STARGEL HF 35 - HF 60 - HF 90

11

GB

+

RESET

7

A7.1

- All STARGEL machines have a magnetic

microswitch located on the upper front part

of the machine.

Their aim is to interrupt all the functions of the

machine, in case he cylinder shutter should be

opened while the machine is working.

A7.2

There is a machine stop button (7) located on

the control panel at the front of the machine,

which interrupts all machine functions when

pressed.

A7.3

Appropriate protection is provided for cases

of power failure so that the machine does not

automatically start up again when power is

restored.

A7.4

The control panel has a 12 volt power supply.

A 7 - SAFETY DEVICES

45) Magnetic microswitch

PROMAGSTARGEL HF 35 - HF 60 - HF 90

12

GB

A 8 - INTENDED MACHINE USE

A9 -DESCRIPTION OFEXTERNALCOMPONENTS(frontview)

For use according to the norms

STARGEL machines are expressly designed for

the preparation of whipped-ice-cream and grated-

ice drinks on a non-industrial basis.

Use for any other purpose will not conform to

the norms.

The manufacturer cannot be held responsible for

any injury or damage resulting from improper

machine use.

Any risks will be borne entirely by the user.

The manufacturer's specified safety precautions

regarding machine operation and maintenance

must be observed.

The norms in force regarding accident prevention

and other recognized technical safety regulations

must also be observed.

Only properly trained and qualified personnel must

use, maintain or repair the machine.

Most of the machine is made of AISI - 304

stainless steel, of a thickness ranging from 10/10

to 35 mm, and plastic material of the kind used in

the food industry. (POM).

Any arbitrary modifications made to the machine

will completely exonerate the manufacturer from

any responsibility in the case of damage and/or

injury.

The machine must only be used with original

accessories and parts made by the manufacturer.

+

RESET

PROMAG

21) Rotating front wheels

16) Hinge

17) Ice cream/grated-ice drink

dispensing cock

15) Mixture loading funnel

18) Shower tap

20) Rubber drip mat

19) Ice cream/grated-ice

drink slide

25) Shower

24) Door

closing cam

23) Door

22) Funnel cover

29) Fixed rear wheels

30) Height adjustable shelf

Direction of the

rotation of the

whipping shaft

PROMAG STARGEL HF 35 - HF 60 - HF 90

13

GB

17) Ice cream/grated-ice drink dispensing cock

16) Hinge

54) Door hinge

50) Closing knob

51) Ice cream outlet

49) Rotating knob

9) Program variation

button to obtain a more

consistent product

8) Start button

4)Ice cream

program

selection

button (A)

5)Grated-ice drink program selection

button (B)7)Emergency stop

button

10)Grated-ice drink program

setting button

11)5 figure display

12) Led lights

13) Program variation button to obtain a

less consistent product

14)Whipped-ice-cream cycle start button,

with pre-mixing with compressor

disconnected

A 9 - DESCRIPTION OF EXTERNAL COMPONENTS (control panel)

1) Whipped-ice-cream/grated

ice drink cycle start button

(The direction of the rotation of is symbolic. The

whippingshaft turnsin acounterclockwis e direction)

2) Fast ice cream

dispensing button

3)Grated-ice

drink dispensing

button

6)Standard program reset button (A) or (B)

RESET

PROMAGSTARGEL HF 35 - HF 60 - HF 90

14

GB

A 9 -DESCRIPTIONOF EXTERNALCOMPONENTS (rearview)

30)

Disconnecting switch

31)

Electricalcable

32)

Cooling system

water inlet

48)

Drinkable water inlet for

shower

33)

Water outlet

In order to avoid mineral

deposits in the tubes and

condenser, caused by water

hardness, the installation of a

water softener is recommended.

PROMAG STARGEL HF 35 - HF 60 - HF 90

15

GB

InformativenotefortheuserwhichstrictlyconcernstheTechnician-Installer

A 10 DESCRIPTION OF INTERNAL COMPONENTS

A 10.1 Description of the internal components

47) Crown/worm reduction unit

43) Whipping shaft

electric motor

35) Electrical box

38) Water-cooled

condenser

42) Compressor

40) Humidity indicator

36) Pressure switch

37) Pressure control valve

44) Cylinder

39) Dehydrator filter

41) Electrovalve

PROMAGSTARGEL HF 35 - HF 60 - HF 90

16

GB

A 11 - DANGEROUS POINTS ON THE MACHINE

Definition of the dangerous areas, the type of danger and the general protection measures taken.

A11.1)

Danger of cuttin and

members in

movement

- In the mixture loading funnel

opening

- On the vertical bars in the door

A11.5)

Dangerous voltage:

- General electrical panel

- Motor compressor

- Motor

A11.3)

Dangerous pressure:

- Refrigeration circuit

under pressure

A11.2)

Danger of hot and cold parts:

- The refrigeration system

- The tube connecting the

compressor, condenser

A11.4)

Danger of clothes, fingers, etc.

getting caught and dragged by the

reduction gear pin connecting the

electrical motor and the whipping

shaft.

PROMAG STARGEL HF 35 - HF 60 - HF 90

17

GB

A 12 - PROTECTION PROVIDED FOR THE MACHINE'S DANGEROUS POINTS

The machine is provided with housing that

prevents access to the machine's interior and its

moving parts.

This housing is secured by means of screws and

should only be removed by qualified, authorized,

PROMAGpersonnel.

A 13 - INFORMATION REGARDING RISKS THAT CANNOT BE AVOIDED

NOTWITHSTANDING THE MEASURES ADOPTED BY THE DESIGNER

The residual risks involved in using the machine are as follows:

A 13.1

Danger of cuts

The mixture loading funnel (15) is welded to

the door of the machine.

The funnel (15) cannot be disassembled and

is protected by a welded grid to prevent,

as much as possible, access to the moving parts

of the whipping cylinder, while still allowing the

easy insertion of mixtures containing solid or

rather dense parts.

It is important to underline that the moving parts

of the whipping cylinder should Never be touched

with any object or part of the body,

as this could result in jamming,

crushing or chopping between the blades and the

fixed parts of the machine.

It is also dangerous to put any mixture pieces into

the funnel that have not been sufficiently reduced

in size, as this could cause the user to try forcing

large pieces using some object,

or worse still, their hands or fingers.

It is advisable to first cut all solid material into very

small pieces so that they will drop easily into the

cylinder without requiring pushing.

In an emergency press the STOP (7) button.

A danger risk is also present during cleaning

and the machine should be disconnected from the

mains before starting any such operation.

Furthermore it can be dangerous to not pay

enough attention when operating the machine as,

with practise, your movements can become

automatic and you can inadvertently make a

wrong move without realizing it.

A 13.2

Danger of cuts

There are vertical bars located in the opening (49)

in the lower part of the door.

This opening permits ice cream dispensing, the

vertical bars do not prevent the ice cream from

being dispensed and are designed to prevent, as

much as possible, access to the moving parts of

the whipping cylinder.

It is very important to underline that under no

circumstances should any object or hands and

fingers touch the moving parts of the whipping

cylinder, as this could cause the whipping shaft

and its blades to jam, crush and chop whatever is

inserted.

PROMAGSTARGEL HF 35 - HF 60 - HF 90

18

GB

A 14 - SPECIAL PREVENTION MEASURES THAT MUST BE TAKEN

A 14.1

Safety norms.

In order to ensure perfect machine operating

conditions and operator safety at all times,

it is recommended that the following norms

be carefully observed.

This machine must only be used for the purpose

for which it was designed.

Any other use is not only considered improper

but can also be dangerous.

During all shipping, loading, unloading and

handling operations, pay great attention to the

hoist points chosen.

Never leave the machine exposed to the weather

(rain, sun, etc.)

Do not allow children or incapable persons to use

the machine.

The machine must only be used by competently

trained persons.

Keep the machine in perfect working order, always

see that the various protective devices are in place,

and have regular periodic maintenance performed

by professionally qualified personnel.

Particular care must be taken to see that all safety

devices are periodically inspected to assure that

they are perfectly functional.

Before connecting the machine check that the data

stated on the data plate corresponds with that of

the electrical and hydraulic supply networks (the

data plate is located on the rear side of the

machine).

Ensure that the machine has been properly

grounded in accordance with the norms in force.

A 13.3 - Dangerous Pressure

The cooling system remains under pressure even

after the machine has been turned off.

Before carrying out any maintenance operations

on the cooling system, remove the pressure to

eliminate this risk .

The greatest danger exists when using the spatula

during ice-cream dispensing and container filling

operations.

The spatula must never be inserted between the

bars or forced perpendicularly against the cover

because, if your hand or the spatula is wet, your

hand may slip and even go as far as to strike the

bars and the moving parts of the whipping

cylinder.

PROMAG STARGEL HF 35 - HF 60 - HF 90

19

GB

Proper electrical grounding is absolutely

necessary.

In case of any doubt have the system inspected by

a professionally qualified electrician.

Check that the mains supply is adequate for the

power required by the machine.

If in any doubt, have the wire cross-section in

the mains inspected by a professionally qualified

electrician to see that it is sufficient for supplying

the required current.

Never touch the machine if your hands or feet are

wet or damp.

Never use the machine barefoot.

Never use extension leads in rooms with bath or

shower facilities.

Neverpulltheelectricalcabletodisconnectitfrom

the wall socket.

In order to prevent the electrical cable from

overheating, unwind it to its full length.

Before carrying out any maintenance

whatsoever, disconnect the machine from the

mains and turn off the main switch.

If the machine is operating badly or has a

malfunction, turn off the main switch.

Do not try to correct any condition or make any

repairs yourself, always call a professionally

qualified, authorized service man.

Any necessary repairs must be done by the

manufacturer or an authorized service centre, and

only original spare parts must be used.

Failure to observe the above precautions can

make the machine unsafe.

Never use water to put out a fire involving the

electrical components, only use a powder-type

extinguisher.

Never leave the machine plugged into the mains

when not in use.

Never modify the protection devices and never

remove them unless the machine is turned off

and disconnected from the mains.

If you decide to no longer use this type of

machine, disconnect it from the mains so that it

cannot be operated.

The drains must be able to withstand a

continuous temperature of 50° C.

When performing cleaning operations carefully

follow the instructions given in the manufacturer's

handbook.

Check that the air-flow grilles are free of any

obstruction.

Work on the control panel must only be carried

out by qualified personnel.

Before carrying out any such operation the

machine must be disconnected from the mains.

Before opening the door, turn off the machine

and wait at least 5 seconds to ensure that the

motor and whipping shaft have come to a

complete stop.

When cleaning the stainless steel parts, never use

steel wool, a wire brush or anything else that

could ruin the finish.

In order to avoid environmental pollution, we

recommend that you do not use corrosive or

contaminating products and do not exceed in

the doses.

PROMAGSTARGEL HF 35 - HF 60 - HF 90

20

GB

A 15 - INSTALLATION

A 16 - MACHINE OPERATION

A 16.1 START UP OPERATIONS

A 16.5 MACHINE PREPARATION

In order to provide sufficient air circulation,

ensure that there is at least 20 cm space

between the back of the machine and the

nearest wall.

The main switch must be turned on at least 5/6 hours

before beginning to use the machine, to allow the

motor-compressor resistance to heat up the oil in it

and thus avoid possible damage that can result from

starting-up cold.

cm 20

+

RESET

PROMAG

Secure the machine by setting the wheel brakes.

A 16.2

Open the water inlet tap.

A 16.3

Turn on the main switch which was

set up during the machine installation

phase.

A 16.4

The word "OFF"will appear on the display.

OFF

RESET

This manual suits for next models

2

Table of contents

Popular Ice Cream Maker manuals by other brands

Proficook

Proficook PC-ICM 1091 N instruction manual

Silvercrest

Silvercrest SECM 12 A1 operating instructions

Proficook

Proficook PC-ICM 1091 instruction manual

Ginnys

Ginnys 735160 instruction manual

Vollrath

Vollrath Stoelting O431I2F Operator's manual

Black & Decker

Black & Decker ARCTIC TWISTER IC200 Series Use and care book