2USER INSTRUCTIONS ................................................................................................................. 3

2.1 Introduction...................................................................................................................................................3

2.2 Typographical conventions.........................................................................................................................3

2.2.1 Bulleted Lists............................................................................................................................................3

2.2.2 Actions......................................................................................................................................................3

2.2.3 Numbers...................................................................................................................................................3

2.2.4 Parameters...............................................................................................................................................3

2.2.5 Directory paths .........................................................................................................................................3

2.2.6 ASCII code ...............................................................................................................................................4

2.2.7 Symbols....................................................................................................................................................4

2.3 Abbreviations................................................................................................................................................5

2.4 Copyright.......................................................................................................................................................6

2.5 Legal requirements.......................................................................................................................................6

2.6 Updates and upgrades .................................................................................................................................6

2.7 Trademarks....................................................................................................................................................6

3SAFETY......................................................................................................................................... 7

3.1 Intended use..................................................................................................................................................7

3.2 General safety notes.....................................................................................................................................7

3.2.1 General safety information.......................................................................................................................7

3.2.2 Electrical safety notes ..............................................................................................................................8

3.2.3 Safety notes for assembly........................................................................................................................8

3.2.4 Safety notes for operation ........................................................................................................................8

3.2.5 Conformity................................................................................................................................................8

3.2.6 Repairs.....................................................................................................................................................8

3.2.7 Maintenance.............................................................................................................................................9

3.3 Disposal...................................................................................................................................................... 11

4PRODUCT DESCRIPTION.......................................................................................................... 12

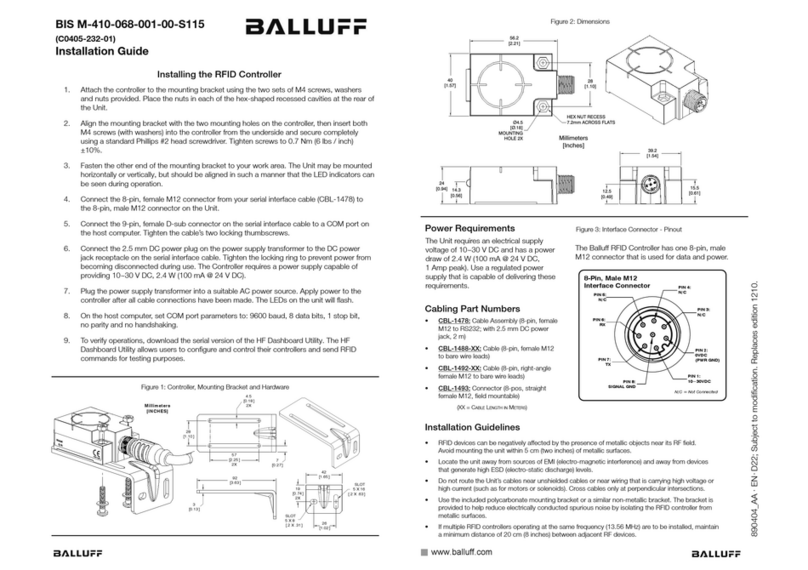

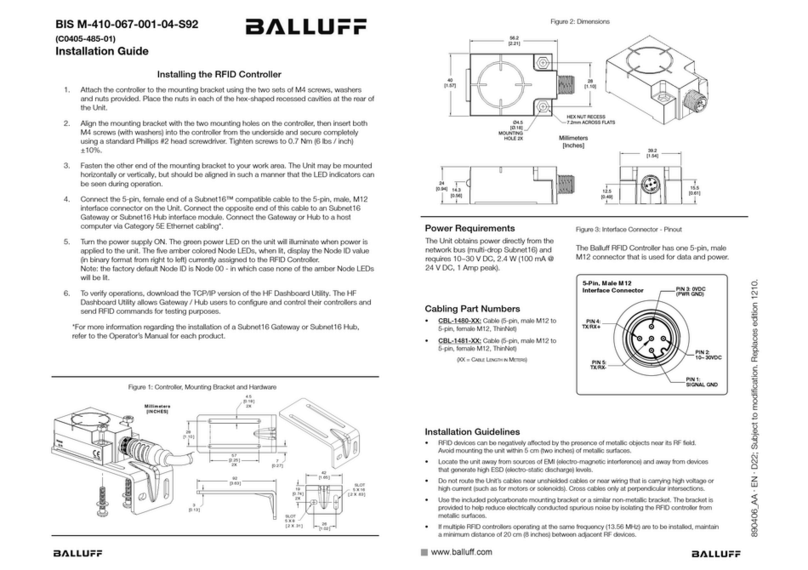

4.1 Product variants......................................................................................................................................... 12

4.2 Scope of delivery....................................................................................................................................... 13

4.2.1 Transport............................................................................................................................................... 14

4.2.2 Unpack and check supply unit............................................................................................................... 14

4.2.3 Identification data of the device............................................................................................................. 14

4.2.4 Ambient and environmental conditions ................................................................................................. 15

4.3 Wall mount.................................................................................................................................................. 16

4.3.1 Mounting via mounting bracket ............................................................................................................. 16

4.3.2 Mounting via profile rail (only if the rail is pre-assembled).................................................................... 17

4.3.3 Installation of the device with wall-mounting kit .................................................................................... 18

4.4 Product specification ................................................................................................................................ 19

4.4.1 Mechanical data .................................................................................................................................... 19

4.4.2 Electrical data........................................................................................................................................ 20

4.4.3 Operating conditions ............................................................................................................................. 20

4.5 Connections and control elements.......................................................................................................... 21

4.6 Display elements........................................................................................................................................ 22

4.6.1 Status LED ............................................................................................................................................ 22

4.6.2 Gigabit Ethernet Status LED................................................................................................................. 22

4.6.3 Cleaning ................................................................................................................................................ 23

5FIRST STEPS.............................................................................................................................. 24

5.1 Step 1: Establishing a network connection with the Balluff SmartVision Controller......................... 24

5.2 Step 2: Switching on the Balluff SmartVision Controller ...................................................................... 24

5.2.1 Connecting the DC power supply (19-28 V) via terminal clamp ........................................................... 24