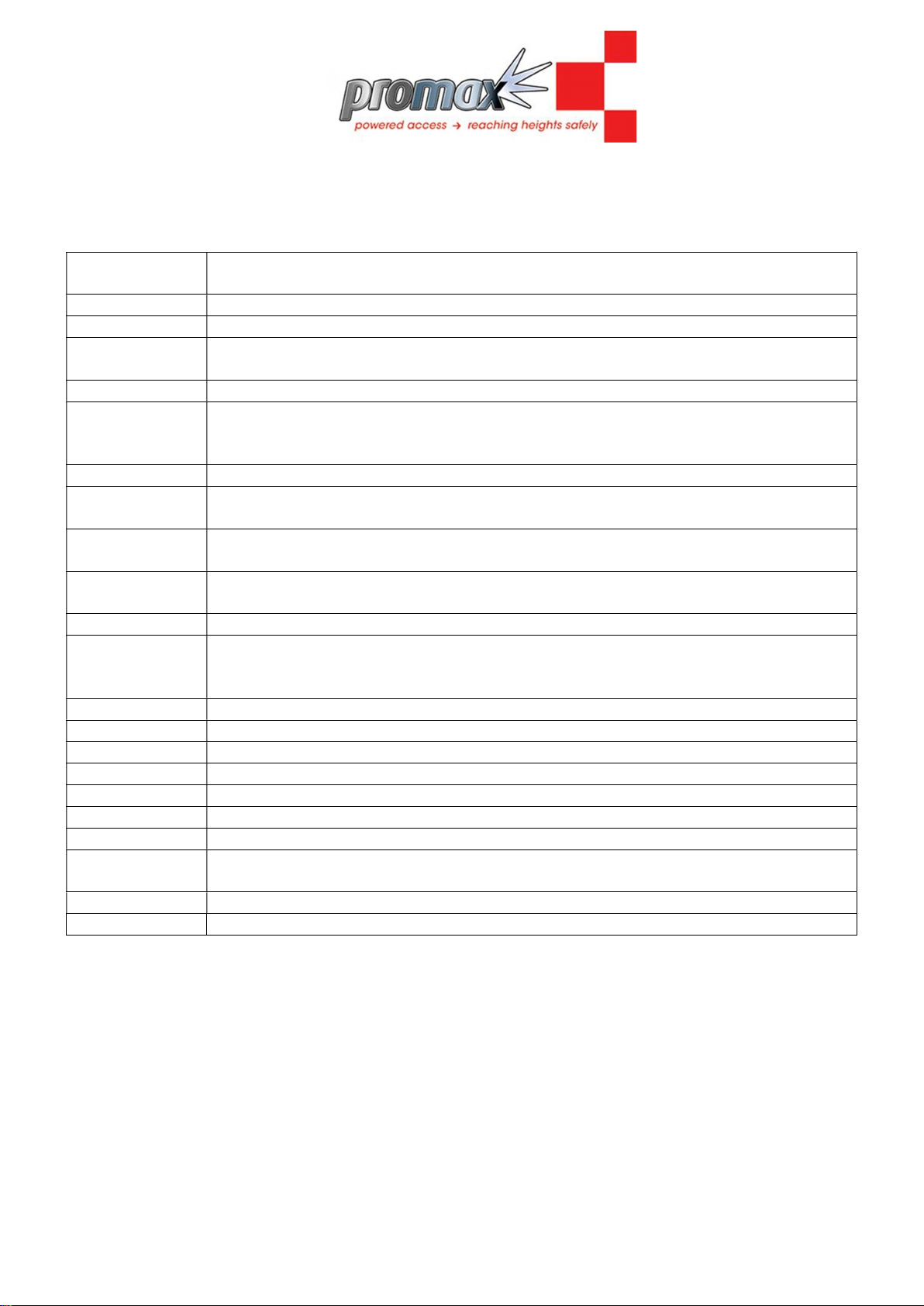

PAMP020RR Revision Record

Revision 2 Page 4 of 73

December 2019 RR 14 EVO 2 400 Hybrid

Contents

Section 1 ........................................................................................................................................................................... 6

Foreword ...................................................................................................................................................................... 6

Staff Competency ......................................................................................................................................................... 7

Facilities ........................................................................................................................................................................ 7

Definitions .................................................................................................................................................................... 8

Section 2 ........................................................................................................................................................................... 9

Introduction.................................................................................................................................................................. 9

Section 3 .........................................................................................................................................................................10

Specifications..............................................................................................................................................................10

Section 4 .........................................................................................................................................................................10

General Safety and Operating Good practice ............................................................................................................10

Section 5 .........................................................................................................................................................................10

Controls, layout and locations ....................................................................................................................................10

Section 6 .........................................................................................................................................................................10

Devices, locations and descriptions ...........................................................................................................................10

Section 7 .........................................................................................................................................................................11

Electrical Circuit and Hydraulic Diagrams ..................................................................................................................11

Fuses / electrical trips.................................................................................................................................................11

Electric Circuit Diagrams ............................................................................................................................................12

Hydraulic Circuit Diagrams .........................................................................................................................................46

Section 8 .........................................................................................................................................................................47

ALO Working procedure .............................................................................................................................................47

Section 9 .........................................................................................................................................................................48

Emergency recovery procedure(s) and times ............................................................................................................48

Recovering aerial parts into gauge (travelling mode)............................................................................................48

Off tracking machine from rail using RRAP ............................................................................................................48

Section 10 .......................................................................................................................................................................49

Maintenance ..............................................................................................................................................................49

Safe Working Practice ............................................................................................................................................49

Warning – Fluids ....................................................................................................................................................49

Warning-Hydraulic Connections ............................................................................................................................49

Hydraulic Hoses .....................................................................................................................................................49

Warning - Batteries ................................................................................................................................................49

Warning - Welding .................................................................................................................................................50

Threaded Fasteners ...............................................................................................................................................50

Tightening of Threaded Fasteners .........................................................................................................................50