©Parker Hannifin GmbH Pat-Parker-Platz 1 41564 Kaarst

Tel.:

+49

2131

4016-0

Fax:

+49

2131

4016-9199

E-Mail: park[email protected] Web: www.olaer.de Stand 06/14

doc 6.140

Page 2 von 2

Assembly

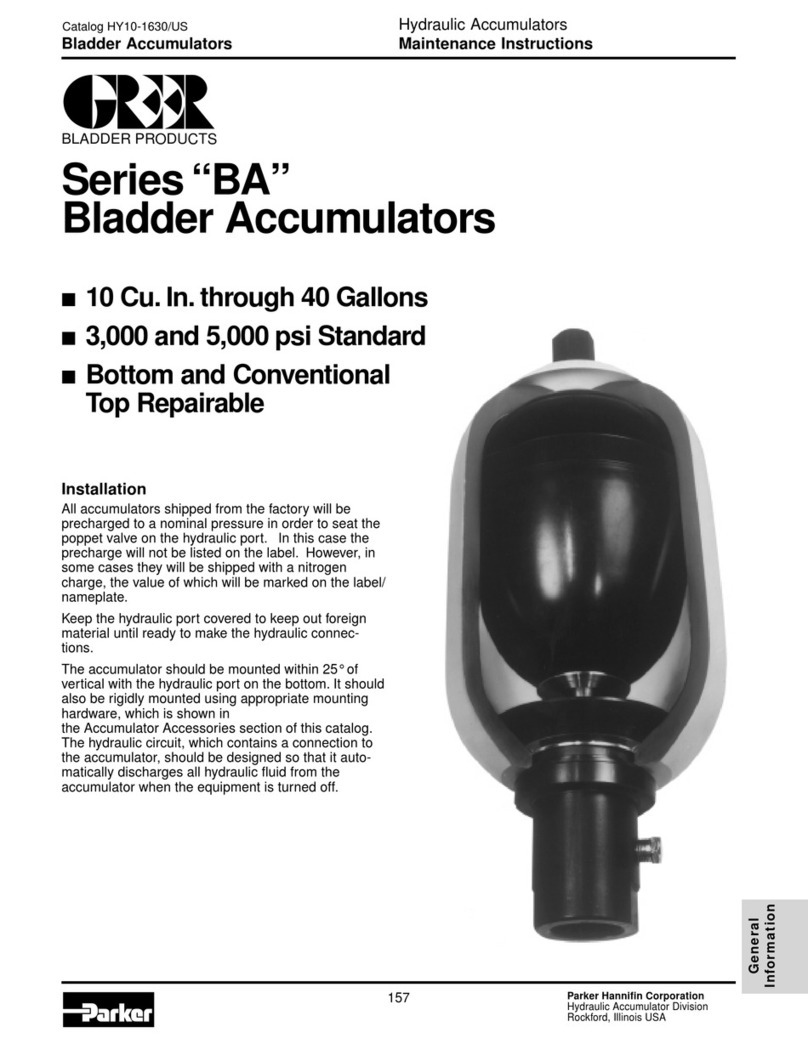

Ensure that no foreign bodies are in the

accumulator.

To facilitate the reassembling of

bladder, smear it and vessel interior

with the system hydraulic fluid.

Press the upper part of the bladder

together and feed in though the

hydraulic end opening

(Fig. 7)

.

Lightly screw the name plate and gas

inlet valve sub-assembly nut on

(Fig. 8).

Check that the bladder is either folded

or twisted.

Insert the grid into the accumulator

shell until it reaches its stop

(Fig. 9).

Reinstall the spring ring

(Fig. 10).

Before mounting the reduction on the

hydraulic end, inflate the bladder slowly

with nitrogen to a pressure of 1 - 1,5

bar with the tester and pressurizer

instrument. Operate the tester and

pressurizer instrument as described in

its manual

(Fig. 11).

Mount the venting screw (not used with

every model) and gasket.

Tighten the name plate and gas inlet

valve sub-assembly nut fully

(Fig. 12).

Inflate the accumulator to the

precharge pressure required by the

system.

Fig. 8

Fig. 9

Fig. 10

Fig. 12

Fig. 11

First operation

Please note doc 6.120!

Before pressurizing the system, vent via the venting

screw if used. Retighten the screw carefully as soon

as the hydraulic fluid has left the vessel finally.

No welding/soldering or mechanical operations of

any kind must be undertaken on the accumulator!

Hydropneumatic accumulators are subject to official

pressure vessel regulations. These regulations

demands that the accumulator must be inspected

on a regular basis. The interval between inspections

varies from state to state.

Request the appertaining intervals for your

operation from the authorities responsible.