promesstec UDA 50-U Series User manual

Device features:

•red display from -1999...9999 digits (optional: green, orange oder blue)

•digit height 10 mm

•display adjustment via factory settings or directly at the sensor signal possible

•min/max memory

•5 parameterizable support points

•display flashes when limit value is exceeded / limit value undershot

•tara-function

•sliding averaging

•two semiconductor switching points galvanically not separated

•programming lock via code entry

•protection class IP65 front side

•pluggable screw clamp

•accessories: PC-based configuration software with CD and USB adapter

user manual UDA 50-…-U

promesstec GmbH

Niedersachsenstraße 4

D –48465 Schüttorf

Fon: +49 (0)25923 / 90229-0

Fax: +49 (0)25923 / 90229-29

www.promesstec.com

version 2.1.1UDA 50-…U…promesstec GmbH

Identification

STANDARD-TYPE ORDER NUMBER

UDA 50-5-U-0 99-003648

Dimension symbols are to be specified on request when ordering, e.g. mbar

Content

1. Short description 1

2. Assembly 2

3. Elektrical connection and connection examples 3

3.1. Pin assignment 3

3.2. Connection examples 3

3.2.1. Voltage / Current 3

3.2.2. Pt100 / Pt1000 / thermocouple 6

3.2.3. Frequency / Rotational speed 7

3.2.4. Counter 10

3.3. Switching points 11

connection examples

4. Functional description and operation 13

4.1. Operation and display elements 13

4.2. Programming software PM-TOOL 14

5. Setting the display 14

5.1.Switch on

6. Parameterization 15

6.1. Selection of the input signal, Type 15

6.1.1. Voltage / Current, Volt, AMPE 16

Setting the end and start value, End, Enda, offs, offa 17

Setting the decimal point, Dot.A 17

Zero point calming of the input signal,zero 17

Tare value, tara 17

Over/underflow behavior,over 17

Input of support points for linearization of the measurement signal,spc.A 18

6.1.2. Pt100, Pt1000, thermocouple, pt.se, ther 19

Temperature display in °C/°F,unit 19

Line adaptation,offs 19

6.1.3. Impulse measurement, impu 20

6.1.3.1. Frequency, freq 20

Impuls actuation,i.typ 21

Frequency range,rang 21

Filter,filt 22

Setting the end and start value,end,endf,offs,offf 22

Setting the decimal point, dot.F 22

Tare value,tara 22

Input of support points for linearization of the measurement signal, spc.F 22

6.1.3.2. Rotational speed, turn 23

Impuls actuation, i.typ 23

Filter,filt 24

Impuls per revolution,ppt 24

Time base,time 24

Setting the decimal point,dot 24

Content 6.1.3.3. Up/down counter, Co.up, Co.dn 25

Impuls actuation, i.typ 25

Counter base / impuls signal,co.ba 26

Flank, edge 26

Prescale,pres 26

Display end value and impulse count end value, end,end.c 26

6.2. General display parameters 27

Setting the measuring time, sec 27

Setting the floating average, glm 27

Start/end value representation in the display,di.hi,di.lo 27

Assigning functions to the direction keys,tast 27

Display flashes when limit value is undershot/exceeded, flas 27

6.3. Alarm parameters 28

Limit value behavior, a1.fu, a2.fu 29

Message in case of limit value error, a1.er, A2.er 29

Switching behavior of the outputs, a1.ty, A2.ty 29

Setting the switching threshold, a1.li,a2.li 29

Setting the hysteresis, a1.hy, a2.hy 29

Upper limit, a1.lo, a2.lo 30

Lower limit, a1.hi, a2.hi 30

Dropout delay, a1.of, a2.of 30

Pick-up delay, a1.on, a2.on 30

6.4. Backup parameter for locking the parameterization 30

Assignment of an individual numerical code, Code 30

Activation/deactivation of the programming lock, run 30

7. Reset to default values 30

Resetting the parameters to the delivery state

8. Technical data 31

9. Safety instructions 34

10. Troubleshooting 35

1

1. Short description

1. Short description

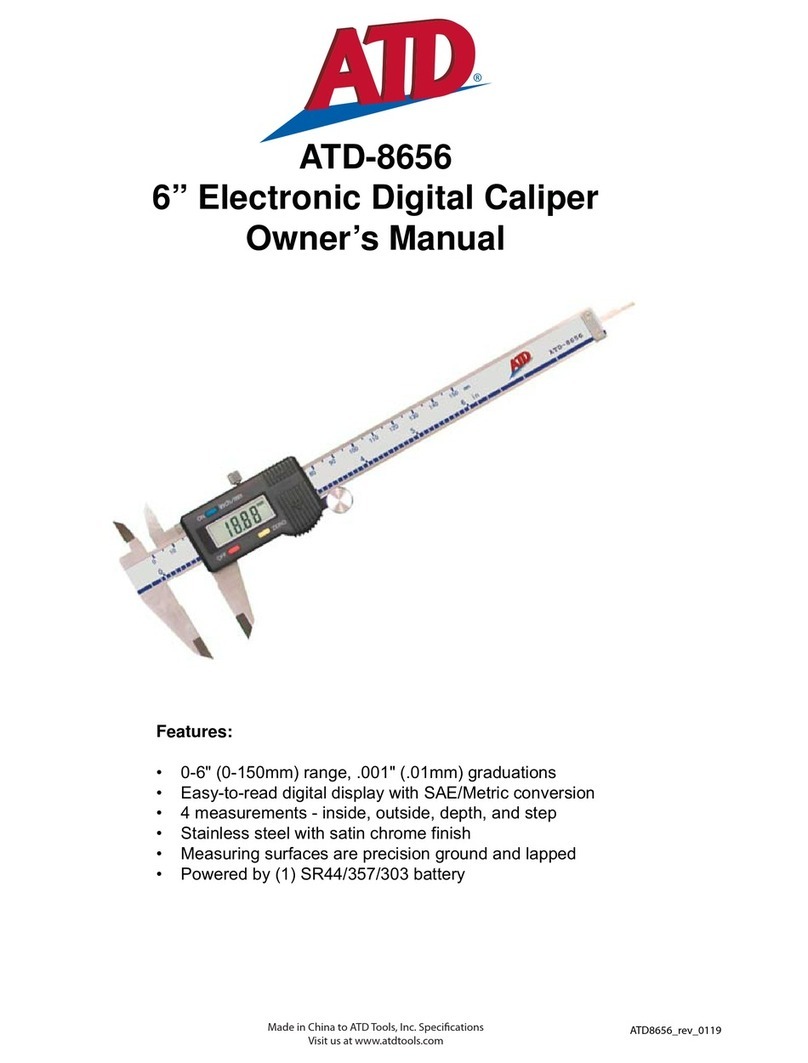

The switch panel meter UDA 50...-U... is a 4-digit digital display for measuring various measuring

signals such as voltage/current, temperature and frequency. The configuration is done via 3 front

keys or by means of an optional PC software PM-TOOL. An integrated programming lock

prevents unwanted changes to parameters and can be unlocked again via an individual code.

With the 2 integrated semiconductor switching points, limit values can be monitored and reported

to a higher-level control room. The electrical connection is made at the rear via plug-in clamps.

Selectable functions such as min/max value query, tare function, averaging, direct limit value

adjustment in operating mode and additional measuring support points for linearization of the

measuring input meet the requirements of measurement and control technology.

2. Assembly

2

2. Assembly

Please read the safety instructions on page 34 before assembly and keep these instructions for

future reference.

1. After removing the fasteners, insert the device.

2. Check seal for good fit.

3. Re-engage fastening elements and tighten clamping screws by hand. Then tighten further by

half a turn with the screwdriver..

ATTENTION! Torque should not exceed max. 0.1 Nm!

3. Electrical connection

3

3. Electrical connection

3.2. Connection examples

In the following you will find some connection examples in which practical applications are

shown:

3.2.1. Current / Voltage

2-wire sensor 4-20 mA

3.1. Pin assignment

Type UDA 50...-U... - Supply 9-28 VDC, galvanically not isolated

Note:

Clamps 3, 5 and 7 are

electrically connected in the

device.

+

9-28 VDC

1 VA

<

_

10V,PNP(HTL)

GND,Pt100(0)

50mV,TC,Pt100,Reset

1V,2V,mA,Frequenz,Pt100(0)

9 8 7 6 5 4 3 2 1

_

Signaleingänge Spannungs-

versorgung Halbleiter-

ausgänge

Schaltpunkt1

Schaltpunkt2

GND

Schaltpunkte

4-20 mA

_ +

9-28 VDC

9 8 7 6 5 4 3 2 1

Signal

GND S2 S1

4

3. Electrical connection

2-wire sensor 4-20 mA with external power supply

3-wire sensor 0/4-20 mA

3-wire sensor 0/4-20 mA with external power supply

Schaltpunkte

0/4-20 mA

_ +

9-28 VDC

9 8 7 6 5 4 3 2 1

Signal

GND S2 S1

_

+

0/4-20 mA

_

+

Transmitter-

versorgung

Schaltpunkte

9 8 7 6 5 4 3 2 1

GND S2 S1

_ +

9-28 VDC

Signal

Schaltpunkte

9 8 7 6 5 4 3 2 1

GND S2 S1

_ +

9-28 VDC0/4-20 mA

_

+

Transmitter-

versorgung

Signal

5

3. Electrical connection

3-wire sensor 0-1/2…10 V

3-wire sensor 0-1/2…10 V with external power supply

4-wire sensor 0-1/2…10 V, 50 mV

4-wire sensor 0-1/2…10 V, 50 mV with external power supply

Schaltpunkte

0-1/2...10 V

_ +

9-28 VDC

9 8 7 6 5 4 3 2 1

Signal

GND S2 S1

_

+

10 V1/2 V

Schaltpunkte

0-1/2...10 V, 50 mV

_ +

9-28 VDC

9 8 7 6 5 4 3 2 1

Signal

GND S2 S1

_

+

10V

1/2V 50mV

0-1/2...10 V

_

Transmitter-

versorgung

Schaltpunkte

9 8 7 6 5 4 3 2 1

GND S2 S1

_ +

9-28 VDC

Signal

1/2 V 10 V

_

+

0-1/2...10 V,

50 mV Transmitter-

versorgung

Schaltpunkte

9 8 7 6 5 4 3 2 1

GND S2 S1

_ +

9-28 VDC

Signal

1/2 V 10 V

50 mV

_

_

+

6

3. Electrical connection

Pt100 3-wire

Pt1000 2-wire

3.2.2. Temperature

Thermocouple

Schaltpunkte

9 8 7 6 5 4 3 2 1

GND S2 S1

_ +

9-28 VDC

Pt100

Schaltpunkte

9 8 7 6 5 4 3 2 1

GND S2 S1

_ +

9-28 VDC

Pt1000

Schaltpunkte

9 8 7 6 5 4 3 2 1

GND S2 S1

_ +

9-28 VDCTC

+ _

7

3. electrical connection

Encoder with TTL output

Encoder with external power supply and TTL output

3.2.3. Frequency / Rotational speed

Encoder with PNP output

Schaltpunkte

9 8 7 6 5 4 3 2 1

GND S2 S1

_ +

9-28 VDC

IN

TTL

Geber Versorgung

_ +

Schaltpunkte

9 8 7 6 5 4 3 2 1

GND S2 S1

_ +

9-28 VDC

IN

PNP

Geber Versorgung

_ +

Schaltpunkte

9 8 7 6 5 4 3 2 1

GND S2 S1

_ +

9-28 VDC

IN

TTL

Geber Versorgung

_ +

_

+

Geber-

versorgung

8

3. electrical connection

Encoder with ext. power supply and PNP output

Encoder with NPN-output

Encoder with ext. power supply and NPN-output

Schaltpunkte

9 8 7 6 5 4 3 2 1

GND S2 S1

_ +

9-28 VDC

IN

PNP

Geber Versorgung

_ +

_

+

Geber-

versorgung

NPN

Schaltpunkte

9 8 7 6 5 4 3 2 1

GND S2 S1

_ +

9-28 VDC

IN

Geber Versorgung

_ +

Schaltpunkte

9 8 7 6 5 4 3 2 1

GND S2 S1

_ +

9-28 VDC

IN

Versorgung

_ +

_

+

Geber-

versorgung

NPN

Geber

9

3. electrical connection

Encoder with NPN-output and required external resistance

Encoder with external power supply, NPN-output and required external resistance

Encoder with PNP-output and external resistance circuit

NPN

Schaltpunkte

9 8 7 6 5 4 3 2 1

GND S2 S1

_ +

9-28 VDC

IN

Geber Spannungs-

versorgung

_ +

RV

PNP

Schaltpunkte

9 8 7 6 5 4 3 2 1

GND S2 S1

_ +

9-28 VDC

IN

Geber Spannungs-

versorgung

_

+

RV1

RV2

Schaltpunkte

9 8 7 6 5 4 3 2 1

GND S2 S1

_ +

9-28 VDC

IN

Spannungs-

versorgung

_ +

_

+

Geber-

versorgung

NPN

Geber

RV

10

3. electrical connection

Encoder with external supply, PNP-output and external resistance circuit

Schaltpunkte

9 8 7 6 5 4 3 2 1

GND S2 S1

_ +

9-28 VDC

Spannungs-

versorgung

+

Geber-

versorgung

RV1

PNP

Geber

_

+

RV2

_

IN

Encoder with external supply and namur output

Schaltpunkte

98 7 6 5 4 3 2 1

GND S2 S1

_ +

9-28 VDC

Versorgung

_

+

Namur

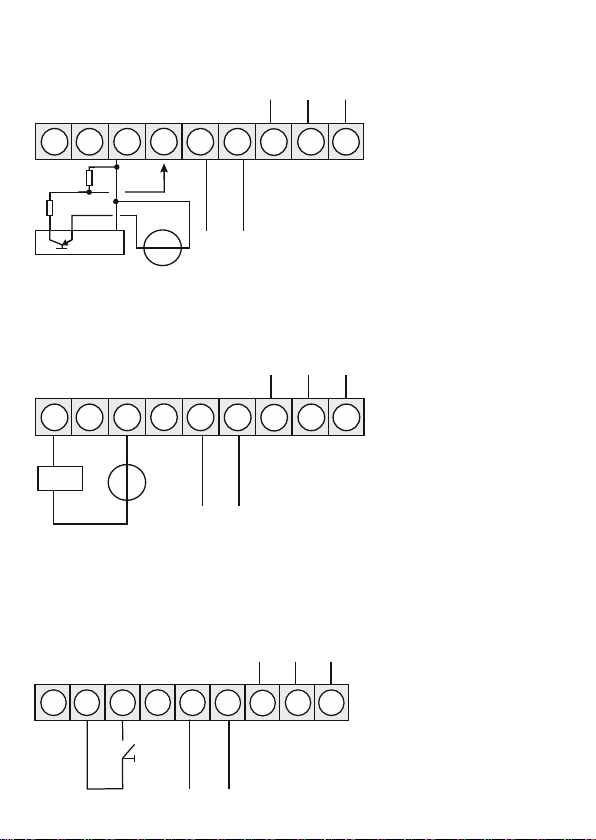

3.2.4. Counter

When used as a counter, use the connection examples for Frequency/Rotation and the reset

input executed below.

Manual reset with external button

Schaltpunkte

9 8 7 6 5 4 3 2 1

GND S2 S1

_ +

9-28 VDC

Reset

11

3. electrical connection

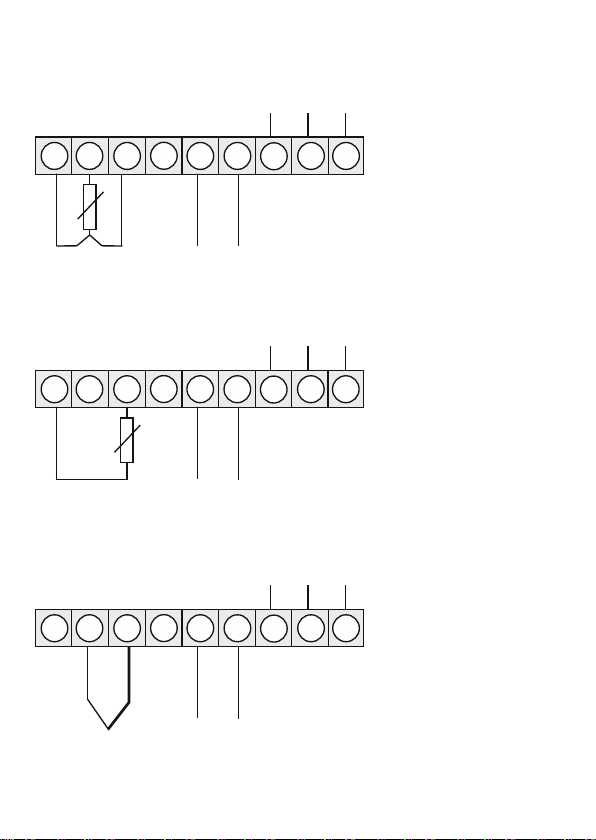

3.3. Switching points

Connection examples

NPN-output GND switching

GND

S2S1

_ +

9-28 VDC

Relais

X

9 8 7 6 5 4 3 2 1

Automatic reset with output 2 and manual reset with external button

Schaltpunkte

9 8 7 6 5 4 3 2 1

GND S2 S1

Reset

12

3. electrical connection

PNP-output L+-switching

9 8 7 6 5 4 3 2 1

_ +

9-28 VDC

XRL

__

L+

Push-Pull-output UV and GND-switching

98 7 6 5 4 3 2 1

_ +

9-28 VDC

_

L+

IN1

IN2

L+

GND

SPS

GND

_

_ _

13

4. Functional description and operation

Key symbol Function in operating mode Function during parameterization

Program key [P] The program key [P] is used to

switch to parameterization. Change to a lower parameter level or

to the stored value.

Minus key [▼]

The minus key [▼] can be used

to call up the min value or change

a lower limit value, depending on

the key function set.

Switching between parameters and

changing parameters in the value

level.

Plus key [▲]

The plus key [▲] can be used to

call up the max value or change a

lower limit value, depending on

the key function set.

Switching between parameters and

changing parameters in the value

level.

4. Functional description and operation

4.1. Operating and display elements

The display has 3 keys with which you can parameterize the device and call up stored functions

during operation. Functions that can be adjusted or changed are always signaled with a flashing

of the display. The settings made in the parameter level are always confirmed with [P] and thus

saved. However, the display also automatically saves all adjustments and switches to operating

mode if there are no further key operations within 10 seconds.

A switched on relay or an activated switching point is visually signaled by a lighting of the

respective switching point LED next to the 7-segment display.

A display overflow/underflow is indicated by 4 bars "- - - -".

Numerical values are adjusted from the smallest to the largest digit with [▲] [▼]and confirmed

digit-selectively with [P]. A minus sign can only be parameterized on the most significant digit.

After the last digit, the display switches back to the menu level.

Example: Setting of device parameters, e.g. selection of input signal

Parameter Selection option

Example: Setting numerical values, e.g. measuring range end value

14

4. Functional description and operation / 5. Setting the display

4.2. Programming via configuration software PM-TOOL:

Part including the software on CD, is a USB cable with device adapter. The connection is

established via a 4-pin micromatch connector on the back of the device and to the PC side with a

USB connector.

System requirements: PC with USB interface

Software: Windows XP, Windows VISTA

With this tool the device configuration can be generated, omitted and saved on the PC. Through

the easy-to-use program interface, the parameters can be changed, whereby the mode of

operation and the possible selection options are specified by the program.

ATTENTION!

When setting parameters with a measuring signal connected, make sure that the measuring

signal does not have a ground reference to the programming plug.

The programming adapter is not galvanically isolated and is directly connected to the PC.

Reversing the polarity of the input signal can cause a current to flow through the adapter and

destroy the device and connected components!

5.1. Switch on

After completing the installation, you can put the device into operation by applying the supply

voltage. Before doing so, check all electrical connections once again to ensure that they are

correctly connected.

Start sequence

During the switch-on procedure, the segment test (8 8 8 8), the message of the software type and

afterwards for the same time the software version are displayed for 1 second. The start sequence

is followed by the change to the operating or display mode.

5. Setting the display

15

6.1. Input signal selection: type

With the type setting an assignment of the input variant takes place, here can be selected

between the five input types voltage, current, Pt100(0), thermocouple and impulse signal.

6. Parameterization

6. Parameterization

Measurement signal

selection

Measuring signal

Special

parameters

General display

parameters

Alarm parameters

Safety

parameters

Voltage

see page 15-18

Power

see page 15-18

Pt100(0)

see page 19

Thermocouple

see page 19

Impulse input

see page 20-22

Measuring time, moving averaging, start/end

value representation in the display, key function,

display flashing

see page 27

Limit value behavior, limit value message,

switching behavior, switching threshold,

hysteresis, delay

see page 28-30

Locking / releasing the parameterization

see page 30

16

Parameter Selection option Default

VoLt

AMPE

6. Parameterization

6.1.1. Device parameters for the assignment of voltage/current signals: VoLT, AMPE

VoLT: Four voltage signals are available for selection : 0-10 V, 0-2 V, 0-1 V and 0-50 mV

AMPE: Here you can choose between the following signals : 0-20 mA and 4-20 mA

Parameter Selection option Default

End to

at or additional

OFFS to

at or additional

dot.A to

EndA to

OFFA to

tArA to

ZErO to

OUEr

This manual suits for next models

2

Table of contents

Other promesstec Measuring Instrument manuals