Promotech PRO 5 PB User manual

Contents

1. GENERAL INFORMATION............................................................................................... 3

1.1. Application................................................................................................................. 3

1.2. Technical data............................................................................................................ 3

1.3. Equipment included ................................................................................................... 5

1.4. Design ....................................................................................................................... 6

2. SAFETY PRECAUTIONS.................................................................................................. 7

3. STARTUP AND OPERATION........................................................................................... 9

3.1. Installing the jaw blocks and tool bits ......................................................................... 9

3.2. Installing (removing) the mandrel and adjusting the clearance..................................10

3.3. Installing the motor....................................................................................................11

3.4. Clamping the machine into the pipe..........................................................................12

3.5. Preparing the air (for machine with air motor) ...........................................................13

3.6. Operating..................................................................................................................13

3.7. Troubleshooting the electric motor............................................................................15

3.8. Troubleshooting the cordless electric motor..............................................................15

3.9. Replacing the spindle disk ........................................................................................16

3.10. Facing and bevelling at the same time....................................................................17

4. ACCESSORIES...............................................................................................................18

4.1. Tool bits for carbon steel...........................................................................................18

4.2. Tool bits for stainless steel........................................................................................20

4.3. Cutting fluid...............................................................................................................21

4.4. Electric motor............................................................................................................21

4.5. Electric motor attachment set....................................................................................21

4.6. Air motor...................................................................................................................22

4.7. Air preparation unit....................................................................................................22

4.8. 75 mm spindle disk...................................................................................................22

4.9. 140 mm spindle disk set............................................................................................23

4.10. Ratchet wrench.......................................................................................................24

4.11. Small expanding mandrel........................................................................................25

4.12. Cordless electric motor............................................................................................25

4.13. Cordless electric motor attachment set ...................................................................26

4.14. 5.2 Ah battery..........................................................................................................26

4.15. Battery charger .......................................................................................................26

5. DECLARATIONS OF CONFORMITY...............................................................................27

6. QUALITY CERTIFICATE..................................................................................................30

7. WARRANTY CARD..........................................................................................................31

PRO 5 PB/PBE/PBC

This document is protected by copyrights.

Copying, using, or distributing without permission of PROMOTECH is prohibited.

3

1. GENERAL INFORMATION

1.1. Application

The PRO 5PB / PBE / PBC is apipe bevelling machine designed to mill edges of pipes

made of carbon and stainless steel, aluminum alloys, and copper-nickels. Depending

on the tool bit used, the machine can perform external bevelling, J-bevelling, internal

calibration, and facing pipes from inside diameters of 32 mm (1.26’’) to outside

diameters of 114 mm (4.49’’). Up to three tool bits can be installed at the same time.

When equipped with an optional 140 mm spindle disk set the machine can bevel

pipes with outside diameters up to 140 mm, and using an optional 75 mm spindle disk,

ratchet wrench, or both, will facilitate working in places hard to reach. An optional small

expanding mandrel will allow machining pipes with internal diameters from 25 mm to

33 mm (0.98–1.30’’).

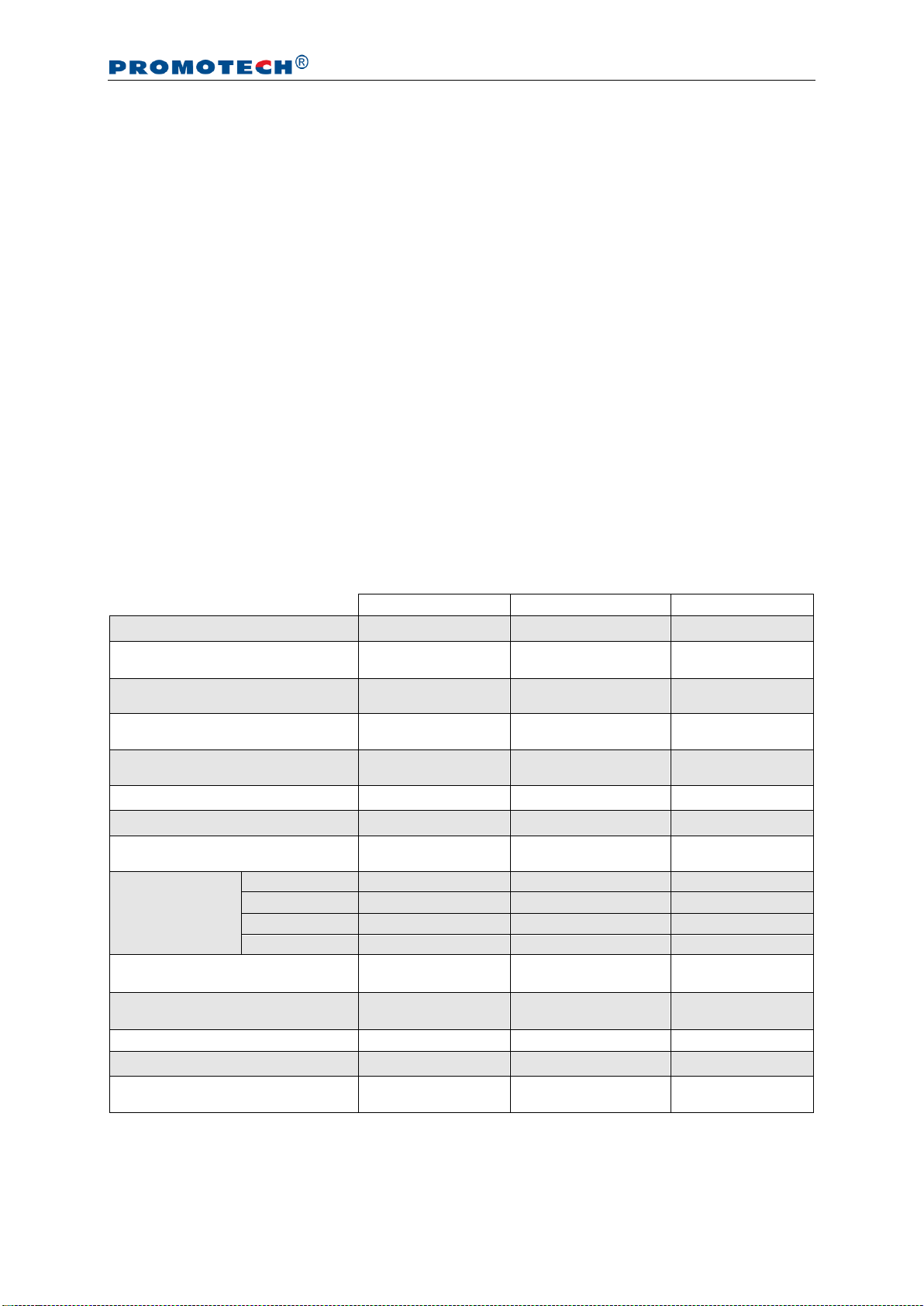

1.2. Technical data

PRO 5 PB

PRO 5 PBE

PRO 5 PBC

Pressure

0.6 MPa (87 psi)

–

–

Voltage

–

1~ 110–120 V, 50–60 Hz

1~ 220–240 V, 50–60 Hz

18 V DC, 5.2 Ah

Air motor

Modec

NT10RT0851FCA1F-CO

–

–

Electric motor

–

Metabo BE1100

Metabo BS 18 LTX

Impuls

Connection

CEJN 410 DN 10.4

R 1/2’’ BSPT coupling

Electrical plug

Battery connection

Air consumption

1400 Nl/min (50 CFM)

–

–

Power

800 W

1100 W

–

Pipe diameter

32 mm ID to 114 mm

OD (1.26–4.49’’)

32 mm ID to 114 mm

OD (1.26–4.49’’)

32 mm ID to 114 mm

OD (1.26–4.49’’)

Maximum pipe

wall thickness for

outside diameter

up to 114mm

12 mm (0.47’’)

12 mm (0.47’’)

12 mm (0.47’’)

114–124mm*

10 mm (0.39’’)

10 mm (0.39’’)

10 mm (0.39’’)

124–132mm*

8 mm (0.31’’)

8 mm (0.31’’)

8 mm (0.31’’)

132–140mm*

6 mm (0.24’’)

6 mm (0.24’’)

6 mm (0.24’’)

Rotational speed without load

180 rpm

–

0–50 rpm (gear 1)

0–180 rpm (gear 2)

Nominal rotational speed

90 rpm

0–90 rpm (gear 1)

0–300 rpm (gear 2)

–

Protection class

–

II

–

Required ambient temperature

0–40°C (34–104°F)

0–40°C (34–104°F)

0–40°C (34–104°F)

Weight with motor

10 kg (22 lbs)

11 kg (24 lbs)

10 kg (22 lbs),

includes battery

* Available with the optional 140 mm spindle disk set.

PRO 5 PB/PBE/PBC

This document is protected by copyrights.

Copying, using, or distributing without permission of PROMOTECH is prohibited.

4

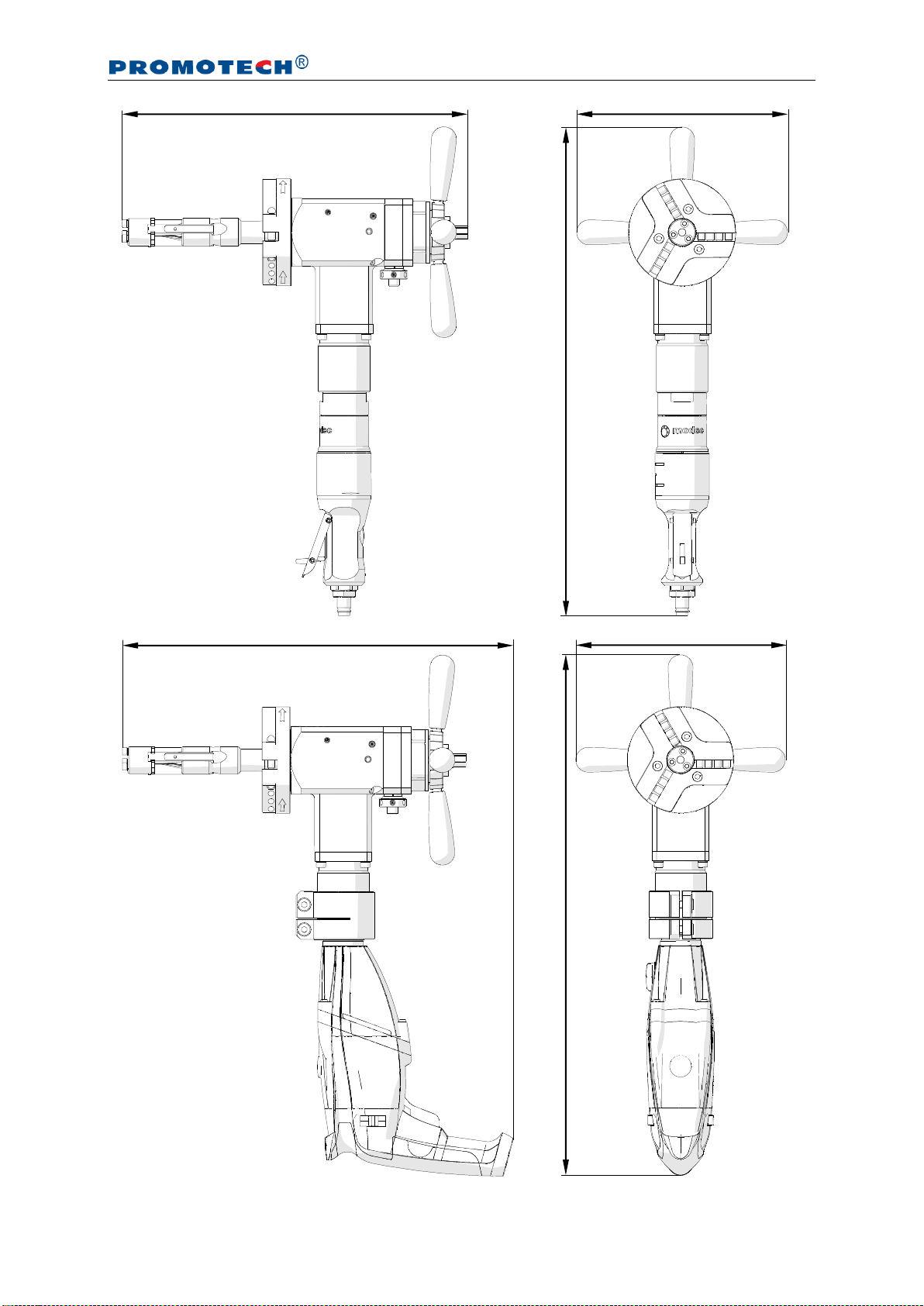

380 mm (15’’)

232 mm (9’’)

539 mm (21’’)

577 mm (23’’)

433 mm (17’’)

232 mm (9’’)

PRO 5 PB/PBE/PBC

This document is protected by copyrights.

Copying, using, or distributing without permission of PROMOTECH is prohibited.

5

1.3. Equipment included

The machine is supplied including the following elements.

Bevelling machine (without tool bits)

1 unit

Metal box

1 unit

Expanding mandrel

1 unit

118 mm spindle disk

1 unit

Jaw blocks (number 1, 2, 3, 4, 5, 6)

3 sets

Coolant container

1 unit

Tool container

1 unit

13 mm socket wrench

1 unit

6 mm hex wrench

1 unit

5 mm hex wrench

1 unit

4 mm hex wrench with handle

1 unit

3 mm hex wrench with ball end

1 unit

Operator’s Manual

1 unit

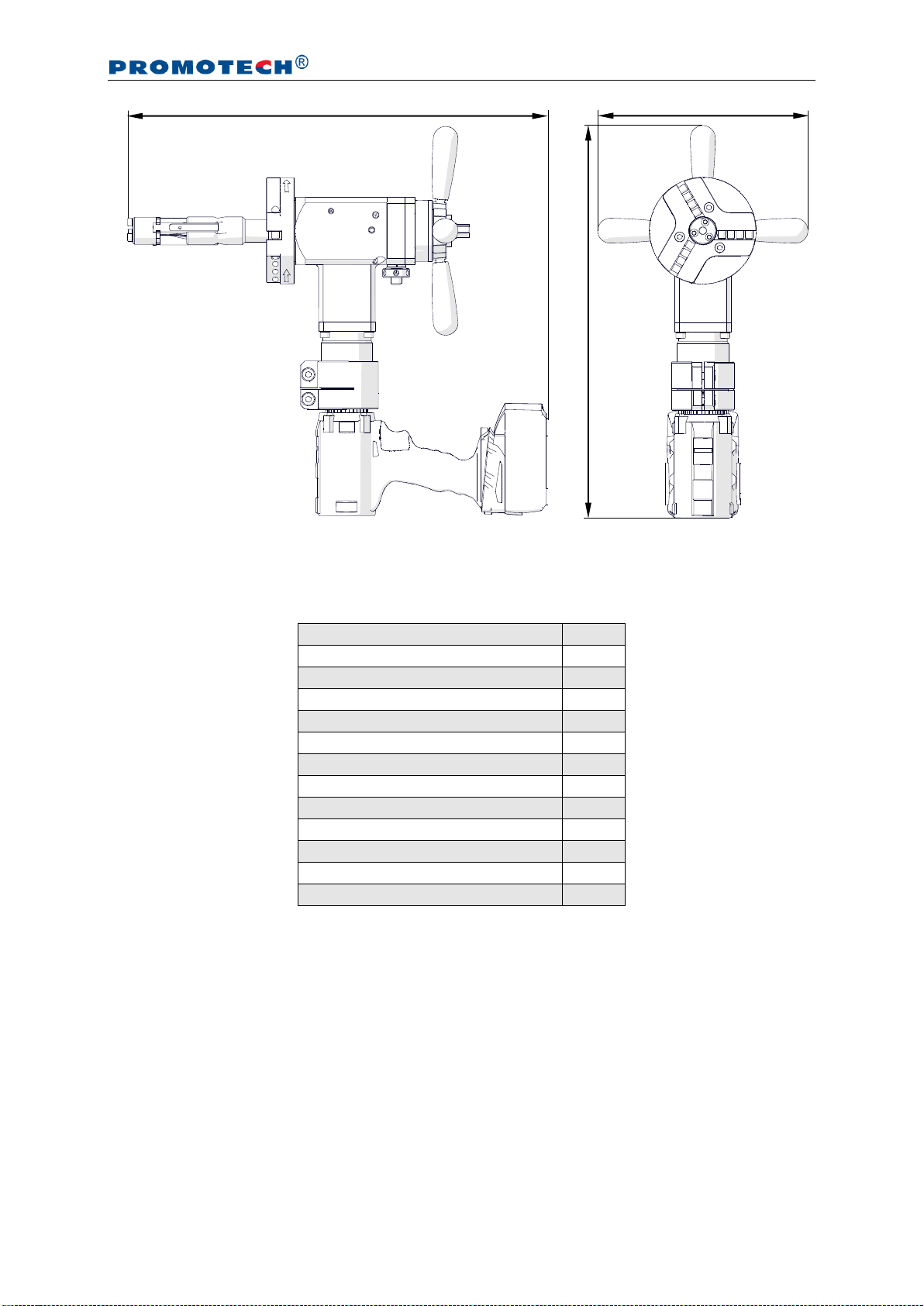

434 mm (17’’)

468 mm (18.4’’)

232 mm (9’’)

PRO 5 PB/PBE/PBC

This document is protected by copyrights.

Copying, using, or distributing without permission of PROMOTECH is prohibited.

6

1.4. Design

Fig. 1. View of PRO 5 PB and of PBE electric motor and PBC cordless electric motor

Spoke handle

Clearance

adjustment

unit

Expanding mandrel

Spindle disk

Air motor

ON/OFF lever

Air connection

Draw nut

Feed

indicator

ON switch lock

ON/OFF switch

Rotation direction switch

(must be set as shown)

Gear switch

Speed adjustment dial / LED

Rotation direction switch

(must be set as shown)

ON/OFF switch

with speed adjustment

Gear switch

Torque adjustment dial

Battery

LED activation button

LED

PRO 5 PB/PBE/PBC

This document is protected by copyrights.

Copying, using, or distributing without permission of PROMOTECH is prohibited.

7

2. SAFETY PRECAUTIONS

1. Before beginning, read this Operator’s Manual and complete proper occupational

safety and health training.

2. Use only the air (electric) motor specified in the technical data.

3. Use the machine only in applications specified in this Operator’s Manual.

4. The machine must be complete and all parts must be genuine and fully operational.

5. The specifications of the air (power) source must conform to those specified on the

rating plate.

6. Supply the machine with air motor only with clean and lubricated air. The air source

must be equipped with a filter, regulator, and lubricator.

7. Never pull the hose (cord) because this may damage it and result in serious injury.

8. Untrained bystanders must not be present near the machine.

9. Before beginning, check the condition of the machine, air (power) source, supply

hose (power cord, battery), coupling (plug), control components, and tool bits.

10. Avoid unintentional starts. Do not lay the machine so that the motor will start and

never carry the machine with air motor by using the ON/OFF lever.

11. Keep the machine dry and never expose it to rain, snow, or frost.

12. Keep the work area well lit, clean, and free of obstacles.

13. Neveruse machinenearflammable liquids orgases, or in explosive environments.

14. Secure the pipe to prevent it from falling or rolling.

15. Use only tool bits specified in this Operator’s Manual.

16. Never use tool bits that are dull or damaged.

17. Install tool bits securely. Remove adjusting keys and wrenches from the work

area before connecting the machine to the air (power) source.

18. Before every use, inspect the machine to ensure it is not damaged. Check whether

any part is cracked or improperly fitted. Make sure to maintain proper conditions

that may affect the operation of the machine.

19. Always use eye and hearing protection, protective footwear, and protective clothing

during operation. Do not wear loose clothing.

20. Operate the machine with an electric motor only when the rotation direction switch

is set to the position shown in Fig. 1. Using left rotation (rotation direction switch

set to the opposite position) may damage the machine.

PRO 5 PB/PBE/PBC

This document is protected by copyrights.

Copying, using, or distributing without permission of PROMOTECH is prohibited.

8

21. Do not touch moving parts or metal chips formed during milling. Prevent objects

from being caught in moving parts.

22. After every use, remove metal chips and excess coolant from the machine. Never

remove chips with bare hands. Clean the machine with a cotton cloth without

using any agents.

23. Cover steel parts with a thin anti-corrosion coating to protect the machine from

rust when not in use for any extended period.

24. Maintain the machine and install/remove parts and tool bits only when the machine

is unplugged from the air (power) source.

25. Repair only in a service center appointed by the seller.

26. If the machine falls from any height, is wet, or has any other damage that could

affect the technical state of the machine, stop the operation and immediately

send the machine to the service center for inspection and repair.

27. Never leave the machine unattended during operation.

28. Remove from the worksite and store in a secure and dry location when not in use,

previously removing the tool bits from sockets.

PRO 5 PB/PBE/PBC

This document is protected by copyrights.

Copying, using, or distributing without permission of PROMOTECH is prohibited.

9

3. STARTUP AND OPERATION

3.1. Installing the jaw blocks and tool bits

Use the following table to select jaw blocks suitable to the diameter of the pipe to be

machined.

Pipe inside diameter

Jaw blocks

number

[mm]

[inch]

32–43.5

1.26–1.71

–

43–55

1.69–2.17

1

54–66.2

2.13–2.61

2

64.7–76.9

2.55–3.03

3

74.9–87.1

2.95–3.43

4

85.2–97.4

3.35–3.83

5

94.8–107

3.73–4.21

6

Use the 3 mm hex wrench to join the jaw blocks to the expanding mandrel (1, Fig. 2).

Then, select up to three tool bits suitable to planned use, and place them in the

sockets, with blades directed according to the rotation direction 2. Next, tighten each

tool bit with two of the screws 3with the 4 mm hex wrench. The entire pressing

surface of the screw must be in full contact with the tool bit.

Fig. 2. Installing the jaw blocks and tool bits

1

2

3

PRO 5 PB/PBE/PBC

This document is protected by copyrights.

Copying, using, or distributing without permission of PROMOTECH is prohibited.

10

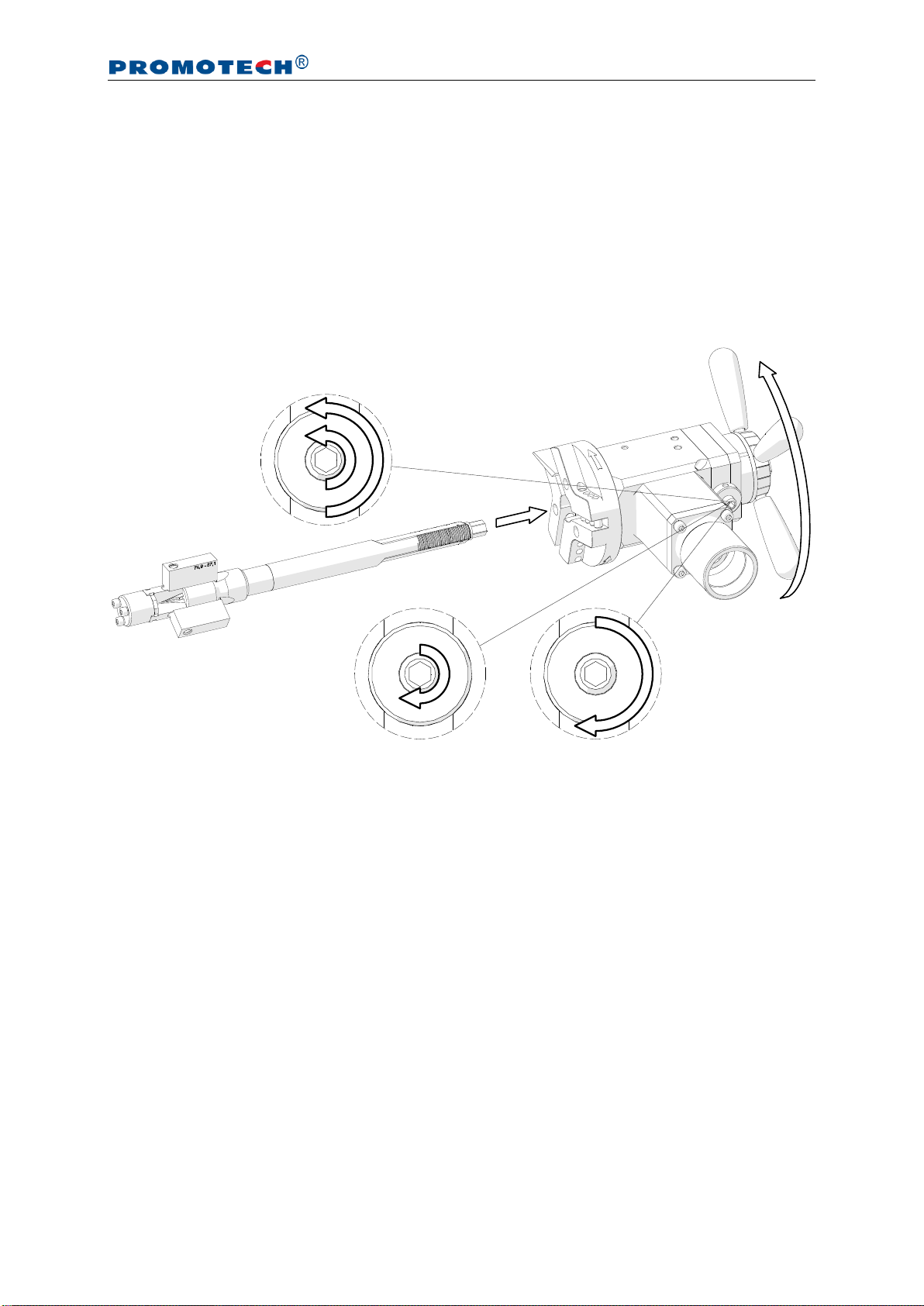

3.2. Installing (removing) the mandrel and adjusting the clearance

Loosen the nut and use the 6 mm hex wrench to loosen the set screw (1, Fig. 3), and

insert the mandrel into the machine (2). Make sure that tool bits installed are not in

contact with the mandrel. Next, rotate the spoke handles to the right (3) by at least 10

turns until the mandrel engages with the machine completely. Then, tighten the set

screw (4)and check whether the spoke handles can be rotated in both directions

easily. If the screw is too tight, readjust it. Finally, tighten the lock nut (5).

Fig. 3. Installing the mandrel into the machine

If the expanding mandrel becomes loose causing vibrations of the tool bits during

machining, perform the above actions without removing the mandrel from the machine.

To remove the mandrel, loosen the nut and use the 6 mm hex wrench to loosen

the set screw (1,Fig. 3) by at least one turn. Then, rotate the spoke handles to the left

to disengage the mandrel from the machine.

1

2

4

5

3

3

PRO 5 PB/PBE/PBC

This document is protected by copyrights.

Copying, using, or distributing without permission of PROMOTECH is prohibited.

11

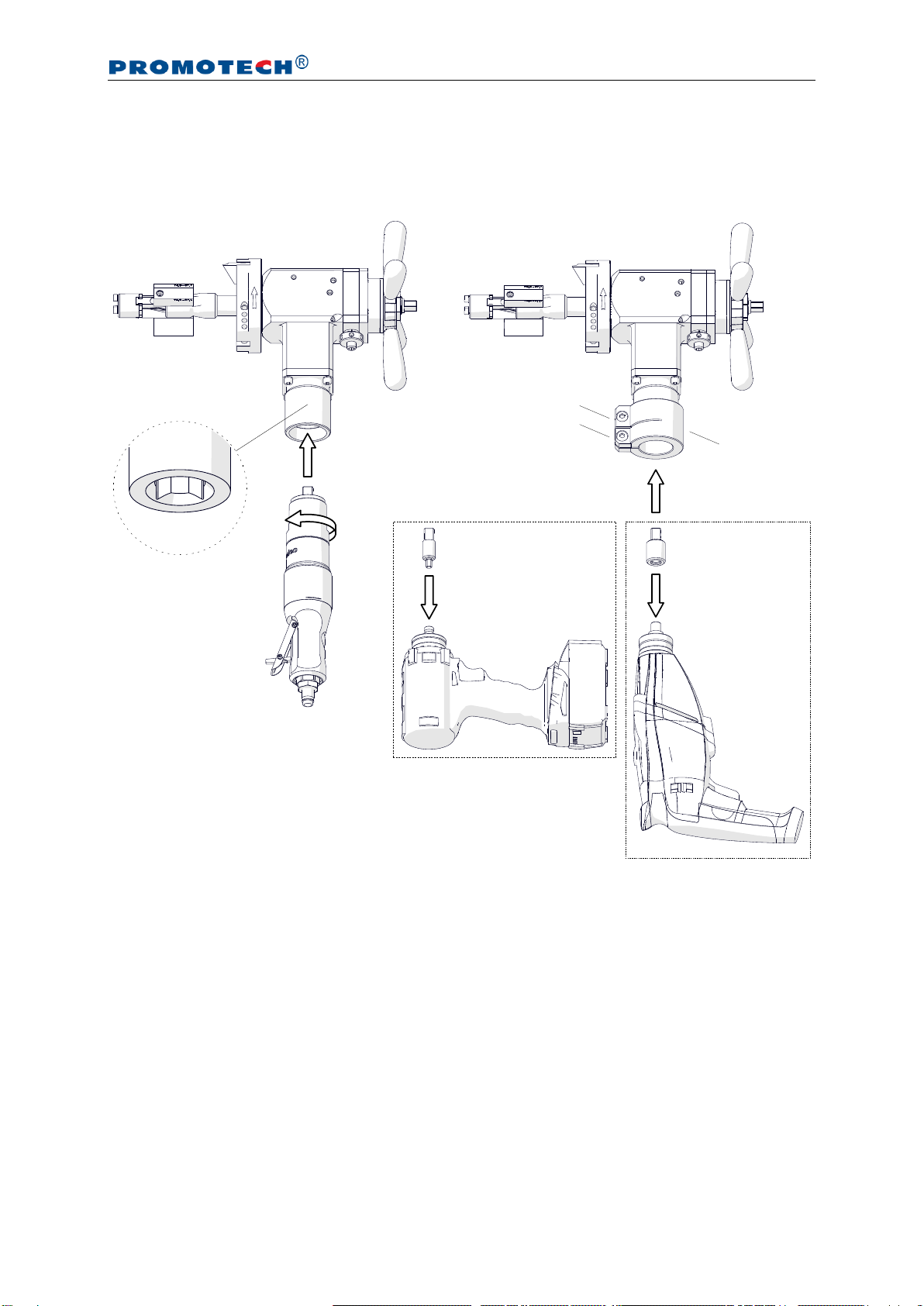

3.3. Installing the motor

Insert the air motor into the machine (1, Fig. 4a) so that the arbor is placed in the

socket 2, and tighten the motor by rotating it to the left (3).

Fig. 4. Installing the air motor (a) and an electric motor (b)

To install an electric motor, slide the clamping ring 4onto the machine. Then, screw

the driver (5) into the motor and insert the motor into the machine (6) by placing the

arbor in the socket 2, and tighten the clamping ring with the 6 mm hex wrench (7).

Finally, set the rotation direction switch to the position shown in Fig. 1.

1

2

3

a)

b)

5

5

6

7

5

4

5

5

PRO 5 PB/PBE/PBC

This document is protected by copyrights.

Copying, using, or distributing without permission of PROMOTECH is prohibited.

12

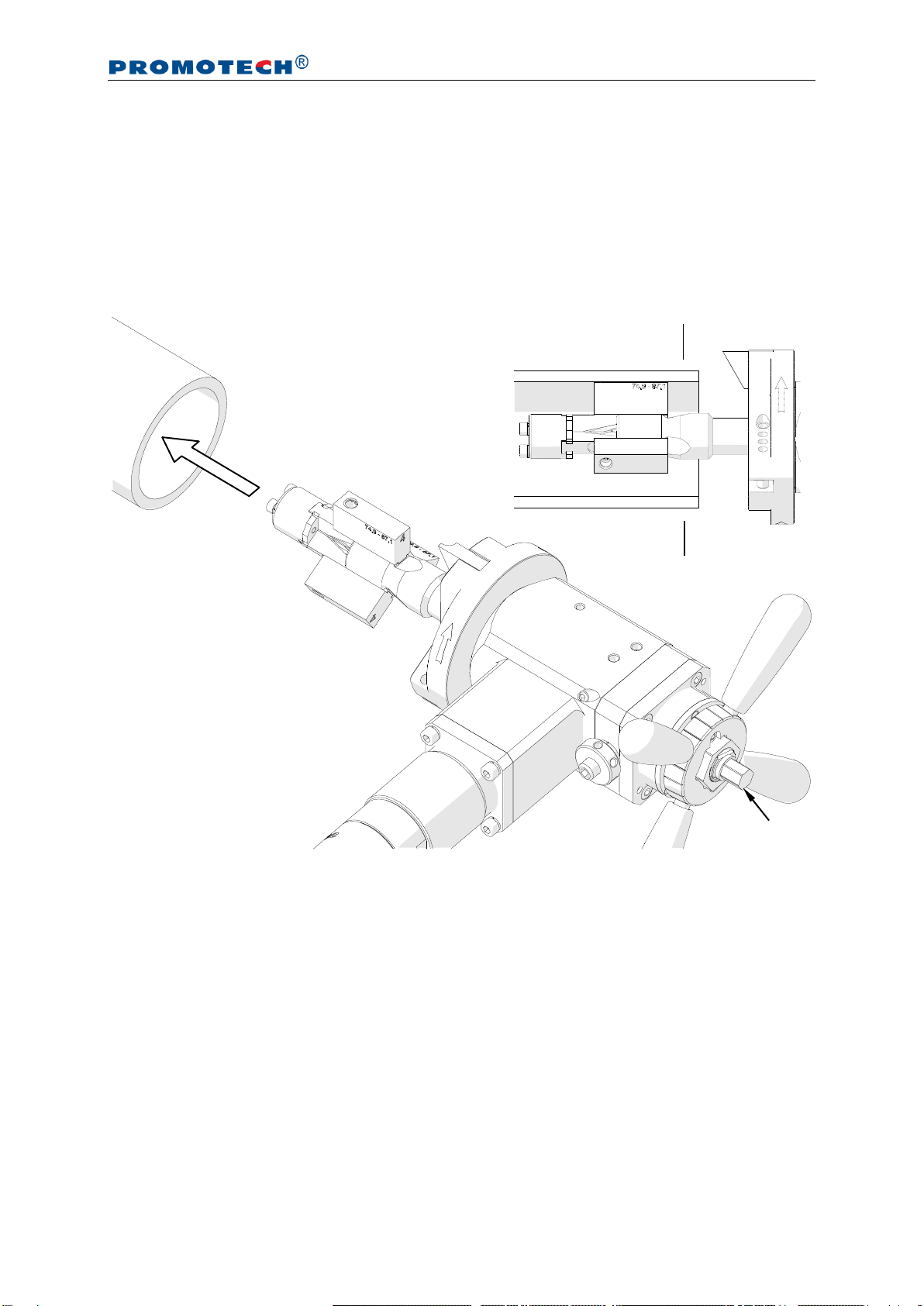

3.4. Clamping the machine into the pipe

Insert the assembled machine into the pipe (1, Fig. 5) so that the tool bit(s) is placed

at the distance of at least 3 mm (0.12’’) from the pipe end. Then, expand the jaw

blocks to the inside diameter of the pipe by rotating the draw nut 2to the right with

the 13 mm socket wrench. The jaw blocks must be installed beyond the end

preparation location 3.

Fig. 5. Clamping the machine into the pipe

2

1

3

3

PRO 5 PB/PBE/PBC

This document is protected by copyrights.

Copying, using, or distributing without permission of PROMOTECH is prohibited.

13

3.5. Preparing the air (for machine with air motor)

Connect the machine to a correctly prepared air source of sufficient purity by using

a hose with the internal diameter of at least 12 mm (0.5’’). The air source must be

equipped with an air preparation unit: filter, regulator, and lubricator (FRL). To achieve

full power of the air motor, all internal diameters of the air source must be at least

10 mm (0.4’’).

Maintain the FRL unit as required to keep the water trap drained, filter cleaned,

and the lubricator oil reservoir filled so that there is a drop of oil every 2–5 seconds.

Use only oil whose ignition temperature is more than 260°C (500°F). If the machine is

to be left idle for at least 24 hours after the work is finished, increase the delivery of oil

and run the motor for 2–3 seconds, which will prevent rusting and degrading of the

rotor vanes.

3.6. Operating

After the machine is connected to a proper supply, press the ON/OFF lever to start.

For the machine with an electric motor, set the gear 1 and, in cordless motor, the

maximum torque, and then press and hold the ON/OFF switch. To lock the switch in

the position ON (not available in cordless), press the ON switch lock before releasing

the ON/OFF switch. To adjust the speed, use a dial or, in cordless motor, change the

extent to which the ON/OFF switch is pressed.

Spread the coolant on the working edge. Then, bring the tool bit(s) close to the

pipe by rotating the spoke handles to the right. If the pipe face is not perpendicular to

the pipe axis, the tool bit will machine only a small segment of the pipe during initial

rotations. Thus, the feed rate should be chosen slow until the tool bit is contacting the

pipe continually during at least one rotation. The axial feed is 0.11 mm (0.004’’) per

graduation (Fig. 6) or 2 mm (0.08’’) per one complete turn of the spoke handles.

Fig. 6. View of the feed indicator

Feed direction

0.11 mm (0.004’’)

PRO 5 PB/PBE/PBC

This document is protected by copyrights.

Copying, using, or distributing without permission of PROMOTECH is prohibited.

14

Continue machining by rotating the spoke handles to the right. Use adequate feed

rate to establish a continuous chip cut. If the feed rate is too slow, only light stringer

chips will be removed, while too fast feed will make machining difficult and the chip

will start to have a rough or torn appearance. Never allow the tool bit to burnish the

surface. If chatter problems occur, reduce the feed rate and speed, and make sure

the type of tool bits corresponds to the material and the tool bits are sharp. Stainless

steel, which work hardens, must be worked with a fast enough feed, 0.08–0.15 mm

(0.003–0.006’’) per rotation, to stay under the work hardened surface.

If the machine with electric motor becomes overloaded, the motor will be shut off

automatically. However, prevent the motor from overloading and, if possible, machine

hardmaterials with not too fast feed rate and rotational speed.

After the pipe end is machined completely, discontinue rotating the spoke handles

and allow several more turns to improve the finish of the surface. Then, turn off the

motor by using the ON/OFF lever/switch, and wait until the rotation stops. Separate

the tool bit(s) from the pipe end to at least 3 mm (0.12’’) by rotating the spoke handles

to the left. Finally, loosen the draw nut with the 13 mm socket wrench to release the

clamping, and then remove the machine from the pipe. Use petroleum ether to clean

the pipe from excess coolant.

Clean the machine with a cotton cloth without using any agents.

PRO 5 PB/PBE/PBC

This document is protected by copyrights.

Copying, using, or distributing without permission of PROMOTECH is prohibited.

15

3.7. Troubleshooting the electric motor

The machine with electric motor has aLED for troubleshooting. The LED permanently

lit means that the machine power is limited to prevent the motor from overheating as

a result of continuous overloading for extended periods.

Rapid flashing means that the safety circuit prevents the machine from starting

automatically when electrical power is restored after a power failure. To start the

machine is such a case, switch the motor off and on again.

Slow flashing means that the carbon brushes are almost completely worn, which

results in the motor shutting off automatically. The brushes must be replaced with

new ones by the manufacturer of the electric motor.

3.8. Troubleshooting the cordless electric motor

The machine with cordless electric motor has aprotection system that automatically

shuts off the motor when it is continuously overloaded for extended periods. To stop

the beeping signal that sounds in such a case, release the ON/OFF switch. If the

motor or battery feels very warm, wait until it cools before proceeding.

The motor can also shut off automatically if the machine jams in the workpiece.

To continue operation, release the ON/OFF switch and press it again. Avoid repeated

jamming in the workpiece.

Flashing of the LED means that the battery is almost completely discharged.

To see the charge level, press the LED activation button and check the LED. If the

battery is discharged completely, charge the battery or replace to a fully charged.

PRO 5 PB/PBE/PBC

This document is protected by copyrights.

Copying, using, or distributing without permission of PROMOTECH is prohibited.

16

3.9. Replacing the spindle disk

Loosen the nut and use the 6 mm hex wrench to loosen the set screw (1, Fig. 7) by

at least one turn. Then, rotate the spoke handles to the left (2) to disengage the

mandrel from the machine (3).

Fig. 7. Removing the mandrel from the machine

Use the 5 mm hex wrench (1, Fig. 8) and remove the spindle disk (2). Then, install

the new disk (3) onto the pin 4 and tighten with the same screws.

Fig. 8. Replacing the spindle disk

1

2

3

1

2

3

4

PRO 5 PB/PBE/PBC

This document is protected by copyrights.

Copying, using, or distributing without permission of PROMOTECH is prohibited.

17

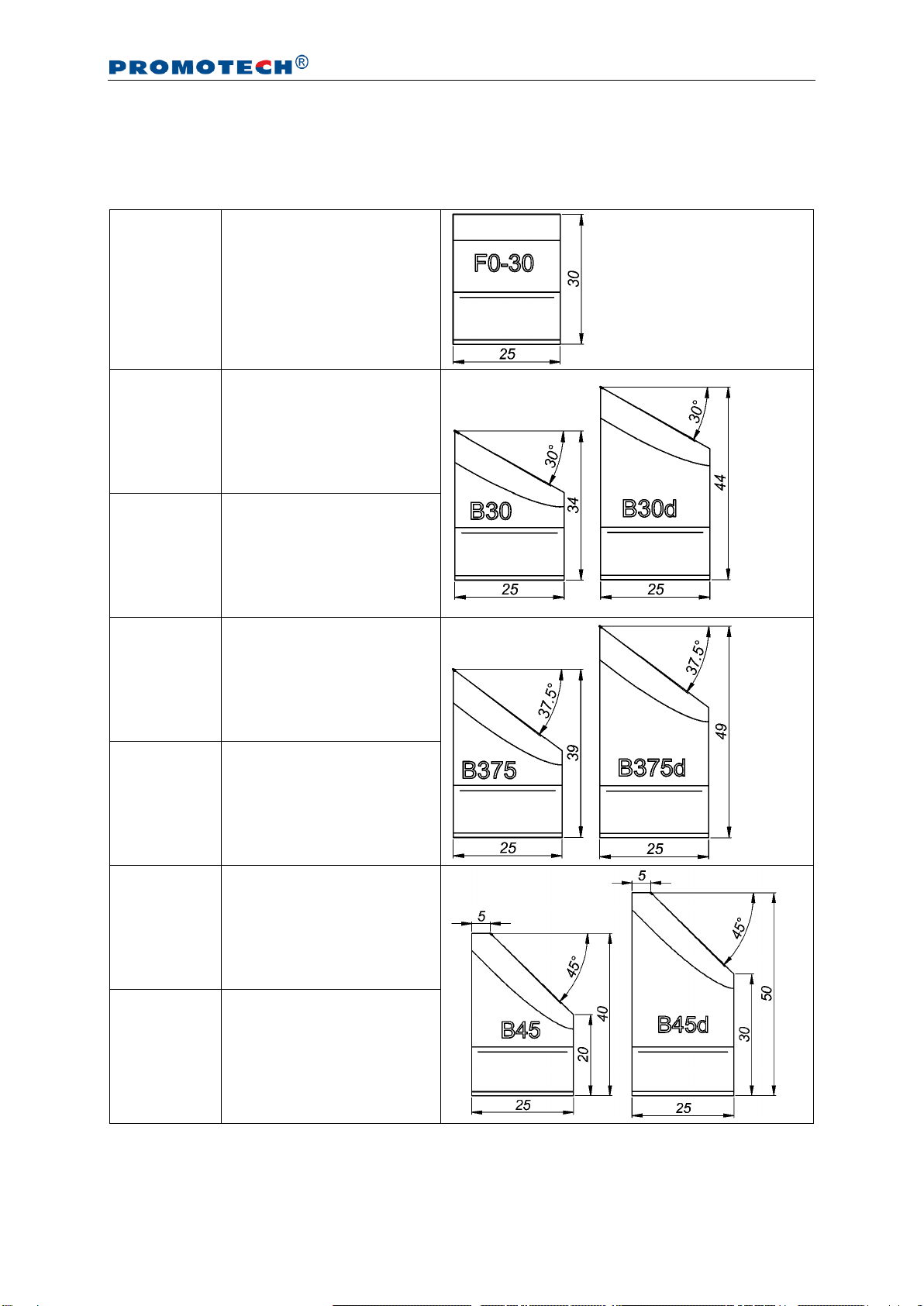

3.10. Facing and bevelling at the same time

When facing and bevelling is performed at the same time, use either short or long

bevelling tool bit depending on the pipe diameter (Fig. 9).

Fig. 9. Positioning the facing tool bit and a short or long bevelling tool bit

F0-30 facing tool bit

Short tool bit

Long tool bit

Short tool bit

Short or long

tool bit

Long tool bit

Long tool bit

Short or long

tool bit

Short tool bit

PRO 5 PB/PBE/PBC

This document is protected by copyrights.

Copying, using, or distributing without permission of PROMOTECH is prohibited.

18

4. ACCESSORIES

4.1. Tool bits for carbon steel

NOZ-000031

F0-30

0° facing tool bit

NOZ-000032

B30

30° bevelling tool bit*

NOZ-000033

B30d

30° bevelling tool bit**

NOZ-000036

B375

37.5° bevelling tool bit*

NOZ-000037

B375d

37.5° bevelling tool bit**

NOZ-000040

B45

45° bevelling tool bit*

NOZ-000041

B45d

45° bevelling tool bit**

* for diameters over 56 mm, if works together with 0°facing tool bit

** for diameters under 83 mm, if works together with 0°facing tool bit

PRO 5 PB/PBE/PBC

This document is protected by copyrights.

Copying, using, or distributing without permission of PROMOTECH is prohibited.

19

NOZ-000052

IC15-40 –on the left

15° internal calibration tool bit

NOZ-000053

IC15-40 –on the right

(for diameters over 56 mm)

15° internal calibration tool bit

NOZ-000058

J10-R6

10° J-bevelling tool bit

NOZ-000057

J15-R2

15° J-bevelling tool bit

NOZ-000059

J20-R8

20° J-bevelling tool bit

PRO 5 PB/PBE/PBC

This document is protected by copyrights.

Copying, using, or distributing without permission of PROMOTECH is prohibited.

20

4.2. Tool bits for stainless steel

NOZ-000067

F0-30

0° facing tool bit

(TiAlN coated)

NOZ-000034

NB30

30° bevelling tool bit*

(TiAlN coated)

NOZ-000035

NB30d

30° bevelling tool bit**

(TiAlN coated)

NOZ-000038

NB375

37.5° bevelling tool bit*

(TiAlN coated)

NOZ-000039

NB375d

37.5° bevelling tool bit**

(TiAlN coated)

* for diameters over 56 mm, if works together with 0°facing tool bit

** for diameters under 83 mm, if works together with 0°facing tool bit

This manual suits for next models

2

Table of contents

Other Promotech Industrial Equipment manuals