Propex Pyramat Series Instruction Manual

Propex Operating Company, LLC - 4019 Industry Drive, Chattanooga, TN 37416 - p 800 621 1273 - www.propexglobal.com

PYRAMAT®SLOPE INSTALLATION

AND MAINTENANCE GUIDELINES

Thank you for purchasing our PYRAMAT®High Performance Turf Reinforcement Mat (HPTRM) or Turf Reinforcement Mat

(TRM) by Propex Operating Company, LLC (Propex). This document provides installation and maintenance guidelines for

PYRAMAT used as slope armoring to increase earthen slope resiliency. PYRAMAT provides permanent erosion protection

on either the flood side and/ or protected side of an earthen slope.

Temporary securing pins (pins) are used during installation to hold PYRAMAT in place. Pins also promote vegetation

establishment keeping PYRAMAT in intimate contact with the soil.

PYRAMAT is an Engineered Earth Armoring Solution TM with a unique design for each specific project. While Propex has

made every effort to ensure general validity, this information should not be used for a specific application without

independent professional examination and verification of its suitability, applicability, and accuracy. The information

provided herein is for general information only, and is intended to present installation guidance. Project specific contract

documents take precedence when pin placements are different than what is represented in this document. Depending

upon the critical nature of the structure to be armored, work restrictions may be in place such as limiting work based on

growing seasons, weather patterns, etc. Work should be performed under the provisions set forth for the specific project.

Propex Engineering Services is available for support during installation to consult for solving constructability issues

encountered in specific applications. Please feel free to call our techincal support hotline at (800) 621-1273.

BEFORE INSTALLATION BEGINS

Coordinate with a Propex Representative: A pre-construction meeting is suggested with the construction team and a

representative from Propex. This meeting should be scheduled by the contractor with at least a two week notice.

Gather the Tools Needed: Tools that you will need to install PYRAMAT include a pair of industrial shears to cut

PYRAMAT, tape measure, and mallet or hammer.

Determine how to Establish Vegetation: The method of vegetation establishment should be determined prior to the

start of installation. Different vegetation establishment methods require different orders of installation. Refer to

VEGETATION ESTABLISHMENT for further guidance.

INSTALLATION OF PYRAMAT ON SLOPES

SITE PREPARATION

It is recommended during all stages of site preparation that disturbed soils remain unprotected for not more than a

single day. Depending on project size this may require progressive site preparation during installation.

1. Grade and compact the area on the slope where PYRAMAT will be installed. The slope surface should be uniform

and smooth, having all rocks, clods, vegetation or other objects removed so that during PYRAMAT LAYDOWN,

PYRAMAT comes in direct, intimate contact with the slope surface.

2. Prepare the area to be armored with PYRAMAT by loosening the topsoil to promote better vegetation establishment.

This may be accomplished with a rotary tiller on slopes 3:1 or flatter. For slopes greater than 3:1, prepare topsoil in a

safe manner.

3. Excavate a Crest of Slope (COS) trench 12 in x 12 in (300 mm x 300 mm) minimum at a distance of 3 ft (900 mm)

from the crest of the slope. (Figure 1).

Page 2of 11

Propex Operating Company, LLC - 4019 Industry Drive, Chattanooga, TN 37416 - p 800 621 1273 - www.propexglobal.com

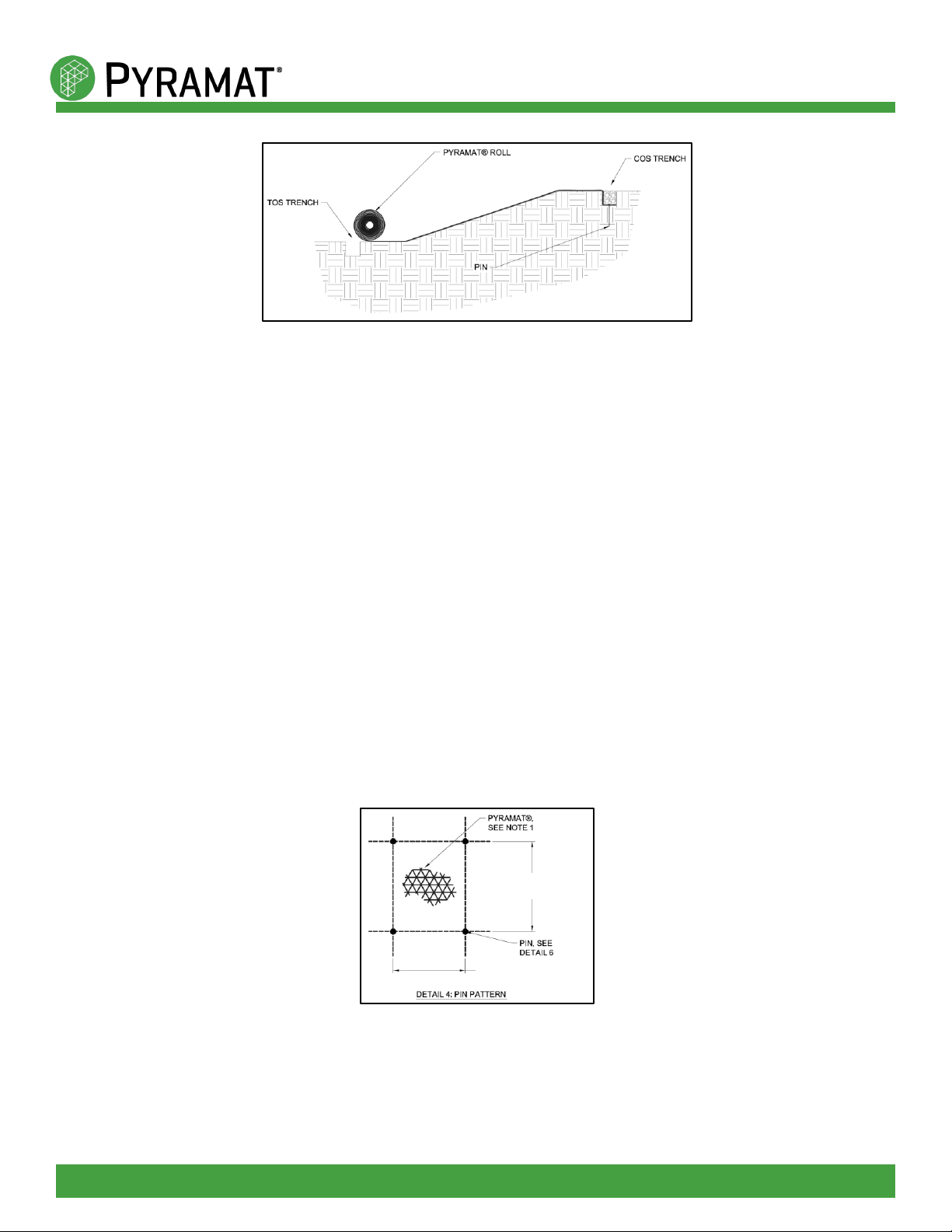

Figure 1: Crest of Slope (COS) Trench

4. Excavate a Toe of Slope (TOS) trench 12 in x 12 in (300 mm x 300 mm) minimum at a minimum distance of 5 ft (1.5

m) from the toe of the slope. (Figure 2)

5. If seeding, refer to VEGETATION ESTABLISHMENT for additional considerations during site preparation.

Figure 2: Toe of Slope (TOS) Trench

PYRAMAT LAYDOWN

1. Begin the PYRAMAT LAYDOWN process by starting with the downstream / downwind end of the site. To ensure

proper pining of the overlapped areas the proceeding roll width must be laid out before the current roll width can be

pinned with exception to the final roll width. For straight sections of a slope, PYRAMAT panel lengths should be long

enough to construct COS and TOS trenches while also covering the surface of the slope being armored (Figure 12).

Panel edges should rest approximately perpendicular to the slope center line. For best results, panels of PYRAMAT

should be continuous and free from seams or roll end overlaps that are parallel to the centerline of the slope. Panel

edge overlapping should follow a pattern of placing each proceeding panel’s edge overtop the previous panel edge,

shingling the panels in the direction of the water flow or prevailing wind.

2. Starting at the COS trench, lay PYRAMAT roll so that the roll ends point towards the crest of the slope (Figure 3), with

a 3 in (75 mm) overlap created at adjacent panel edge locations. Ensure that adjacent panel edges maintain a

minimum 3 in overlap during PYRAMAT LAYDOWN (Figure 8).

Page 3of 11

Propex Operating Company, LLC - 4019 Industry Drive, Chattanooga, TN 37416 - p 800 621 1273 - www.propexglobal.com

Figure 3: Crest of Slope (COS) Trench Alignment

3. Secure PYRAMAT with pins in the COS trench. Pins should be made of steel with a 0.20 in (5 mm)

minimum diameter, having a 1.5 in (38mm) diameter washer at the head, and a length between 12 and

24 in (300-600 mm) with sufficient ground penetration to resist pullout (Figure 4). Longer pins may be

required for looser soils. Heaver metal stakes may be required in rocky soils. Suggested placement of pins

for the COS trench is along the bottom of the trench with pins on 12 in (300 mm) centers. Pins should

also be installed on panel edge overlaps in the COS trench.

Figure 4: Securing Pin

4. Backfill and compact the COS trench in the location of the first PYRAMAT panel only (Figure 5).

Figure 5: Crest of Slope (COS) Trench Placement

5. Unroll the PYRAMAT roll on the slope surface in the area to be armored (Figure 6). Ensure that PYRAMAT

has intimate contact with the ground and all irregular surfaces beneath PYRAMAT are removed.

Page 4of 11

Propex Operating Company, LLC - 4019 Industry Drive, Chattanooga, TN 37416 - p 800 621 1273 - www.propexglobal.com

Figure 6: Placement of PYRAMAT across Slope

6. Secure PYRAMAT panels in place using pins across the slope surface according to the project’s engineered

design. Pin placement should reflect a checkerboard pattern across the slope surface for best results

(Figure 7 and Figure 8).

The leading edge of the first PYRAMAT panel should be secured on the Slope Armoring Edge (SAE) with

pins on 12 in (300 mm) centers.

Roll edges shall be overlapped a minimum of 3 in (75 mm) with pins placed on 12 in (300 mm)

centers (Figure 8).

Roll ends shall be overlapped a minimum of 6 in (150 mm) with upstream / upwind panel on top.

Secure roll end overlaps with two rows of pins staggered 6 in (150 mm) apart on 12 in (300 mm)

centers (Figure 9)

For slope lengths greater than 45 ft (13.7 m), install simulated check slots. This method includes

placing two rows of pins 12 in (300 mm) apart on 12 in (300 mm) centers at 45 ft (13.7 m) maximum

intervals or across the midpoint of the slope for slope lengths less than 60 ft (18.2 m) (Figure 10).

At the break in slope interface towards the TOS, it is suggested that pins be installed on 12 in (300

mm) centers (Figure 11).

Figure 7: Example Pin Pattern

HORIZONTAL PIN SPACING

PER PIN SCHEDULE

VERTICAL PIN SPACING PER

PIN SCHEDULE

Page 5of 11

Propex Operating Company, LLC - 4019 Industry Drive, Chattanooga, TN 37416 - p 800 621 1273 - www.propexglobal.com

Figure 8: Example of Panel Overlap

Figure 9: Roll End Overlap

OFFSET PINS AS SHOWN TO CREATE A

CHECKERBOARD PATTERN

PINS ON 12” (300 mm)

CENTERS ON ROLL EDGE

OVERLAPS

This manual suits for next models

2