Contents MVI69-PDPMV1 ♦CompactLogix or MicroLogix Platform

User Manual PROFIBUS DPV1 Master

Page 6 of 225 ProSoft Technology, Inc.

July 8, 2011

4Mailbox Messaging 81

4.1Mailbox Message Queuing..................................................................................... 82

4.1.1Queue Timeouts ..................................................................................................... 82

4.2Sending a Mailbox Message in RSLogix 5000....................................................... 83

4.3Receiving Mailbox Message Responses from the Module..................................... 84

4.4Special Function Mailbox Messaging Commands.................................................. 85

4.4.1Mailbox Message: Set Operating Mode ................................................................. 88

4.4.2Mailbox Message: Set Slave Mode ........................................................................ 90

4.4.3Mailbox Message: Get Slave Diagnostics.............................................................. 94

4.4.4Mailbox Message: Get Slave Configuration ........................................................... 96

4.4.5Mailbox Message: Set Slave Address.................................................................... 98

4.4.6Mailbox Message: Get Live List............................................................................ 100

4.4.7Mailbox Message: Start Slave.............................................................................. 102

4.4.8Mailbox Message: Stop Slave .............................................................................. 104

4.4.9Mailbox Message: Class 1 Acyclic Data Read..................................................... 106

4.4.10Mailbox Message: Class 1 Acyclic Data Write ..................................................... 108

4.4.11Mailbox Message: Initiate Class 2 Connection..................................................... 110

4.4.12Mailbox Message: Class 2 Acyclic Data Read..................................................... 116

4.4.13Mailbox Message: Class 2 Acyclic Data Write ..................................................... 118

4.4.14Mailbox Message: Abort Class 2 Connection....................................................... 120

4.4.15Mailbox Message: Class 2 Connection Abort Indication...................................... 122

4.4.16Mailbox Message: Alarm Indication...................................................................... 126

4.5Mailbox Messaging Error Codes........................................................................... 128

4.5.1Acyclic Message Status Word.............................................................................. 128

4.5.2Return Codes........................................................................................................ 129

4.5.3Error Codes........................................................................................................... 130

4.5.4DPV1 Class 1-Related Error Codes ..................................................................... 131

4.5.5DPV1 Class 2-Related Error Codes ..................................................................... 132

5Diagnostics and Troubleshooting 133

5.1Verifying Correct Operation.................................................................................. 134

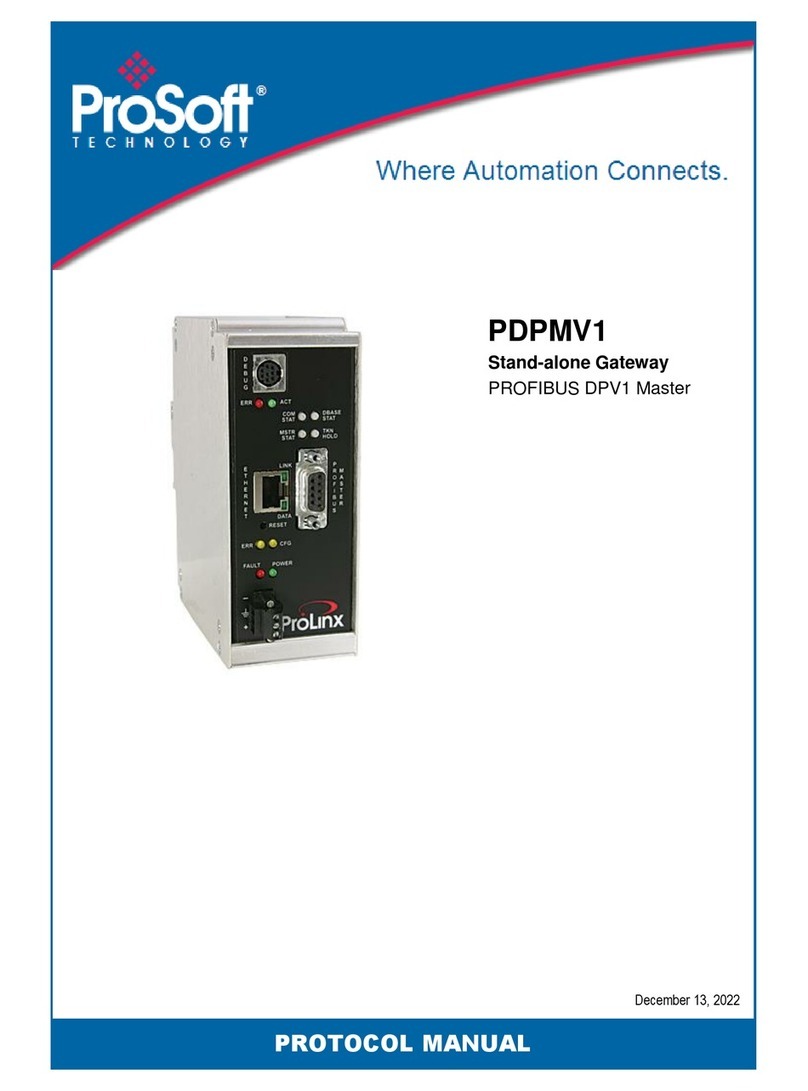

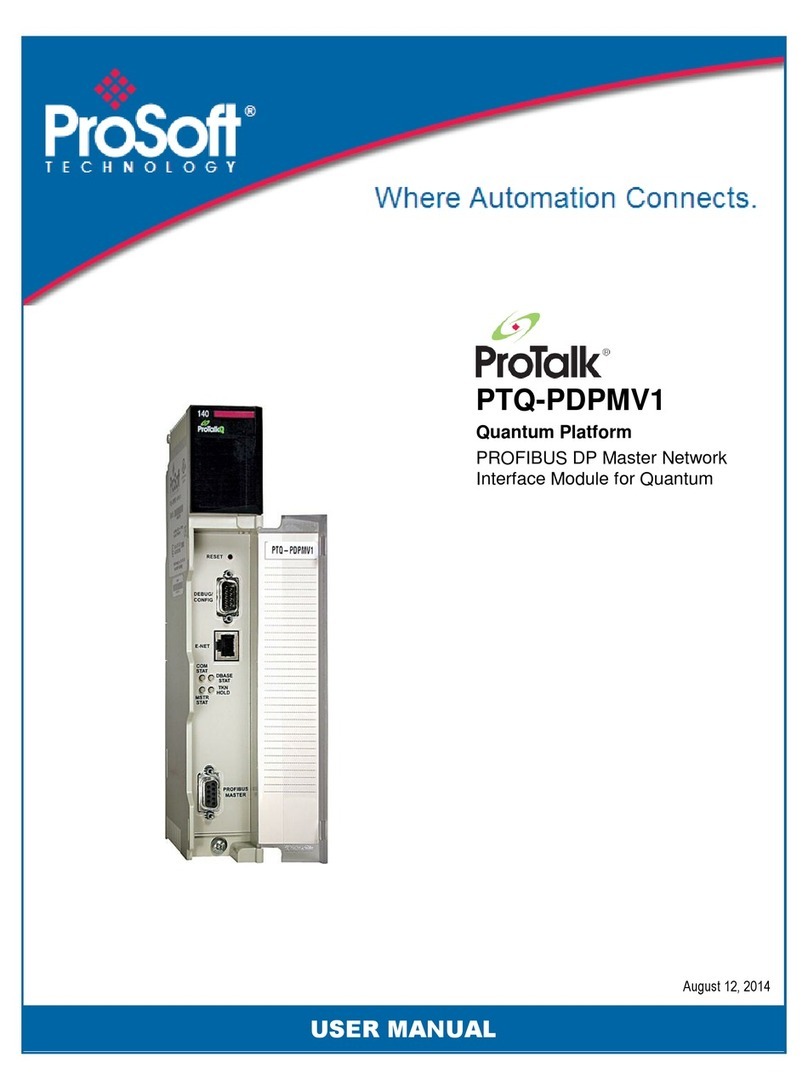

5.1.1Checking the PROFIBUS LEDs on the MVI69-PDPMV1..................................... 134

5.1.2Viewing the Online Status of the PROFIBUS Network......................................... 135

5.1.3Viewing the Fieldbus Data from the MVI69-PDPMV1’s Configuration/Debug Menu137

5.1.4Viewing the Controller Tags in RSLogix 5000...................................................... 141

5.2Basic Troubleshooting Steps................................................................................ 143

5.3LED Indicators: Front of MVI69 Module ............................................................... 144

5.3.1Module Status Indicators...................................................................................... 144

5.3.2PROFIBUS Master Indicators............................................................................... 145

5.4Using ProSoft Configuration Builder (PCB) for Diagnostics................................. 147

5.4.1Using the Diagnostic Window in ProSoft Configuration Builder........................... 147

5.4.2Navigation............................................................................................................. 150

5.4.3Main Menu............................................................................................................ 151

5.5Reading Status Data from the Module ................................................................. 154

5.6Standard PROFIBUS Slave Diagnostic Bytes...................................................... 155

5.6.1Byte 0 - Station Status 1 Bits................................................................................ 155

5.6.2Byte 1 - Station Status 2 Bits................................................................................ 155

5.6.3Byte 2 - Station Status 3 Bits................................................................................ 156

5.6.4Byte 3 - Master Address....................................................................................... 156

5.6.5Byte 4 - Ident Number High.................................................................................. 156

5.6.6Byte 5 - Ident Number Low................................................................................... 156