ProtACT PRY Series User manual

Series PRY

PNEUMATIC ACTUATORS

Documentnr.: BWA.PRY.200116| Issue: Jan. 2020

MANUAL AND

MAINTENANCE GUIDELINES

MANUAL & MAINTENANCE GUIDELINES

PNEUMATIC ACTUATORS SERIES PRY

BWA.PRY.200116

January 2020

2

MANUAL & MAINTENANCE GUIDELINES

PNEUMATIC ACTUATORS SERIES PRY

BWA.PRY.200116

January 2020

3

Content:

Chapter1: Preparaon

1.1 Marking of safety instrucons Page 4

1.2 Safety fundamentals Page 4

1.3 Instrucons for storage Page 4

Chapter 2: Preliminary

2.1 Design descripon Page 5

2.2 Intended use Page 6

2.3 Technial informaon Page 6

2.4 Typecode Page 7

Chapter3: Installaon

3.1 Remarks Page 8

3.2 Installaon instrucons Page 9

3.3 Seng the end posions Page 10

3.4 Assembly to a valve Page 11

3.5 Tightening torques for screw connecon Page 11

Chapter 4: Maintanance

4.1 General Page12

4.2 Safety instrucons Page12

4.3 Disassembly and maintenance of the modules Page13

4.3.1 Spring module Page13

4.3.2 Pneumac module Page14

4.3.3 Center module Page14

4.3.4 Manual hydraulic module Page15

4.3.5 Mechanical manual module Page16

4.4 Field reversion Page17

4.4.1 Changing the direcon of spring acon Page17

4.4.2 Conversion from double-acng to single-acng Page18

4.4.3 Conversion from single-acng to double-acng Page18

4.5 Components Page19

Copyright

This document is protected by copyright. We reserve all rights to this manual before proceeding, even the reproduc-

on and / or duplicaon in any thinkable form, e.g. photocopying, prinng, on data medium or in translated form.

Reproducon of this manual only with wrien permission of ProtACT GmbH. The technical state at the me of deliv-

ery of device and manual is decisive, if no other informaon is given. We reserve the right to make technical modi-

caons without specic noce. Earlier instrucons then become invalid.

MANUAL & MAINTENANCE GUIDELINES

PNEUMATIC ACTUATORS SERIES PRY

BWA.PRY.200116

January 2020

4

Chapter1:Preparaon

Content:

• Marking of safety instrucons

• Safety fundamentals

• Instrucons for storage

1.1Markingofsafetyinstrucons

1.2 Safety fundamentals

The installaon, assembly, commissioning, maintenance and any other work on pneumac actuators must be

performed by qualied personnel.

This manual is part of the device and must be available for the operang personnel at all mes. This manual must

be read and understood before operaon.

The device may only be operated in perfect condion. No safety devices are removed or deacvated. A rebuilding

or modicaon of the device is strictly prohibited.

1.3 Transport, storage and packaging

The devices must be carefully handled, transported and stored.

The devices should be transported to the end desnaon in their original packaging and unpacked immediately

before installaon.

The actuators are to be stored in a clean, dry storage, which is neither exposed to excessive vibraon nor to rapid

temperature changes.

Prevent ingress of dirt or moisture into the actuator. Close or ghten both air connecons.

Proper disposal of packaging is the customer´s responsibility.

Thissymbolindicatessafetyinstruconswhichcancausepersonalinjuryifnotrespected.

This symbol indicates an important note

Rotaryactuatorsmustbeisolatedbothpneumacallyandelectricallybeforeanyintervenon.

Failuretofollowthesafetybasicscanvoidthewarrantyclaims.

Installaon,operaonandmaintenanceoftheproductsarestrictlysubjecttothelocalsafetyand

accidentprevenonregulaons!

Failuretocomplymayvoidthewarrantyclaims.

MANUAL & MAINTENANCE GUIDELINES

PNEUMATIC ACTUATORS SERIES PRY

BWA.PRY.200116

January 2020

5

Chapter 2: Preliminary

Content:

• Design descripon

• Intended use

• Technical informaon

• Type code

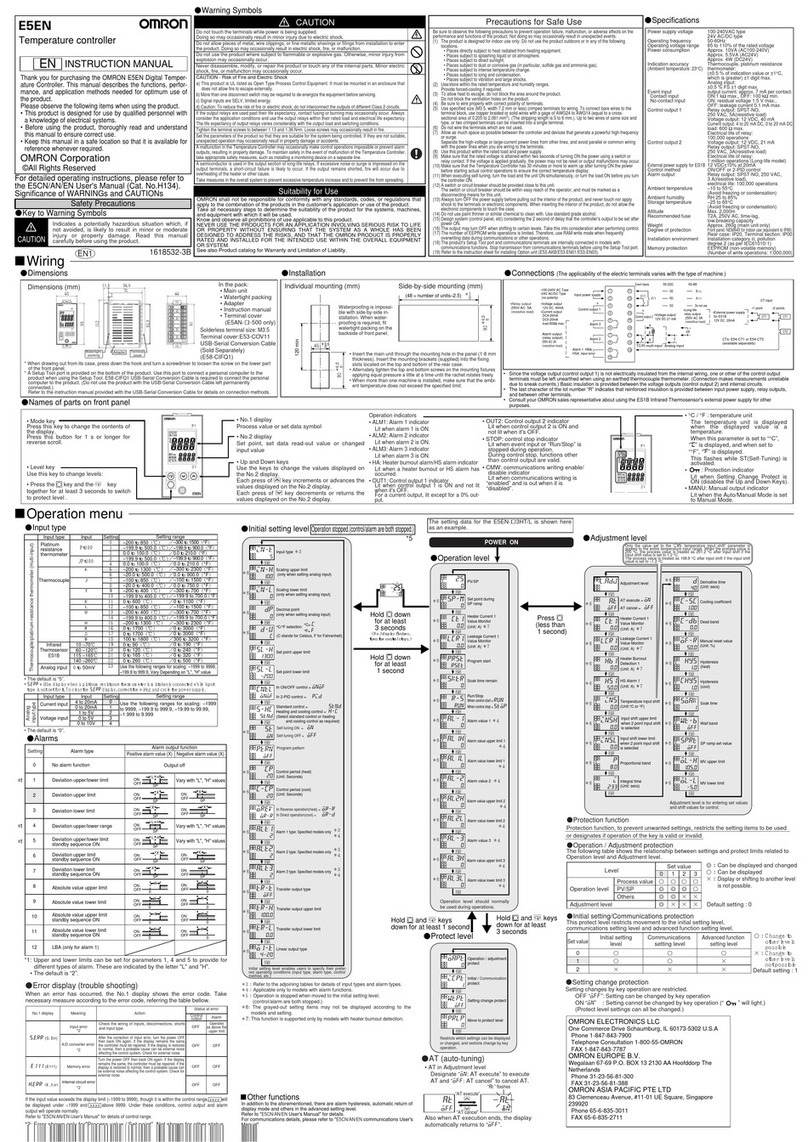

2.1Designdescripon

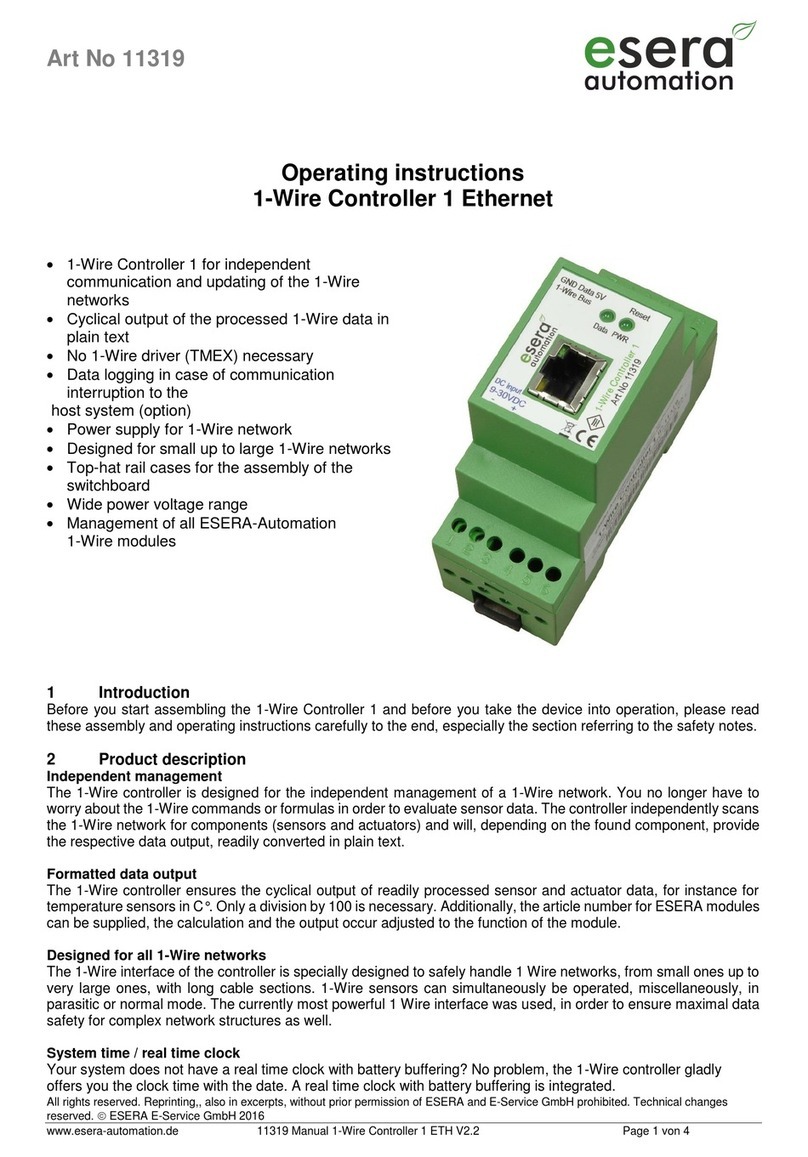

Pneumac actuators of the PRY series are designed for the automaon of rotary valves with a 90° rotaon angle.

They have a modular structure and, depending on the applicaon, consist of one or two pneumac modules, a

center module, a spring module and an oponal module for manual actuaon. In the single-acng version, the spring

module ensures closing or opening in the event of a control media failure (spring-closing or spring-opening).

Two characterisc torque proles are available for generang a drive torque that is adapted to the valve torque.

These are created using either a symmetrical or a canted yoke.

The PRY actuator series oers a torque range of 1000 – 250.000 Nm (double-acng) and 300 – 150.000 Nm (single-

acng). The standard version of the actuators provides valve mounng interfaces according to ISO 5211 and an

accessory interface according to VDI/VDE 3845.

The maximum operang pressure of the pneumac Scotch-Yoke actuators of the PRY series is between 3 and 10 bar

depending on size and conguraon. The maximum operang pressure is specied on the typelabel of the respecve

actuator.

MANUAL & MAINTENANCE GUIDELINES

PNEUMATIC ACTUATORS SERIES PRY

BWA.PRY.200116

January 2020

6

2.3TechnicalInformaon

Construconprinciple: Pneumac heavy-duty rotary actuator in Scotch-Yoke design; double and single

acng version

Materials See secon 4.5

Temperature range

Standard

Low temperature version

High temperature version

-20°C to +80°C

-40°C to +80°C

-15°C to +150°C

Control pressure 3 … 10 bar (depending on the actuator version, check typelabel!)

Pressure media

dry, ltered air or inert gases in respect of remaining oil-,

dust and water-content according to DIN ISO 8573-1 / class 4,

maximum parcle diameter 30µm,

dew point minimum 10°C below ambient temperature

Nominalrotaonangle 90°, adjustable in both end posions +/-6°

Torque range double-acng: up to 250.000Nm

single-acng: up to 150.000Nm

Standards

Interface actuator/control-unit: VDI/VDE 3845 resp. NAMUR

Interface actuator/control media supply: G- or NPT-Thread

Interface actuator/valve: ISO 5211

2.2 Intended use

Actuators of the PYR series are primarily used for the automaon of quarter-turn valves such as ball valves, buery

valves or plug valves, but can also be used for other applicaons. Contact our qualied personnel where required.

The specied operang and liming values for temperature, pressure, control medium, etc. must be observed.In

operaon of valves high kinec energies may arise, which are transmied to the actuator. Make sure that the drive

is protected from damage by complying with the minimum travel mes safely. Control speed can be reduced by the

use of throle valves, which can be purchased from our sales department.

For valve types with high ywheel mass and low torque requirements the operang condions of the actuator must

be coordinated with us in advance.

The actuator may only be used:

• in perfect condion

• as spulated

• safety- and danger-conscious in consideraon of the operang instrucons

• if all safety devices are in place and funconing

Anyusenotpre-approvedbythemanufacturerisconsideredimproper!

MANUAL & MAINTENANCE GUIDELINES

PNEUMATIC ACTUATORS SERIES PRY

BWA.PRY.200116

January 2020

7

PRY .C1 .50 1 S .04 .1625 S 55 .P R S .00

Type

Body size

Cylinder size

Quantycylinders(1or2)

Funcon

D: double-acng

S: single-acng

Spring set

ISOvalveinterface

14: F14 1625: F16 + F25

16: F16 2530: F25 + F30

25: F25 3035: F30 + F35

30: F30 4048: F40 + F48

35: F35 4860: F48 + F60

40: F40

48: F48

60: F60

Stemconnecon

S: Square acc. to ISO 5211 or DIN 3337

D: Double-D

K: Key connecon

Stemconnecondimension

Dimension in mm (not applicable for key connecon)

Mounngdirecon

P: Parallel to pipe

T: Transversal to pipe

Springrotaonsense

R: Clockwise CW (Normally closed)

L: Counterclockwise CCW (Normally open)

Temperatureversion

S: Standard (-20°…+80°C)

H: High temperature version (-15°…+150°C)

T: Low temperature version (-40° … +80°C)

Manualoperaon

00: without

01: Screw manual

02: Gear manual

03: Hydraulic manual

2.4 Typecode

MANUAL & MAINTENANCE GUIDELINES

PNEUMATIC ACTUATORS SERIES PRY

BWA.PRY.200116

January 2020

8

Chapter3:Installaon

Content:

• Remarks

• Installaon instrucons

• Seng the end posions

• Assembly to valve

• Tightening torques for screw connecons

3.1 Remarks

1. Onlylithedriveusingsuitableliingstraps.Theholesprovidedfortheeyeboltsareonlyfor

liingtheactuatorandnotforliingtheenreassemblyincl.valve.

2. Toachievethedesiredservicelifeoftheactuator,onlytherecommended,lteredcontrolmedia

may be used

3. Theactuatormustnotbeinstalledinpotenallyexplosiveareasthatarenotcompablewith

thespeciedgasgroupsandtemperatureclasses.

4. Whenusingaseparatemanualemergencygearbox,itmustbeensuredthatthegearboxoersa

rotaonanglethatcorrespondsatleasttothatoftheactuator.

5. Theactuatorscanbeinstalledinanyposion.However,caremustbetakentoensurethatsome

accessories,suchaslterregulangunits,reservoirsforhydraulicoverrideunits,etc.,whose

properfunconingdependsongravity,arerealignedappropriately.

6. Thespringcontainerandtheendcoverofthespringmoduleprotectthespring.Duetothe

preloadforceofthespring,itisstrictlyforbiddentocutopentheendcoverorthespring

containerinordertoavoidseriousinjuries.

MANUAL & MAINTENANCE GUIDELINES

PNEUMATIC ACTUATORS SERIES PRY

BWA.PRY.200116

January 2020

9

3.2Installaoninstrucons

1. Ensure that the pneumac module is completely depressurized by venng it into the atmosphere and discon-

necng all power sources from the accessories.

2. Make sure that the valve and the actuator are aligned in the same posion (i.e. valve closed - actuator in the

closed posion or both open). In the case of actuators with spring return, align the valve to the safe posion of

the actuator. If a manual override is used, it must also be ensured that it corresponds to the valve and actuator

posion.

3. Posion the valve, aach the mounng bracket and then mount the coupling sha on the valve sha (when

using a mounng kit). Check the posion of the actuator and valve, align the valve sha (or sha coupling)

with the actuator sha and slide the actuator onto the mounng surface of the mounng bracket (or onto the

ISO ange of the valve if no mounng bracket is used).

4. When using an emergency manual gearbox between actuator and valve, the gearbox must rst be aached

and fastened to the valve according to the prescribed procedure. Then turn back the stop screws on the gear-

box. Mount the actuator with the coupling sha on the gearbox and x the actuator on the gearbox ange.

5. To align the screw holes, the valve mounng screws on the mounng bracket may need to be loosened slightly.

The actuator xing screws should be easy to screw into the threaded holes of the actuator interface without

the mounng bracket (or the ISO ange of the valve) being loaded by transverse forces. If necessary, turn the

drive a lile and/or adjust the adjusng screws of the drive. Fasten the actuator to the mounng bracket/on

the gearbox ange/on the head ange of the valve.

6. Before operang the actuator, the manual override (if available) must be disengaged.

7. Adjust the adjusng screws of the quarter turn actuator correctly for open and closed valve posions according

to the recommendaons of the valve manufacturer. The adjusng screws of the quarter turn actuator should

dene the end stops, not that of the gearbox.

8. Tighten the lock nuts on the stop screws aer adjusng the stop screws. Make sure that the screws on the

gearbox (if present) are now set and locked so that they are slightly behind the end posion of the drive.

9. Make sure that the manual actuaon modules are unlocked before you start up the actuator.

10.Pneumacally operate the actuator several mes to check that it is operang correctly and smoothly. If the

actuator is equipped with a switch box or other accessories, set it now.

MANUAL & MAINTENANCE GUIDELINES

PNEUMATIC ACTUATORS SERIES PRY

BWA.PRY.200116

January 2020

10

3.3Sengtheendposions

Sengtheendposionclockwise(CW):

1. Turn the actuator clockwise unl it reaches the end

stop and check the seng.

2. Loosen lock nut "X"

3. Vent the actuator and turn the adjusng screw

in the desired direcon (unscrewing expands the

swivel angle, screwing in reduces the swivel angle)

4. Vent the actuator and check the seng again.

5. Repeat the seng procedure (steps 2 to 4) if

necessary.

6. Tighten the lock nut again.

Sengtheendposioncounterclockwise(CCW):

1. Turn the actuator counterclockwise unl it reaches

the end stop and check the seng.

2. Loosen lock nut "Y"

3. Vent the actuator and turn the adjusng screw

in the desired direcon (unscrewing expands the

swivel angle, screwing in reduces the swivel angle)

4. Vent the actuator and check the seng again.

5. Repeat the seng procedure (steps 2 to 4) if

necessary.

6. Tighten the lock nut again.

Stop screws

By adjusng the stop screws, both end

posions can be adjusted by +/- 6° for

ne adjustment of the valve end posi-

on. The respecve seng posion is

secured by ghtening the lock nut.

X

Y

MANUAL & MAINTENANCE GUIDELINES

PNEUMATIC ACTUATORS SERIES PRY

BWA.PRY.200116

January 2020

11

3.4Assemblytoavalve

• The valve bore (for ball and plug valves) resp. the valve disc (for buery valves) must correspond to the

groove on the top of the actuator pinion sha during installaon in order to make signal- or control units work

correctly. The groove symbolizes the valve posion (acc. to VDI/VDE 3845).

• Make sure that the valve sha corresponds to the connecon in the drive pinion in shape and size. Dierences

can be compensated by using adaptaon inserts. These can be ordered separately via our sales department.

• Check whether valve and actuatorhave corresponding ISO interfaces. If not, an addional mounng kit will be

required. It can be ordered separately via our sales department.

• Fasten the actuator to the valve by using matching screws. We recommend using stainless steel screws to

ensure appropriate corrosion resistance. The number of screws is relevant for the stability of the assembly and

power transmission. Therefore, do not miss any aachment point. Take the correct ghtening torques into

account during xaon.

3.5Tighteningtorquesforscrewconnecon

Tightening torques in Nm

Nominal size Nm

M16 220

M20 430

M22 425

M24 585

M27 785

M30 1250

M33 1400

M36 1750

M48 5000

M64 9200

MANUAL & MAINTENANCE GUIDELINES

PNEUMATIC ACTUATORS SERIES PRY

BWA.PRY.200116

January 2020

12

1. Rotaryactuatorsmustbepneumacallyandelectricallyisolatedpriortoanyintervenon.

2. Rotaryactuatorsandtheconnectedvalvecanmovewhenthecontrolpressuregets

disconnectedand/oranelectricalcontrolsignalisswitchedo.

3. Insingle-acngactuatorswithanincompletespringstroke,thereisahighspringforcethatcan

triggerasuddenrotarymovementwhentheactuatorisdisassembled.Thiscancauseserious

injuriesordamages.

4. Intervenonsinelectricalinstallaonsmayonlybecarriedoutbyappropriatespecialists.A

switchedopowersupplymustbesecuredagainstunintenonalrestart.

Chapter 4: Maintenance

Content:

• General

• Safety instrucons

• Disassembly and maintenance of the modules

• Field reversions

• Components

4.1 General

Actuators of the PRY series are designed to be maintenance-free and supplied with sucient lubricaon for their

normal service life. The normal lifespan depends on the size and applicaon condions and is subject to EN 15714-3.

Carry out regular inspecons to ensure a failure-free operaon. Check whether there are visible or audible defects.

Regular maintenance and exchange of seals and bearings extends the normal lifespan. Corresponding spare part

sets are available from our sales department.

4.2Safetyinstrucons

MANUAL & MAINTENANCE GUIDELINES

PNEUMATIC ACTUATORS SERIES PRY

BWA.PRY.200116

January 2020

13

4.3 Disassembly and maintenance of the modules

4.3.1 Spring module

Disassembly of the spring module

1. Shut o the air supply and ensure that the control

media has been completely vented from the actua-

tor into the atmosphere.

2. Release the spring module from the center module.

3. Carefully pull the spring module away from the

center module in order not to damage the threads

on the spring rod and the stud bolts of the adapter

plate.

4. The spring module is welded as an integral com-

ponent and the internal components cannot be

disassembled.

Maintenance of the spring module

1. Clean and lubricate the spring rod and push it back in.

2. Replace the O-ring between the spring module and the

center body module.

1. Beforedismantlingtheactuator,disconnectallairandpowerfromtheactuator,removeall

accessoriesfromtheactuator,andremovetheactuatorfromthevalve(ordisablethegearbox,

ifpresent).

2. Iftheactuatorisequippedwithamanualoperaonmodule,rstmakesurethattheoverrideis

completelyresettorelieveitofanyspringforce.

Toavoidinjuries,pleasereadtherelevantoperangandmaintenanceinstrucons.Before

removingordisassemblingthespringmodule,makesurethattheactuatorisdepressurized,the

strokelimitaondevicesaredeacvatedandtheendstopposionsarefullyreached.Donot

manipulatefactory-weldedpartsofthespringtank!

MANUAL & MAINTENANCE GUIDELINES

PNEUMATIC ACTUATORS SERIES PRY

BWA.PRY.200116

January 2020

14

4.3.2Pneumacmodule

Disassemblyofthepneumacmodule

1. Remove the pneumac module from the quarter

turn actuator.

2. Loosen the e rod nuts and remove the end plate

from the pneumac module.

3. The e rods can be unscrewed from the adapter

plate.

4. Remove the cylinder.

Maintenance of the cylinder module

1. Clean the cylinder and grease the inside of the

cylinder.

2. Replace the piston and the O-ring on the cover.

Makesurethatthecontrolmediahasbeencompletelyventedfromtheactuatorintothe

atmospherebeforeyoudisassemblethepneumacmodule.Otherwise,seriousinjuriescanresult.

Toremovethepneumacmodulefromthespring-resetactuator,rstdisassemblethespring

moduleasdescribedinsecon4.3.1.

4.3.3 Center module

Disassembly of the center module

1. Remove the posion indicator, if applied.

2. Loosen and remove the top cover screen.

3. Loosen the screws on the housing cover and open

it.

4. Turn the yoke to the appropriate posion, loosen

the screw on the cover plate of the pin roller and

take out the cover and the drive pin.

5. Take out the yoke.

Eitherthespringmoduleorthepneumacmodulemustberemovedfromthecentermodule

before it can be disassembled.

MANUAL & MAINTENANCE GUIDELINES

PNEUMATIC ACTUATORS SERIES PRY

BWA.PRY.200116

January 2020

15

4.3.4 Manual hydraulic module

Instrucons

1. Aer installaon, the hydraulic unit must be vented

rst.

2. For the single-acng pump, open the relief valve and

quickly move the operang lever a few mes.

3. With the single-acng pump, the hydraulic cylinder

remains in the original posion aer stopping opera-

on. When the relief valve is opened, the hydraulic

cylinder is slowly reset under the spring force. When

the reset process is nished, close the relief valve

again to make the hydraulic unit ready for the next

process.

4. In case of a double-acng pump, the threaded

connector that is connected to the oil line must be

loosened. Move the operang lever up and down

several mes unl hydraulic oil seeps out of the

thread and then ghten the thread again.

5. Before operang the double-acng pump, the

compensaon valve of the hydraulic cylinder must

be closed. If the reversing lever is on the le side,

the le connecon builds up oil pressure, while the

hydraulic oil on the other side ows back to the oil

tank via the right connecon and vice versa.

6. In the case of double-acng actuators it must be en-

sured that the compensang valve is open and there

is no pressure dierence between the le and the

right side of the hydraulic cylinder, before canceling

manual operaon and returning to automac mode

via the pneumac control.

Pleaseusemineraloilorphosphateesterhydraulicoilinthehydraulicunit.Thehydraulicoillter

shouldhaveaporesizeofmax.20μm.Thedegreeofpolluonofthehydraulicuidisnotbelow

requirementsofISO19/16(NAS10).Oilpolluonleadsdirectlytodamageofthepumpandvalve

funcon.Thehydraulicuidcanbeanenvironmentallyharmfulproduct.Donotpourhydraulic

uidintocollecontanksandprotectyourselfagainstaccidentalleakageandspillageofthe

hydraulicuidwithoil-absorbingproducts.

hydraulic module single-acng

hydraulic module double-acng

MANUAL & MAINTENANCE GUIDELINES

PNEUMATIC ACTUATORS SERIES PRY

BWA.PRY.200116

January 2020

16

4.3.5 Mechanical manual modules

The manual modules are either a screw- or a gear-module for double-acng and single-acng actuators.

Instruconsforthespindleandgearmodules

1. ForactuatorswithspringaconCW:

If there is a loss of compressed air, turn the handwheel counterclockwise to move the actuator in the CCW

direcon. The handwheel must be turned clockwise to the starng posion before the drive resumes automac

operaon.

2. ForactuatorswithCCWspringacon:

If there is a loss of compressed air, turn the handwheel clockwise to move the drive in the CW direcon. The

handwheel must be turned counterclockwise to the starng posion before the drive resumes automac opera-

on.

Thepushrodofthegearmodulemovesbackandforthinnormaloperaon.Donotremove

protecvecoverswithoutensuringthattheairsupplyisinterruptedandtheautomacoperaon

oftheactuatorisdeacvated.

screw module double-acng screw module single-acng

Themanualmodulesarenotusedasastrokelimitaondevice.Forautomacoperaon,the

manualactuaonunitmustbemovedcompletelyintothebasicposion.

double-/single-acng gear module

MANUAL & MAINTENANCE GUIDELINES

PNEUMATIC ACTUATORS SERIES PRY

BWA.PRY.200116

January 2020

17

4.4Fieldreversions

4.4.1Changingthedireconofspringacon(forsingle-acngactuators)

The safety posion of the single-acng actuator can be changed from CW to CCW and vice versa. This requires

swapping the pneumac and spring modules.

1. Follow the steps to remove the spring and pneumac modules from the actuator as described in secons

4.3.1 and 4.3.2.

2. Change the posions of the two modules and rst assemble the pneumac module. Make sure that the

module seal O-ring is properly seated in the groove.

3. Mount the actuator back on the valve/gearbox and adjust the adjusng screws as required for the correct

operaon of the valve. Tighten the lock nuts on the stop screws.

4. Check the actuator for correct operaon at the nominal operang pressure.

Neveraempttounscrewandremovethespringbarwithoutcompletelyrelievingthesprings.

Mounng

version Actuatorconguraon Safetyrotaon

PR CW

PL CCW

MANUAL & MAINTENANCE GUIDELINES

PNEUMATIC ACTUATORS SERIES PRY

BWA.PRY.200116

January 2020

18

4.4.2Conversionfromdouble-acngtosingle-acng

1. To convert a double-acng actuator to single-acng (fail-CW mode), a spring module must be mounted

opposite on the center module. If the CCW mode is to be achieved, the pneumac module must rst

be dismantled and mounted on the opposite side of the center module. Then the spring module can be

mounted at the previous posion of the pneumac module.

2. If the pneumac module needs to be enlarged for the required conguraon of the single-acng actuator,

rst carry out the complete replacement of the pneumac module. Follow the instrucons in secon 4.3.2 to

remove the pneumac module. Then mount the new pneumac module accordingly.

3. Connect the spring module and the center module with stop screws, insert the O-ring of the module into the

adapter groove of the spring module.

4. Reassemble the actuator.

5. Adjust the stop screws to ensure correct installaon with the valve.

4.4.3Conversionfromsingle-acngtodouble-acng

1. Remove the spring module from the actuator (see secon 4.3.1).

2. Aach the end cover with the O-ring to the spring module side of the center module.

3. Adjust the adjusng screws if necessary.

MANUAL & MAINTENANCE GUIDELINES

PNEUMATIC ACTUATORS SERIES PRY

BWA.PRY.200116

January 2020

19

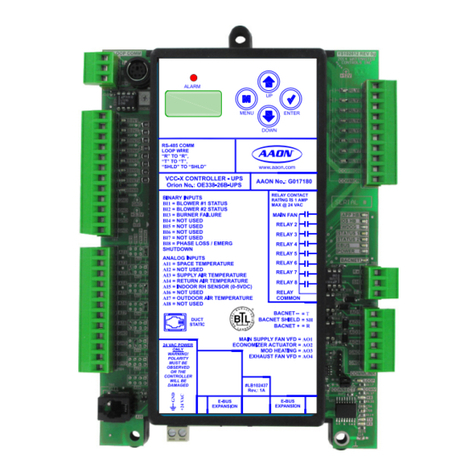

4.5 Components

Item Designaon Quanty Material

Center module

5 Bear Seat 1 Carbon Steel

7 Screw n Carbon Steel

8 Indicator 1 Carbon Steel

9 Screw n Carbon Steel

10 Center Body Cap 1 Ducle Iron

11 Yoke 1Ducle Iron

12 Center Body 1 Ducle Iron

13 Cap O-ring 1 Rubber

14 Drive Mechanism 1 Alloy Steel

Spring module

1 Flange Cap 1 Carbon Steel

2 Spring Seat 1 Carbon Steel

3 Spring 1 Spring Steel

4 Spring Body 1 Carbon Steel

6 Spring Stem 1 Alloy Steel

Pneumacmodule

15 Cylinder Seat 1 Ducle Iron

16 O-ring 1 Rubber

17 Piston 1 Carbon Steel

18 Guide Ring 1 Resin

19 Cylinder Body 1 Carbon Steel

20 Cylinder Cap 1 Ducle Iron

21 Screw n Carbon Steel

22 Nut n Carbon Steel

ProtACTGmbH

Mayener Straße 9

56729 Eringen

Tel: +49 (0) 2605 96 25 19-0

Fax: +49 (0) 2605 96 25 19-6

Email: protact@protact-gmbh.de

Website:www.protact-gmbh.de

Table of contents

Other ProtACT Controllers manuals

Popular Controllers manuals by other brands

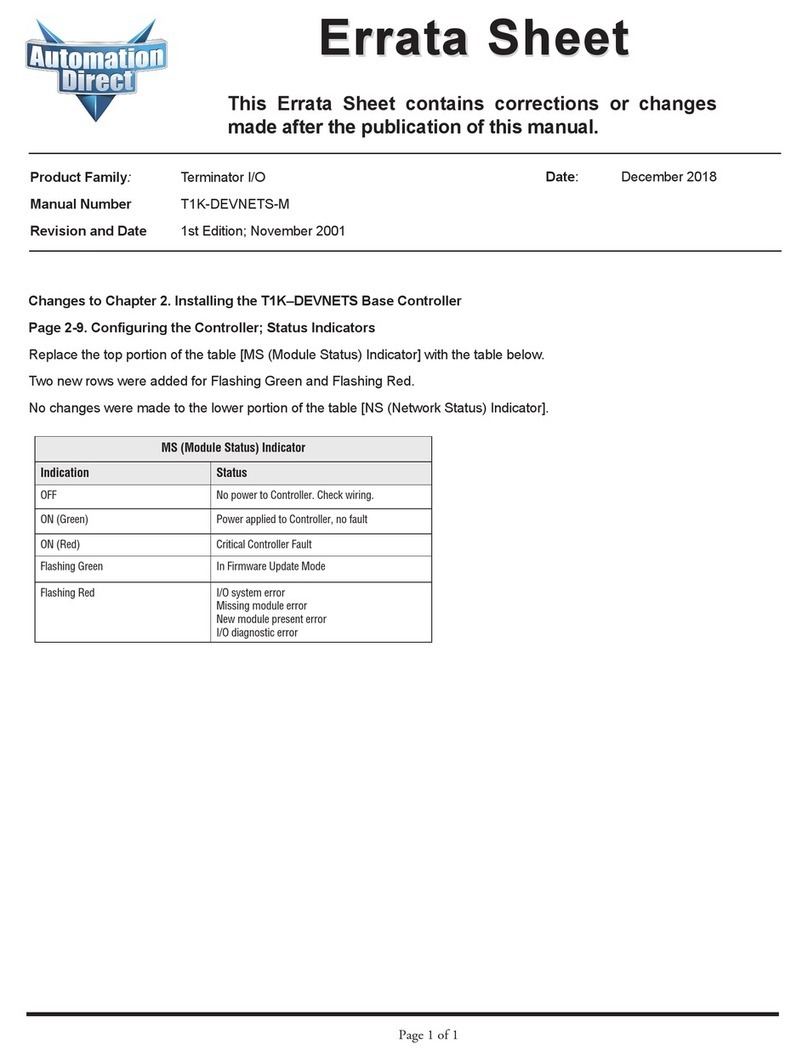

AutomationDirect

AutomationDirect T1K-DEVNETS user manual

Servomech

Servomech ILA 15 A Installation, operation and maintenance manual

Belimo

Belimo LF24-SR-E US manual

GE

GE EntelliPro ES Series Installation and instruction manual

flamco

flamco MeiTronic W10B user manual

Acuity Brands

Acuity Brands nLight rIO quick start guide

Atlas Copco

Atlas Copco POWER FOCUS 6000 quick start guide

Leviton

Leviton BITWISE BWBC1 quick start guide

ABB

ABB Jocab Safety Vital 2 Operating instruction

Andover Controls

Andover Controls CMX 240 Series installation guide

Burkert

Burkert 8605 Series operating instructions

Snell Advanced Media

Snell Advanced Media 2460 user manual