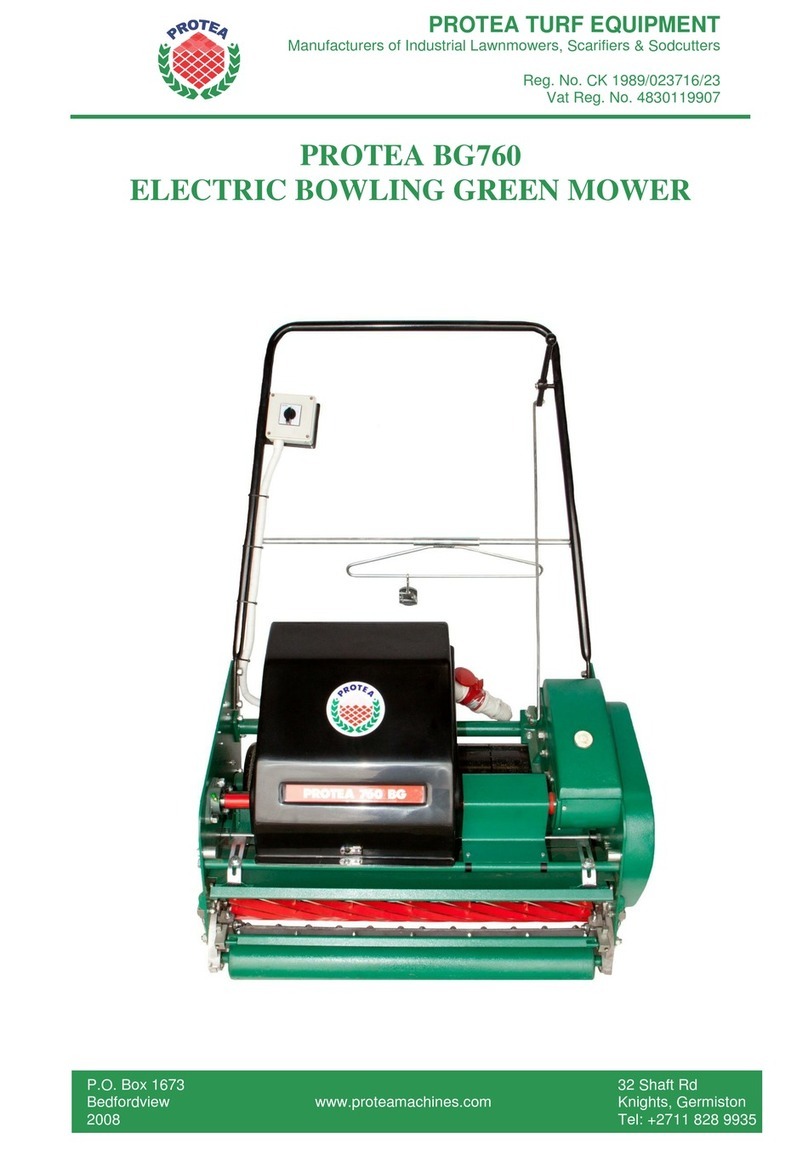

PROTEA BG 760 User manual

SPARES

&

INSTRUCTION MANUAL

Ref. No.: CK 91/04496/23 Vat No.: 4830119907

Tel: 011 828 9935

011 822 1850

Fax: 011 828 6869

Mobile: 082 458 7257

Physical Address

BEDFORDVIEW

Telephone/Fax Numbers

Email: [email protected]

Email: sean@proturf.co.za

For further information on any Protea products, please visit our website www.proturf.co.za

Postal Address

Germiston

Gauteng

South Africa

Knights

2008 GAUTENG

Manufacturers of Protea Range of Mowers, Sodcutters, Scarifiers

PROTEA TURF EQUIPMENT cc

SOUTH AFRICA

32 Shaft Road

CONTACT DETAILS:

P.O.BOX 1673

SPECIFICATIONS

MOTORS CUTTING CYLINDER

Standard 220 Volt 1,5kw 1 phase 762mm long x 152mm diameter

Other single or three phase motors (30” x 6”) 16 single helix

available on request reversible blades; each blade

25mm (1”) x 8 gauge.

(10 blade optional)

TRANSMISSION BOTTOM BLADE

Twin “V” Belt to countershaft then by Precision ground to less than 1.3mm

Heavy duty drive chains and sprockets to (.050”) at the cutting edge and

attached roller and cutter to the cast iron soleplate by 9

countersunk machine screws.

1mm Blade also available.

ADJUSTMENTS

Height of cut: by independent micro-adjusters

with dual lock nuts.

Cutter to bottom blade: By independent

micro-adjusters with dual lock nuts

(Precision setting bar supplied)

GEARBOX

16 Bladed Cutting Cylinder

Heavy-duty gears, 2 speed on traverse constant

Cutter revolutions. High gear 5.15km/h (3.2mph).

Clip frequency 200 clips per meter

(186 clips per yard). Low gear 3.88km/h (2.1mph)

Clip frequency 291 clips per meter (276 clips per yard)

MASS BEARINGS

(Complete with Grassbox) Sealed ball races fitted throughout

110/220 Volt –156 kg (343 lbs) (Prepacked with Lubricant)

1Know your controls. Read the owner's manual 13 Stop the engine whenever you leave the

carefully. Learn how to stop engine quickly in an mower, even for a moment.

emergency. 14 Stop the engine before pushing mower

2Make sure the lawn is clear of sticks, stones, across gravel drives, walks or roads.

bones, wire and debris. They could be thrown

by the blade. 15 Do not allow children or people

unfamiliar with these instructions to use

3Stop the engine and disconnect spark plug wire the mower.

before checking or working on the mower. 16 On slopes or wet grass, be extra careful of

4Before using, always visually inspect to see that your footing.

blade bolts and cutter assembly are not worn or

damaged. Replace worn or damaged blades 17 Never cut grass by pulling the mower towards

bolts in sets to preserve balance. you.

Damaged blades and worn bolts are a

major hazard. 18 Never use an electrically powered mower in

the rain or when grass is wet.

5Check all nuts, bolts and screws often, always

be sure the mower is in safe operating 19 Be extremely careful when using a ride on

condition. Use only replacement parts made

mower on slopes.

and guaranteed by the original manufacturer

of your mower 20 Never leave wind-up starters in a wound

condition.

6

Add fuel BEFORE starting engine. Avoid spilling

petrol and do not fill the tank while the engine is 21 Do not over speed the engine or alter governor

running or while you are smoking. settings. Excessive speed is dangerous

and shortens mower life.

7Do not mow whilst people, especially children

or pets are in the mowing area. 22 It is advisable to wear suitable eye protection

when operating a mower.

8Never use the mower unless the grass catcher ,

or guards provided by the manufacturer, 23 Turn the fuel off at the conclusion of mowing

are in position. and reduce the throttle setting during

engine run-ou.

9Do not mow barefoot or in open sandals.

Wear long trousers and heavy shoes. 24 Store fuel in a cool place in a container

specifically designed for the purpose. In

10 Disengage all blade and drive clutches before general, plastic containers are unsuitable.

starting.

25 Never pick up or carry a mower when it is

11 Start the engine carefully with feet well away operating.

from the blades.

12 Do not operate engine in a confined space where

exhaust fumes (carbon monoxide) can collect.

POWER LAWNMOWER SAFETY PRECAUTIONS

1

MAINTENANCE AND ADJUSTMENT

Normal Speed: 3.2 m.p.h –116 cuts per yard (127 cuts per meter)

Low Speed: 2.1 m.p.h –167 cuts per yard (183 cuts per meter)

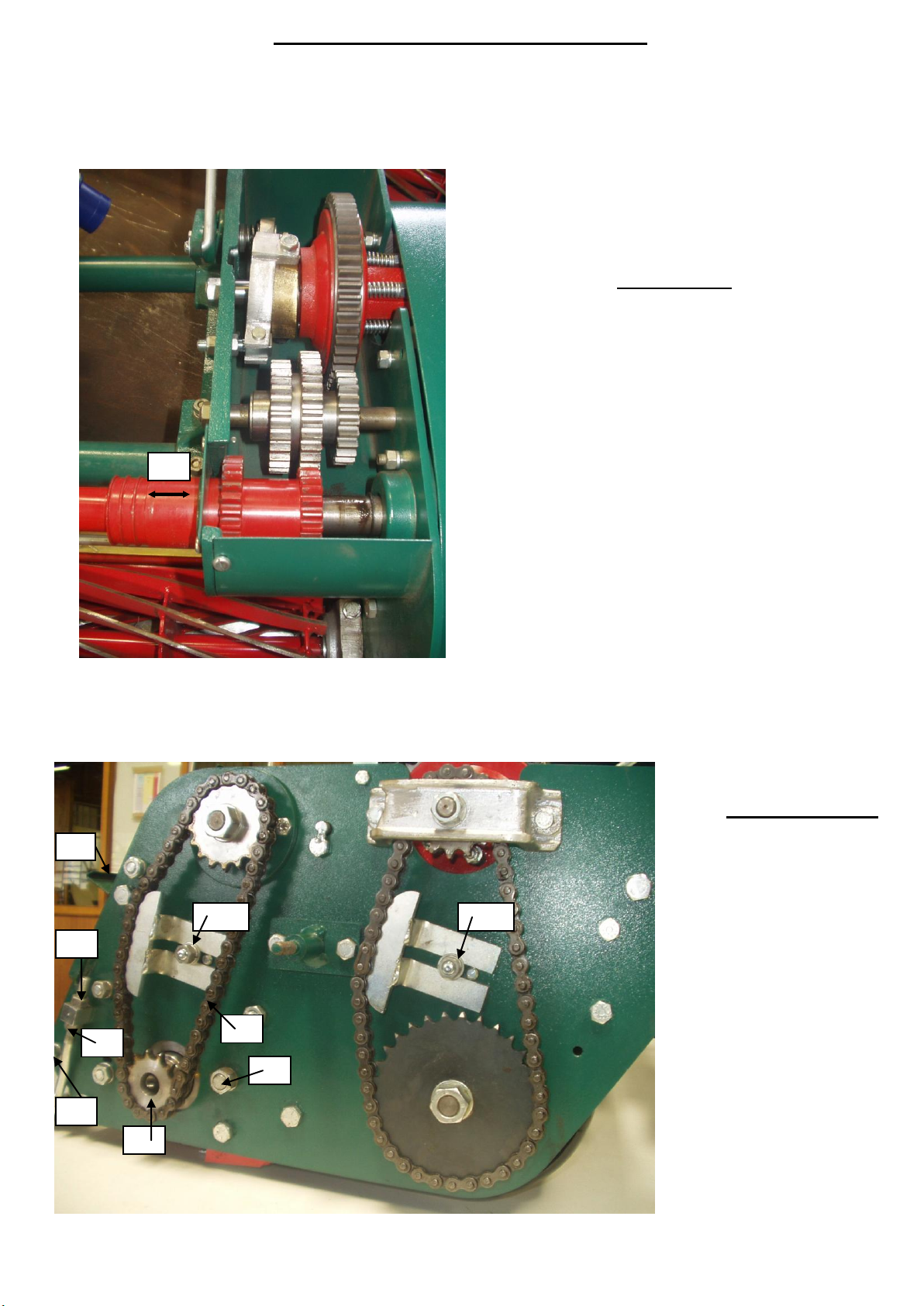

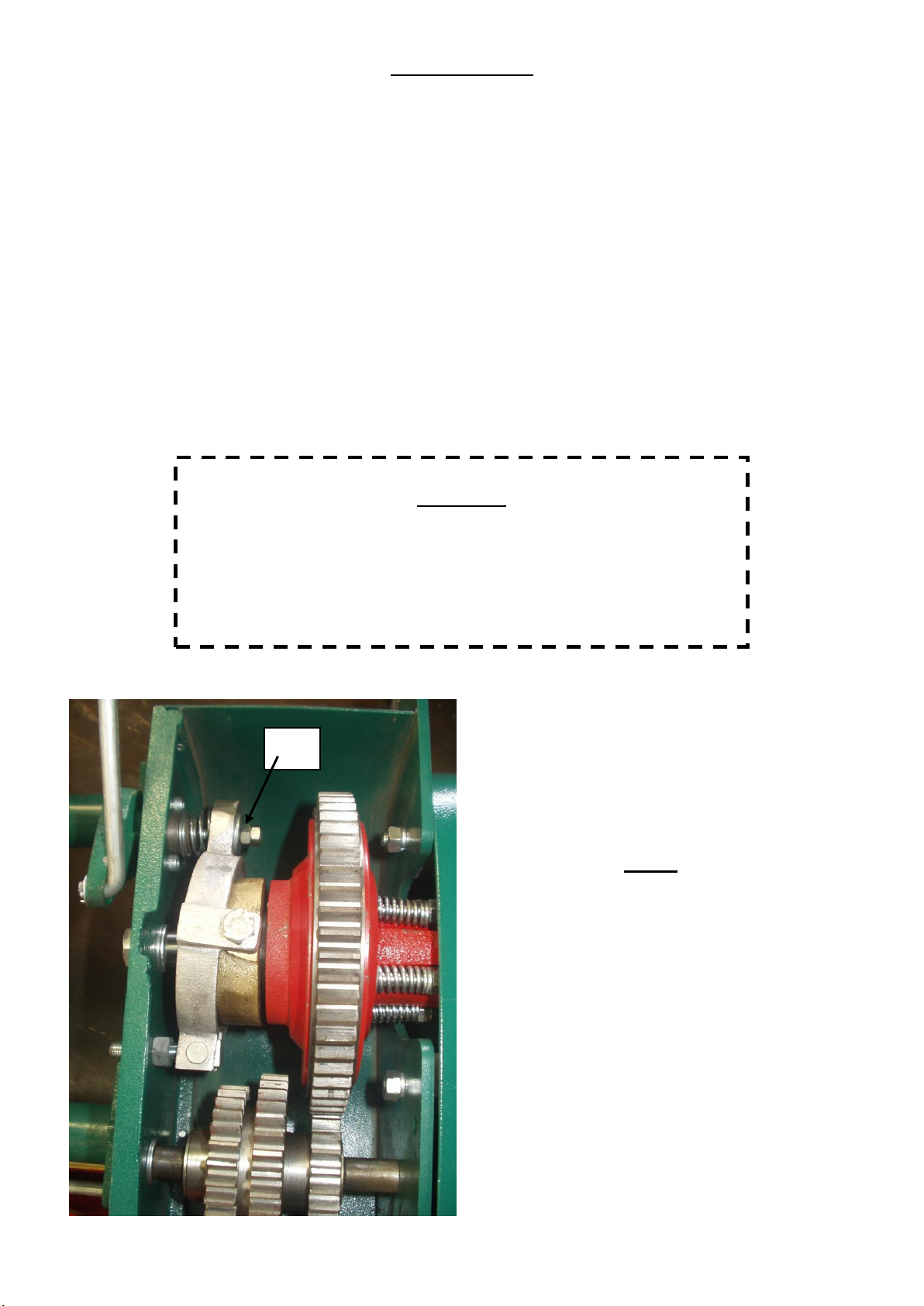

Speed Control

To change speed, stop motor and move

ribbed sliding sleeve (A) inwards to engage

normal speed outwards for low speed as

required. It may be necessary to twist the

sleeve or countershaft backwards and

forwards slightly whilst sliding the sleeve

into position to allow the gear teeth to line

up and mesh fully.

Height Adjustment

To cut lower,

slacken quadrant

clamp bolt nuts (1),

also the lower

adjusting screw nut.

Then tighten top

adjusting screw nut

until desired height

of cut is obtained.

To cut higher,

reverse procedure.

Re-tighten all nuts

after desired setting

is obtained

Refer setting gauge

instructions.

A

9

3

1

14

14

4

2

8

7

2

To check the mower for alignment –Your mower is designed to produce

the perfectly flat cut that is required for a top quality green. Ridging or

stepping between cuts means that the height of cut is unevenly set or more

likely, that the mower is “out of square”. That is, the rear roller is not

perfectly in line with the cutting edge of the bottom blade. This condition

can be brought about by transport of the mower or undue stress caused by

bumping while moving the mower from the equipment shed onto the green.

Re-alignment can be achieved by different means but the recommend

procedure is

1. Lay mower back on the handle

2. Chalk the thin front edge of the bottom blade about 6” of its length

at both ends.

3. With the front roller remaining in approximately its normal height

setting, “sight” the bottom of the front roller relative to the chalked

cutting edge of the blade

4. Adjust the front roller into exact alignment with the cutting edge,

continually sighting while adjustment proceeds

5. Lock the roller and re-check

6. Now use your height setting bar as an alignment tool by placing the

bar against the front roller and the rear roller on the extreme LEFT

HAND SIDE (Chain cover Side)

7. Adjust the setting bar screw so that it just contacts the bottom blade

cutting edge.

8. Test the right hand side of the rear rollers with the same setting, and

adjust the rear roller up or down Loosen (A) until the same screw

contact is achieved on the blade.

9. As the movement of the rear drum could affect the original L.H.S

setting slightly, reset he screw at the L.H.S. and recheck the R.H.S.

10. All elements of you machine will now be in perfect alignment.

11. After tightening all adjustments a final check should be made.

12. The required height of cut can now be checked and set in the

normal manner

While the procedure may seem complicated it is in fact very simple to

perform and can be carried out in less than 15 minutes. The sighting is easy

and accurate because it is done from the front roller, which is nearest to the

operator. A machine that is “true” will pay dividends by precision cutting

of your green.

Setting Gauge

This illustrates the method of setting the gauge to

the height of cut, where in this instance height of

cut is a 20-cent piece and a 5-cent coin. The

distance between the setting gauge bar and the

underside of the adjustable screw head represents

the height of cut. Lock the screw in the desired

position with the wing nut. To use the setting

gauge, rest it against the underside of the front and

rear roller, as illustrated, and by adjusting the front

roller, the desired height of cut will be obtained

when the underside of the screw head lightly

touches the top cutting edge of the bottom blade

across its full width.

Note: When using the setting gauge, take

care not to force the head of the adjusting

screw onto the bottom blade, as this could

distort the blade and affect the setting.

A

3

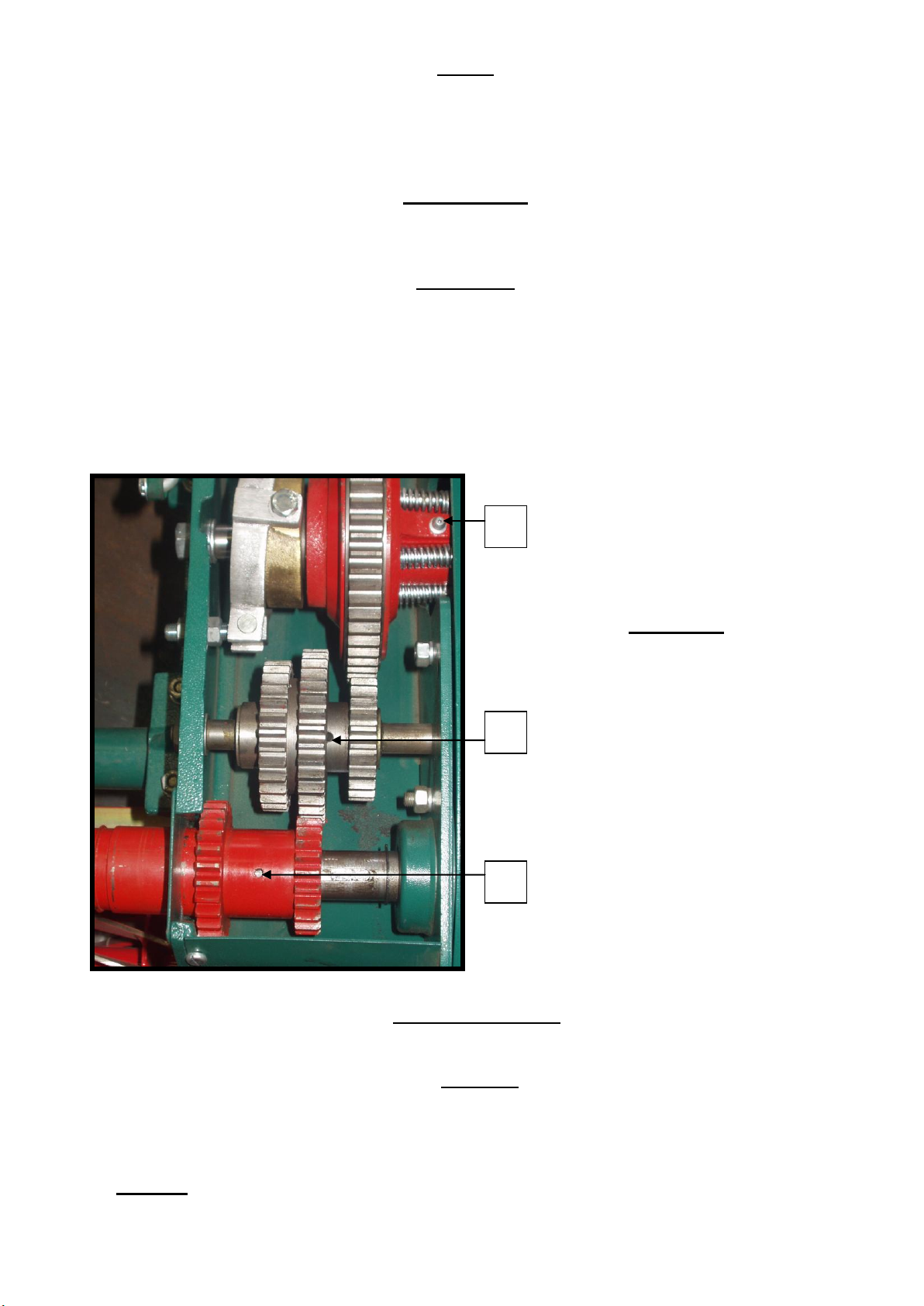

Cutter

To adjust the cutter setting, slacken cutter

hanger clamp bolts (4) at each side of the

machine, and proceed as follows;

Adjustment: Slacken the top nuts (5) on

adjusting screws. Then by tightening the

bottom nuts (6), the cutter is lowered on to the

bottom blade. To raise the cutter, loosen the

bottom nuts and tighten the top nuts. Re-

tighten cutter hanger clamp bolt nuts. Always

adjust cutter to bear very lightly on bottom

blade. If the cutter rubs harshly on the bottom

blade, there will be excessive wear of both

cutter blades and bottom blade, and an

unnecessarily heavy load on the power unit.

A grass trough is

incorporated that can be

adjusted closely to the

rear drum so that grass

and dirt build up is

scraped from the drum

and caught in the trough.

To empty:

Remove the cover plate from the trough opening in the side frame. The cover unclips by pivoting it

upwards. Withdraw the trough, as illustrated. When replacing, the end of the trough could come into

contact with its adjusting screw, when halfway in. A twisting action will allow the bottom edge of the

trough to clear the screw and push right in. Replace the cover plate.

Note: the trough can be withdrawn more easily if the deflector clamp bolts are loosened and the

deflector lowered to allow extra clearance.

Adjustment –The adjusting screw can only be operated when the trough is removed as it is located under

the center of the trough. To adjust trough closer to roller, release lock nut and lower screw lightly –to

move it away, raise screw slightly. Replace trough and check clearance from the drum. If satisfactory

withdraw trough and tighten lock nut.

10

6

5

4

4

Reversing Cutter:

A feature of this machine is that the cylinder may be easily removed, reversed end for end

and replaced. This provides a new keen cutter edge. If the bottom blade is badly worn, this

should be replaced at the same time that the cutting cylinder is reversed or replaced.

To withdraw cutter from machine, first remove cutter chain (7), sprocket (8) and grass

deflector (9), refer illustration PAGE 1. The sprocket is removed by inserting tommy bar in

hole in sprocket and giving tommy bar a sharp tap with hammer, NOTE: The sprocket has a

left hand thread, to unscrew, turn in a clockwise direction. Remove the grass deflector

and the deflector-supporting bar. Remove the cutter hanger caps by undoing the holding

bolts (10) at each side of the machine. Then the cutter may be taken from the machine by

lifting and moving to the chain side of the machine. The opposite side will then clear side

frame. Continue with a diagonal lift to complete removal. Remove the nut from the end of

the cutter (it has a left hand thread). Reposition this nut at the other end of the cutter. Turn

the cutter end for end and replace in the machine. Then reverse operations used to remove

cutter from machine. Replace all bolts and tighten firmly. After reversing cutter it will be

necessary to adjust the same. Also see detail on chain adjustment

Important:

When reversing or replacing the cutter do not remove the cutter bearing

hangers. Remove the bearing caps only as instruction. The bearing caps

must not be changed over; each cap must be replaced in its original

location.

Clutch:

To be certain that the clutch is fully

engaged without possibility of slip, there

should be approximately 1½” of free

movement (at the clutch operating lever

knob) before the resistance of clutch

operation is felt. This adjustment is made

by means of the self-locking nut “E”

E

5

Chains:

Adjustment: Loosen chain adjuster locking bolt (14) and slide the chain adjuster in the desired

direction. A chain should ever be adjusted tightly. It is advisable to leave the cutter chain with a

little slackness so that slight adjustment of the cutter can be made without having to re-adjust this

chain each time.

Grass Deflector:

The grass deflector is adjustable to permit grass to be thrown into the box at the desired angle.

Adjustment: Loosen clamping screws and raise or lower as required.

V Belt Drive:

The V Belt tension is correct when there is about ½” up and down movement of the belt midway

between the pulleys.

Adjustment: To tighten belt, remove motor cover, loosen four nuts holding down the motor, and

force the motor to rear. Then re-tighten nuts.

Note: V Belts are designed to run dry, and under no condition is belt dressing required.

Lubrication:

Pre-lubricated, sealed ball races

are fitted to the cutter; drum shaft,

countershaft and front roller. No

further lubrication is necessary to

theses 8 races. Drums are fitted

with special self-lubricating

bushes and do not require

lubrication.

Driving Chains: grease or

medium oil used sparingly

Gearbox: use medium oil at

points B, C and D. Use grease

sparingly on gear teeth

C

D

B

Front Roller Scraper:

Loosen clamp bolt each end, adjust scraper to just clear the roller and re-tighten clamps.

Cleaning:

This mower is constructed of first class materials, and will give longer and more efficient service if

kept clean. After cutting and before putting machine away, wipe blade down with an oily rag.

Occasionally check nuts and bolts for tightness.

Warning: State Electricity Authority regulations provide that it is always necessary to disconnect

power supply before effecting and adjustments to the machine.

6

2

3

6

7

4

5

1

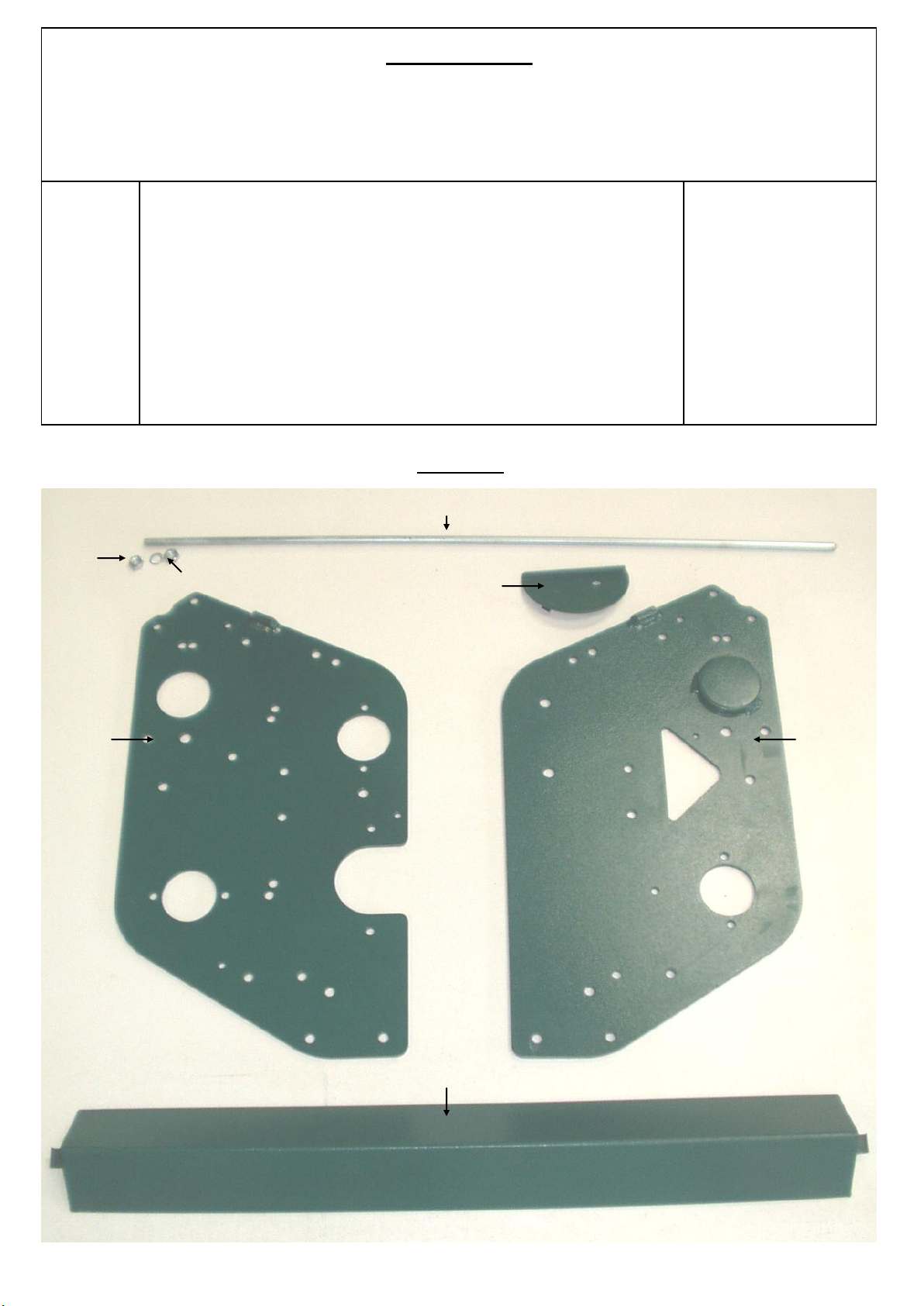

SECTION 1

REFER FIGURE 1

ILLUS.

NO DESCRIPTION PART NO.

Side Frame Assy. LH

Side Frame L.H. (Click System)

Side Frame Assy. RH

Side Frame R.H. (Click System)

Scraper Trough Assy.

Trough Cover Plate Assy.

Trough Pivot Bar

Washer M10 Spring Washer

Nut M10

1

1

2

2

3

4

5

6

7

305795

305800

305779

305782

305664

305728

305701

Standard

Standard

FIGURE 1

7

SECTION 2

REFER FIGURE 2

ILLUS. NO. DESCRIPTION PART

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

Main Stay Tube Assy.

Housing Side Seat Block

Bolt 1” x 3/8” UNF

Bolt 1 ¼ x 3/8 UNF

Washer 3/8 INT. S/Proof

Nut 3/8 UNF

Seat Block Clamp

Washer M2

Nut M8

Deflector Strip Assy.

M6 x 12 Set Screw

M6 Spring Washer

Sole Plate

Trough Support

Pan Head Screw M6 x 25

Nut M6

Bottom Blade LC

Bottom Blade Screw (9 off)

Sole Plate Mounting Bolt 1 ¼ x 7/16 UNF

Nut 7/16 UNF

Washer 7/16 EXT. S/Proof

301428

302076

Standard

Standard

Standard

Standard

302084

Standard

Standard

301065

Standard

Standard

301735

305752

Standard

Standard

393000

2071924

Standard

Standard

Standard

FIGURE 2

1

4

5

6

5

6

5

6

5

3

6

7

7

2

9

8

9

8

10

11

11

14

12

12

13

21

20

19

21

20

19

17

18

18

18

18

18

2

16

15

FIG 3

8

`

1

2

1

3

1

3

2

5

4

6

7

7

8

8

9

9

9

10

10

10

10

M8 x 20

Serscrew

springwasher &

washer

1

12

1

12

1

M8 x 20

Serscrew

springwasher &

washer

1

13

13

14

14.1

15

16

17

17

16

18

18

9

9

19

38

19

38

20

21

20

21

22

23

23

24

38

25

25

26

27

28

29

28

29

30

30

31

32

31

32

33

34

34

35

12

21

9

37

39

21

37

9

36

35

12

43

41

38

38

38

40

10

40

10

43

10

38

40

10

10

41

40

40

10

11

42

10

FIG. NO

1

2

3

4

5

6

7

8

9

10

11

12

13

14

14.1

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

9

3/8 UNF x 1" Set Screw

Standard

Teasing Brush

304486

Height Adjuster Stud

303407

Teasing Brush Mounting Brackets

303423

Cutter Sprocket

165340

FIG 3

M10 x 40 Cup Sq, Flat washer, Nylock nut

Standard

M10 Nut

Standard

Cutter Adj Screw

301719

Cutter Adj Screw Purchase Block

301727

Nut 1/2" UNF

Standard

RH Bearing Lock Nut Assy

161277

M10 x 30 Cup Square Bolt

Standard

Hanger Cap Bolt Spacer

301680

Bearing Housing Pivot Bolt

163440

M12 Star Washer

Standard

RH Cutter Bearing Housing Assy

301647

LH Cutter Bearing Housing Assy

301698

Bolt 3" x 5/16" W

1185887

Cutting Cylinder Washer

163432

Teasing Rake Bar

304488

Cutter Bearing

1123423

M10 Flat Washer

Standard

M10 Nut

Standard

Blade Cutter Assy 30" x 16 Blade

305074

M5 Spring Washer and Nut

Standard

Pin Mills 1/2 x 3/16 Type 4

2211047

Scraper Bolt Assy

303503

Scraper Strip

305920.3

Front Roller Scraper Block

305802

M5 x 12 Set Screw

Standard

M10 Flat Washer

Standard

M10 Spring Washer

Standard

New Front Roller Scraper Bar

305920

Nut 5/16 UNF

2321180

Nut 3/8 UNF

2321208

Top Spacer Bar

305630

Front Roller Adj. Rod Assy

301559

Adj Rod Retainer

2501036

Adj Rod Purchase Block

301583

Front roller Bearing

1122327

LH Front Roller Bracket

301030

RH Front Roller Bracket

301049

COMPONENT

PART NUMBER

Front Roller Assy

301516

Bearing Seal Washer

301057

10

FIG 4

1

2

2

1

4

4

4

4

7

7

13

12

11

6

6

6

6

3

3

3

20

29

9

9

9

30

30

29

5

13

12

10

21

8

15

14

17

18

19

18

19

16

17

34

31

32

26

19

23

14

35

26

24

25

36

28

FI

FIG 4

DESCRIPTION

1 Drum Outer Assy. 303992

2 Inner Drum Assy. 304012

3 Bush 1771189

4 Ratchet Box Assy. 301188

5 Drum Pawls 333024

6 Ratchet Box Screw 5/8 x 1/4 UNC Standard

7 Drum Shaft Sleeve 301808

8 Drum Shaft 301217

9 Key No.9 Woodruff 3802267

10 Drum Shaft Collar LH 301840

11 Drum Shaft Collar RH 301858

12 Grub Screw M10 x 20 Standard

13 Locknut M10 Standard

14 Drum Shaft Bearing 1122422

15 LH Drum Bearing Circlip 47mm 1502474

16 LH Drum Bearing Housing 301815

17 S/Screw 3/4 x 5/16 UNF Standard

18 M8 Spring Washer Standard

19 Nut 5/16 UNF Standard

20 Drum Sprocket Assy. 301866

21 Drum Shaft Lock Nut 171660

22 RH Bearing Seal Washer 301831

23 RH Drum Bearing Housing 301823

24 Drum Adjusting Screw Assy. 304434

25 Drum Adjuster Screw Purchase Block 301583

26 Nut 3/8 UNF Standard

27 Washer 5/16 Bright Standard

28 Adjuster Screw Pivot Sleeve 304469

29 Pawl Retainer 301196

30 CPCH Screw 3/4 x 5/16 W 3162306

31 Chain Adjuster 161453

32 Chain Adjuster Bolt Assy. 161461

33 Washer M10 Standard

34 Clutch to Drum Chain 2986543

35 Drum Adjuster Screw Pivot Bolt 304477

36 Seal Washer 301831

11

ILLUS.

NO.

PART

NO.

12

15

10

12

11

6

14

7

3

2

1

3

17

46

18

17

24

16

36

23

41

4

26

40

5

29

30

25

39

16

8

31

38

31

8

60

22

23

21

40

24

32

15

35

44

43

57

34

59

33

37

9

20

45

53

19

50

49

54

47

48

59

55

57

52

58

51

FIGURE 5

1 Clutch Housing Side 302068

2 Clutch Housing Body Assy 302092

3 M5 x 10 Set Screw Standard

4 Clutch Ramp Moveable 305509

5 M6 x 80 Hex Bolt Standard

6 Washer M6 Standard

7 Nut M6 Standard

8 M8 Spring Washer Standard

9 5/16 UNF Nut Standard

10 Clutch Ramp Fixed 302340

11 Clutch Ramp Stop 302359

12 M5 x 12 Cap Screw Standard

13 Washer 1/4 S/Proof 3711163

14 Clutch Ramp Spring 302375

15 Seat Block Clamp 302084

16 Housing Side Seat Block 302076

17 Washer M8 Standard

18 Nut M8 Standard

19 Drum Clutch Gear 302252

20 Bush (Drum Clutch Gear) 172216

21 Drum Clutch Shaft 302279

22 Clutch Shaft Thrust Race 3531020

23 Washer 1/2 Bright Standard

24 Nut 1/2 UNF Standard

25 Clutch Release Yoke 302308

26 Clutch Yoke Pillar 302316

27 Washer M10 Clutch Yoke Pillar (Not Shown) Standard

28 Nut 3/8 UNF - Clutch Yoke Pillar (Not Shown) Standard

29 Yoke Pin 302332

30 Pin Retainer 1/4 Circlip Standard

31 Trunnion Pivot Screw 302324

32 Clutch Plate Assy (Stud Side) 301286

33 Clutch Spring Stud 302236

34 Clutch Spring 302244

35 Clutch Release Trunnion 302287

36 Clutch Plate Lining 301276

37 1/4 BSW Nylock Nut Standard

38 M5 x 10 Panhead Screw Standard

39 Clutch Plate Assy (Sprocket Side) 301252

40 Clutch Plate Bush 3111271

41 Drum Clutch Sprocket 14T 302228

42 Clutch Shaft Washer 11/8 x 1/2 (Not Shown) 3659011

43 Clutch Release Thrust Race 3531026

44 Release Thrust Washer 302295

45 Circlip 1 1/2 EXT Standard

46 Felt Oil Strip 302210

47 Clutch Housing Cover Assy. 302130

48 Clutch Shaft Support Bracket 302121

49 Bolt 1" x 5/16 UNF Standard

50 Washer M8 Standard

51 Cover Holding Bracket Assy. 302172

52 Inter. Cluster Gear 302412

53 Bush 5/8 x 3/4 x 3/4 3111030

54 Circlip 5/8 EXT. Standard

55 Intermediate Gear Shaft 302420

56 Washer 5/8 Bright Standard

57 Washer M11 Standard

58 Housing Cover Screw 302164

59 Nut 7/16 UNF Standard

60 Clutch Housing Side Cover 302201

13

ILLUS.

NO.

PART

NO.

DESCRIPTION

FIG 5

14

3

29

2

27

1

10

8

5

4

9

6

7

40

40

39

38

32

33

39

15

17

12

33

21

28

19

20

30

32

23

13

11

26

25

24

14

18

16

22

FIGURE 6

31

ILLUS.

NO.

DESCRIPTION

PART

NO.

1 Counter Shaft 302875

2 Counter Shaft Bearing 1122422

3 Counter Shaft Bearing Housing LH 301815

4 Counter Shaft Bearing RH 301825

5 Internal Circlip 40mm Standard

6 M12 x 35 Set Screw Standard

7 M12 Nylock Nut Standard

8 5/16 UNF Screw x 1" Standard

9 5/16 UNF Nut Standard

10 M8 Spring Washer Standard

11 Counter Shaft Pulley 301954

12 8mm Woodruff Key Standard

13 Grubscrew M10 x 30 Standard

14 Taper Lock 301954

15 Nut 171660

16 Counter Shaft Sprocket 301962

17 Woodruf Key 3/16" Standard

18 Counter Shaft Gear 302383

19 1/4" Ball Bearing 3421166

20 Locating Spring 302391

21 Circlip EXT. 25mm Standard

22 "O" Ring 1501052

23 Chain Adjuster 161453

24 Chain Adjuster Bolt 161461

25 M10 Washer Standard

26 3/8 UNF Nut Standard

27 Chain - Counter Shaft to Cutting Cylinder 2986519

28 Counter Shaft Gear Key 302402

29 Clutch Housing Cover Side Cover 302201

30 Clutch Shaft Cover 302093

31 Pan Head Screw M5 x 10 Standard

32 Clutch Shaft Cover Clip Standard

33 M5 x 15 Screw Standard

38 M5 Nut Standard

39 M5 Washer Standard

40 M5 INT. Star Washer Standard

15

SECTION 6

REFER FIGURE 6

16

FIGURE 7

1

14

11

17

3

13

15

4

16

2

12

19

18

16

17

5

6

18

9

8

19

7

2

3

4

1

Other manuals for BG 760

2

This manual suits for next models

1

Table of contents

Other PROTEA Lawn Mower manuals