1

1. WARNINGS AND GENERAL SAFETY INSTUCTIONS

This manual contains important safety information.

An incorrect installation or an improper use may cause serious damages to persons or objects.

Read this manual carefully and completely. Pay particular attention to the sections marked by the symbol: .

This indicates that risk to personal injury may occur if not adhered to.

Store this manual safety for future use.

Always disconnect main power supply before operating in the automatic gate.

Make sure that the earth system is perfectly working and always connect the automatic gate to it.

The installation of automatic gates and doors must fully comply with the requirements set forth in 2006/42/EC Directive, with particular

reference to EN 12445 and EN 12453 standards.

The final connection to the electrical mains, testing and start-up of the automation must be performed by skilled and qualified personnel

(professional gate installers), who is responsible for carrying out the risks analysis and verifying the compliance of the system with the

current safety standards.

This product is exclusively designed and manufactured for the intended use specified in this manual.

Any other use than stated could compromise the integrity and the safety of the product and therefore is strictly prohibited.

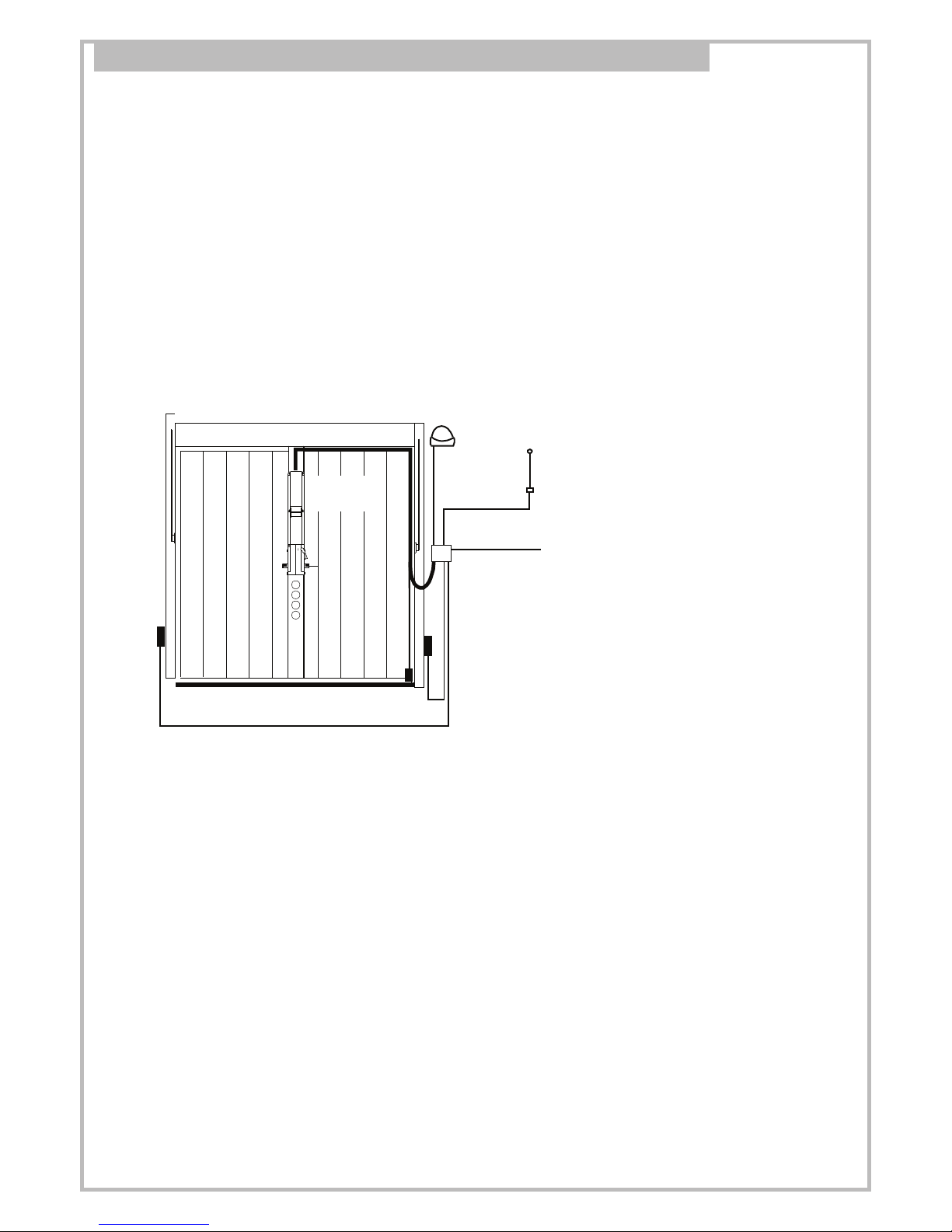

The automation is designed to move driveway gates and not intended to be used for any other purpose.

Do not let children play with the radio transmitters and any other device which could accidentally start the gate automation.

Use exclusively original parts by manufactured by Proteco for maintenance.

Do not carry out any alteration on the components of the automatic gate.

Proteco SRL will not accept liability for any components and/or additional devices used in-conjunction with the automation that has not

been produced exclusively by Proteco.

CE COMPLIANCE DECLARATION

Manufacturer: PROTECO S.r.l.

Address: Via Neive, 77 – 12050 Castagnito (CN) – ITALIA

declares that

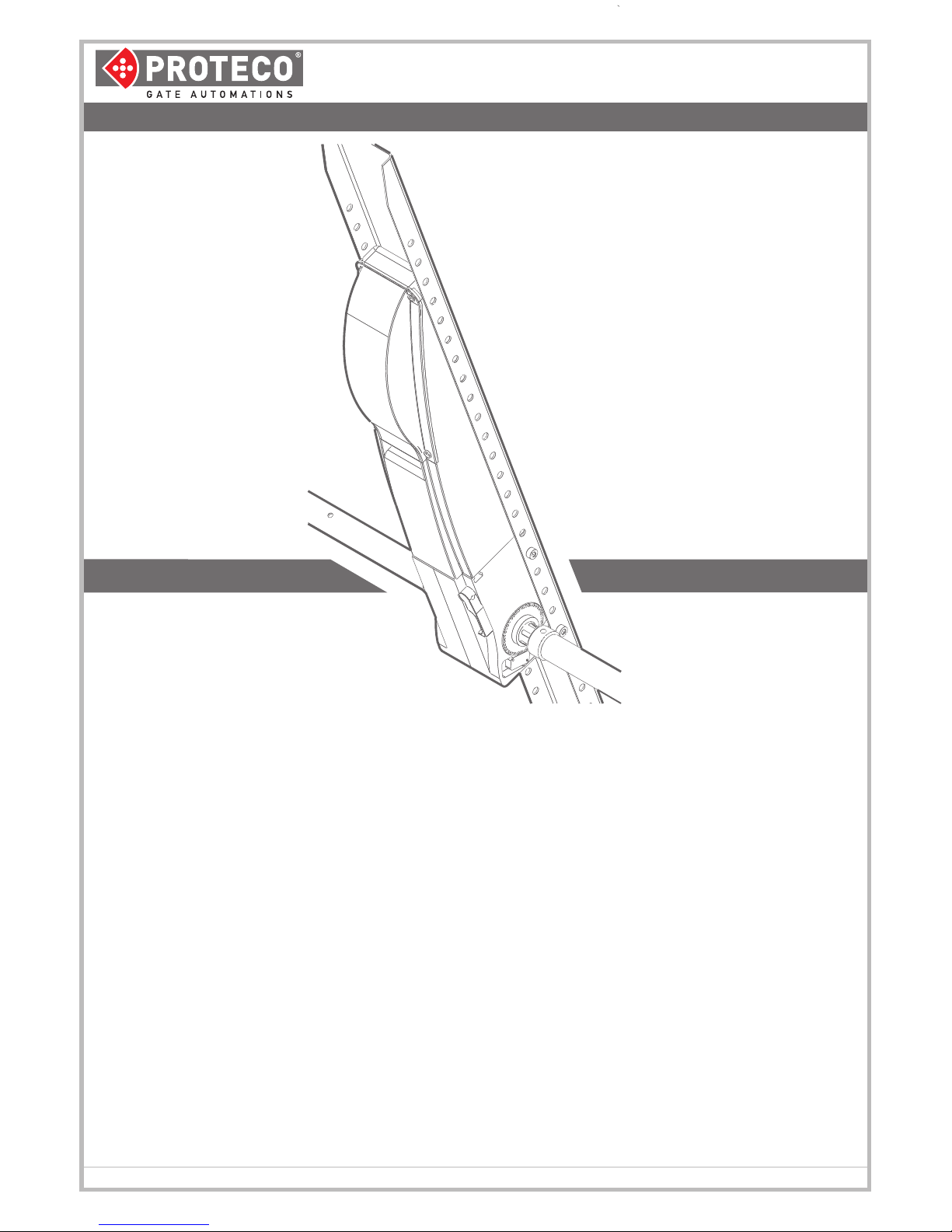

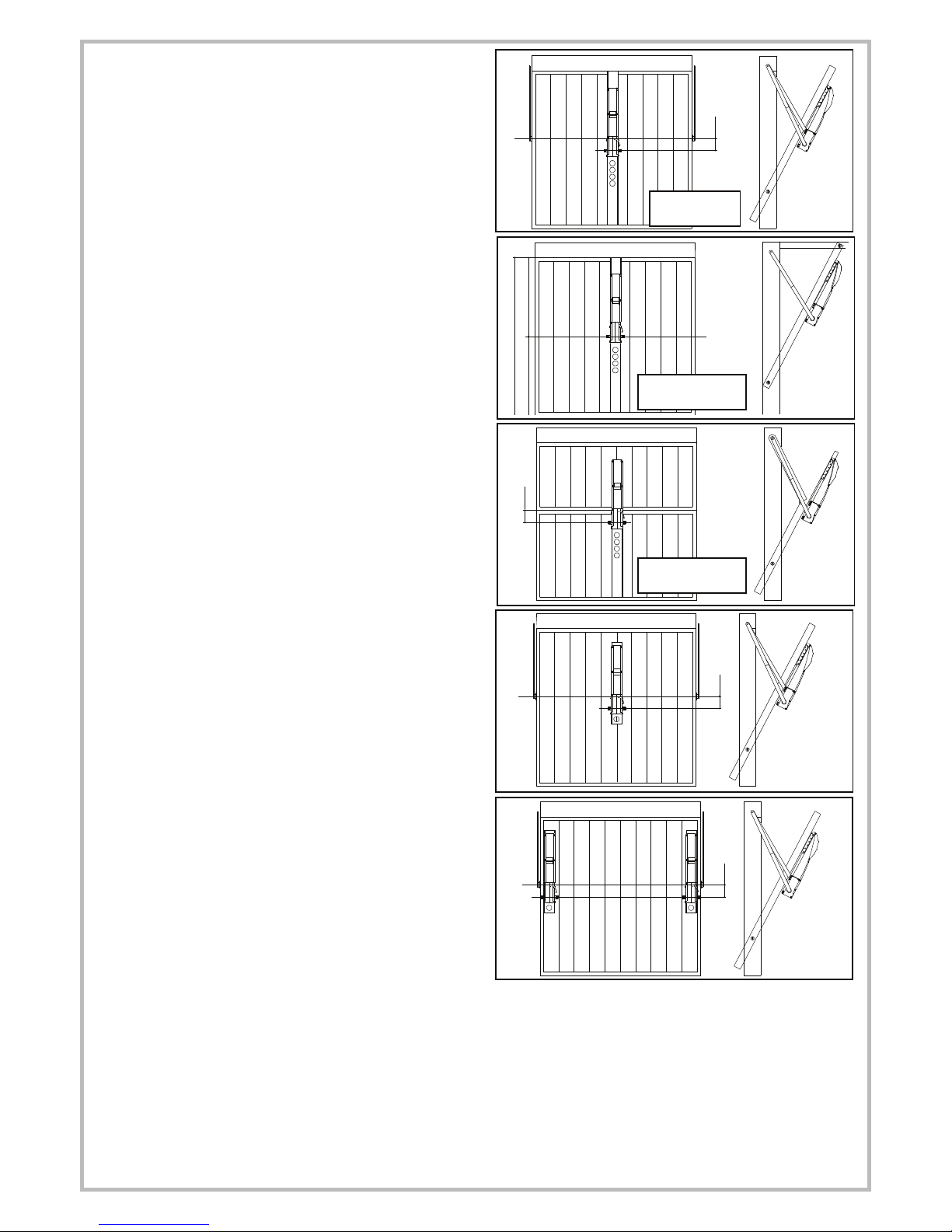

IThe product type: SWING Electromechanical gear motor for up and over balanced garage doors

Models: SWING, SWING C

Accessories: E102/C, E102/L, E101

Is built to be integrated into a machine or to be assembled with other machinery to crate a machine under provisions of 2006/42/EC Machinery

Directive, with reference in particular to the following requirements: 1.1.2, 1.1.3, 1.1.5, 1.2.1, 1.2.2, 1.2.3, 1.2.4.1, 1.2.6, 1.3.1, 1.3.4, 1.3.7, 1.3.8.2, 1.3.9,

1.4.1, 1.4.2.1, 1.4.2.2, 1.5.1, 1.5.4, 1.6.1, 1.6.2, 1.6.3, 1.6.4, 1.7.1, 1.7.3, 1.7.4, 1.7.4.1, 1.7.4.2, 1.7.4.3.

ÈIt complies with the essential requirements of EEC Directives:

2006/95/CE Low Voltage Directive

2004/108/CE Electromagnetic Compatibilità Directive

It complies with the essential requirements of EEC Directives:

EN 12453, EN 12445, EN 12604, EN12605, EN 13241-1

EN 55014-1,EN 55014-2

EN 60335-1, EN 60335-2-103

EN 61000-3-2

EN 61000-3-3

The manufacturer also declares that the start-up of the machinery is not permitted unless the machine, in which the product is incorporated or of

which is becoming a component, has been identified and declared as conformed to 2006/42/EC Machinery Directive.

Castagnito, September 14 2015 Marco Gallo

C.E.O.