Protecta EuroProt+ User manual

PROTECTION,AUTOMATION AND

CONTROL FOR POWER INDUSTRY

DOCUMENT ID: PP-13-22030

VERSION:1.2

2020-08-14, BUDAPEST

EuroProt+ Operating Manual with

Troubleshooting Guide

APPLICATION GUIDE

2

VERSION INFORMATION

EuroProt+ Operating Manual with Troubleshooting Guide

www.protecta.hu

VERSION INFORMATION

VERSION

DATE

MODIFICATION

COMPILED BY

1.0

2020-02-18

First published version

Zsarnai, Erdős

1.1

2020-03-03

Internal Fault Relay operation description added

Erdős

1.2

2020-08-14

Information about checking the hardware in the

status/log menu added

Erdős

3

CONTENTS

EuroProt+ Operating Manual with Troubleshooting Guide

www.protecta.hu

CONTENTS

1Introduction........................................................................................................................... 6

2Starting the device................................................................................................................6

2.1 The hardware modules of the device............................................................................6

2.2 Fast startup.................................................................................................................... 6

3Local operation on the front panel........................................................................................7

3.1 The structure of the human-machine interface of the device........................................7

3.2 Using the touch buttons.................................................................................................8

3.3 Using the menu provided by the touch screen............................................................10

3.3.1 The main menu....................................................................................................10

3.3.2 The parameters menu......................................................................................... 11

3.3.3 On-line functions, Events, System settings.........................................................13

3.3.4 User-defined/Custom screens.............................................................................13

4Remote operation via web browser....................................................................................15

4.1 Properties of the Ethernet communication..................................................................15

4.1.1 The Ethernet connection .....................................................................................15

4.1.1.1 Using the RJ-45 connection ........................................................................15

4.1.1.2 Using the EOB connection ..........................................................................16

4.1.1.3 Using fiber optic connections.......................................................................16

4.1.2 Settings needed for the Ethernet connection......................................................16

4.1.2.1 Connection to the device with fix IP address............................................... 16

4.1.2.2 Connection to the device with the embedded DHCP server.......................17

4.1.3 Using web browsers............................................................................................18

4.2 Menu items in the web browser...................................................................................19

4.2.1 Main panel...........................................................................................................19

4.2.2 Parameters..........................................................................................................20

4.2.2.1 Managing multiple parameter sets .............................................................. 22

4.2.3 System settings ...................................................................................................23

4.2.4 Online data ..........................................................................................................24

4.2.5 Events..................................................................................................................25

4.2.6 Disturbance recorder...........................................................................................26

4.2.7 Commands ..........................................................................................................28

4.2.8 Network protectionHood......................................................................................29

4.2.9Documentation ....................................................................................................30

4.2.10 Advanced.............................................................................................................30

4.2.10.1 Password manager......................................................................................30

4.2.10.2 Status/log.....................................................................................................31

4.2.10.3 I/O tester......................................................................................................34

4.2.10.4 Update manager..........................................................................................35

5Troubleshooting..................................................................................................................36

5.1 Warning and Error Messages......................................................................................36

5.1.1 Warning messages in the web browser ..............................................................36

4

CONTENTS

EuroProt+ Operating Manual with Troubleshooting Guide

www.protecta.hu

5.1.2 Error messages in the web browser....................................................................39

5.1.3 Error messages on the LCD screen.................................................................... 42

5.1.4 Operation of the IFR (Internal Fault Relay)......................................................... 43

5.2 Necessary data before contacting Protecta Support................................................... 44

5.2.1 Serial Number of the Device ...............................................................................44

5.2.2 Information about RDSP, CDSP and configuration versions..............................45

5.2.3 Black and white display for S24 devices.............................................................46

5.3 Quick Troubleshooting ................................................................................................47

6Appendix.............................................................................................................................49

5

INTRODUCTION

EuroProt+ Operating Manual with Troubleshooting Guide

www.protecta.hu

USED SYMBOLS

Additional information

Useful information for settings.

Important part for proper usage.

6

INTRODUCTION

EuroProt+ Operating Manual with Troubleshooting Guide

www.protecta.hu

1 Introduction

The EuroProt+ type complex protection in respect of hardware and software is a modular device.

The modules are assembled and configured according to the requirements, and then the software

determines the functions. This manual describes the common properties of the numerous

possibilities. It also provides technical guidance to operate the device locally with the LCD and

remotely with a web browser. The individual characteristics of the specific applications are

described in the manuals of the factory configurations.

2 Starting the device

In order to meet the device at the first time, this chapter provides information for new users to

secure a safe first start-up of the device.

2.1 The hardware modules of the device

For technical details of the modules of the EuroProt+ type complex protection please see the

document “Hardware description”. The applied modules for a certain application are listed in

the corresponding “Configuration description”document. These documents are available on-

line on the Protecta website by selecting the desired product.

2.2 Fast startup

The CPU module of the device is equipped with two processors: one for performing the application

functions (RDSP), the other one for processing the communication tasks (CDSP).

After powering up the device, the RDSP processor starts-up with the previously saved

configuration and parameters. Generally, the power-up procedure for the RDSP and application

functions takes approx. 4-5 sec. During this time the “Status LED” (see Figure 3-1) is red. If the

protection functions are ready for operation the red LED turns to green, the fault relay NO contact

closes (3-4 or 5-6) and the device is ready to trip after this short period. During the restart

procedure after a new downloaded configuration the LED is also red for a short time. Latched red

LED however means general error. In this case the protection functions are not available.

The CDSP’s start-up procedure is longer, because its operating system needs time to build its file

system, initializing user applications such as HMI functions and IEC61850 software stack. The

availability of the touch screen of the front panel after about 25-30 seconds indicates successful

termination of the start-up procedure.

7

LOCAL OPERATION ON

THE FRONT PANEL

EuroProt+ Operating Manual with Troubleshooting Guide

www.protecta.hu

3 Local operation on the front panel

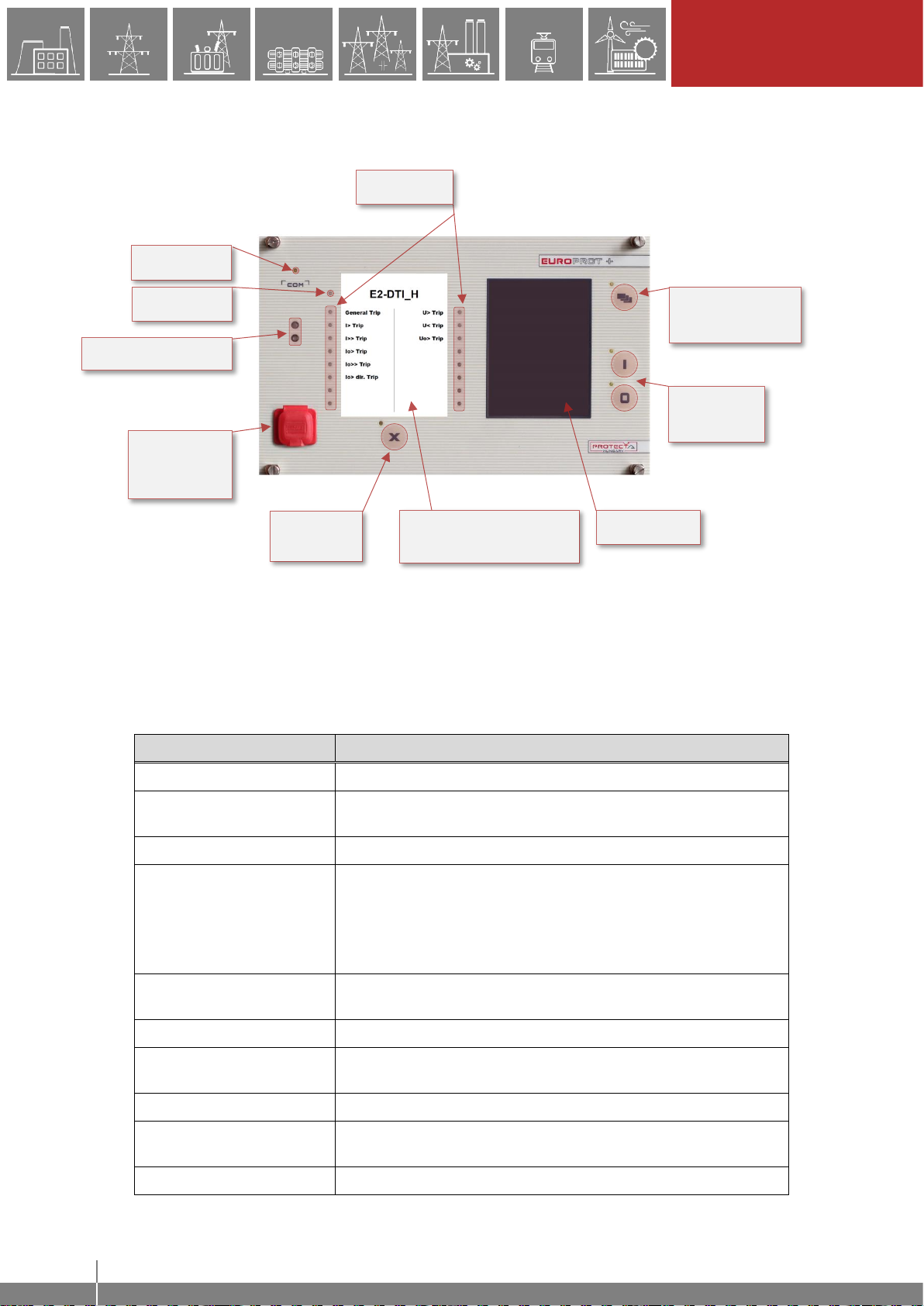

Figure 3-1 The front panel of the device

3.1 The structure of the human-machine interface of the device

The EuroProt+ device HMI on the front panel contains the following elements:

Table 3-1 The elements of the front panel

FUNCTION

DESCRIPTION

User LEDs (16 pcs)

Three-colors, 3mm circular LEDs programmable by the user.

COM LED (1 pc)

Yellow, 3mm circular LED indicating front panel communication

link and activity

Touch button LEDs (4 pcs)

Yellow, 3mm circular LEDs indicating touch button actions

Status LED (1 pc)

Three-color, 3mm circular LED

Green: normal device operation

Yellow: device is in warning state

Red: device is in alarm state

Touch buttons (4 pcs)

Capacitive touch buttons (On/Off Operation, Change Screen,

LED acknowledgement), see Chapter 3.2 for details.

Buzzer

Audible touch button pressure feedback

Changeable LED

description label

Describes user LED functionality

3.5” or optional 5.7” display

320*240 pixels TFT display with resistive touch screen interface

Optical interface

This inteface is made for EOB connection, and/or serves as a

service port for Protecta personnel only.

RJ-45 connector

Supporting 10/100Base-T Ethernet connection

CHANGE SCREEN

BUTTON

OPERATION

BUTTONS

USER LEDS

LED RESET

BUTTON

COM LED

STATUS LED

TFT DISPLAY

REPLACEABLE

LED DESCRIPTION LABEL

RJ-45

(OR EOB)

CONNECTOR

OPTICAL INTERFACE

8

LOCAL OPERATION ON

THE FRONT PANEL

EuroProt+ Operating Manual with Troubleshooting Guide

www.protecta.hu

EOB connector (option)

Ethernet Over Board: communication interface accomplishes

isolated, non-galvanic Ethernet connection with the help of a

magnetically attached EOB device. This is a proprietary and

patented solution from Protecta Ltd.

EOB1: Supporting 10Base-T Ethernet connection. Passive

device with one RJ45 type connector. Obsolete module.

EOB2: Supporting 10/100Base-Tx Ethernet connection. An

active device that has a USB port in addition to the RJ45

connector for powering up. All EOB topics in this manual are

referring to EOB2.

3.2 Using the touch buttons

The main screen of the local LCD together with the red marked “Change screen button” and the

“Operation buttons” is shown in the picture below.

Figure 3-2 The main screen

Change screen button - This hardware button changes the currently displayed screen for the

subsequent one. The available screens and the order in which they appear by default are: the

main screen, parameters, on-line, events, system settings and the custom screens which can be

added by the user with the help of the EuroCAP software. The order can be changed in the LCD

editor in the EuroCAP configuration tool. When pressing the “Change screen button” –as an

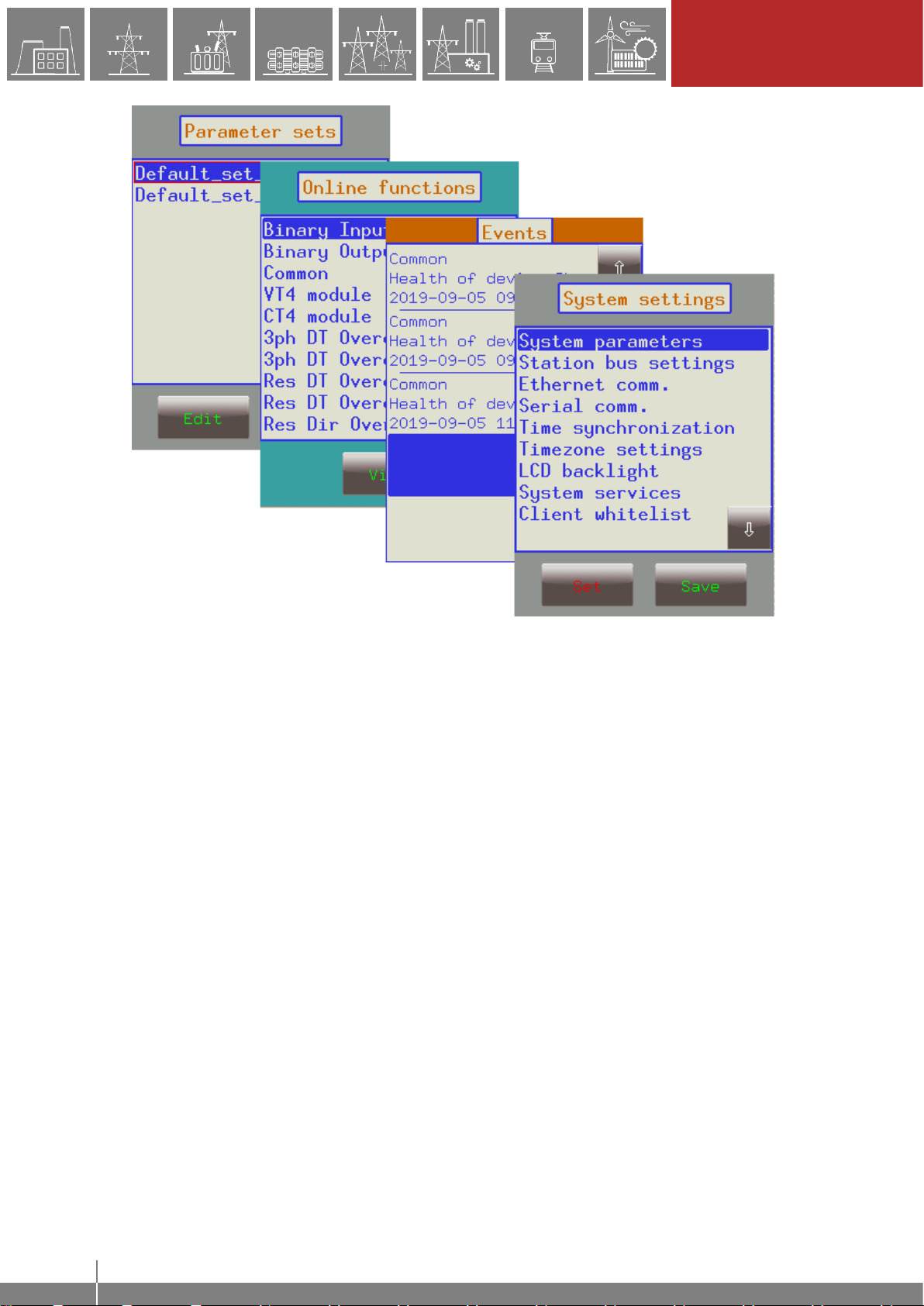

example - the windows shown in Figure 3-3 can be seen and applied one-by-one, cyclically.

9

LOCAL OPERATION ON

THE FRONT PANEL

EuroProt+ Operating Manual with Troubleshooting Guide

www.protecta.hu

Figure 3-3 Default menu screens (excluding the main screen) displayed on the LCD

Touch the navigation icons or the displayed text lines to perform any actions via the LCD screen.

Operation buttons - These buttons can be used to define certain functions on customer-defined

windows. For example, the user can set up these buttons to turn on/off a circuit breaker or

increment/decrement the position of the tap changer of a transformer. For more information,

please refer to the User-defined/Custom screen section.

LED reset button - This button resets all the user LEDs. The user may configure other means

for this button as well by programming the ‘Ackbutton’ output of the Common function block with

the EuroCAP software, see their external descriptions for more details.

10

LOCAL OPERATION ON

THE FRONT PANEL

EuroProt+ Operating Manual with Troubleshooting Guide

www.protecta.hu

3.3 Using the menu provided by the touch screen

The touchscreen is the main control area where the user will enable functions and input values

by touching the screen. The touchscreen can be also remotely accessed and controlled through

the web interface (for more information see the corresponding sections in the remote user

interface).

3.3.1 The main menu

Lock icon –The factory setting of the device excludes the password protection function. When

touching this icon, the picture changes, enabling the modification of parameters and system

settings. If limitation by password protection at operation is needed, the password application can

be set via web interface. In this case the icon changes only if the correct password is entered.

Figure 3-4 Changing the lock icon

Default/secondary languages (optional) - If available, the user can change the language of the

device by pressing the corresponding flag. With this, the language will change (provided that the

translations exist) on the following objects:

•remote web interface

•all menu points

•newly generated events

•newly created disturbance records

•device messages (e.g. command confirmation)

Note: if the language is changed by using the button on the web interface (see Chapter 4.2.1), it

will change on the web interface only; the other parts from the list above will remain as they were

set here

11

LOCAL OPERATION ON

THE FRONT PANEL

EuroProt+ Operating Manual with Troubleshooting Guide

www.protecta.hu

Information buttons –There are two “i” buttons located on the top corners of the main screen.

By pressing either of them, additional information can be displayed as shown in Figure 3-5.

Figure 3-5 Additional information on main screen

3.3.2 The parameters menu

In this screen, the user can view, set and edit certain parameters within the device. The user can

also choose which parameter set the device should use; this is done with the “Activate” button.

The currently active parameter set has a red box around it (first set in the picture below).

In order to edit or activate a parameter set, touch its name first to select it: it will be highlighted in

blue. Then touch the "Edit" or "Activate" button accordingly.

Figure 3-6 Parameter sets

12

LOCAL OPERATION ON

THE FRONT PANEL

EuroProt+ Operating Manual with Troubleshooting Guide

www.protecta.hu

Activate button - Activates the selected parameter set so the device will use those values. The

activated parameter set will have a red box around it. Only devices configured with multiple

parameter sets have an activate button. Note: if the parameterset change has a condition

configured to it, the activation button will disappear. In this case, activation of the parameter sets

is defined in the device configuration (e.g. binary input or software switch).

Edit button - This button takes the user to another screen listing the available function blocks

(FBs).

The screen in Figure 3-6 will only appear if there are more than one parameter sets. Otherwise,

the user is immediately taken to the function blocks. Normally, the various function blocks appear

in blue. In case someone has changed a certain value within a given function block, the name of

the function block in this menu item will turn red to notify the user. Within function blocks, the

values of the parameters are normally green, but if they have been modified, they will also turn

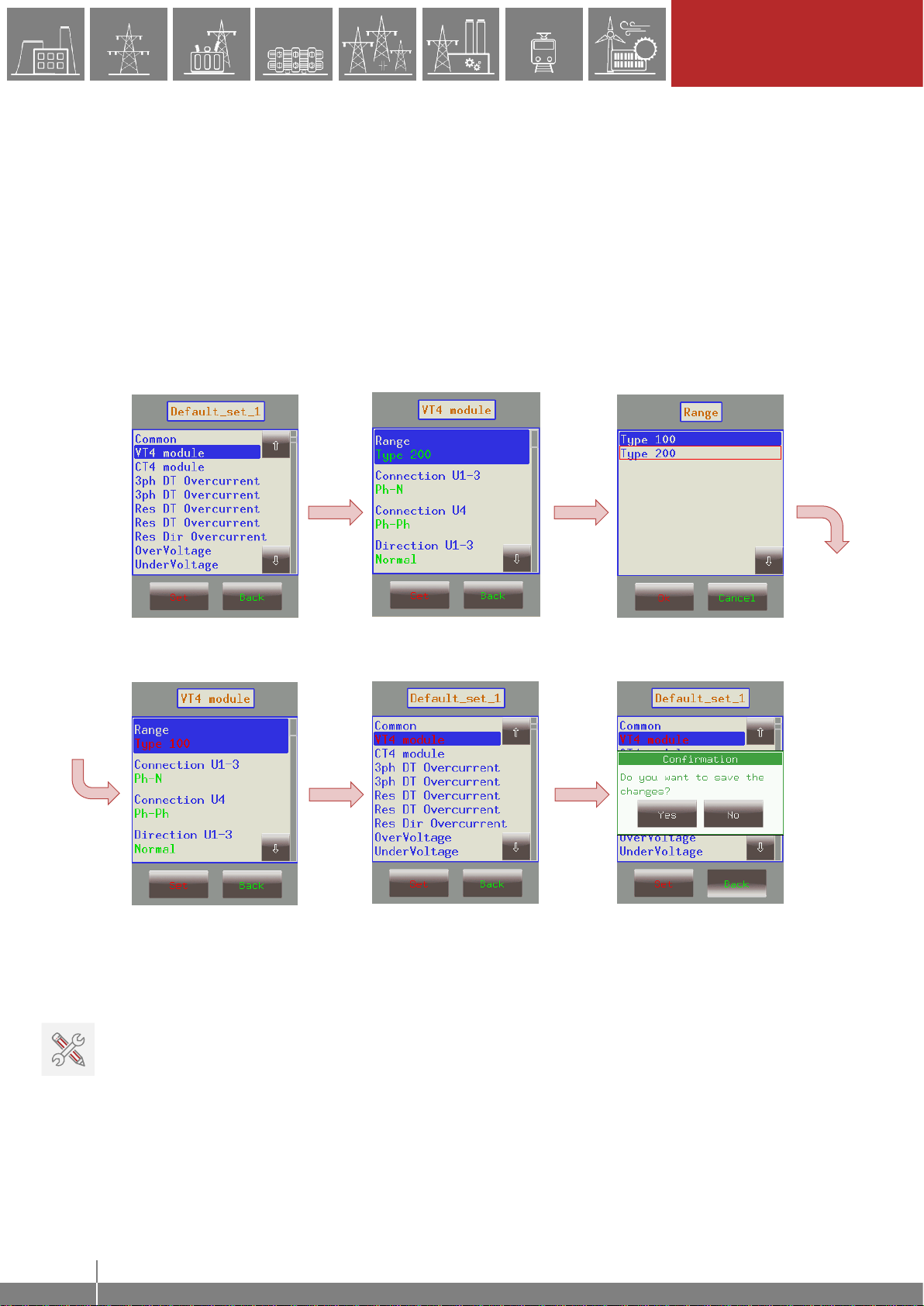

red. As an example, change the VT4 voltage type from 200V to 100V as follows:

“Set” function block “Set”parameter “Ok” for new value

“Back” to FB “Back” to save data “Yes” to confirm changes

Figure 3-7 Changing VT4 module Type

IMPORTANT! In order to finalize all changes, the user has to go back to the screen where all the

function blocks are listed and save the changes as shown above.

Also, make sure that while someone is modifying the parameters in the LCD touchscreen, another

person is not doing so on the web interface since this could lead to confusion as to what the

values of a parameter set are.

13

LOCAL OPERATION ON

THE FRONT PANEL

EuroProt+ Operating Manual with Troubleshooting Guide

www.protecta.hu

Other parameters can be modified similarly to the previously described VT4 voltage type. The

following parameter types are available in the function blocks:

Integer or timer - This is a whole number, and it can be entered with the help of the number pad.

Floating-point number - This is a number that has a decimal point. This can also be input through

the number pad.

List item - A list is displayed with all the possible choices. In this case the user simply needs to

select the desired one (e.g. VT4 voltage type).

Checkbox - The user has the option of enabling or disabling the parameter.

3.3.3 On-line functions, Events, System settings

These menu items have the same content as described in section 4. System settings can be

modified similarly to the parameters in section 3.3.2.

3.3.4 User-defined/Custom screens

It is possible to add screens based on the user's needs with the help of the EuroCAP software.

The operation buttons can also be set up to perform certain functions. An example can be seen

using a Single Line Diagram on the following page.

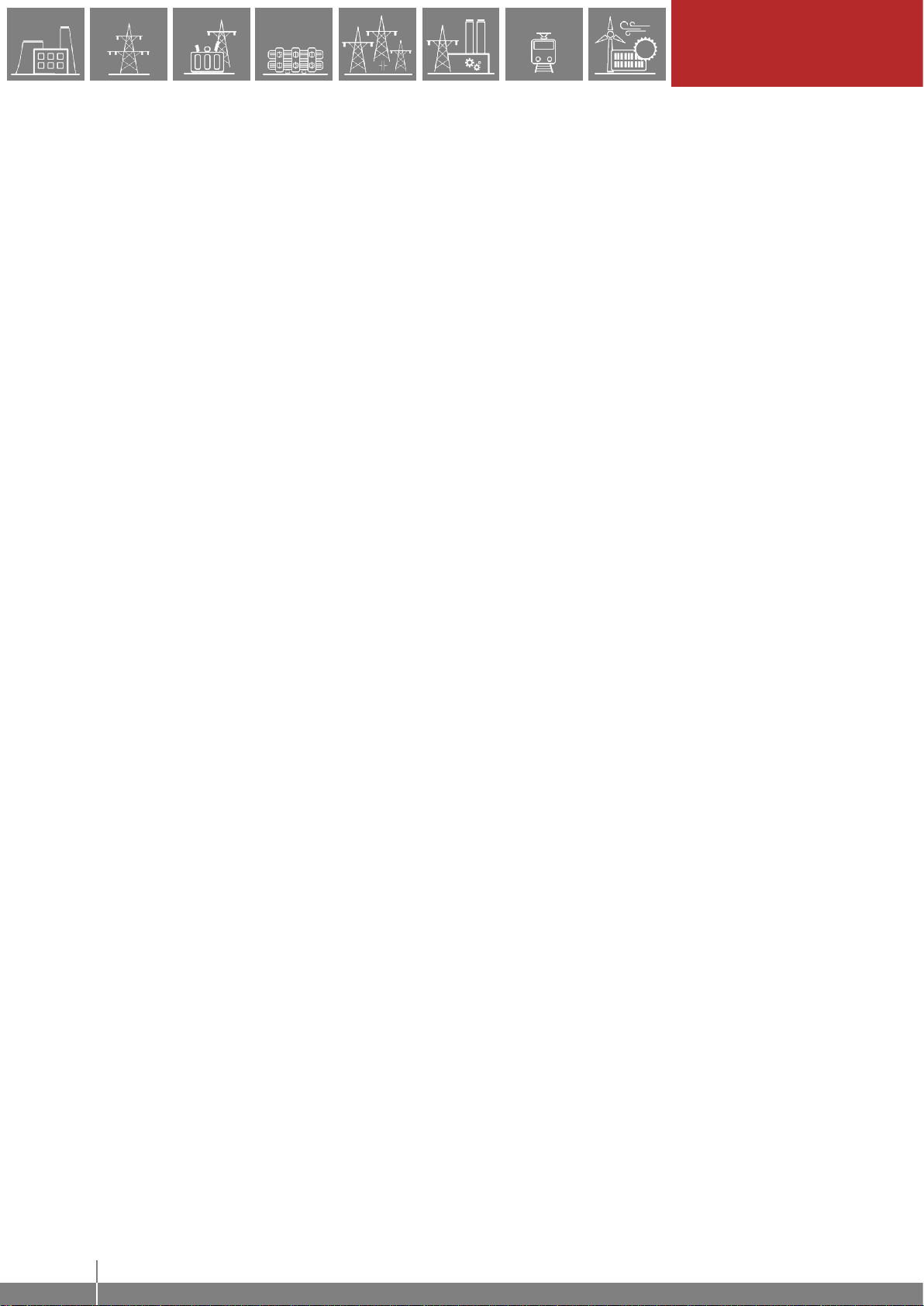

Let us say there is a network that is shown below and we have set up the required operational

buttons to function as "on"/"off". To switch "on" the busbar disconnector Q1, touch the icon of Q1

on the touchscreen; this will highlight the chosen object, which will start blinking. Once it starts

blinking, some action must be performed with the chosen object; otherwise it will be deselected

after a given timeout period. So, while it is blinking, press the "I" button, which has been configured

to be the "on" button when the Q1 object is highlighted.

Now a message pops up for confirmation of this operation. Again, a limited time is available to

answer this, otherwise the requested operation is canceled. Press “Ok” to confirm and another

panel pops up stating that the operation was successful. After acknowledging this, the LCD is

updated accordingly, with the Q1 line disconnector in the "on" position.

Note again that this behavior was only an example; it may vary according to the configuration of

the actual device.

14

LOCAL OPERATION ON

THE FRONT PANEL

EuroProt+ Operating Manual with Troubleshooting Guide

www.protecta.hu

Figure 3-8 Closing Q1 disconnector

This screen is being updated continuously; a change in any sort of state or any parameter that is

set up to be measured, will be shown and updated accordingly.

If there is an error with the operation (e.g. block by interlocking), the device will notify the user

with anodther another panel popping up with the reason of the error.

15

REMOTE OPERATION VIA

WEB BROWSER

EuroProt+ Operating Manual with Troubleshooting Guide

www.protecta.hu

4 Remote operation via web browser

A web browser and an Ethernet connection are needed in order to access the device interface.

HTML5 compatible web browser is recommended. To properly display the data on the screen, it

is recommended to have a screen resolution of at least 1024x768. The latest version of the

following web browsers shall be used:

•Mozilla Firefox

•Apple Safari

•Google Chrome

•Microsoft Edge

JavaScript must also be enabled within your browser. For security reasons, the device allows only

limited number of connections over the network (a maximum of 10 is guaranteed).

4.1 Properties of the Ethernet communication

The built-in 5-port Ethernet switch allows EuroProt+ to be connected to IP/Ethernet based

networks. The following Ethernet ports are available in general:

On the front panel of the device:

•RJ-45 Ethernet or EOB (Ethernet over Board) user interface

On the rear side of the CPU unit:

•Station Bus (100Base-FX Ethernet)

•Redundant Station Bus which can be:

o100Base-FX Ethernet, or

o10/100Base-T port via RJ-45 (only one can be active of these two)

•Process bus (100Base-FX Ethernet)

The different HMI and CPU types are utilizing different ports. Further information about the

available ports and the applied interfaces on various HMI and CPU types can be found in the

“Hardware description” document.

The embedded web-server supports the following actions:

•Modifying user parameters

•Managing the event list and disturbance records

•Managing passwords

•Online displaying measured data and generated binary information

•Performing commands

•Firmware update

•Performing other administrative tasks

4.1.1 The Ethernet connection

There are several ways to be connected to an Ethernet network. The availability of the below

listed connection types depends on the device hardware configuration.

4.1.1.1 Using the RJ-45 connection

RJ-45 connector is available on the front panel if no EOB is selected for the configuration. In

addition, many CPU types also utilize an RJ-45 connector, which is located on the rear side of

the device on the CPU card. Using an UTP cable with RJ-45 connector at both ends, the device

can be connected directly to a computer or an ethernet switch.

16

REMOTE OPERATION VIA

WEB BROWSER

EuroProt+ Operating Manual with Troubleshooting Guide

www.protecta.hu

4.1.1.2 Using the EOB connection

EOB connection is available on the front panel if no RJ-45 connector is selected for the

configuration. Attach the magnetic EOB connector to the front panel of the device (see Figure

3-1). The magnets assure the correct position of the adapter. Connect the other two ends of the

cable to the RJ-45 connector and to the USB port of a computer. The special cable with magnetic

connector on one end and RJ-45+USB connectors on the other end shall be ordered from

Protecta.

4.1.1.3 Using fiber optic connections

The different types of fiber optic interfaces for 100Base-FX Ethernet provides connection to an

Ethernet switch with identical fiber optic inputs. Using this connections all IED-s on the network

with client functionalities, e.g. a computer, has access to the device. For more details about the

fiber optic connector types see the CPU and COM module sections in the “Hardware

description”.

4.1.2 Settings needed for the Ethernet connection

The web interface of the EuroProt+ devices can be accessed over Ethernet based protocols only.

Therefore, it is extremely important to set up the network before accessing the device.

To connect the device to a station or corporate network, contact the system administrator for

available IP address, gateway address, net-mask, DNS and NTP server addresses.

The user can also connect directly to the device via Ethernet protocol. In the following guidance

we assume, that the user connects directly to the device via computer without the presence of

any active network component (e.g.: switch, ruoter).

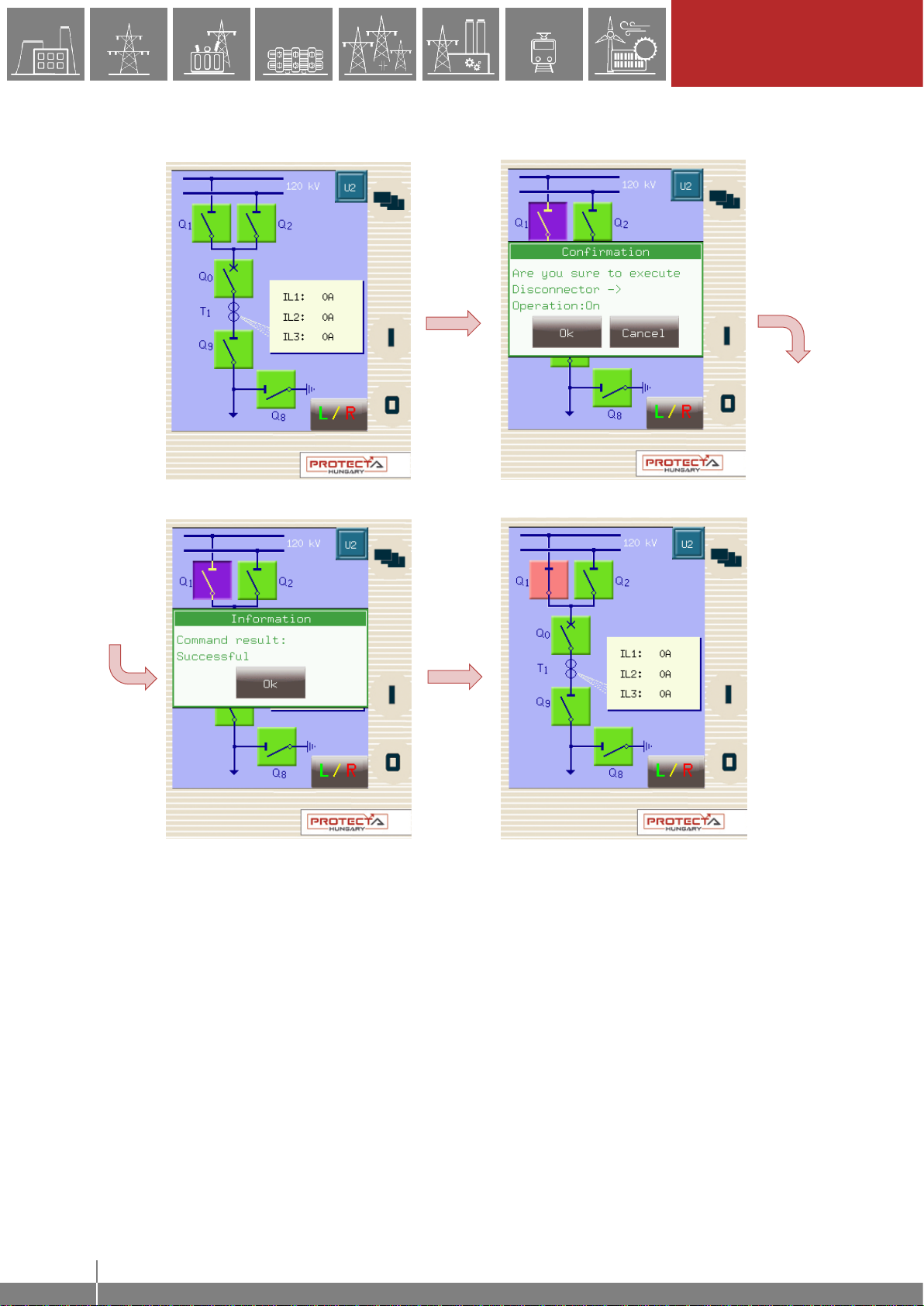

4.1.2.1 Connection to the device with fix IP address

The device uses fix IPv4 address range and the user is allowed to modify the address. User’s

computer must be set with fix IP address and netmask according to the used IP address range

and netmask in the device.

Settings of the device:

The IP settings of the device get the following default values at the first start:

IP address: 192.168.0.15

Netmask: 255.255.0.0

Default gateway: 192.168.1.1

IP address mode: Static IP

DNS1 and DNS2 address: 0.0.0.0

DHCP server: Disabled

These can be changed in the System settings menu Station bus settings submenu.

Settings of the user's computer (with fix IP address):

The possible IP settings of the user’s computer according to the (optional) device settings above:

IP address: in range from 192.168.0.1 to 192.168.254.254*

Netmask: 255.255.0.0

Default gateway:192.168.0.1

*Note: the IP address must differ from that of the device

17

REMOTE OPERATION VIA

WEB BROWSER

EuroProt+ Operating Manual with Troubleshooting Guide

www.protecta.hu

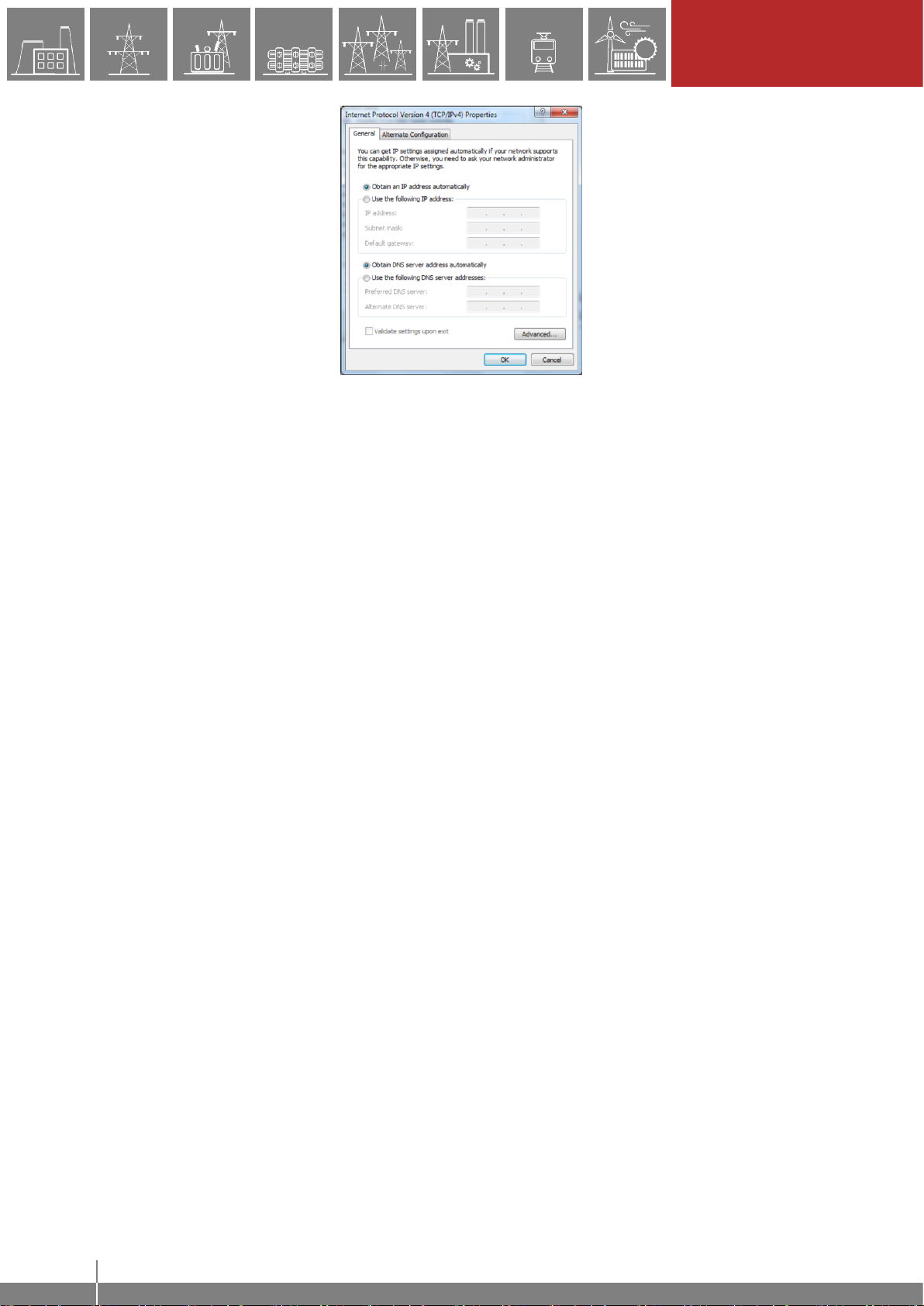

Figure 4-1 An example of settings in the user’s computer with fix IP address

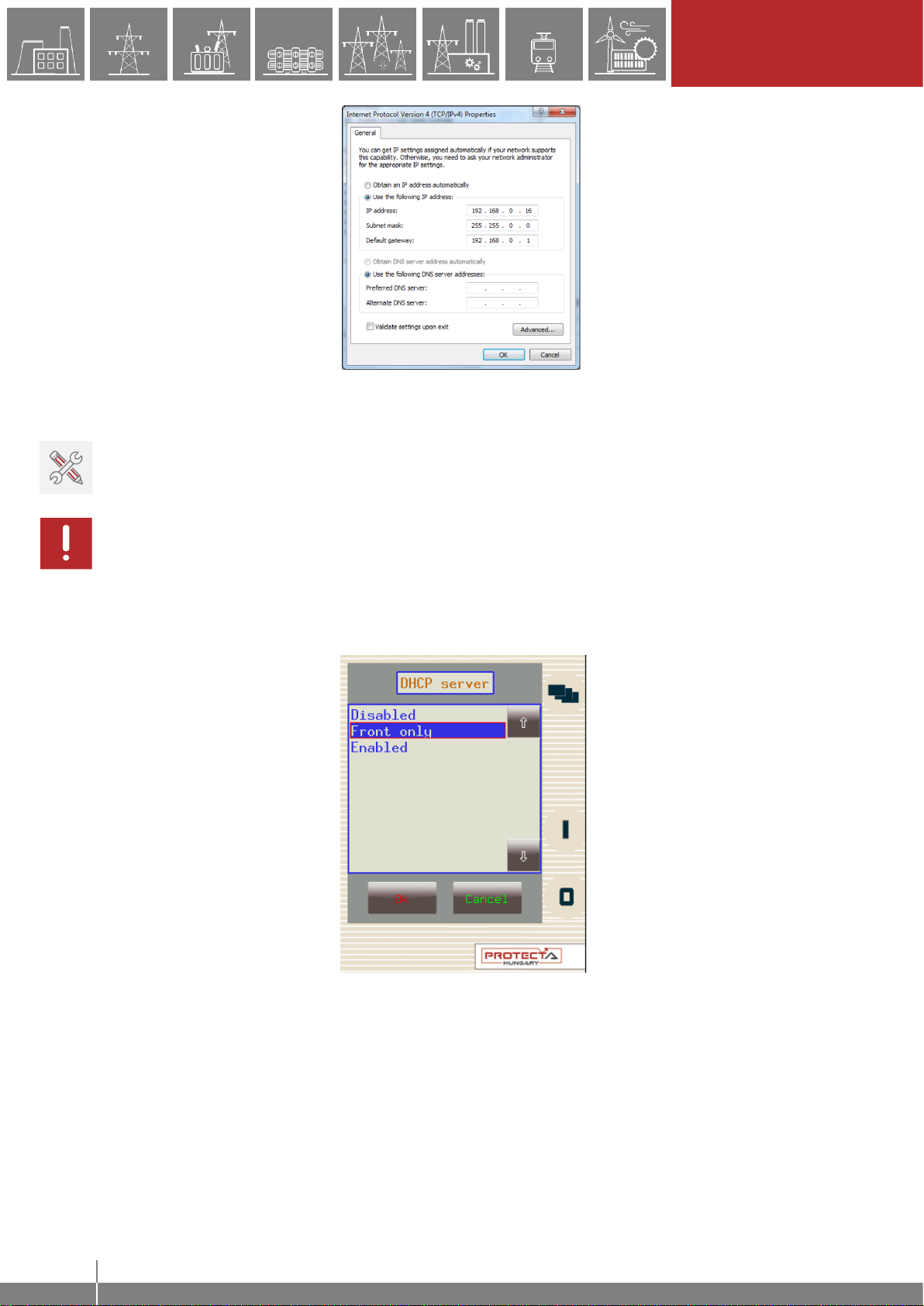

4.1.2.2 Connection to the device with the embedded DHCP server

The embedded DHCP server can be enabled in System settings menu Station bus settings

submenu.

Do not use the DHCP server function when another DHCP server is already in use on the network!

If this type of connection needs to be used only through the front panel connector, then the “Front

only” setting has to be chosen for this parameter.

Figure 4-2 Enabling DHCP server for front panel control

If the DHCP server of the device is used, the following settings are recommended to be applied

in the user’s computer:

18

REMOTE OPERATION VIA

WEB BROWSER

EuroProt+ Operating Manual with Troubleshooting Guide

www.protecta.hu

Figure 4-3 Possible seetings in the user’s

computer with DHCP server

4.1.3 Using web browsers

First the user must check if the browser is accessing the device via proxy-server. If there is a

proxy-server in the network, the system administrator shall be contacted in order to get access.

If this is clarified, the user can type the IP address of the device into the browser’s address bar.

(The IP address can be read on the main screen of the local LCD, see Figure 3-2.) After that the

usual procedures of web browsing shall be followed.

19

REMOTE OPERATION VIA

WEB BROWSER

EuroProt+ Operating Manual with Troubleshooting Guide

www.protecta.hu

4.2 Menu items in the web browser

4.2.1 Main panel

Figure 4-4 Main menu

The front panel of the device can be controlled from here (Figure 4-4). The image in the center

of the screen behaves the same way as the touch screen and the LEDs, except the on (1) and

the off (0) buttons. These two buttons are inactive for security reasons.

The X button on the bottom of the front panel picture initiates a LED reset. LED description text

is determined by the configuration and may be different than the actual label inserted in the device

front panel.

Identification - User can change the station and device names from this panel by typing in

the new values and clicking on the Rename button. IEC61850 IED name is only for display

here but can be edited in the EuroCAP tool if needed.

Information part - There are two fields for measuring device operating time. Uptime field

displays the time elapsed from the last power on of the device. Device lifetime field value

equals the number of days of the device's energized state. In case of a CDSP update, the

device uptime disappears and RDSP/CDSP uptime appear.

The language button (if present) under the menus changes the displayed language of the website

only. This means that the menus (parameters, settings etc.) will be shown in the chosen language,

but the events and disturbance records will still be generated on the on the language set on the

main local LCD screen (see Chapter 3.3.1 for details)

20

REMOTE OPERATION VIA

WEB BROWSER

EuroProt+ Operating Manual with Troubleshooting Guide

www.protecta.hu

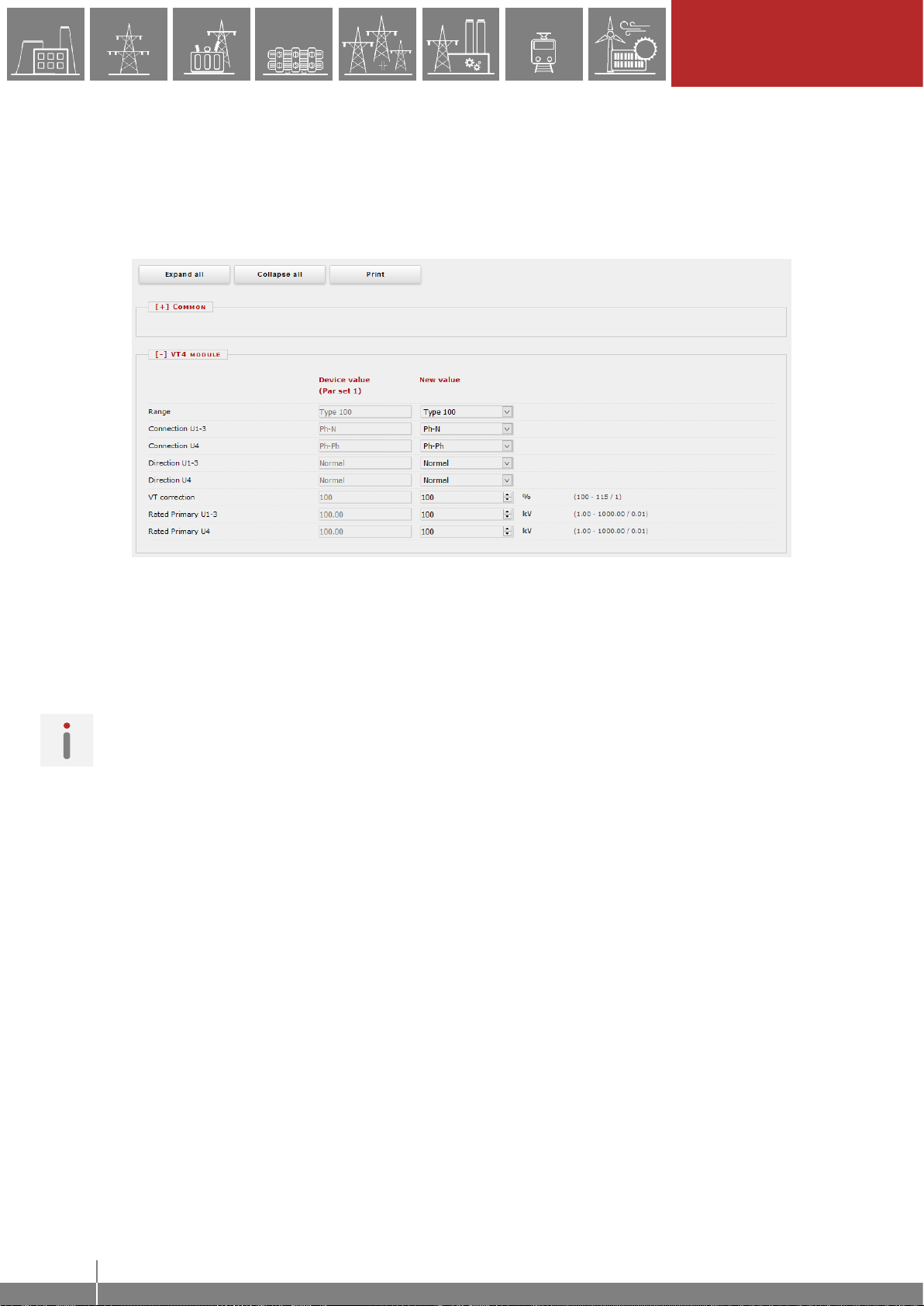

4.2.2 Parameters

Various parameters and variables can be viewed and changed in this menu item. The user can

manage different parameter sets with the ability to set, rename, export and import them. A

password can be applied for the import, export and set settings options. All parameters are part

of a certain function block which can be individually opened or closed using the [+] or [-] symbol.

Parameter values are displayed and can be modified in text fields, list boxes or check boxes.

Figure 4-5 Parameter settings

Buttons on the top of the parameter's sheet provide fast expanding and collapsing all the function

panels and make finding a parameter easy. Print button generates a printer-friendly layout opened

in a new browser window.

General layout of the parameter's sheet consists of columns:

The first column contains the name of the parameter, this text is coming from the configuration of

the device.

Second column displays the current values of the selected parameter set stored in the device.

The parameter set can be chosen from the combo-box of the main menu (see Figure 4-6).

Changing the parameter set here doesn't mean activating it, only loading to the fields. You can

find more information on activation in this chapter later.

Third column is used for entering the desired values by the user. The expected value range and

step are shown on the right side of the parameter column.

Changing any setting in the third column will be marked with blue function block name and with

blue text in the corresponding line of the first column.

The detailed description of fields are as follows:

Textfield - Text fields hold values that can be modified. To prevent invalid values from being

loaded into the device, make sure that all values entered are within proper range. In case a

wrong value is entered, the user will be alerted and the value is reset to the last correct value.

Listbox - By clicking on the list box, the user can choose from the available values listed

within the box. (The list box represents enumerated type parameters.)

Other manuals for EuroProt+

3

Table of contents

Other Protecta Protection Device manuals

Popular Protection Device manuals by other brands

MULTISPAN

MULTISPAN MPD-152 manual

Acrel

Acrel AM5SE Series Operational manual

ABB

ABB REB650 2.1 IEC Product guide

nvent

nvent ERICO System 3000 Installation, operation and maintenance manual

Manson Engineering Industrial

Manson Engineering Industrial SSB-6113 Operation manual

ABB

ABB REG650 ANSI Technical manual

ABB

ABB RELION REX640 Product guide

FireFlex

FireFlex TOTALPAC X Owner's operation and maintenance manual

SCHUNK

SCHUNK PGN-plus-E Repair instructions

Cedes

Cedes cegard/Lift LX/LY Installation and operation manual

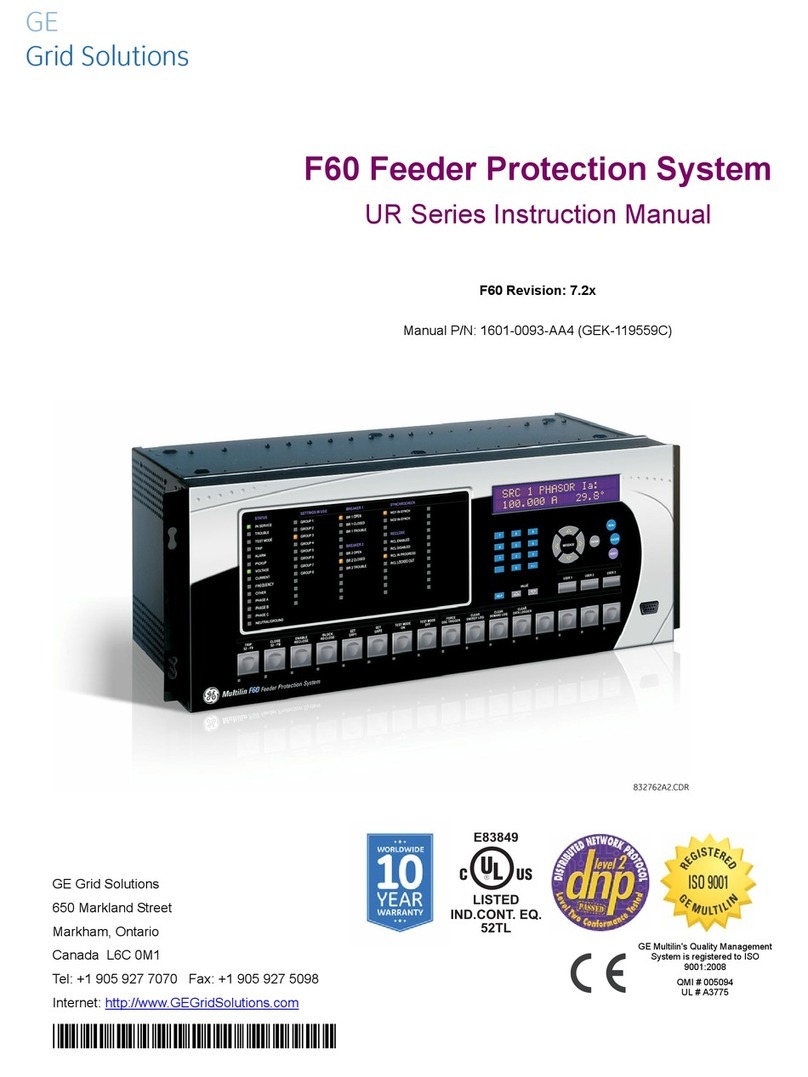

GE

GE F60 instruction manual

Belden

Belden Hirschmann BAT-ANT-Protector m-f Mounting instruction