cegard/Lift LX/LY English

© CEDES | V 2.10 5

The function of interface signals is described in detail in the

following chapters.

The plug-in system controller monitors the correct function

of interface signals. The elevator is immediately shut down

if an error is detected and an appropriate error message

appears on the diagnosis display.

The polarity at connections is irrelevant when actuating

internal call signals with AC voltage. Correct polarity should

be ensured for all other signals (see also Chapter 6.2.

and 7).

5.2.1 Internal call signal / Reset signal

- See also Chapter 7: K7K15

If an emergency stop is caused by the interruption of the

light curtain, an His displayed. The elevator can only be

released from this emergency stop state by the pressing

of a reset button from within the elevator car itself. There

are eight independent reset inputs for this purpose. The

journey can be continued if, with a free protection field, at

least one of the inputs receives a negative or positive pulse

(i.e. a reset button, for example, can be allocated to one of

the internal call signals).

A call signal (and consequently, a test) during a journey

does not adversely affect the function (i.e. safety contacts

do not drop out (double or multiple start).

Special operating mode:

The service button on the plug-in system controller provides

the elevator fitter with the possibility to simulate an internal

call signal during commissioning and inspection (after an

emergency stop). This enables the safety contacts to be re-

closed from the elevator cabin roof.

5.2.2 Latch power supply (Latch_In (Riegel_

In))

- See also Chapter 7: K24K25

The latch power supply is used to enable transit and to

unlock the door.

The bypassing of the light curtain is cancelled by the

Latch_In latch power supply HIGH signal, the Latch_Out

output is switched through and the door is locked as a

result. An Fis displayed and every interruption of the light

curtain now results in an emergency stop.

The latch circuit is described in Chapter 8.

5.2.3 Override delay and Option 2 (premature

overriding)

- See also Chapter 7: K18K19 / K22K23

The light curtain can be bypassed with the Override delay

(bypass delay) and Option 2 inputs. An Uis displayed.

Bypassing can begin before the Latch signal switches to

LOW. The light curtain is then overridden if both inputs are

LOW:

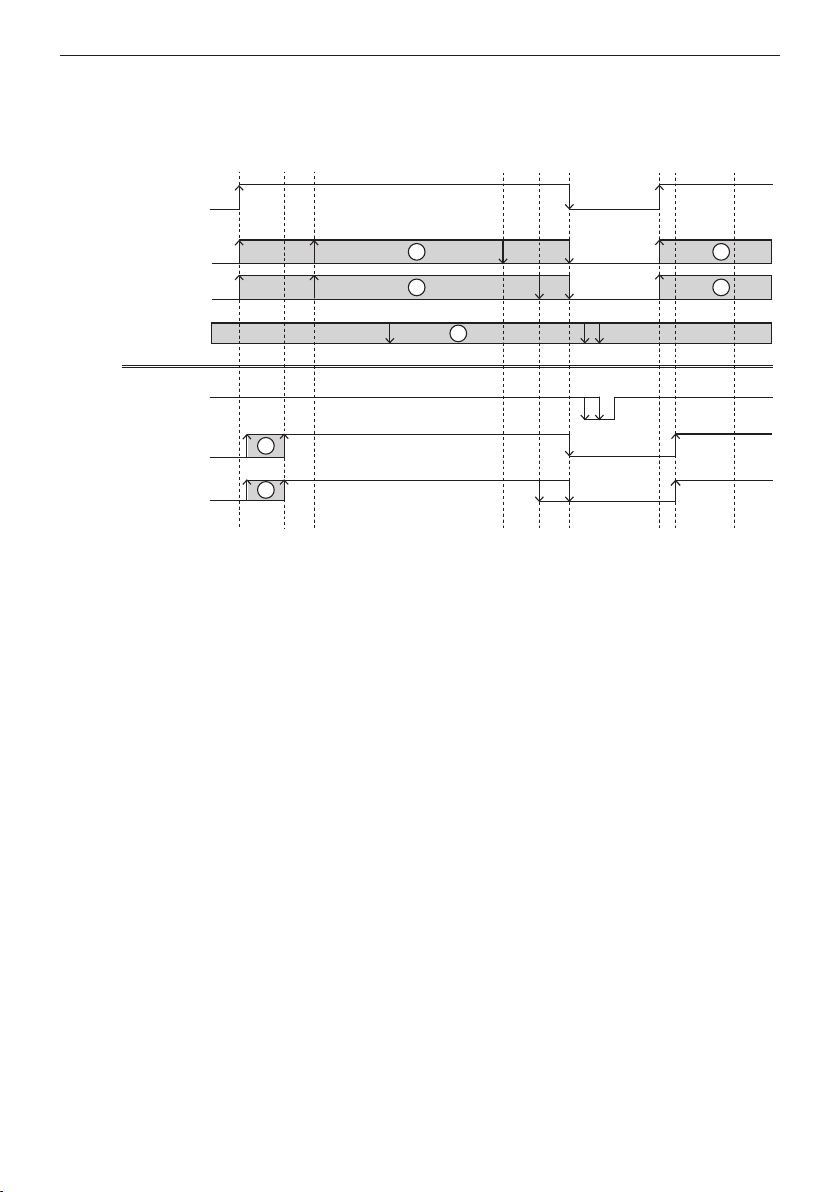

Override delay Option 2 Light curtain

overriding

HIGH HIGH Inactive

LOW HIGH Inactive

HIGH LOW Inactive

LOW LOW Active

These signals should have changed status at least twice

during a travel cycle (journey enabled - journey - stop at

floor - journey enabled). If one of the signals remains LOW

an error is interpreted and the elevator is shut down by

breaking the safety contacts (see also Chapter 11.1, error

no. 5 and 6).

5.2.4 Flush position (Testing)

- See also Chapter 7: K20K21

Safe function of the output relays should also be checked,

as these are located in the evaluation plug-in safety

components in the elevator safety circuit. Testing of the

plug-in system controller breaks the output contact for

approx. 100 ms. This test is carried out after each elevator

trip. The test timing can be controlled with the Flush

position (Bündigstellung) input to avoid any influence on

the elevator control system.

The cegard/Lift offers three test control versions:

1. The output relays are automatically tested 5 s after

Latch_In (Riegel_In) drops out, if the input remains

broken. The test is carried out immediately if a travel

command occurs during this time period.

2. The output relays are automatically tested 10 s after

Latch_In (Riegel_In) drops out, if the input is under a

permanent voltage of >12 VAC/DC. The test is carried

out immediately if a travel command occurs during this

time period.

3. A test is carried out if the input is HIGH in the neutral

status (>12 VAC/DC) and receives a negative edge

when Latch_In (Riegel_In) has dropped out.

The timing of the test can thus be specified by the

elevator control system (e.g. at flush position). It

means, for example, that the Latch_In input will be

frequently bypassed with the ‘Flush’ position input

(Bündigstellung), which leads to a test immediately

after the Latch signal switches to LOW.

5.2.5 Automatic start during power-up

The cegard/Lift automatically carries out a self-test after a

power cut and only closes the safety circuits when the test

has been concluded successfully. The cegard/Lift is ready

for operation after the safety circuits are closed.