nVent.com/ERICO | 7

Pre-Installation Requirements

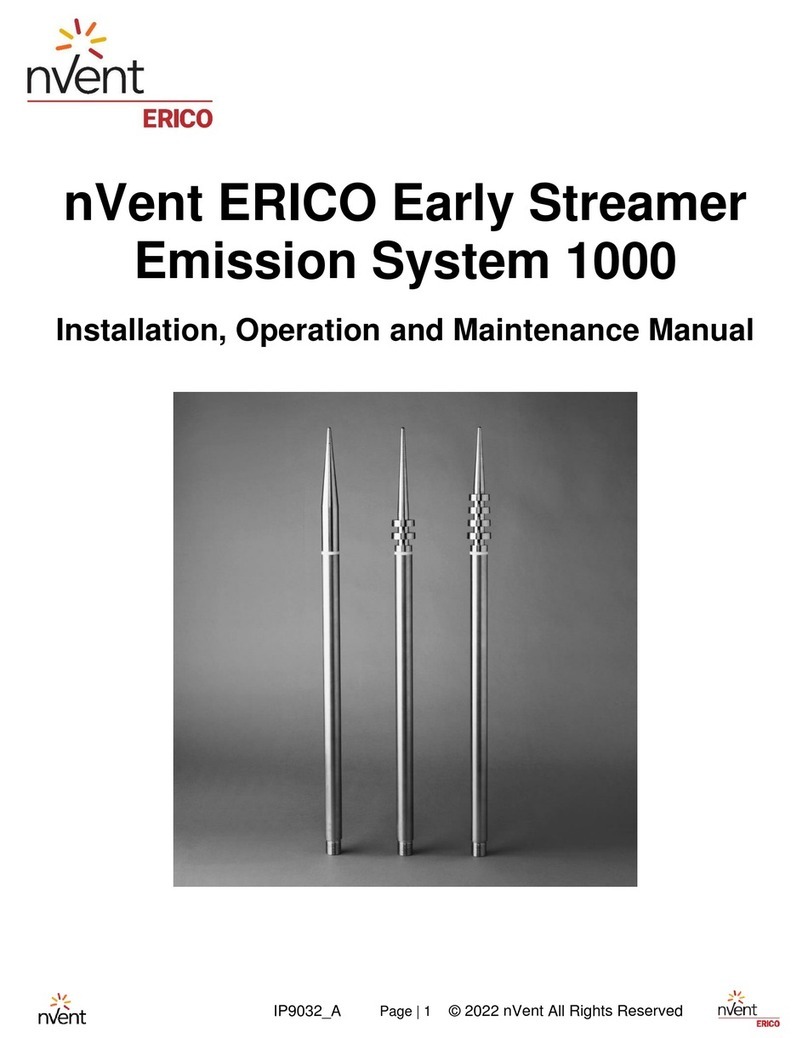

This manual is a guide to the installation,

operation and maintenance of the

nVent ERICO System Lightning

Protection System.

It assumes that the system to be installed

has been designed by an authorized nVent

ERICO representative. The system design

will include:

• Grounding system designed as a result of

soil resistivity analysis.

• Downconductor routes chosen

to avoid other services, maintain

minimum bending radii and minimize

downconductor run length.

• Downconductor securing requirements..

• Terminal types – operating environment.

• CAD software design report which

determines terminal placement, mast &

height requirements as well as protection

level calculations.

All of the above are recommendations for

a successful installation. If there is any

doubt about any of the points mentioned,

please contact nVent ERICO or your nearest

distributor for clarification.

CHECKING LIGHTNING

PROTECTION COMPONENTS

PRIOR TO INSTALLATION

Before installation, perform following

inspection:

Terminal(s)

• nVent ERICO Dynasphere terminals have

not been dented.

• The correct finial tip has been installed,

based on the overall height of the air

terminal above grade.

nVent ERICO Ericore downconductor(s)

• The cable drum (if supplied) is in a

serviceable condition.

• Correct length(s).

• That there is no obvious damage to

the cable.

• Make sure that the end of cable is

properly sealed to prevent moisture

migragting into cable strands.

• Is teminated as required. If the

downconductor has been preterminated

before shipment, check that the

termination is still intact and in good

order. See note on Page on removing

protective covers.

• If the Upper Termination Kit has been

supplied separately, check that the cold-

shrink tube in the kit is in good order, has

no tears or cuts and has not collapsed.

• Applications engineering does not

recommend field installations of upper

terminations unless the operators are

trained by nVent Applications Engineering.

This information along with downconductor

lengths and quantities (if more than one

length on the one drum), will be printed on

a label on the side of the cable drum(s).