9221973A

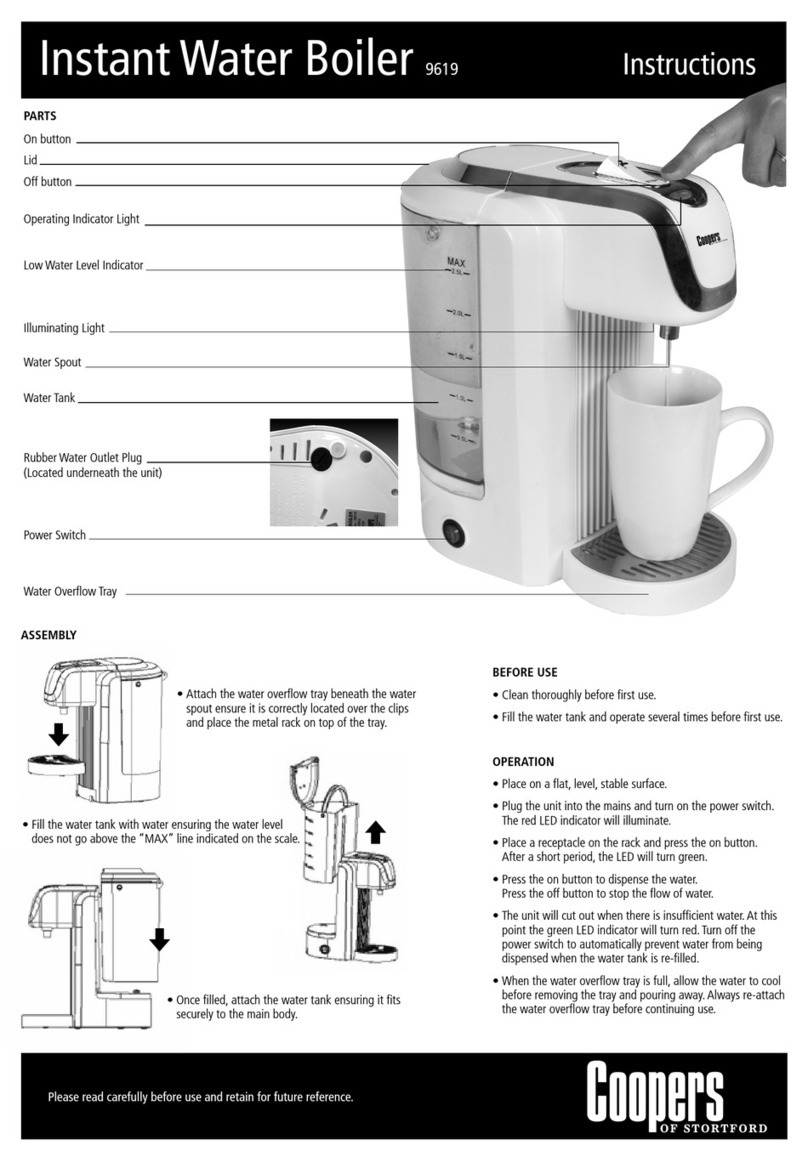

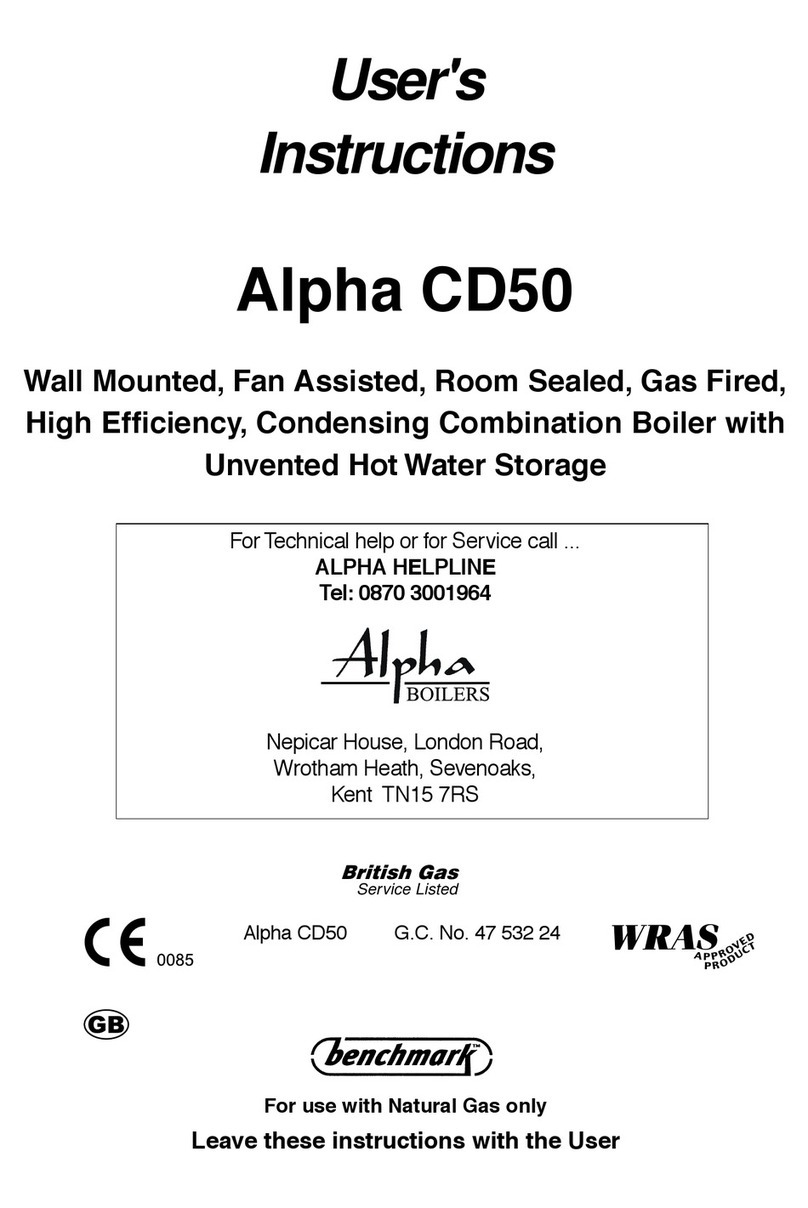

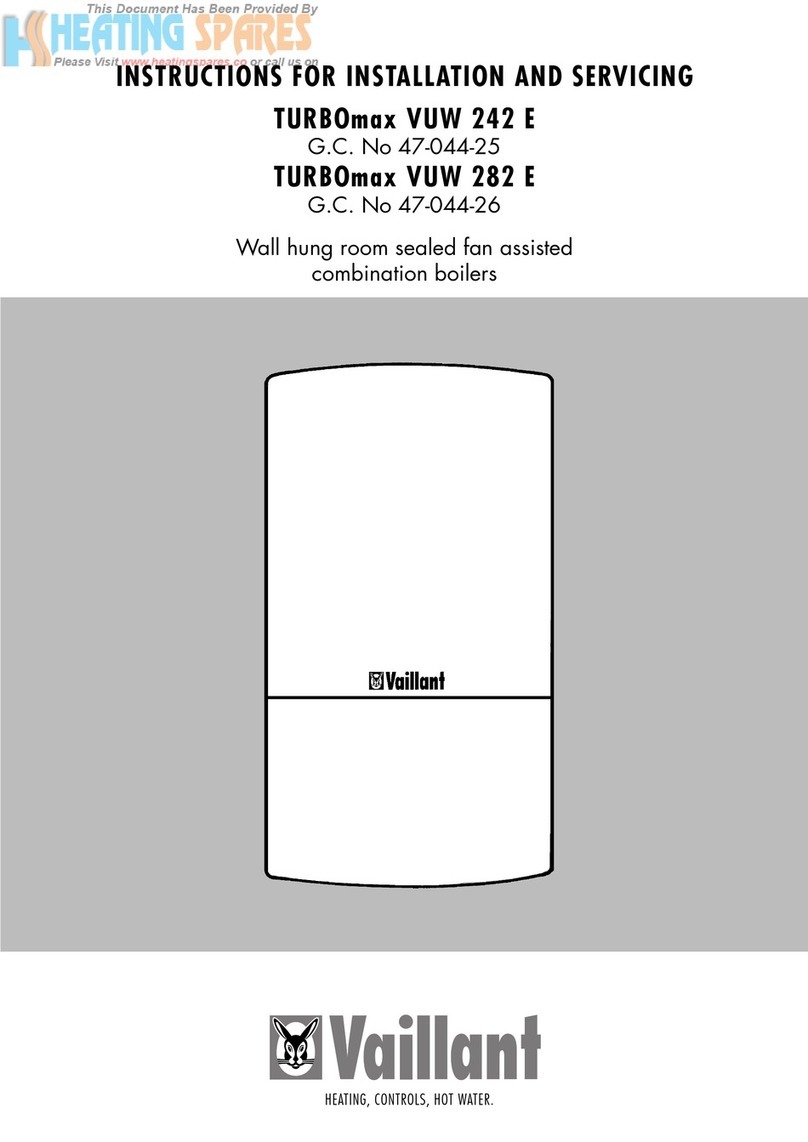

Diagram 3.1

3Water Systems

Theinstallationoftheboilermustcomplywiththerequirements

of the current issue of BS6798.

3.1 Frost Protection

If the position of the boiler is such that it may be vulnerable to

freezing it should be protected as specified in the current issue

ofBS5422.Itisrecommendedthatafrostprotectionthermostat

be fitted.

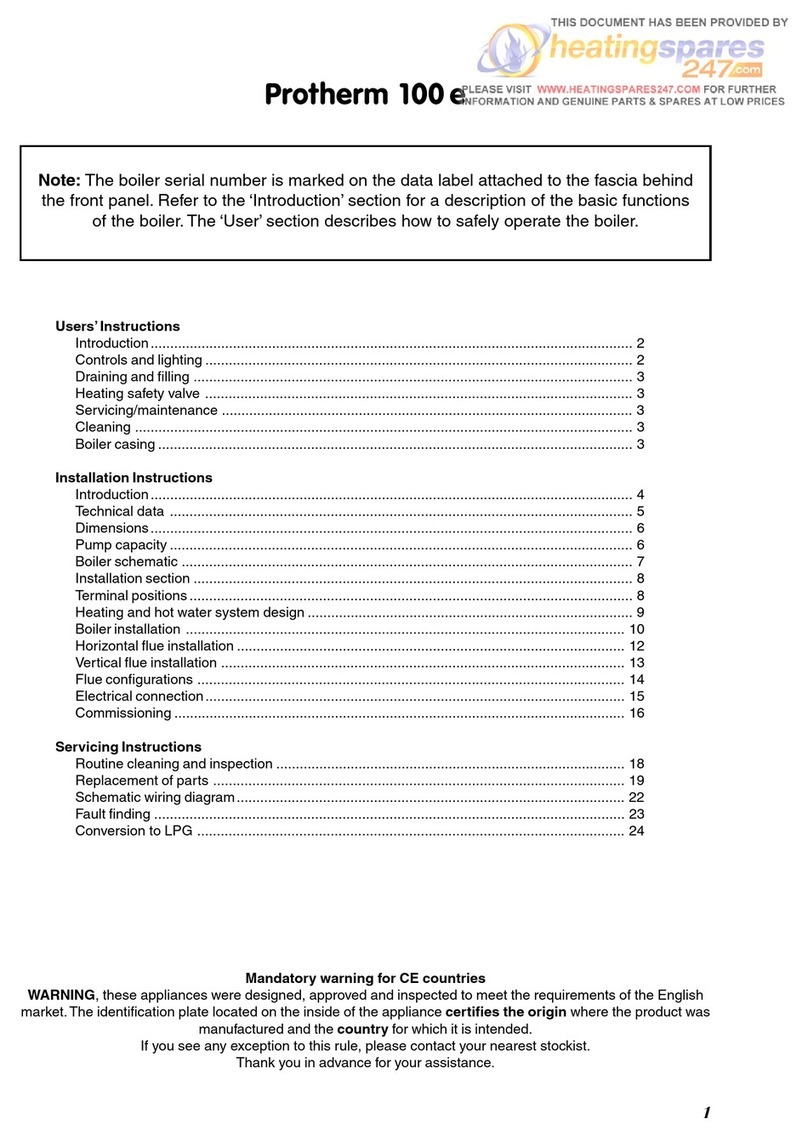

3.2 Pump

The pump, with integral valves, should be fitted in the heating

flow pipework from the boiler, it should be set to produce a

temperature difference of 11oC (20oF) between the flow and

return, with the boiler thermostat set at “MAX”, which is about

82oC (180oF).

The pressure loss of the boiler can be found from diagram 3.1.

High resistance microbore systems may require a higher duty

pump.

3.3 Bypass - Fully Pumped and Sealed Water

System

A bypass is usually unnecessary on systems using a 3 port

diverter valve since one port will remain in the open position at

all times. This allows satisfactory operation of the pump

overrun.

Howeverifthermostaticradiatorvalvesarefittedtoallradiators

or two port valves are used a bypass is required.

Thebypassconnectionmustbeatleast2metresawayfromthe

boiler.

Theflow through theboilermust not beallowedto fall suchthat

thereisatemperaturedifferencegreaterthan20oCbetweenthe

flow and return.

3.4 Water System

Foran openvented systemthe boilermustbesuppliedfrom an

unrestricted water supply taken from a feed and expansion

cisternfittedatamaximumheightof27metresabovetheboiler.

The cold feed must be 15mm minimum size.

It is important that the relative positions of the pump, cold feed

and open vent are as shown in diagram 3.2.

Theunrestrictedopenventfromtheboilermustrisecontinuously

to discharge over the feed and expansion cistern.

3.5 Domestic Hot Water System

General. Thedomestichotwaterservicemustbeinaccordance

withthecurrent issue of BS5546,referalsoto the current issue

of BS6700.

3.6 Cylinder

Forallsystems supplying domestic hot water the cylinder must

be indirect. It is recommended that the cylinder be fitted with

some form of temperature control.

3.7 Gravity Domestic Hot Water with Pumped

Heating

Important: If domestic hot water is to be provided by a gravity

circulation to the cylinder the blanked off connections must be

opened and used, using 22x28mm connections , see diagram

3.3.

3.8 Fully Pumped Heating and Domestic Hot

Water

The connection for this type of system MUST be as shown in

diagram 3.2 and 3.4.

3.9 Inhibitor

Attention is drawn to the current issue of BS5449 and BS7593

on the use of inhibitors in central heating systems.

Ifaninhibitoristobeused,contactamanufacturerorHepworth

Heating Ltd., for their recommendations as to the best product

to use.

When installing in an existing system take special care to drain

theentiresystem,includingradiators,thenthoroughlycleaning

outbeforeinstallingtheboilerwhetherornotaddinganinhibitor.

3.10 Sealed Water Systems

Theinstallationshouldcomplywiththeappropriaterequirements

ofthecurrent issue of BS4841, BS5449, BS6759,BS6798and

BS7074 Part 1 and 2, see diagram 3.5 for suggested layout.

3.11 Safety Valve

A safety valve must be fitted to a sealed water system.

It shall be preset, nonadjustable with a lift pressure of 3bar,

incorporating seating of a resilient material, a test device and a

connection for drain.

The drain from the safety valve must be routed clear of any

electrical fittings and positioned so that any discharge can be

seen.

3.12 Expansion Vessel

A diaphragm type expansion vessel, conforming to the current

issue of BS4814 (see also BS7404 Part 1 and 2) must be

connected at a point close to the inlet side of the circulating

pump, see diagram 3.5 unless laid down differently by the

manufacturer.

The expansion vessel volume depends upon the total water

systemvolume andtheinitial systemdesign pressure. For any

systeman accuratecalculation ofthe vesselsizeisgivenin the

current issue of BS7074 Part 1.

Example. For an initial system design pressure of 0.7bar the

minimum total vessel volume required is 0.063xTotal System

volume.

Note. A higher initial design pressure requires a larger volume

expansion vessel.

Guidance on vessel sizing is also given in the current issue of

BS5449 and BS7074 Part 1.

Thechargepressuremustnotbelessthanthestaticheadofthe

system, that is, the height of the highest point of the system

above the expansion vessel.

The water content of the boiler is given in Data Table 1.

1000

750

500

250 19.1

0051015 20 25 30

Flow rate (litres/minute)

Water pressure loss

(mm head of water)

0088

The insertion point indicates the flow rate required to achieve

11°C temperature difference