Protocol Insight Falcon G300 Series User manual

Protocol Insight® Falcon G300 Series

UFS/UniPro Exerciser/Analyzer with Trace

Validation™

Solder-down probing quick start guide

Contents

Probe overview ............................................................................................................................................. 1

Solder-down probe components ..................................................................................................................2

Preparing probe tips for installation............................................................................................................. 4

Installing the probe tip.................................................................................................................................. 5

To determine the best sampling points........................................................................................................ 5

Ground wire installation ............................................................................................................................... 6

Connect probe tips to the Falcon instrument............................................................................................... 6

Differential flex tip ........................................................................................................................................7

Multi-lead pod configuration........................................................................................................................ 8

Contact information...................................................................................................................................... 9

Product specifications and descriptions in this document

are subject to change without notice.

© Protocol Insight, LLC 2017, 2018

Revision 1.1 February 21, 2018

P a g e | 1

Probe overview

The Protocol Insight solder-down probe allows developers using an embedded MIPI Alliance M-PHY bus

in their PCB designs to tap into the signal traces directly and capture bus traffic for protocol analysis and

debugging. It is compatible with the Protocol Insight Falcon G300 Analyzer or G350 Exerciser/Analyzer

and supports M-PHY speeds up to HS-G3B.

Figure 1. Protocol Insight solder-down probe and Components

Product specifications and descriptions in this document

are subject to change without notice.

© Protocol Insight, LLC 2017, 2018

Revision 1.1 February 21, 2018

P a g e | 2

Solder-down probe components

The solder-down probe has a multi-lead pod (Pod or E in Figure 2), high bandwidth coax cables (C) to

connect to the probe tips, differential flex tips for easy connection to the DUT, and connects to the Falcon

instrument with an iPass-to-SMA cable (iPass in Figure 2).

Figure 2. solder-down probe POD and Components

Probe system components include:

•iPass-to-SMA cable

C

Pod

iPass

E

Product specifications and descriptions in this document

are subject to change without notice.

© Protocol Insight, LLC 2017, 2018

Revision 1.1 February 21, 2018

P a g e | 3

•Power Supply

•High bandwidth coax cable

•Solder-down probe differential flex tip

The solder-down probe pod has three primary connections:

Product specifications and descriptions in this document

are subject to change without notice.

© Protocol Insight, LLC 2017, 2018

Revision 1.1 February 21, 2018

P a g e | 4

iPass-to-SMA cable to analyzer

Power Jack

DC IN 12V

Connectors for coaxial cables to probe

tips

Preparing probe tips for installation

The first step in preparing for installation is to ensure that the probe tips are in good condition. If you are

using new probe tips for the first time, examine the leads under magnification to ensure the leads are

clean and secure, and then proceed to step 7.

If the probe tips have been used previously, it may be necessary to clean the leads of excess solder or to

remove and replace the leads. A small spool of wire is included with each probe tip to be used in replacing

broken or damaged tip leads. To replace the tip leads, follow this procedure:

1. Using a soldering iron, heat the existing lead wire at the via where the lead enters the probe tip.

Carefully remove the existing wire segment from the via.

2. Clean the via barrel of any excess solder.

3. Cut a new length of wire of approximately 2-3” from the wire spool supplied with the probe tip.

4. Thread the wire segment through the clean via located at the tip of the probe.

5. Heat with a soldering iron and apply small amounts of solder on the under-side of the tip at the

via until the wire is secured within the via.

6. Trim the excess wire on the top of the probe tip as closely as possible to the surface of the

probe tip.

7. Trim the lead wire on the underside of the probe tip to a maximum length of 2.5 mm (0.1”).

8. Repeat steps 1-7 with the other lead wire.

Product specifications and descriptions in this document

are subject to change without notice.

© Protocol Insight, LLC 2017, 2018

Revision 1.1 February 21, 2018

P a g e | 5

9. Trim the final lead lengths as short as possible to improve signal fidelity while allowing sufficient

room to attach the leads to the signal test point and maintaining equal lengths of the two leads

[to within 0.25 mm (0.01”) if possible to improve signal fidelity—use calipers to measure lead

length.

10. Trim the probe wire to a maximum length of 0.1 ± 0.01 inches.

Installing the probe tip

To install the M-PHY solder-down probe tip, attach the probe tip leads to the signal of interest on the

device under test (DUT), connecting each probe tip to the two differential sampling points for that

signal.

1. Use probe tip leads that are of equal length, and are not longer than 2.5 mm (0.1”). The flex tip

is pre-installed with 0.1 inch long leads. It is recommended to trim the length of the tip as short

as possible to improve signal fidelity margin at the analyzer. The two leads must be cut to the

length of +/- 0.01 inches.

2. Solder the leads to the appropriate sampling points

using the minimum amount of solder necessary to

maintain a secure connection.

3. Once soldered, the probe tip should be angled at 30-60

degrees to the plane of the PCB under test, as shown in

the figure to the right.

4. Avoid placing the tip over any PCB components.

For more information see DIFFERENTIAL FLEX TIP below.

To determine the best sampling points

The solder-down probe tip is designed to sample two points in

close proximity, either the Rx+ and Rx- differential pair, or the

Tx+ and Tx- differential pair. Each bi-directional lane requires

two probe tips, one for each direction (or up to 4 probe tips for

a x2 design).

Typical probe points might include exposed pins of components,

or exposed traces or vias on the board along the M-PHY channel.

For each bi-directional lane of a M-PHY bus, the probe tips need to make contact with four signals, Rx+,

Rx-, Tx+ and Tx- to capture data traffic going in each direction.

The locations for the probe points must be selected considering the following criteria:

1. The probe locations must be within sufficient physical proximity to each other that the probe

cables and probe tips can easily reach back to the probe pod, which gathers and amplifies the

signals prior to passing them along to the analyzer. The probe pods are then connected back to

the analyzer using 1-meter cables. The dimensions of the probe components are as follows:

•Probe Pod: 163 x 37 x 106 mm (6.4” x1.5” x 4.2”)

•Probe Cable: 294 mm (11.6”)

30-600

Rx+

Rx-

Product specifications and descriptions in this document

are subject to change without notice.

© Protocol Insight, LLC 2017, 2018

Revision 1.1 February 21, 2018

P a g e | 6

•Probe Tip: 71 mm (2.8”)

2. The probe locations should be selected to provide the best possible signal with minimum

distortion along the M-PHY channel. As a general rule of thumb, this location is typically as near

as possible to the Tx component pins (see illustration below).

Ground wire installation

Systems with high ground noise may need an additional ground wire to a pad available near the tip of

the probe. If greater than 50mV drop in common mode voltage, it is recommended that you install a

ground wire. Abundant solder is recommended to avoid ripping the pad off. It is recommended to keep

the wire length shorter than 5in to minimize the ground loop. Ground wires are supplied with the probe

tips and are inserted into the connection on the side of the probe tip.

Connect probe tips to the Falcon instrument

After the tips have been soldered to the signals of interest on the DUT, the tips should then be

connected to the Falcon instrument. First, connect the high bandwidth cables into the probe pod,

starting with the lowest left port as shown in the illustration below. For more information, see MULTI-

LEAD POD CONFIGURATION.

Product specifications and descriptions in this document

are subject to change without notice.

© Protocol Insight, LLC 2017, 2018

Revision 1.1 February 21, 2018

P a g e | 7

Then connect the probe tip to the high bandwidth coax cable assembly by plugging the probe tip into

the smaller end of the probe cable. Make sure you connect the soldered Lane 0 to the coaxial pair

connected to Lane 0 in the pod and so on.

With the probe cables plugged into the multi-lead pod, connect the multi-lead pod to the Falcon

instrument using the iPass cable. For instructions on the proper connections from the iPass cable to the

SMA connectors on Falcon, see the FALCON QUICKSTART GUIDE or the “General Instrument

Configuration” section in the FALCON USER MANUAL.

Finally, power up the multi-lead pod by plugging in the power supply. If the probe system is properly set

up a blue light will illuminate on the probe tip connector.

Differential flex tip

Attaching the tip to the probing point

1. The flex tip is pre-installed with 0.1 inch long leads.

a. It is recommended to trim the length of the tip as short as possible to improve signal fidelity

margin at the analyzer. The two leads must be cut to the length of +/- 0.01 inches.

2. Once soldered, the tip head must be angled at 30-60 degrees to the plane of printed circuit

board. Refer to the following figure:

Product specifications and descriptions in this document

are subject to change without notice.

© Protocol Insight, LLC 2017, 2018

Revision 1.1 February 21, 2018

P a g e | 8

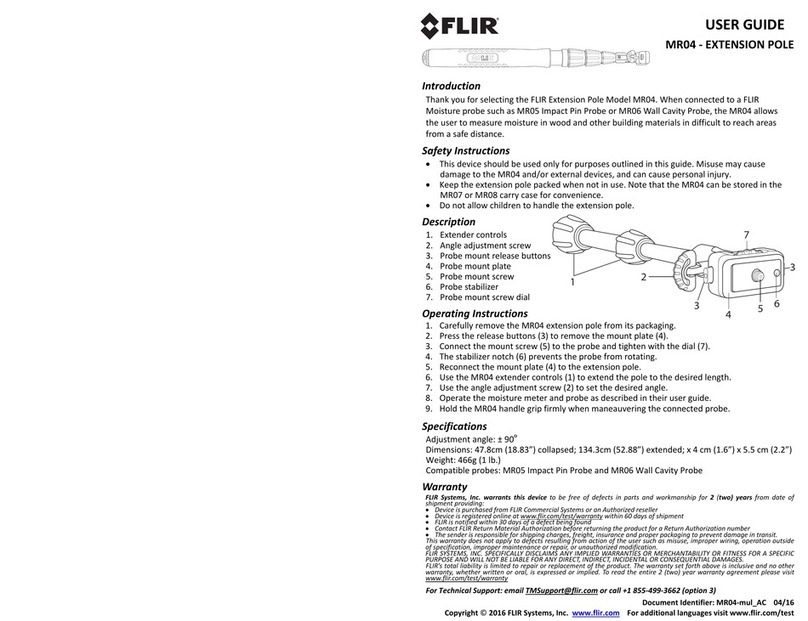

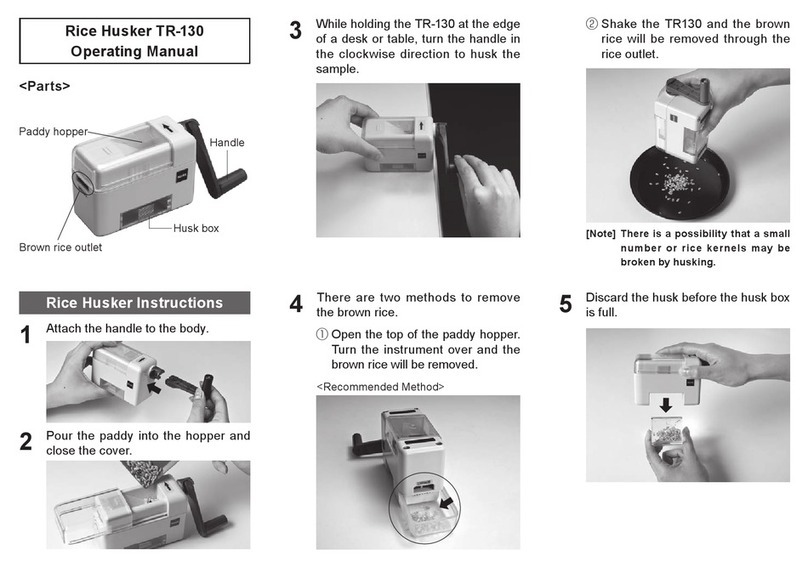

Multi-lead pod configuration

Connect the Probe tips to the Pod according to the following table. The probe cables are connected to the

probe pod as shown in the table below:

For a x1 design, the two probe cables would be plugged into DS0 and US0. For a x2

design, the four probe cables would be plugged into DS0, US0, DS1 and US1. The “DS”

and “US” designations refer to the routing of the signals through the iPass cable to

connect the single probe pod to both the “Upstream” and “Downstream” ports of the

analyzer.

US3

DS1

DS2

DS3

DS0

US0

US1

US2

Product specifications and descriptions in this document

are subject to change without notice.

© Protocol Insight, LLC 2017, 2018

Revision 1.1 February 21, 2018

P a g e | 9

Contact information

For additional information, to request a demonstration or quote, or place an order, please contact your

local Protocol Insight representative or sales@protocolinsight.com

Support materials and examples files are available at www.protocolinsight.com/support

For technical support please contact your local Protocol Insight representative or

support@protocolinsight.com

This manual suits for next models

1

Table of contents