PSG Wilden XSD HS Series Instruction Manual

XSD HS

Sanio™Hygienic Series

Surge Dampener

WIL-12230-E-04

REPLACES WIL-12230-E-03

Where Innovation Flows

www.wildenpump.com

EOM

Engineering

Operation &

Maintenance

Section 1 cautions—Read FiRst! .............................................1

Section 2 Wilden PumP designation system ................................2

Section 3 HoW it WoRks—PumP & aiR distRibution system. . . . . . . . . . . . . . . .3

Section 4 dimensional dRaWings.............................................4

Section 5 PeRFoRmance

XSD1-1/2 HS .............................................................5

XSD2 HS ................................................................6

XSD3 HS ................................................................7

Section 6 suggested installation & tRoublesHooting ....................9

Section 7 disassembly / Reassembly ........................................11

Reassembly Hints & Tips..................................................14

Cleaning-CIP ............................................................15

Section 8 exPloded VieW & PaRts listing

XSD1-1/2 HS ............................................................16

XSD2 HS ...............................................................18

XSD3 HS ...............................................................20

Section 9 elastomeR oPtions ................................................22

table oF contents

WIL-12230-E-04 1 WILDEN PUMP & ENGINEERING, LLC

CAUTION: Do not over-lubricate air supply —

excess lubrication will reduce performance.

CAUTION: Do not exceed 8.6 bar (125 psig) air

supply pressure.

CAUTION: When choosing dampener materials,

be sure to check the temperature limits for

all wetted components. Example: Viton®

has a maximum limit of 177°C (350°F) but

polypropylene has a maximum limit of only 79°C

(175°F).

CAUTION: Maximum temperature limits are

based upon mechanical stress only. Certain

chemicals will significantly reduce maximum

safe operating temperatures. Consult Chemical

Resistance Guide (E4) for chemical compatibility

and temperature limits.

TemperATUre LImITs:

Polypropylene 0°C to 79°C 32°F to 175°F

PVDF –12°C to 107°C 10°F to 225°F

PFA 7°C to 107°C 20°F to 225°F

Neoprene –18°C to 93°C 0°F to 200°F

Buna-N –12°C to 82°C 10°F to 180°F

EPDM –51°C to 138°C –60°F to 280°F

Viton®FKM –40°C to 177°C –40°F to 350°F

Wil-Flex™ –40°C to 107°C –40°F to 225°F

Saniflex™ –29°C to 104°C –20°F to 220°F

Polyurethane –12°C to 66°C 10°F to 150°F

Polytetrafluoroethylene (PTFE)

14°C to 104°C 40°F to 220°F

Nylon –18°C to 93°C 0°F to 200°F

Acetal –29°C to 82°C –20°F to 180°F

SIPD PTFE

with

Neoprene-backed

4°C to 104°C 40°F to 220°F

SIPD PTFE

with

EPDM-backed

–10°C to 137°C 14°F to 280°F

Polyethylene 0°C to 70°C 32°F to 158°F

Geolast®–40°C to 82°C –40°F to 180°F

NOTE: Not all materials are available for all

models. Refer to Section 2 for material options

for your dampener.

WArNING: Prevent static sparking. If static

sparking occurs, fire or explosion could result.

Dampener, pump, valves and containers must

be grounded to a proper grounding point

when handling flammable fluids and whenever

discharge of static electricity is a hazard.

CAUTION: The process fluid and cleaning fluids

must be chemically compatible with all wetted

dampener components. Consult Chemical

Resistance Guide (E4).

CAUTION: Dampener(s) should be thoroughly

flushed before installing into process lines.

FDA- and USDA-approved dampeners should be

cleaned and/or sanitized before being used.

CAUTION: Always wear safety glasses when

operating dampener. If diaphragm rupture occurs,

process fluid may be forced out air exhaust.

CAUTION: Before any maintenance or repair

is attempted, the compressed air line to the

dampener and pump should be disconnected

and all air pressure allowed to bleed from the

system. Disconnect all intake, discharge and air

lines. Drain the dampener by allowing any fluid

to flow into a suitable container.

CAUTION: Blow out air line for 10 to 20 seconds

before attaching to dampener to make sure all

pipeline debris is clear. Use an in-line air filter. A

5µ (micron) air filter is recommended.

CAUTION: Dampeners cannot be used in

submersible applications.

CAUTION: Tighten all hardware prior to

installation.

CAUTION: ATEX products have been assessed

for use in potentially explosive atmospheres in

accordance with the European Directive 94/9/

EC (ATEX 95). Users of ATEX products must

be familiar with ATEX requirements and follow

all safety guidelines. (Refer to Wilden Safety

Supplement WIL-18510-E.)

1

4°C to 149°C (40°F to 300°F) - 13 mm (1/2") and 25 mm (1") models only.

Section 1

cautions—Read FiRst!

Wilden PumP & engineering, llC 2 Wil-12230-e-04

Section 2

WildeN desigNatioN system

Xsd

HygieNiC seRies

eQUaliZeR®

legeNd

Xsd X / XX XX /XXX /xxxx

eQUaliZeR

®

sURge

damPeNeR diaPHRagm

RegUlatoR Body

aiR CHamBeR

Wetted PaRts / oUteR PistoN

iNlet siZe

sPeCialty Code

(if applicable)

sPeCialty Codes

mateRial Codes

model

XSD = ATEX EQUALIZER

®

SURGE DAMPENER

iNlet siZe

1-1/2 = 38 mm (1-1/2”)

2 = 51 mm (2”)

3 = 76 mm (3”)

Wetted PatH /

oUteR PistoN

SS = STAINLESS STEEL/

STAINLESS STEEL

SZ = STAINLESS STEEL/

NO PISTON

aiR CHamBeR

N = NICKEL-PLATED

ALUMINUM

S = STAINLESS STEEL

RegUlatoR Body

N = NICKEL-PLATED

ALUMINUM

S = STAINLESS STEEL

diaPHRagm

BNU = ULTRA-FLEX™ BUNA1

EPU = ULTRA-FLEX™ EPDM1

FBS = SANITARY BUNA1

(Two Yellow Dots)

FES = SANITARY EPDM1

FSS = SANIFLEX™ 1

FWL = FULL STROKE SANITARY

WIL-FLEX™ IPD1,2,3

FWS = SANITARY WIL-FLEX™ 1

LEL = PTFE-EPDM BACKED

LAMINATE IPD1,2,3

TEU = PTFE W/EPDM

BACKUP1,2

TSU = PTFE W/SANIFLEX™

BACK-UP1,2

0770 SaniFlo®HS

NOTE: MOST ELASTOMERIC MATERIALS USE COLORED DOTS FOR IDENTIFICATION.

Viton®is a registered trademark of DuPont Elastomers.

Santoprene®is a registered trademark of Exxon Mobil Corporation.

NOTE:

1Meets requirements of FDA CFR21.177

2Meets of USP Class VI

3Required for EHEDG certification

Maximum temperature limits are based upon

mechanical stress only. Certain chemicals will

significantly reduce maximum safe operating

temperatures. Consult Wilden Chemical Guide for

chemical compatibility and temperature limits. Plastic

Equalizers are manufactured with virgin plastic and

are not UV-stabilized. Direct sunlight for prolonged

periods can cause deterioration of these plastics. In

this situation a metal Equalizer®is suggested.

Wear safety glasses. When diaphragm rupture occurs,

material being pumped may be forced out air exhaust.

WARNING Prevent static sparking. If static sparking

occurs, fire or explosion could result. Pump, Equalizer®,

valves and containers must be grounded when

handling flammable fluids and whenever discharge of

static electricity is a hazard.

caution: Do not exceeD 8.6 bar (125 psig) air pressure.

A compressed air line attached to the air regulator body sets

and maintains pressure on the air side of the diaphragm. As the

reciprocating pump begins its stroke, liquid discharge pressure

increases which flexes the Equalizer®diaphragm inward. This

action accumulates fluid in the liquid chamber (see Phase 2).

When the pump redirects its motion upon stroke completion,

the liquid discharge pressure decreases and compressed air

in the air side forces the Equalizer®diaphragm to flex outward

displacing the fluid into the discharge line (see Phase 3). This

motion provides the supplementary pumping action needed to

minimize pressure fluctuation.

Section 3

How It works—DAMPENEr

The Equalizer®automatically sets and maintains the correct air

pressure matching the variations in liquid flow or discharge

pressure generated by the pump. A shaft attached to the Equalizer®

diaphragm triggers the addition or deletion of the air within the

non-wetted side of the Equalizer®. The Equalizer®automatically

adjusts to any pressure and/or flow setting of the pump with

no need for manual adjustment of the unit and/or system. The

Equalizer®has proven to be the cost effective choice for protecting

your liquid process system from unwanted pulsation or pressure

fluctuation. Contact your local Wilden distributor for further

information on the Equalizer®and other pumping solutions.

All reciprocating pumps experience a pressure fluctuation. The

Equalizer®minimizes unwanted pressure fluctuation by providing

a supplementary pumping action. This is accomplished by using

a diaphragm as a separation membrane within the Equalizer®to

trap a given volume of liquid on one side and pressurized air on the

other. When the fluid pressure falls in the system, the Equalizer®

supplies additional pressure to the discharge line between

pump strokes by displacing fluid via diaphragm movement. This

movement provides the supplementary pumping action needed

to virtually eliminate pressure variation and pulsation.

AIR

REGULATOR

BODY

AIR

REGULATOR

BODY

AIR

REGULATOR

BODY

LIQUID SIDE LIQUID SIDE LIQUID SIDE

DIAPHRAGM DIAPHRAGM DIAPHRAGM

AIR

SIDE

AIR

SIDE

AIR

SIDE

AIR

REGULATOR

BODY

AIR

REGULATOR

BODY

AIR

REGULATOR

BODY

LIQUID SIDE LIQUID SIDE LIQUID SIDE

DIAPHRAGM DIAPHRAGM DIAPHRAGM

AIR

SIDE

AIR

SIDE

AIR

SIDE

AIR

REGULATOR

BODY

AIR

REGULATOR

BODY

AIR

REGULATOR

BODY

LIQUID SIDE LIQUID SIDE LIQUID SIDE

DIAPHRAGM DIAPHRAGM DIAPHRAGM

AIR

SIDE

AIR

SIDE

AIR

SIDE

PHAsE 1 PHAsE 3PHAsE 2

WIL-12230-E-04 3 WILDEN PUMP & ENGINEERING, LLC

WILDEN PUMP & ENGINEERING, LLC 4 WIL-12230-E-04

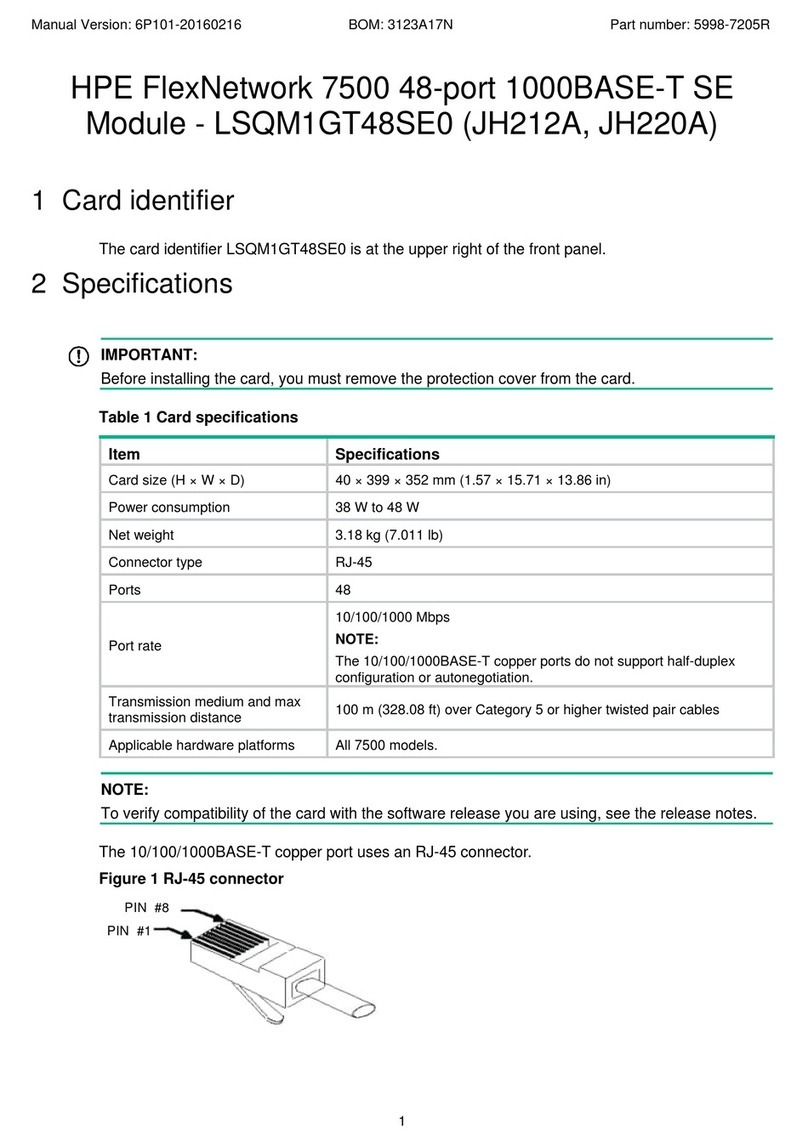

Section 4

DIMENSIONAL DRAWINGS

XSD1-½ SanifloTM HS

XSD2 SanifloTM HS

DIMENSIONS

ITEM METRIC (mm) STANDARD (inch)

A 284 11.2

B 259 10.2

C 160 6.3

D 305 12.0

E 320 12.6

DIMENSIONS

ITEM METRIC (mm) STANDARD (inch)

A 292 11.5

B 259 10.2

C 170 6.7

D 305 12.0

E 338 13.3

XSD3 SanifloTM HS

DIMENSIONS

ITEM METRIC (mm) STANDARD (inch)

A 358 14.1

B 312 12.3

C 241 9.5

D 363 14.3

E 482 19.0

WIL-12230-E-04 5 WILDEN PUMP & ENGINEERING, LLC

Section 5

XSD1½ HS PERFORMANCE

These charts show discharge head fluctuations for

a diaphragm pump with and without a dampener.

By reviewing the variation in pressure, the level of

dampening can be estimated for an application. For

example, the head pressure generated by a 38 mm

(1-1/2")” pump operating at 6.8 bar (100 psig) air

inlet pressure and 6.2 bar (90 psig) head pressure

varies between 0.8 bar (12 psig) and 7.4 bar (108 psig)

resulting in a total pressure fluctuation of 96 psig

for each stroke. When an XSD1 1/2/SZSS/LEL/0770

dampener is installed in the application, the head

pressure varies between 5.1 bar (74 psig) and 6.8 bar

(99 psig) resulting of a pressure fluctuation of only 1.7

bar (25 psig). This results in a 74% reduction in head

pressure fluctuation.

WILDEN PUMP & ENGINEERING, LLC 6 WIL-12230-E-04

XSD2 HS PERFORMANCE

These charts show discharge head fluctuations for

a diaphragm pump with and without a dampener.

By reviewing the variation in pressure, the level of

dampening can be estimated for an application.

For example, the head pressure generated by a 51

mm (2") pump operating at 6.8 bar (100 psig) air

inlet pressure and 6.2 bar (90 psig) head pressure

varies between 1.4 bar (20 psig) and 7 bar (102 psig)

resulting in a total pressure fluctuation of 5.7 bar

(82 psig) for each stroke. When an XSD2/SZSS/

LEL/0770 dampener is installed in the application, the

head pressure varies between 5.2 bar (75 psig) and

6.8 bar (100 psig) resulting of a pressure fluctuation of

only 1.7 bar (25 psig). This results in a 70% reduction

in head pressure fluctuation.

WIL-12230-E-04 7 WILDEN PUMP & ENGINEERING, LLC

XSD3 HS PERFORMANCE

These charts show discharge head fluctuations for

a diaphragm pump with and without a dampener.

By reviewing the variation in pressure, the level of

dampening can be estimated for an application. For

example, the head pressure generated by a 76 mm (3")

pump operating at 6.8 bar (100 psig) air inlet pressure

and 6.2 bar (90 psig) head pressure varies between 1.4

bar (21 psig) and 7.1 bar (103 psig) resulting in a total

pressure fluctuation of 82 psig for each stroke. When

an XSD3/SZSS/LEL/0770 dampener is installed in the

application, the head pressure varies between 4.9 bar

(71 psig) and 6.5 bar (94 psig) resulting of a pressure

fluctuation of only 1.6 bar (23 psig).This results in a 72%

reduction in head pressure fluctuation.

NOTES

WIL-12230-E-04 9 WILDEN PUMP & ENGINEERING, LLC

The model XSD1-1/2 Hygienic Series™ has a 38 mm (1-1/2”)

tri clamp style inlet/discharge. The model XSD2 has a 51 mm

(2”) inlet/discharge. The model XSD3 has a 76 mm (3”) inlet/

discharge. The Equalizer®can be installed in either direction.

A variety of materials are available to satisfy temperature,

chemical compatibility, abrasion and flex concerns. The

Equalizer®installed on the discharge side of the pump

minimizes pulsation and protects in-line equipment. It can also

be connected on the suction side to prevent water hammer

associated with a positive inlet condition. The model XSD1-1/2

Hygienic Series™ is engineered for use with Wilden 38 mm (1-

1/2”) PX4 Hygienic Series™ pumps. The model XSD2 Hygienic

Series™ is engineered for use with Wilden 51 mm (2”) PX8

Hygienic Series™ pumps. The model XSD3 is engineered for

use with Wilden PX15 Hygienic Series™ pumps.

Install the Equalizer®as shown above. The use of flexible

connections and a Filter, Regulator, Lubricator (FRL) will extend

parts life on the. Shut-off valves on the suction side of pump

and the discharge side of Equalizer®will enable maintenance

personnel to safely service the equipment. To maximize

effectiveness install the Equalizer®as close as possible to the

discharge of the pump. It is important to support the pipe

immediately downstream from the Equalizer®. Use a tee

connector on the pump air supply line and connect the line to

the Equalizer®regulator body. This tee connector should be

installed after the FRL. The Equalizer®consumes very little air,

therefore, a 1/4” hose is more than adequate to supply enough

air volume. When the air supply to the pump is shut down, the

air to the Equalizer®will be shut off as well.

Section 6

SuggeSted InStallatIon

WILDEN PUMP & ENGINEERING, LLC 10 WIL-12230-E-04

tRouBleSHootIng

1) When there is a significant drop in the fluid discharge

pressure, there will be a noticeable release of air

through the small bleed hole in the air regulator body.

This is how the Equalizer®automatically adjusts itself

for optimal suppression. This is a good way of verifying

proper operation of the unit. If there is a continuous

discharge of air out this hole during steady fluid

discharge pressure, the Equalizer®is not functioning

properly and should be inspected. The air regulator

body houses three (3) Glyd rings.

2) Fluid leakage around the clamp band area is normally

stopped by tightening the clamp band bolts. If

leakage continues, unit should be disassembled and

inspected.

3) Air leakage between the adapter plate and air chamber

requires tightening of four air chamber bolts on the

inside of the air chamber.

WIL-12230-E-04 11 WILdEn PumP & EngInEErIng, LLC

Tools Required:

• Deepwellsocketand

ratchet(3/4”)

• Deadblowmallet

• Hex(Allen®)wrenches

(3/16”and1/4”)

• Largeadjustable

wrenchorchannel

lockpliers

Tools

Recommended:

• Largepipewrench

• Viseequipped

w/softjaws(such

asaluminum,plastic,

plywoodorother

suitablematerial)

CAUTION: Beforeanymaintenanceorrepairisattempted,thecompressedairline

totheEqualizer®andthepumpshouldbedisconnectedandallairpressureallowed

tobleedfromthesystem.Disconnectallintake,dischargeandairlines.Beaware

of any hazardous effects of contact with your process uid. PLEASE READ ALL

DIRECTIONSBEFORESTARTINGDISASSEMBLY.

NOTE: The model photographed for these instructions is a XSD1-1/2 Hygienic

Series.OtherEqualizer®modelsshouldbesimilarindesignbutmaycontainslightly

differentcomponentsandfastenersizes.

Step 1

Removelargeclampband.

Step 2

Setliquidchamberaside.

Step 3

Remove reducer bushing at top of

regulator.

Section 7

SURGE DAMPENER DISASSEMBLY

WILdEn PumP & EngInEErIng, LLC 12 WIL-12230-E-04

SURGE DAMPENER DISASSEMBLY

Step 4

Loosen shaft assembly by using

a 3/4” socket on shaft bolt inside

air regulator body. Turn counter

clockwise.Oneoftwoscenarioswill

occur: the diaphragm will loosen

from shaft, or the shaft bolt will

loosenfromshaft.

Step 5

In either case, this will allow the

removal of the diaphragm, shaft

stop, shaft, shaft stop washer and

bolt.

Step 6

Inspect shaft for nicks or abrasion.

Smallnickscanusuallybedressed

out.Ifshaftischemicallyattackedor

nicksarehinderingoperation,shaft

shouldbereplaced.

Step 7

Disassembly of the air chamber

from the regulator adaptor plate

is needed only in the event of air

leakage.

Step 8

Intheevent of an airleak,remove

the air chamber and replace the

gasket.

Step 9

Disassembly of the regulator body

from the regulator adaptor plate

is needed only in the event of air

leakage.

WIL-12230-E-04 13 WILdEn PumP & EngInEErIng, LLC

Step 10

Intheevent of an airleak,remove

the regulator adaptor plate and

replacetheO-ring.

Step 11

Using an O-ring pick remove the

Glyd-ringsfromairregulatorbody.

SURGE DAMPENER DISASSEMBLY

WILdEn PumP & EngInEErIng, LLC 14 WIL-12230-E-04

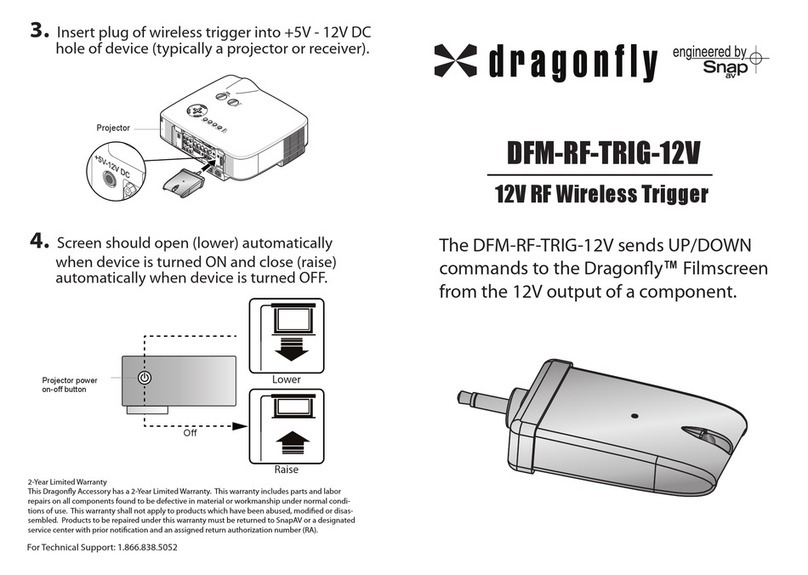

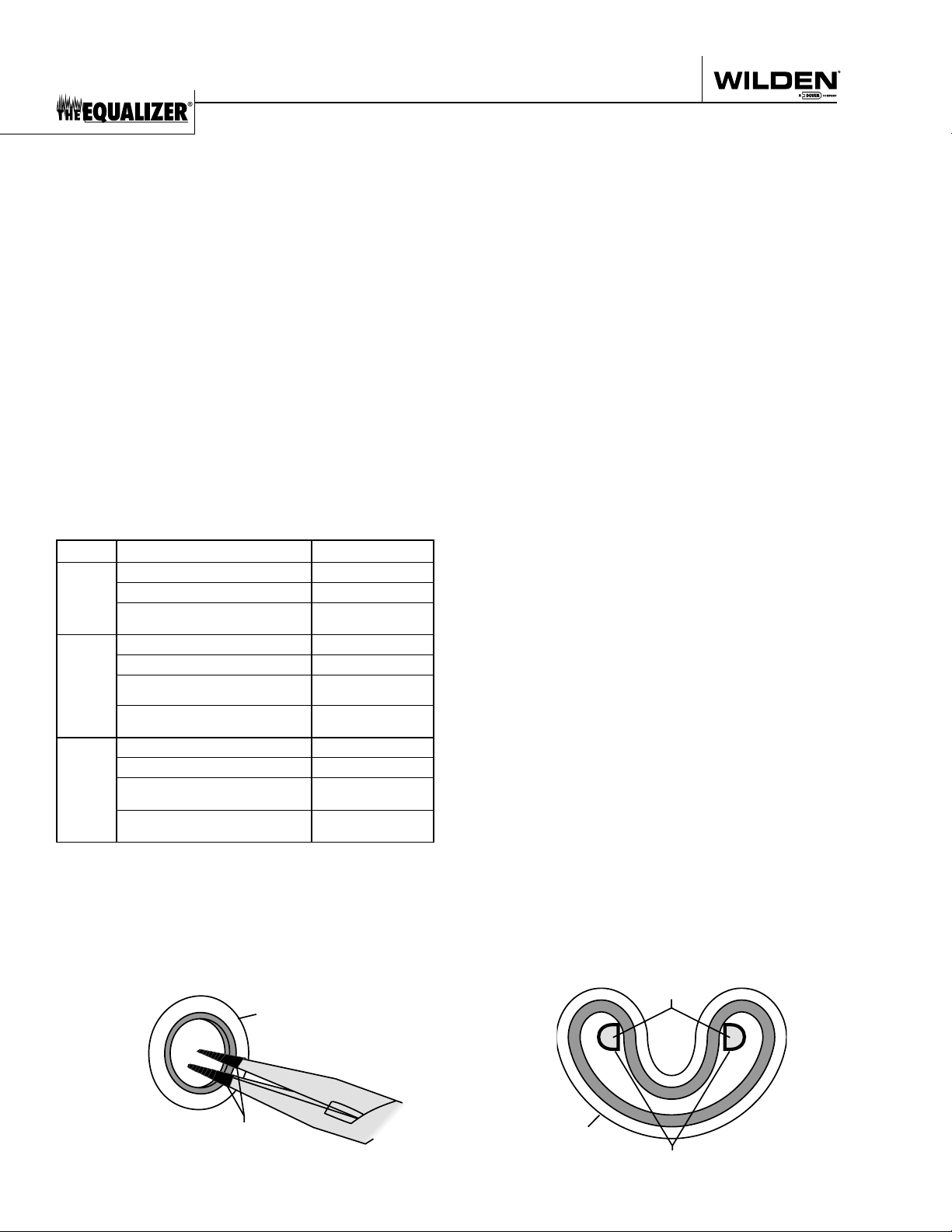

REASSEMBLY HINTS & TIPS

Figure A

SHAFT SEAL

TAPE

Figure B

SHAFT SEAL

TAPE

NEEDLE NOSE

PLIERS

ASSEmbly:

Upon performing applicable maintenance to the

air distribution system, the Equalizer® can now

be reassembled. Please refer to the disassembly

instructions for photos and parts placement. To

reassemble the Equalizer®, follow the disassembly

instructions in reverse order. The air regulator body

needs to be assembled rst, then the diaphragms

andnallythewettedpath.Pleasendtheapplicable

torquespecicationsonthispage.Thefollowingtips

willassistintheassemblyprocess.

• Lubricate air regulator body, Glyd rings and shaft

bore, center with NLGI grade 2 white EP bearing

greaseorequivalent.

• Cleantheinsideoftheairregulatorbodyboreto

ensurenodamageisdonetonewshaftseals.

• Stainless bolts should be lubed to reduce the

possibilityofseizingduringtightening.

mAXImUm TORQUE SPECIFICATIONS

Model Description of Part Torque

XSD1-½ HS

Air chamber/adapter plate 24.4 N·m (18 ft-lb)

Air regulator body/adapter plate 7.9 N·m (70 in-lb)

Outer piston/shaft bolt assembly

(all diaphragms) 54.2 N·m (40 ft-lb)

XSD2 HS

Air chamber/adapter plate 24.4 N·m (18 ft-lb)

Air regulator body/adapter plate 7.9 N·m (70 in-lb)

Outer piston/shaft bolt assembly

(rubber & PTFE) 109 N·m (80 ft-lb)

Outer piston/shaft bolt assembly

(Ultra-Flex™ & SIPD) 74.6 N·m (55 ft-lb)

XSD3 HS

Air chamber/adapter plate 24.4 N·m (18 ft-lb)

Air regulator body/adapter plate 7.9 N·m (70 in-lb)

Outer piston/shaft bolt assembly

(rubber & PTFE) 109 N·m (80 ft-lb)

Outer piston/shaft bolt assembly

(Ultra-Flex™ & SIPD) 74.6 N·m (55 ft-lb)

SHAFT SEAl INSTAllATION:

PRE-INSTAllATION

• Once all of the old seals have been removed, the

insideoftheairregulatorbodyshouldbecleaned

toensurenodebrisisleftthatmaycausepremature

damagetothenewseals.

INSTAllATION

Thefollowingtoolscanbeusedtoaidintheinstallation

ofthenewseals:

NeedleNosePliers

PhillipsScrewdriver

ElectricalTape

• Wrapelectricaltapearoundeachlegoftheneedlenose

pliers(heatshrinktubingmayalsobeused).Thisisdone

topreventdamagingtheinsidesurfaceofthenewseal.

• Withanewsealinhand,placethetwolegsoftheneedle

nosepliersinsidethesealring.(SeeFigureA.)

• Openthepliersaswideasthesealdiameterwillallow,

thenwith twongers pulldownon the topportionof

thesealtoformkidneybeanshape.(SeeFigureB.)

• Lightly clamp the pliers together to hold the seal into

thekidneyshape.Besuretopullthesealintoastight

ofakidneyshapeaspossible,thiswillallowthesealto

traveldownthebushingboreeasier.

• Withthesealclampedinthepliers,insertthesealinto

the bushing bore and position the bottom of the seal

intothecorrectgroove.Oncethebottomofthesealis

seatedinthegroove,releasetheclamppressureonthe

pliers.Thiswillallowthesealtopartiallysnapbacktoits

originalshape.

• After the pliers are removed, you will notice a slight

bumpinthesealshape.Beforethesealcanbeproperly

resized, the bump in the seal should be removed as

much as possible. This can be done with either the

Phillipsscrewdriveroryournger.Witheithertheside

of the screwdriver or your nger, apply light pressure

to the peak of the bump. This pressure will cause the

bumptobealmostcompletelyeliminated.

• Lubricate the edge of the shaft with NLGI grade 2

whiteEPbearing

grease.

• Slowly insert the center shaft with a rotating motion.

Thiswillcompletetheresizingoftheseal.

• Performthesestepsfortheremainingseal.

WIL-12230-E-04 15 WILdEn PumP & EngInEErIng, LLC

Section 8

CLEANING - CIP

Thedesignofthepulsationdampenerallowsforease

ofcleaning.Thisequipmentcanbedisassembledfor

cleaning or cleaned in place without disassembly if

the user has an appropriate CIP system. Before any

cleaningisattempted,ensurethatthecleaninguids

arecompatiblewithallwettedcomponents.

For best cleaning results consider the following

information prior to cleaning of the dampener.

• For best Clean in Place (CIP) results, the pulsation

dampener should be congured to the EHEDG

conguration.

• Actual CIP effectiveness and processes should

be validated on location by the end user’s quality

assurance personnel or meet internal guidelines.

Postcleaningswabtestisonemethodtoaccomplish

this.

• The user should establish periodic inspections

withfullteardowntoverifythattheCIPprocesses

continuetobeeffectiveasrstvalidated.

• When CIP pressures are greater than 10 psig (0.7

bar), the dampener should be pre-loaded with air

pressuretobalancetheCIPpressureinthepulsation

dampenerinordertomaximizediaphragmlife.

The following are some details to consider when

cleaning the pulsation dampener.

• Through the EHEDG certication process, the

dampenerhasbeenvalidatedtocleanequivalentto

theinlettubingofthesamediameter.Thecleaning

chemicalsuppliershouldbeconsultedandadvised

of this for their chemical solution and application.

Thesameguidelinesfordurationofcleaningcycle

andtemperatureofcleaninguidapply.

• Suggestedowrateforthe38mm(1-1/2")dampener:

6.5m3/hr(3gpm);forthe51mm(2")dampener:11

m3/hr(50gpm);forthe76mm(3")dampener:22m3/

hr(100gpm)(usuallyhigherisbetter).

• Typical CIP temperature is 77°C to 82°C (170°F to

180°F).

• TypicalchemicalsincludeNaOH(sodiumhydroxide)

caustic for wash and light acid and sanitizers for

rinse.

• Once an initial CIP regimen is established, it may

need to be modied to accommodate specic

process and product differences or requirements.

Themostcommonadjustmentsinclude:

º Changing cleaning time (extended or reduced

pre-rinse,wash,rinses)

º Changingcleaningowrate

• The cleaning variables are related so that a pump

user may be able to reduce the cleaning time by

increasingtheowrateorchemicalmix.

• Chlorinatedsanitizersareknowntocausepremature

failureofstainlesssteelandshouldbeavoided.

• Activate the CIP system and in the process of

cleaning other equipment in series, the dampener

willbecleanedaswell.

Draining the dampener.

• Toassurethatthedampenerdrainsaftercleaning,

it should be mounted in a vertical position with

respecttoinlet/outletports.

10

9

20 18

20

20 18

17

14

15

20 18

19

17

15

14

18

17

15

14

18

17

15

14

17

16

8

15

7

6

14

54

3

2

1

21

22

12

23

14

13

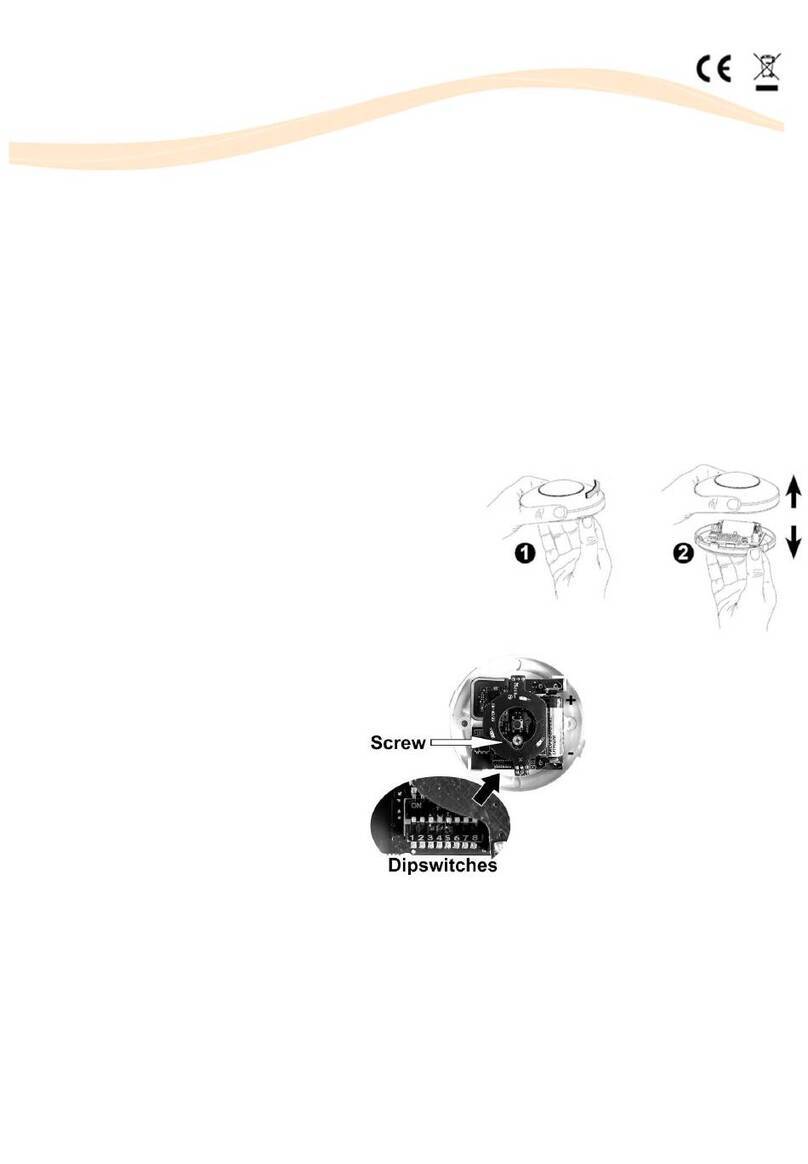

SD1½ SANIFLO HS RUBBER FITTED

SD1½ SANIFLO HS ULTRA-FLEX FITTED

SD1½ SANIFLO HS SIPD FITTED

SD1½ SANIFLO HS PTFE FITTED

Wilden PumP & engineering, llC 16 Wil-12230-e-04

Section 8

EXPLODED VIEW & PARTS LISTING

XSD1-½ SanifloTM HS EXPLODED VIEW

1Air Regulator Body includes qty. 3 Glyd Rings.

*Elastomer options listed on page 22.

All Bold face items are primary wear items.

Item Description Qty.

XSD1½/SSNN/0770

P/N

XSD1½/SSSS/0770

P/N

1 Body, Regulator11 76-8515-06 76-8515-03

2 Ring II, Glyd 3 08-3210-55-225 08-3210-55-225

3 O-Ring -230 (Ø2.484 x Ø.139) 1 76-1285-52 76-1285-52

4 Plate, Regulator Adapter 1 76-8510-06 76-8510-03

5 Screw, 1/4-20 x .75 Soc Hd Cap 4 76-6250-03 76-6250-03

6 Gasket, Center Block 1 04-3529-52 04-3529-52

7 Chamber, Air 1 04-3660-06 04-3660-03

8 Screw, 3/8-16 x 1.00 Soc Flt Csk Hd Cap 4 71-6250-08 71-6250-08

9 Chamber, Liquid 1 76-5000-10-385P 76-5000-10-385P

10 Clamp Band, Half 2 04-7330-03 04-7330-03

11 Bolt, 5/16-18 x 2.50 Rnd Hd Sq Neck 2 04-6070-03 04-6070-03

12 Washer, Plain 2 01-6732-03 01-6732-03

13 Nut, 5/16-18 Hex 2 08-6661-10 08-6661-10

14 Shaft, Straight 1 76-3800-03 76-3800-03

Shaft, Ultra-Flex™ 1 04-3830-03-07 04-3830-03-07

15 Stud, 1/2-20 x 1.50 Threaded 1 04-6150-08 04-6150-08

Stud, 3/8-16 x 1.50 Threaded, Ultra-flex™ 1 04-6152-08 04-6152-08

16 Stop, Shaft 1 76-8800-17 76-8800-17

17 Piston, Rubber & TPE Inner 1 04-3700-01-700 04-3700-01-700

Piston, Ultra-Flex™ Inner 1 04-3760-01-700 04-3760-01-700

Piston, PTFE Inner 1 04-3752-01 04-3752-01

Piston, SIPD Inner 1 04-3700-08 04-3700-08

18 Diaphragm, Primary 1 * *

Diaphragm, Ultra-Flex™ 1 * *

Diaphragm, PTFE 1 * *

Diaphragm, SIPD 1 * *

19 Diaphragm, Back-Up 1 * *

20 Piston, Rubber & TPE Outer 1 04-4550-10-385P 04-4550-10-385P

Piston, Ultra-Flex™ Outer 1 04-4560-10-385P 04-4560-10-385P

Piston, PTFE Outer 1 04-4600-10-385P 04-4600-10-385P

21 Washer, Stop 1 70-6790-08 70-6790-08

22 Screw, 1/2-20 x 1.00 Hex Cap 1 04-6090-08 04-6090-08

23 Reducer Bushing 1 70-6950-08 71-6950-03

Wil-12230-e-04 17 Wilden PumP & engineering, llC

EXPLODED VIEW & PARTS LISTING

XSD1-½ SanifloTM HS PARTS LISTING

Wilden PumP & engineering, llC 18 Wil-12230-e-04

XSD2 SanifloTM HS EXPLODED VIEW

Section 9

EXPLODED VIEW & PARTS LISTING

This manual suits for next models

3

Table of contents

Other PSG Control Unit manuals

Popular Control Unit manuals by other brands

GEA

GEA ECOVENT TEFASEP-Gold ECO E Assembling Instruction

Acromag

Acromag XMC-6280-LF user manual

Festo

Festo EXCM-10 quick start guide

Wildlife Acoustics

Wildlife Acoustics Echo Meter Touch 2 manual

ZURN

ZURN LEAD-FREE ZW209 Installation, Troubleshooting, Maintenance Instructions

Pilz

Pilz PNOZ mc6p operating instructions