GEA ECOVENT TEFASEP-Gold ECO E User manual

Other GEA Control Unit manuals

GEA

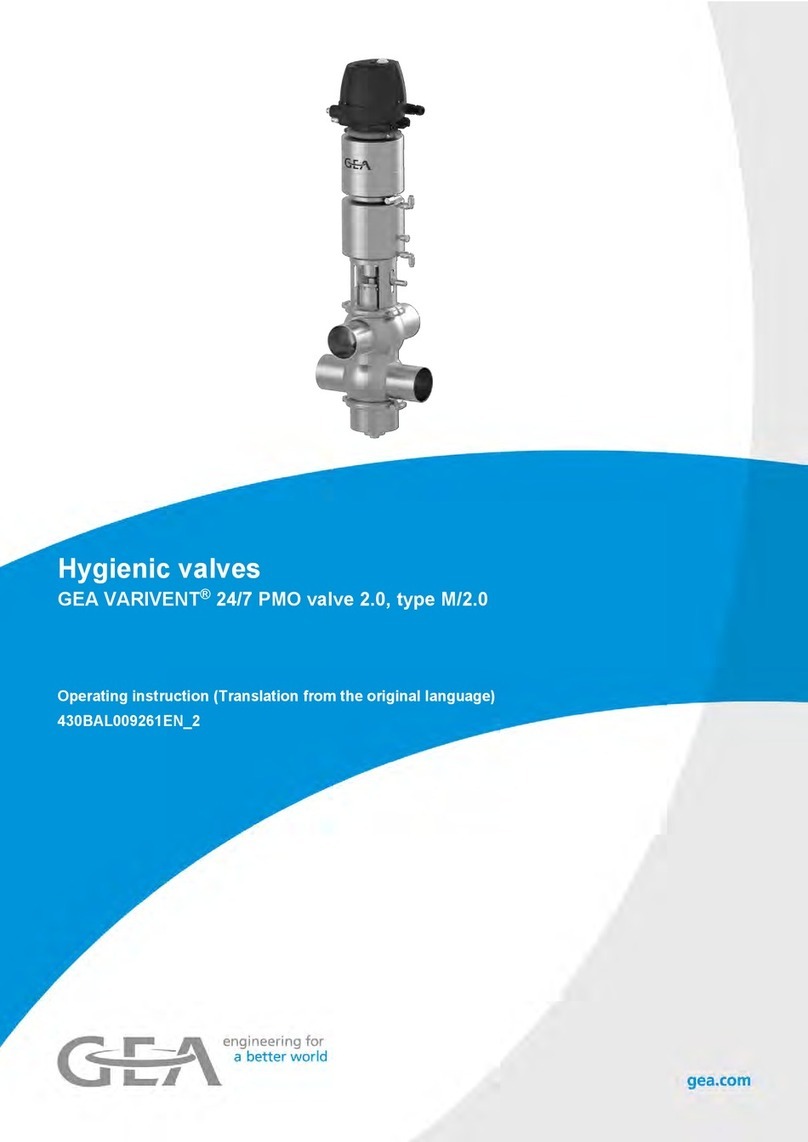

GEA VARIVENT 24/7 PMO User manual

GEA

GEA VARIVENT X R Series User manual

GEA

GEA Aseptomag AMV User manual

GEA

GEA VESTA XL User manual

GEA

GEA DHV User manual

GEA

GEA Aseptomag GD User manual

GEA

GEA Aseptomag AV User manual

GEA

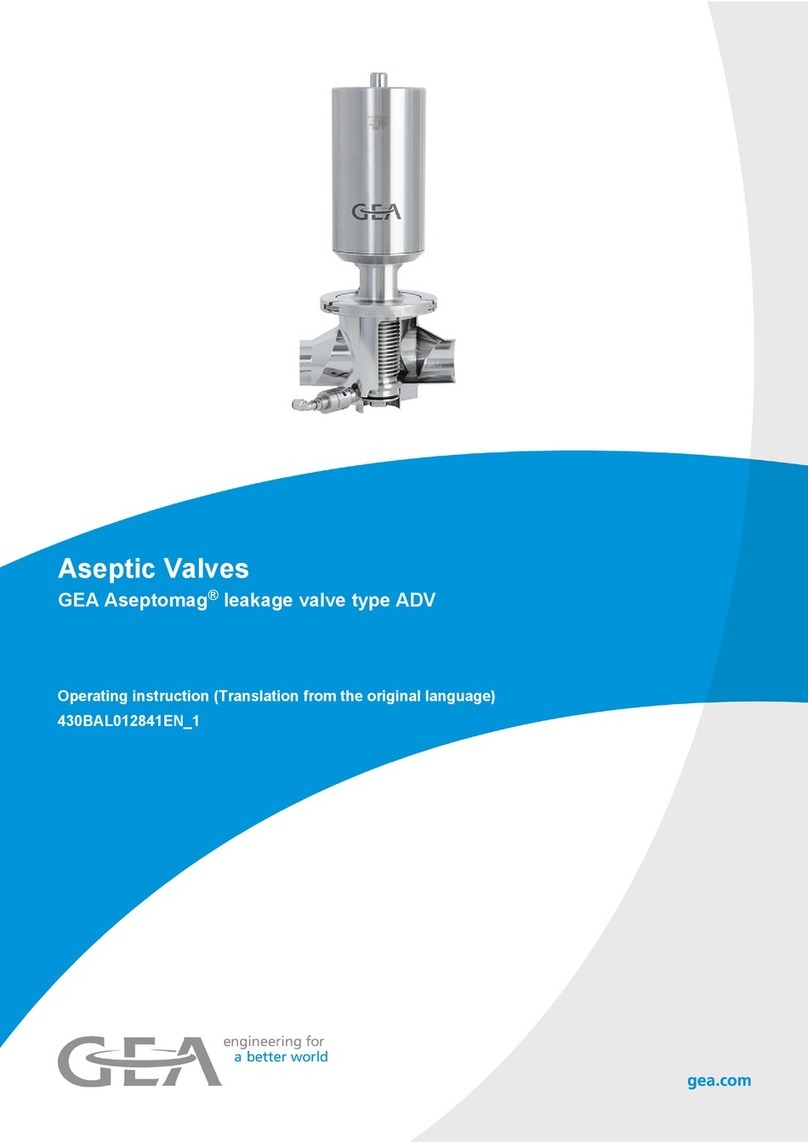

GEA Aseptomag ADV User manual

GEA

GEA VARIVENT D User manual

GEA

GEA SIMATIC C7-623 User manual

GEA

GEA VARIVENT K User manual

GEA

GEA SVU 446 User manual

GEA

GEA VARIVENT T R User manual

GEA

GEA DHV User manual

GEA

GEA HRAB User manual

GEA

GEA VARIVENT 24/7 PMO User manual

GEA

GEA ECOspace User manual

GEA

GEA ECOVENT N ECO Series User manual

GEA

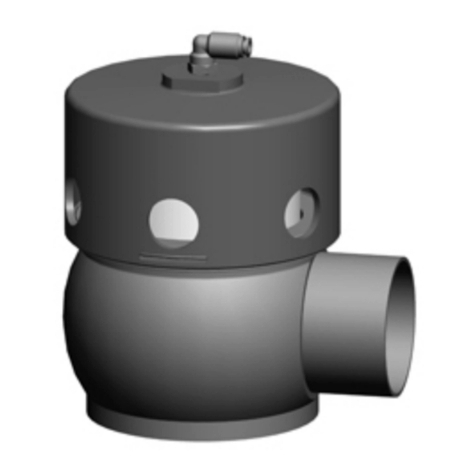

GEA DHV DN65/50 KVS 16 User manual

GEA

GEA DHV DN65/50 KVS 16 User manual

Popular Control Unit manuals by other brands

Festo

Festo Compact Performance CP-FB6-E Brief description

Elo TouchSystems

Elo TouchSystems DMS-SA19P-EXTME Quick installation guide

JS Automation

JS Automation MPC3034A user manual

JAUDT

JAUDT SW GII 6406 Series Translation of the original operating instructions

Spektrum

Spektrum Air Module System manual

BOC Edwards

BOC Edwards Q Series instruction manual

KHADAS

KHADAS BT Magic quick start

Etherma

Etherma eNEXHO-IL Assembly and operating instructions

PMFoundations

PMFoundations Attenuverter Assembly guide

Walther Systemtechnik

Walther Systemtechnik VMS-05 Assembly instructions

Altronix

Altronix LINQ8PD Installation and programming manual

Eaton

Eaton Powerware Series user guide