PSL D600 User manual

OWNERS MANUAL

D600

Rev: 4: 07/22

Portable Pump

2

NOTE: This manual is an integral part of the pump

package and MUST be read before operating the unit.

This manual must be kept and regularly referred to

throughout the lifetime of the equipment. Failure to do

so could result in injury and damage to the equipment.

Please ensure that any amendment received is

incorporated in the text and that this manual is passed

on to any subsequent holder or user of the equipment.

3

Manufactured by Vortex Holdings Ltd

31 Murchison Street Tikokino Central Hawkes Bay New Zealand. Tel +64 21435811

www.firepumps.co.nz email admin@firepumps.co.nz Page 2of 14

Health and safety

WHEN ENGINE IS RUNNING DO NOT:

1. Run with any guard removed.

2. Attempt any work in the guarded area.

3. Attempt to move the unit.

4. Refill the fuel tank (without removing it from the frame into a safe area first)

5. Remove the pressure cap from the expansion tank (wait until the engine has cooled.)

6. Place hands inside the volute housing.

7. Place any part of body near suction inlet. (If running with no suction hose connected,

always connect the end cap.)

WHEN ENGINE IS RUNNING DO:

8. Run the unit on level ground wherever possible. Inclination must never exceed 45°.

9. Check all couplings are secure before increasing pressure.

10. Wear ear protection when working near a running pump. It is also advised that eye

protection is used. Loose fitting clothing should not be worn whilst operating the pump.

WARNING: The gas priming exhaust reaches extreme temperatures.

WARNING: This pump weighs 122Kg (dry with 2 X Batteries)

WARNING: The pump should not be run in underground or poorly ventilated spaces.

WARNING: The guards on the exhaust side of the engine can become hot after prolonged

running at high speed.

WARNING:This pump can emit Noise levels over 85dB and ear protectors should be worn

at all times when running the pump.

WHEN ENGINE IS NOT RUNNING:

1. Do not place any heavy or loose items on the unit.

2. Do not drop the unit from any height.

MAINTENANCE

1. Allow the unit to cool before attempting to remove any part.

2. Before starting any maintenance ensure the ignition switch is off and disconnect one battery

lead or remove the battery.

3. Use only authorised spare parts supplied by Phoenix Firepumps or Lombardini / Kohler

WARNING

The pump body, when delivering water under pressure, is a pressure vessel. Failure to

assemble the pump body correctly can lead to leaks or in extreme cases failure of the pump

body. Ensure that the body is correctly positioned and that all bolts are tightened using a

spanner of the correct size and length.

DISPOSAL OF DIESEL FUEL AND OIL

Always dispose of surplus diesel and oil from the engine in a safe and environmentally safe

way. Only use receptacles specifically provided for diesel and oil.

Only dispose of surplus diesel and oil at authorised sites.

4

Manufactured by Vortex Holdings Ltd

31 Murchison Street Tikokino Central Hawkes Bay New Zealand. Tel +64 21435811

www.firepumps.co.nz email admin@firepumps.co.nz Page 3of 14

TO THE OPERATORS OF THE

D600 PORTABLE FIRE PUMP

Your new Phoenix D600 fire pump will deliver years of efficient and trouble free service if given

reasonable care and properly operated.

A study of the following pages should enable you to overcome any difficulties, which might

arise in the operation of this equipment. We request that you read this manual carefully before

placing this fire pump into service.

Several pages of useful data are contained herein to help you answer many of the questions

that may arise relative to the hydraulics of fire fighting.

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE

WARRANTY

Phoenix Firepumps unconditionally guarantees to replace, for a period of two years, any

defective part or parts in the D600 pump.

Every new D600 pump is guaranteed to deliver performance as specified in our sales brochure.

This warranty does not obligate us to bear costs of labour or transportation charges incurred in

the replacement of parts.

We shall not be responsible, under the terms of this warranty, for the cost of repairs or

alterations not authorised by us.

We shall not be responsible for damages or contingent liabilities resulting from failures of any

Phoenix pump.

We make no warranty of any trade accessories incorporated in the assembly or employed in

conjunction with any phoenix pump.

Excessive overloading of this pump beyond our recommended limits of capacity and pressure

shall void this warranty.

5

Manufactured by Vortex Holdings Ltd

31 Murchison Street Tikokino Central Hawkes Bay New Zealand. Tel +64 21435811

www.firepumps.co.nz email admin@firepumps.co.nz Page 4of 14

OPERATION OF D600 FIRE PUMPS

SUMMARY OF WHAT TO REMEMBER

1. Close delivery valves and drain valves, before attempting to prime pump.

2. Always keep primer shut off valve closed when working from hydrants or relay pumping.

3. Open primer-operating valve fully with 1/4 throttle to re-prime or eliminate trapped air

from suction line.

4. Never run pump without water in it except during priming.

5. Accelerate and retard speed of engine gradually.

6. Watch gauges periodically to ensure pump is operating normally.

7. Keep good gaskets in suction hose, and handle carefully to avoid damage to coupling

threads.

8. Air leakage into suction line is the most frequent source of trouble when pumping from a

suction lift.

9. Always use a suction strainer when pumping from open water.

10. Foreign matter in impellers is a result of failure to use adequate strainers and a common

source of trouble.

11. Drain pump immediately after each run.

12. Check oil level in motor after each pumping run.

13. Do not run a pump long with discharge completely shut off.

14. Do not close a “shutoff” type nozzle when pumping with throttle wide open.

6

Manufactured by Vortex Holdings Ltd

31 Murchison Street Tikokino Central Hawkes Bay New Zealand. Tel +64 21435811

www.firepumps.co.nz email admin@firepumps.co.nz Page 5of 14

Engine Operation

General information.

D600 Diesel series pumps use Lombardini / Kohler diesel engines. This is a two cylinder,

overhead valve, air-cooled engine. All drilled/tapped holes and fasteners on this engine are ISO

metric. However, where the pump attaches to the engine SAE standards apply.

This engine will operate satisfactorily at any angle at which the operator and pump can function

safely but not exceeding a maximum inclination 0f 35 degrees

Engine power will decrease 1% for each 100 metres above sea level and 2 % for each 5

degrees above 20 degrees Celsius. However, the pump unit has been design so, as no

perceptible loss of pumping will be noticed up to 1500 metres.

Important Information Running in:

During the first 50 hours of operation do not exceed 70% of the maximum rated

output.

Starting and Stopping

Before starting engine

•Use the correct oil for the starting temperature expected.

•Check the engine oil level. If the oil level is under the minimum, fill up.

•Unscrew the fuel cap and visually inspect the fuel level.

•If the fuel has been drained use the manual pump on the fuel pump to prime the injector

pump.

•A warm battery has more starting capacity than a cold battery.

•Set speed control at half throttle position

•Ensure the “Stop” control is fully closed.

•Turn key to start.

•Once engine has started release the key so it returns to the on position, and throttle back to

idle position.

•If the fuel circuit has been emptied or in harsh weather, several attempts may be necessary

before the engine starts. In such cases, alternate a 15 second attempt with a 15 second

pause to avoid overheating the starter motor.

Note:

This D600 pump is fitted with two REC 22 batteries wired in parallel. This gives a built in

redundancy should one battery fail.

Charge batteries fully before trying to start engine fitted with electric starting.

Stopping the engine

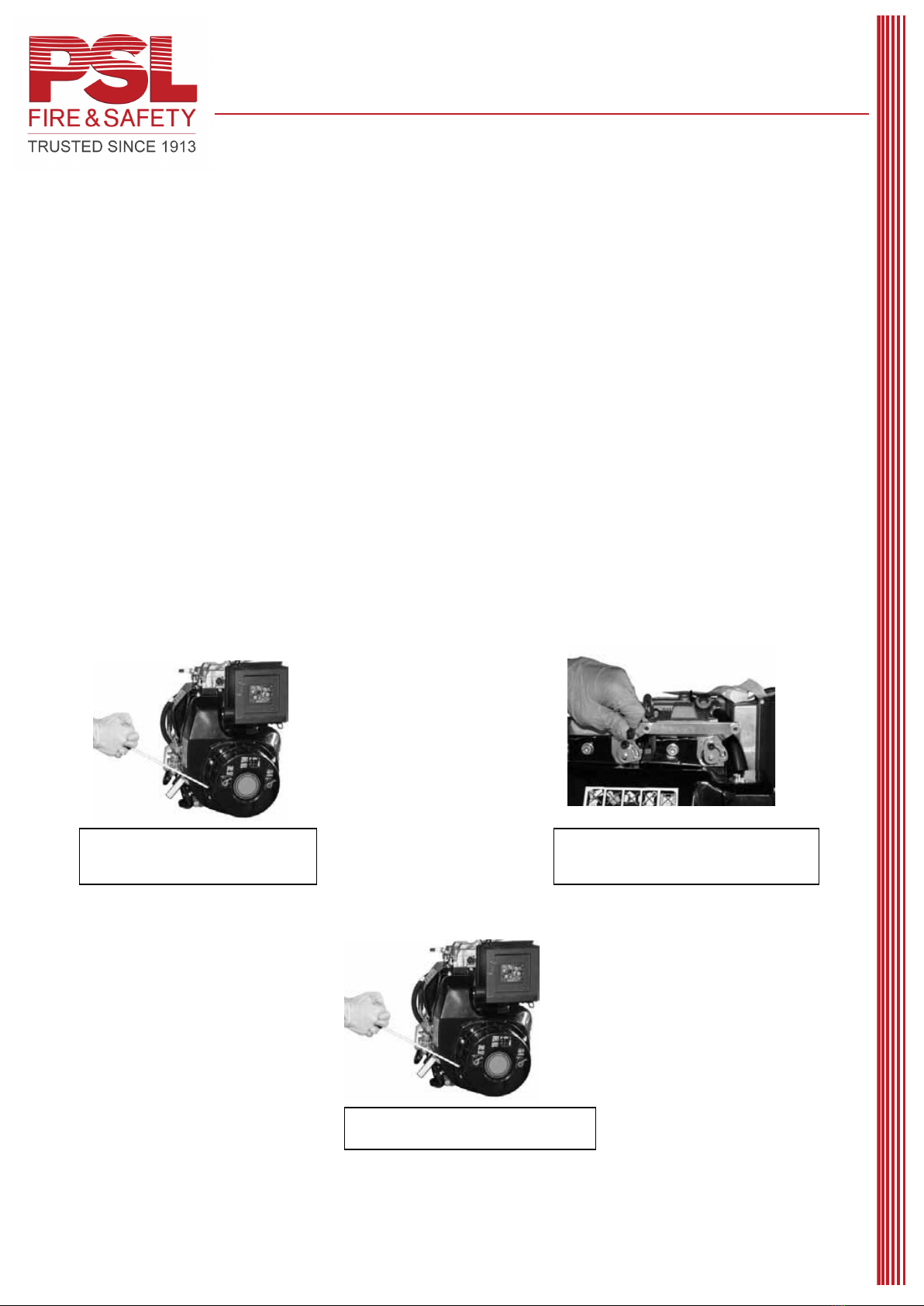

Move the throttle control to the SLOW position wait for a few seconds, and then turn the key to

the OFF position and pull the stop control fully out to stop the engine. (See Fig: 1 Below)

Fig: 1

Pull up to stop engine

7

Manufactured by Vortex Holdings Ltd

31 Murchison Street Tikokino Central Hawkes Bay New Zealand. Tel +64 21435811

www.firepumps.co.nz email admin@firepumps.co.nz Page 6of 14

Starting The Engine If The Electric Start Will Not Turn The Engine Over:

Starting the engine with the recoil starter can be difficult if not practiced as the compression

ratio of a diesel engine is high. However with practice and the right technique the engine will

start with the recoil starter by following the recommended steps below.

1. Turn the key to the “On” position. Ensure the stop control is fully in the closed

position.

2. Pull the rope starter until the engine comes up to compression.

3. Pull the decompression lever fully forward.

4. Using 2 hands on the starter handle and 1 foot firmly placed on the bottom of the

pump frame.

5. Give one hard pull (you need to be strong enough to get it to roll over the

compression stroke to fire)

6. Remember the compression ratio of a diesel engine is 19:1 so you really need to

pull hard with two hands or if the person is small or weak have two people pull

on the starter rope with one person holding down the pump.

.

2: Pull decompression levers over. The

starting position is correct only if the levers

remain engaged.

3: Let the starter cord recoil back into

position, then pull starter cord hard.

1: Pull the rope starter until the engine

comes up to compression.

8

Manufactured by Vortex Holdings Ltd

31 Murchison Street Tikokino Central Hawkes Bay New Zealand. Tel +64 21435811

www.firepumps.co.nz email admin@firepumps.co.nz Page 7of 14

Priming the LD600 Pump

Operating the primer

The D600 primer should typically develop up to minus 0.6 bar in an airtight pumping system.

The primer is an exhaust-eject type, extremely reliable and requires only minimal maintenance.

The primer is activated by a combination spring return, on-off valve connected to the exhaust

system and a one-way valve situated at the pump inlet. Pulling the valve closes off the exhaust

outlet redirecting the gases through the primer. The velocity of the passing exhaust gases

causes a vacuum at the primer, which lifts the one-way valve off its seat and evacuates the air

in the pump and suction line.

A ball valve is located immediately after the one-way valve and should only be closed if the

pump inlet is under pressure, i.e. when pumping in closed circuit relays or from a hydrant

supply.

Before the pump can be primed, delivery valves, drain valves, and other openings to the pump

must be closed and absolutely air tight.

When operating from draft, suction hose connections must be tight and free of air leaks.

Make certain the suction hose strainer is properly submerged and free from foreign material.

Pull the primer valve all the way out and open throttle up to 50% revs to start priming.

Hold the valve open until water discharges from the primer exhaust port and a positive reading

shows on the delivery gauge. Crack open delivery valve to flow water. Push valve all the way

in to shut off primer and throttle back.

If water does not discharge from primer exhaust within about 40 seconds, stop priming and

check for air leaks.

The primer should achieve a 1-metre lift within 10 seconds and a 3-metre lift within 30 seconds

using 4” (100mm) suction hose.

When pumping from hydrants, the primer is not needed and must be kept closed.

9

Manufactured by Vortex Holdings Ltd

31 Murchison Street Tikokino Central Hawkes Bay New Zealand. Tel +64 21435811

www.firepumps.co.nz email admin@firepumps.co.nz Page 8of 14

PUMP OPERATION

Source of water supply

Water may be drafted from a pond, lake, stream, cistern, stock tank, or well but, whatever the

source, the static lift must not exceed 5 metres (16 ft) from the center of the pump to the

surface of the water, and a lift not exceeding 3 metres (10 ft) is recommended. The source of

supply should be reasonably clear and free from foreign matter. It is recommended that all

water holes, which may be needed for fire protection, be deepened if necessary and kept free

from weeds and refuse. In many fire protection areas, cisterns or reservoirs are built and

allowed to fill up with rainwater to allow them to be used in emergencies.

Pumping in cold weather

The first insurance against cold weather trouble is to keep fire apparatus stored in heated

quarters. All water must be eliminated from pump casing and primer line between periods of

operation.

When setting up for pumping, unnecessary delays should be avoided by having thoroughly

trained pump operators. Be sure that the primer and hose lines are kept closed until ready for

use. Have hose lines ready so that the pump may be started as soon as it has become primed.

Do not stop flow of water through the pump until ready to drain and return to station.

When finished pumping

Drain water out of pump casing immediately. (Drain valve is located at lowest point in pump

casing).

Do not forget to close the drain valve after all water has been drained out. Trouble in priming

will follow on the next run if this is forgotten.

Pumps not often used for fire service should be inspected and run periodically to ensure that

they will be in readiness for an emergency.

Pumping salt water

The pump should be flushed out with fresh water immediately after pumping salt water to

prevent excessive corrosion.

A centrifugal pump will show 2½% higher pressure and require 2½% more power when

handling seawater than when handling fresh water, if operated at the same speed and capacity.

Use of pump for emergency practices

It frequently happens that operators of a portable fire pump, who are not thoroughly familiar

with its operation, become confused under the stress of an emergency and neglect some small

detail that may cause trouble or delay in getting the equipment into operation. Therefore, we

strongly urge that practice tests be conducted repeatedly until operators are thoroughly trained.

More than one person in the brigade should be a competent operator.

Practice should include pumping from low lifts, high lift with short and long suction lines, with

suction line elevated to form an air trap, and from hydrants, at large and small capacities.

It is well, also, to note the effects of air leaks in hose, insufficient submergence and restriction

of suction line (suction line can be restricted by placing a can or strong closure around the

suction strainer).

NEVER BREAK OR RESTRICT SUCTION OR ADMIT AIR INTO SUCTION LINE WHILE

MOTOR IS OPERATING WITH THROTTLE OPEN. This will release the load and could allow

the motor to over speed.

10

Manufactured by Vortex Holdings Ltd

31 Murchison Street Tikokino Central Hawkes Bay New Zealand. Tel +64 21435811

www.firepumps.co.nz email admin@firepumps.co.nz Page 9of 14

PUMP TESTING

Measurement of pump performance

Pump performance is measured by the quantity of water it can deliver per minute against a

certain pressure called “Total Head”, or “Net Pump Pressure” as it is usually termed in fire

pump testing.

The Net Pump Pressure is the sum of the pump discharge pressure as shown on the pressure

gauge with which the pump is equipped, and the total suction lift converted to equivalent kPa.

If a pump is operating from a hydrant, the Net Pump Pressure is the discharge pressure less

the incoming pressure from the hydrant measured at the suction entrance to the pump.

Capacity of a fire pump is measured in litres per minute. The usual method of measurement is

to determine the pressure of the jet of water leaving a given size nozzle by means of a “Pitot

Gauge” from which the capacity is computed mathematically.

A Pitot Gauge consists of a small tube adapted so as to point directly into the nozzle from the

center of the issuing stream, the other end of the tube being connected to an accurate pressure

gauge.

The nozzle jet drives straight into the Pitot tube and converts the velocity of the jet into

pressure, which is an accurate measure of the velocity of the water as it leaves the nozzle. The

tip of the Pitot tube should be one-half the diameter of the nozzle away from the nozzle tip while

taking readings.

If a Pitot Gauge is not available, approximate pump capacities can be determined by reference

to the following chart.

Flow rate

(Liters/minute)

Pump Pressure

Nozzle Size

13

16

19

22

23

25

28

32

(KPa)

(mm)

100

111.5

169

238

319

349

412

517

676

200

157

239

337

451

493

583

731

955

300

193

292

412

553

605

714

896

1170

400

223

338

476

638

698

825

1035

1351

500

249

378

532

714

780

922

1157

1511

600

273

414

583

782

855

1010

1267

1655

700

295

446

630

844

923

1091

1368

1787

800

315

477

673

903

987

1166

1463

1911

11

Manufactured by Vortex Holdings Ltd

31 Murchison Street Tikokino Central Hawkes Bay New Zealand. Tel +64 21435811

www.firepumps.co.nz email admin@firepumps.co.nz Page 10 of

14

Oil and Fuel Recommendations

Check oil level regularly. See oil chart, capacity, checking and filling procedures.

Always refer to engine manufacturers handbook

Maintain correct oil level. Check daily before starting engine.

Change Oil

Change oil after the first 50 hours of operation. Drain oil while engine is warm.

Note: Change oil there after every 50 hours of operation or yearly.

Lubricants

Use diesel engine lubricants which meet APICC 2104B specifications. A multigrade oil such as

AGIP SUPER DIESEL MULTIGRADE 15W/40 can be used.

If the engine is used in places with temperatures under –15 degrees celcius, use SAE 5W/30

oil.

Oil Capacity.

Approximately 1.8 Litres

Fuel Recommendations

•Fuel vapours are highly toxic. Only carry out refueling operations outdoors or in a well-

ventilated area.

•When refueling it is advisable to use a funnel to prevent fuel from spilling out. The fuel

should also be filtered to prevent dust or dirt from entering the tank.

•Use the same type of diesel fuel as used in cars or trucks. The use of other types of

fuels could damage the engine.

•The Cetane rating of the fuel must be higher than 45 to prevent difficult starting.

•Do not use dirty diesel fuel or mixtures of fuel and water this will cause serious engine

faults.

•Do not fill the fuel tank completely, but just up to 1cm from the top of the tank, to provide

space for fuel movement. Wipe any fuel spillage from engine before starting.

12

Manufactured by Vortex Holdings Ltd

31 Murchison Street Tikokino Central Hawkes Bay New Zealand. Tel +64 21435811

www.firepumps.co.nz email admin@firepumps.co.nz Page 11 of

14

Service, Storage & Specifications

For engine service.

See an Authorized Kohler / Lombardini Service Dealer. Each one carries a stock of Genuine

Kohler / Lombardini Parts and is equipped with special service tools. Trained mechanics assure

expert repair service.

Only dealers advertising as “Authorized Kohler or Lombardini Dealer” are required to meet

Kohler / Lombardini standards.

Pump Service.

Most Authorized Kohler / Lombardini dealers are capable of performing minor repairs and

adjustments to the pump components. Any major repairs or overhauls should be returned to the

factory or referred back to the importer to assure expert repair service.

Storage Instructions.

The engine components may rust over time, especially if left inactive, prejudicing the efficiency

and performance of the machine. A number of precautions are set out below, which may prove

useful if the engine is left unused for long periods.

Storage up to 6 months

•Run the engine without load and at low speed for about 15 minutes and the switch off.

•Change the fuel filter.

•Disconnect Batteries.

•Pour a mixture of diesel and AGIP RUSTIA 81 (10%) into the fuel tank;

•Run the engine for about 10 minutes at a speed of between ½and ¾nominal RPM, so

that the tubes, injector pump And filters are filled with the protective mixture, then switch

off.

•Spray AGIP RUSTIA C SAE 30 into the exhaust and intake ducts and manually turn

with starting recoil.

•Thoroughly clean the fins and external parts of the engine and protect the unpainted

external surfaces with AGIP RUSTIA C 30.

•Seal the silencer and air filter with adhesive tape.

•Wrap the engine in a plastic sheet.

Storage for more than 6 months

In addition to the above operations, do the following:

13

Manufactured by Vortex Holdings Ltd

31 Murchison Street Tikokino Central Hawkes Bay New Zealand. Tel +64 21435811

www.firepumps.co.nz email admin@firepumps.co.nz Page 12 of

14

•Change or wash the oil filter

•Replace the engine oil with AGIP RUSTIA C SAE 30.

•Periodically inspect the engine and check that there are no traces of rust or corrosion, if

present, consult a Kohler assistance center.

Re-commissioning

•Remove the protective covers.

•Remove the external protective product with solvent or a degreasing agent.

•Check the setting of the injectors, the clearances of the valves and the tightness of the

heads and filters.

•Carry out the normal preliminary checks prior to starting the engine.

•If protective oil such as AGIP RUSTIA C SAE 30 has been used, change it after not

more than 100 hours of work.

Tune-up specifications: refer to engine manufacturer’s handbook for additional

information.

Valve clearance cold intake and exhaust .006 in (0.15 mm).

Electrical

Batteries: Two X Yuasa 12 Volt REC 22

•Check battery Condition using a voltmeter, voltage should not be below 12 volts. If voltage

is below 12 volts recharge the battery by connecting battery charger through the 12-volt

accessory socket on the dash.

•Clean battery terminals from time to time.

•Always maintain battery in good charged condition

•Battery should be Charged once a month when not in use

Battery Charging.

The engine has a built in alternator with an output of 16 amps

14

Manufactured by Vortex Holdings Ltd

31 Murchison Street Tikokino Central Hawkes Bay New Zealand. Tel +64 21435811

www.firepumps.co.nz email admin@firepumps.co.nz Page 13 of

14

TROUBLESHOOTING

Refer to engine manufacturer’s handbook for additional information.

DEFECT CAUSE

•Fails to start. Incorrect fuel. Air in fuel. Fuel tank empty.

•Starts and stops Air filter clogged. Air in fuel. Diesel filter clogged.

•Lack of power Air filter clogged. Diesel filter clogged.

•Light Blue smoke. Too much oil in crankcase.

•Black smoke. Excessive load.

•Knocking in head area. Incorrect fuel.

•High oil consumption. Too much oil in crankcase.

•Leaks oil. Vent tube bent.

•Oil comes out of exhaust. Engine running in.

•Overheats. Head and cyl fins clogged. Excessive load.

•Misfires. Incorrect fuel. Air in fuel. Engine cold. Tank vent.

•No increase in rpm. Incorrect fuel. Air in fuel. Tank Vent clogged.

The above troubleshooting guide is a general outline of the main causes of defects, which the

operator can easily remedy. In the case of more serious problems it is advisable to contact a

Kohler / Lombardini service center.

15

Manufactured by Vortex Holdings Ltd

31 Murchison Street Tikokino Central Hawkes Bay New Zealand. Tel +64 21435811

www.firepumps.co.nz email admin@firepumps.co.nz Page 14 of

14

D600 FIRE PUMPS

DATA SUMMARY

1. General Description.

The pump set consists of two cylinder air-cooled diesel that is coupled to a single stage centrifugal

pump.

The Pump set consists of the following main components:

A: Kohler KD 425-2 diesel engine

B: Phoenix Centrifugal pump end

C: Exhaust ejector primer

D: Stainless Steel Carry Frame.

2. Manufacturers Data

The Manufacturers details are:

Vortex Holdings Ltd

31 Murchison Street

Tikokino 4273

New Zealand

Tel +64 (6) 21 435811

Email adm[email protected]

Web site www.firepumps.co.nz

3. Physical Data

Dimensions and mass:

A: Length 760mm

B: Width 530mm

C: Height 550mm

D: Weight 122 kg (With Twin Batteries)

16

Manufactured by Vortex Holdings Ltd

31 Murchison Street Tikokino Central Hawkes Bay New Zealand. Tel +64 21435811

www.firepumps.co.nz email admin@firepumps.co.nz Page 15 of

14

DATA SHEET CONT.

4. Engine

A: Make Kohler / Lombardini

B: Model KD 425

C: Type 4 stroke, overhead valve, air-cooled, diesel engine

D: Bore & Stroke 85X 75mm

E No of cylinders 2

F: Displacement 851 cc

G: Fuel Tank capacity 4 litres

H: Fuel Type Diesel

I: Lubrication Forced with lobe pump

J: Starting System Recoil or electric if fitted

K: Battery 12 Volt

5. PUMP

A: Make Phoenix Maxflo

B: Type Centrifugal

C: Discharge Rate model M 600 Litres/min @ 700 kPa

D: Discharge Port size 50 mm

E: Primer Type Exhaust Eject

F: Maximum draft height 7.5 metres

G: Discharge Valve 2 X Globe valves 50mm BSP

6. Couplings

A: Suction 100mm round thread

END

Table of contents

Other PSL Water Pump manuals

Popular Water Pump manuals by other brands

Power Craft Garden

Power Craft Garden 71999 instruction manual

Gianneschi

Gianneschi CP Series operating manual

Wilo

Wilo VeroLine-IP-E Series Installation and operating instructions

GORMAN-RUPP

GORMAN-RUPP SFEV3C Installation, operation and maintenance manual

Speck pumpen

Speck pumpen BADU Eco Touch-pro manual

WDM

WDM ME Series Operation manual

Bosch

Bosch AGS10-2 Installation and servicing instructions

HNP Mikrosysteme

HNP Mikrosysteme mzr-2509 Ex operating manual

Holmatro

Holmatro HTW Series manual

Monarch Industries

Monarch Industries ACT-SD Series owner's manual

Villager

Villager JGP 1100 F Original instructions

Omega Engineering

Omega Engineering FPU4500 user guide