PTI SENTRY Supervisor Owner's manual

Installation, Operation and

Serial Communication Programmer’s Guide

SENTRY™Supervisor

Section 1: General Information & Part Descriptions

12279 Rev 1.0 Page 1of 3

1.1General Information

About This Manual

This manual is intended for those responsible for programming a computer or tool to

operate with the SENTRY process exhaust control system through the use of serial

communications. Although this manual may contain additional information not

included in the controller manuals, the complete instructions for installing and

operating a SENTRY system may be found in the controller’s (i.e. SENTRY 1000,

SENTRY 1510, etc.) installation and operation manual.

Note:

• Diagrams included in this manual depict the “CE” version. With exception to

connector styles, both “CE” and “non-CE” versions are installed, operated and

programmed in the same manner. There are no functional differences between

the two versions.

This manual describes the following:

• Physical Installation (Supervisor Only)

• Commonly Used Command Menu Parameters

• Operation in Manual, Analog and Serial Communication Modes

• Required Programming for Using Serial Communication

Description

The SENTRY Supervisor is a microprocessor-based interface used in conjunction

with many of Progressive Technologies' process exhaust controllers. The SENTRY

Supervisor allows the user to communicate electronically with the process exhaust

controller (such as the SENTRY 1000) for changing the set point and reading actual

process exhaust values. It can be configured at the PTI factory to be used with

controllers that maintain constant pressure or constant flow. It can be operated in

stand-alone mode (manual mode), with a 0-5 Volt process tool interfaced analog

signal (analog mode) or with process tool/facility computer interfaced serial

communications (serial mode).

12279 Rev 1.0 Page 2of 3

1.2 Part Descriptions

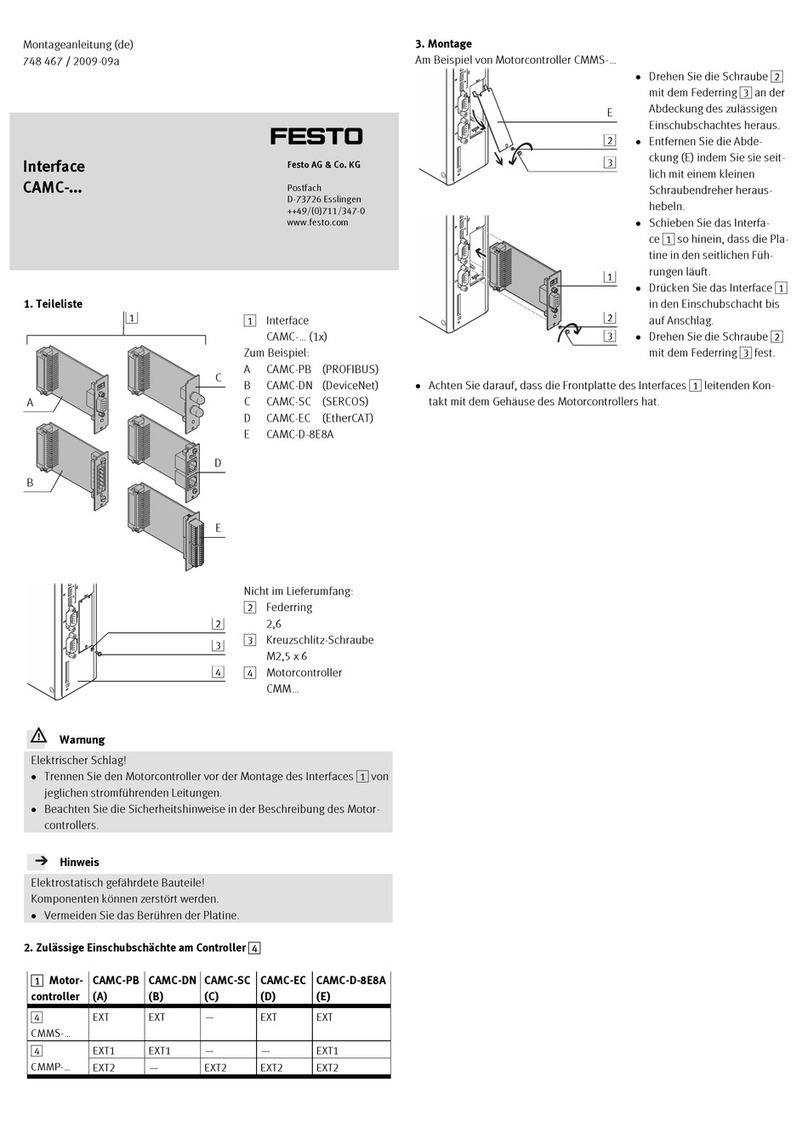

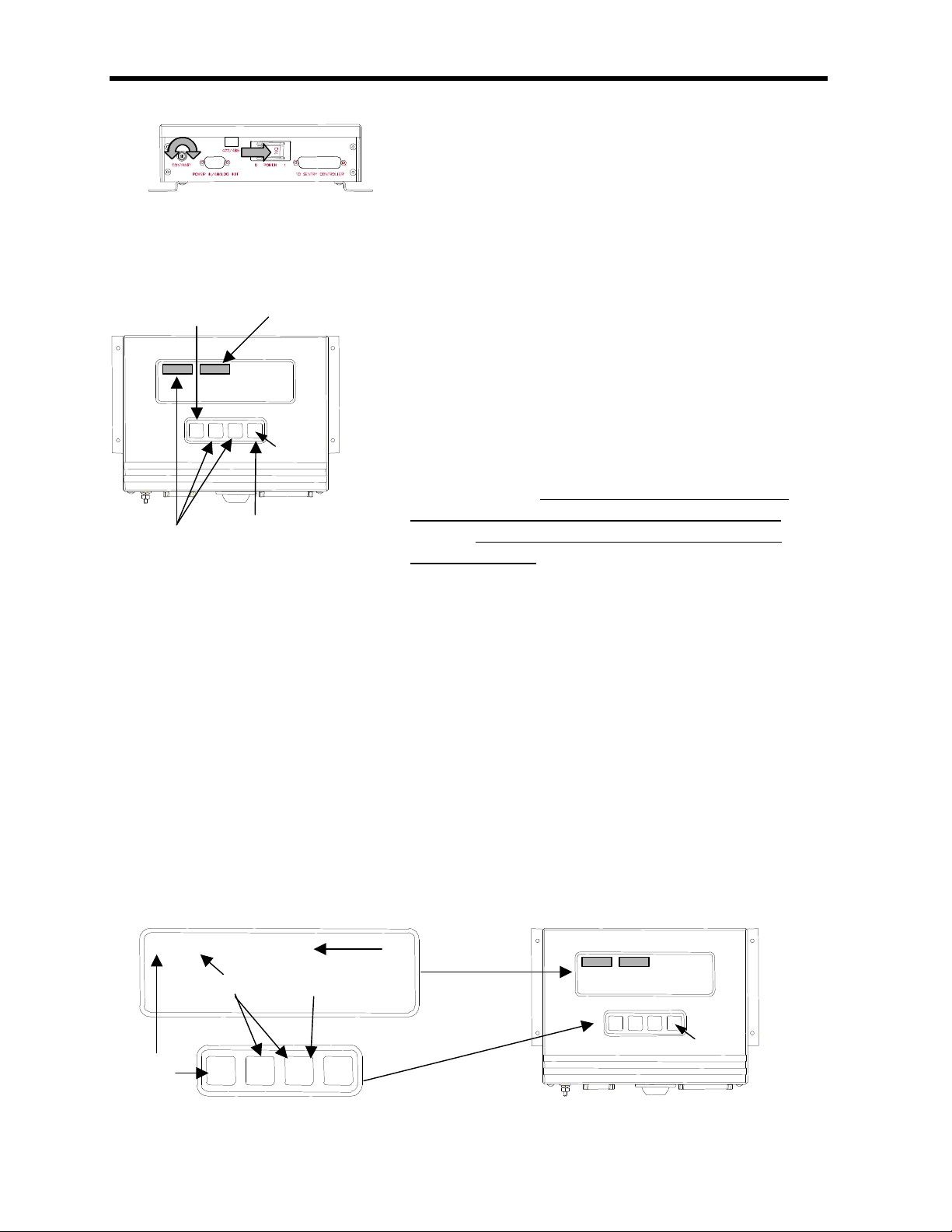

Part Names –Supervisor

ŒŒ SENTRY Supervisor The SENTRY

Supervisor is a microprocessor-based

interface used in conjunction with the

SENTRY exhaust controllers (SENTRY

1000, 1510, and 9000). The SENTRY

Supervisor provides the user with the

ability to interface with the SENTRY

controller through direct manual input

from the user or through electronic

communication from the process tool.

•• Mounting Brackets The brackets are

used to mount the Supervisor to the

process tool.

ŽŽ Display The display provides a real

time read-back of pressure control. It also

allows the user to view and change the

menu parameters.

•• Keypad The keypad contains the

four keys used to navigate and change

the menu tree and parameters.

•• Contrast Knob The contrast knob

allows the user to adjust the display

contrast.

‘‘ Power/Interface Port The port

accepts the power cable or power and

interface cable.

’’ 422/485 Port The port accepts the

serial communication cable.

.““ On/Off Switch The switch is an

on/off rocker with a circuit breaker. The

switch acts as a safety cut-off device

and detects over-current situations and

cuts power to the Supervisor.

”” SENTRY Port The port accepts the

Supervisor to SENTRY controller

cable.

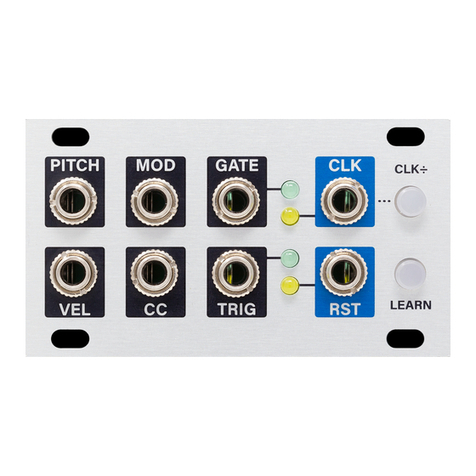

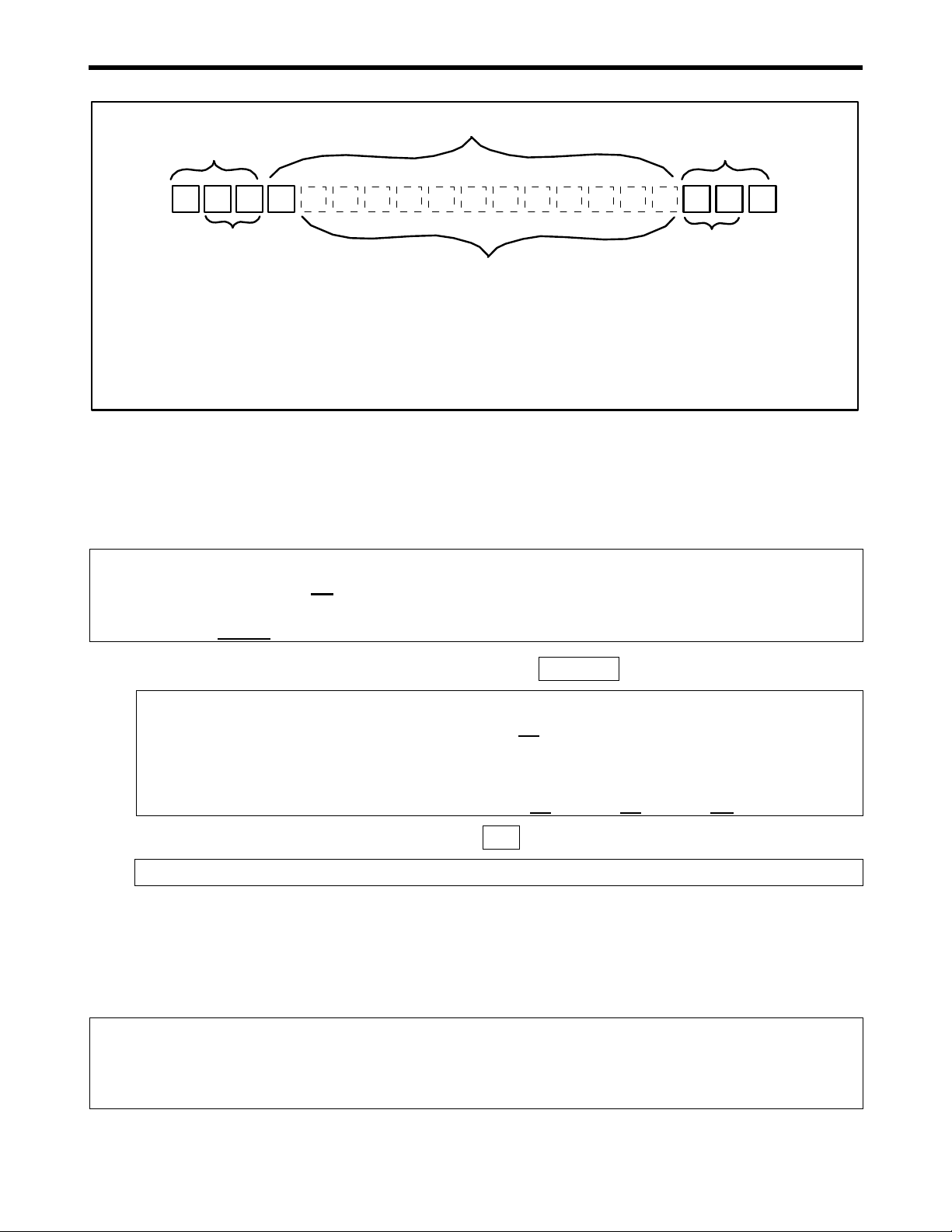

Part Names –Key Pad

ŒŒ Star Key [*] The star key enables a menu

item to be modified when the star key is

depressed on the key pad. A star [*] will appear

in the selection indicator box.

•• Up Arrow [áá] and Down Arrow [ââ] Keys

The arrow keys allow the user to scroll through

the menu items. Once a menu item is chosen

using the star key, the arrow keys provide a

means for selecting a value or option available under the individual menu item.

ŽŽ Enter Key [ENT] The enter key is used to enter into memory the selected menu

item that has been changed. Any change made to a menu item is only activated

after the enter key is pressed.

Ž

•

Œ

•

’

“

•

‘

”

*↑↑ ↓↓ ENT

Œ • Ž •

12279 Rev 1.0 Page 3of 3

1.1 Part Descriptions

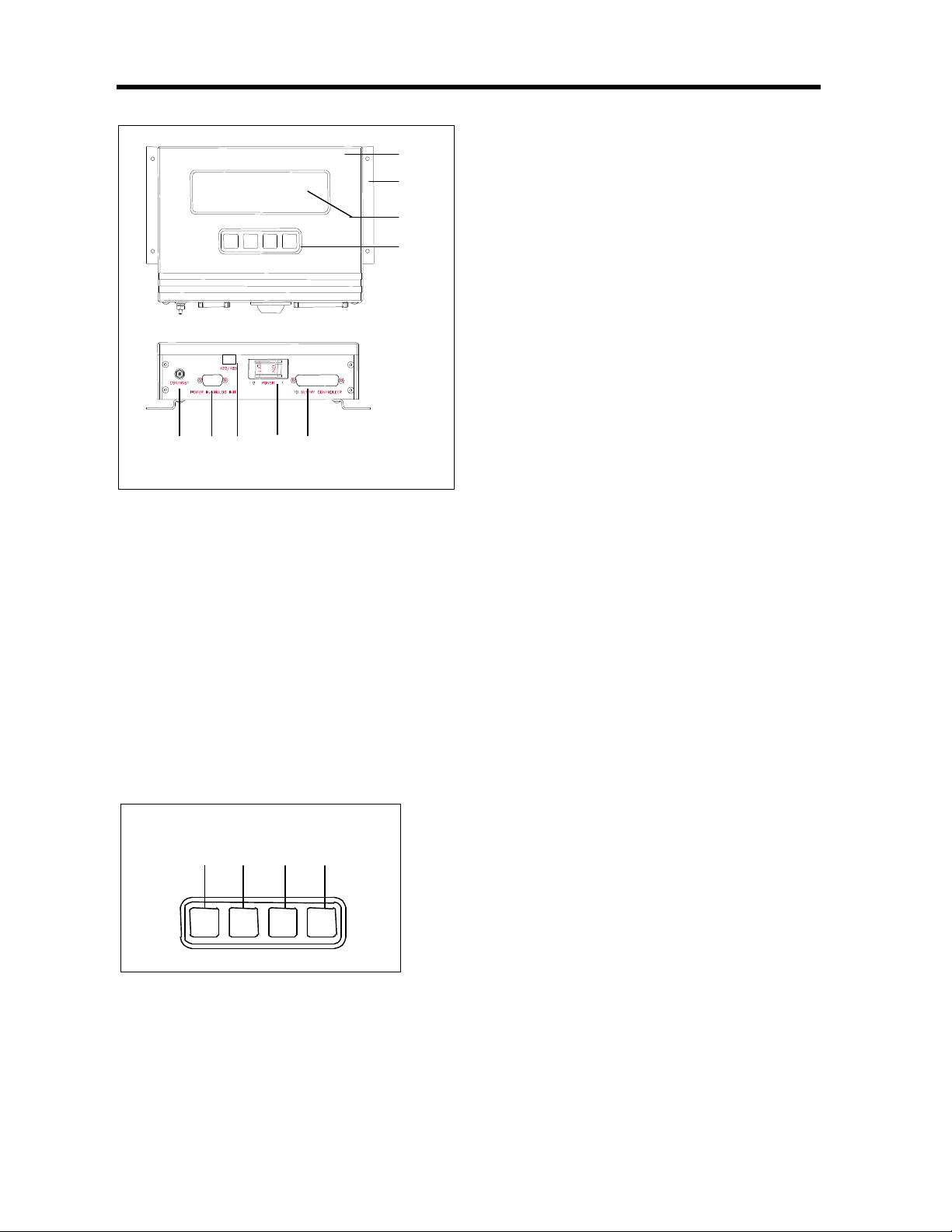

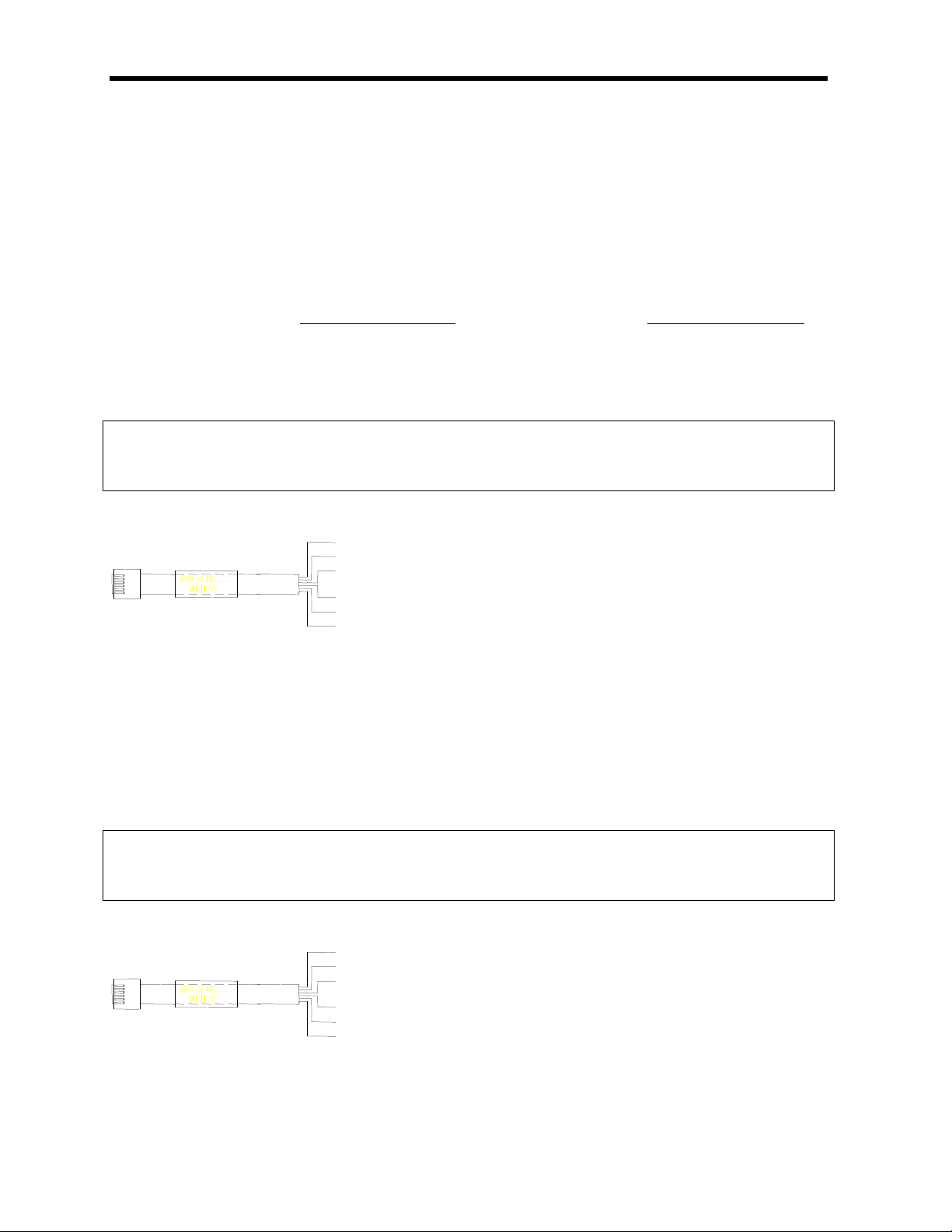

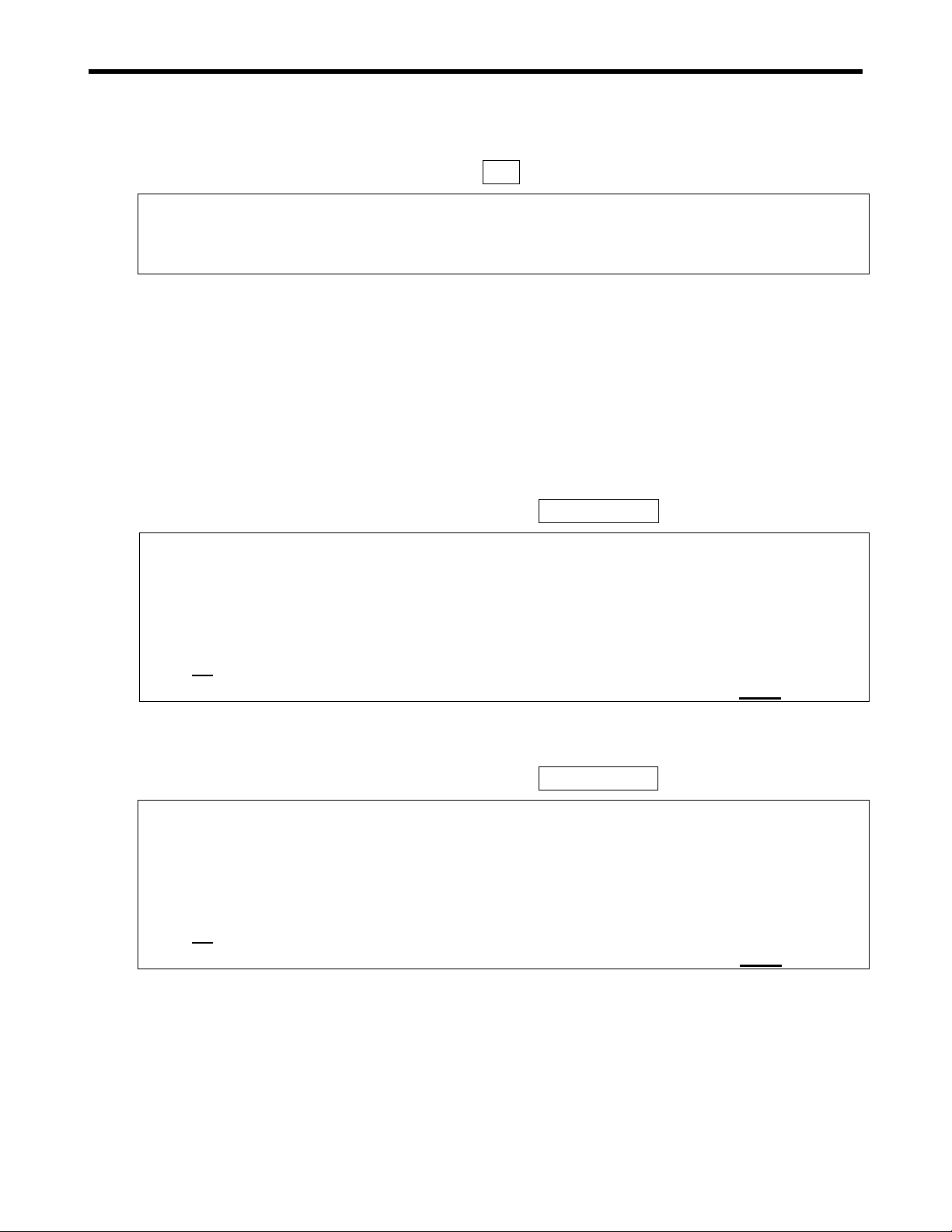

Part Names –Display

ŒŒ Selection Indicator A star symbol

“*” will appear in the selection indicator

box when a menu item is chosen by

pressing the star key [*] on the key

pad.

•• Menu Item Name The menu item

name display region indicates the

current menu item available for

modification. The menu is scrollable

through the use of the arrow keys on

the key pad.

ŽŽ Process Exhaust Set Point The

label “Pres S” or “Flow S” indicates

whether the unit is capable of pressure

or flow set point control. The number

indicates the currently active (desired)

set point. Depending on the SENTRY

model, this value will indicate pressure

(“H2O, mm H2O) or flow (CFM). There

may be an implied decimal point.

Refer to the controller manual for

details.

•• Menu Item Value The menu item

value display region indicates the

current set value for the menu item

displayed.

•• Process Exhaust (Actual) Read-

Back The label “Pres” or “Flow ”

indicates whether the read-back is in

units of pressure or flow. The number

indicates the currently achieved

(actual) process exhaust read-back.

Depending on the SENTRY model, this

value will indicate pressure (“H2O, mm

H2O) or flow (CFM). There may be an

implied decimal point. Refer to the

controller manual for details.

‘‘ Graphical Display The graphical

display provides a real-time plot of the

process exhaust read-back.

’’ Full Scale Process Exhaust The

full scale process exhaust indicates the

factory configured full scale range of

the unit being operated. Depending on

the SENTRY model, this value will

indicate pressure (“H2O, mm H2O) or

flow (CFM). There may be an implied

decimal point. Refer to the controller

manual for details.

SS StptMode Single

Pres S 1700 Pres 1713

2000

0

Œ • Ž • • ‘ ’

Installation, Operation and

Serial Communication Programmer’s Guide

SENTRY™Supervisor

Section 2: Installation & Power-Up

12279 Rev 1.0 Page 1of 3

2.1 Installation & Power-Up

The SENTRY Supervisor is only one component of the SENTRY exhaust control

system. Please follow the complete installation instructions for the specific controller

to be installed in the controller manual included with the system.

CE Compliant Installation Note

To maintain CE certification, if applicable, the SENTRY Supervisor must be installed

at a height above the floor greater than 24” (0.6 meter).

Power Requirements

The SENTRY Supervisor operates using both positive and negative DC voltages.

These may be supplied directly from the tool via an interface cable or through a stand-

alone universal power supply available directly from PTI.

The DC supplies required for Supervisor operation are:

1. Positive Voltage: + 15 to +24 VDC @ 500 mA

This voltage is used to power the electronic circuitry of the Supervisor and

controller.

2. Negative Voltage: -15 to -24 VDC @ 50 mA

This voltage is used solely to power the Supervisor display.

Note:

• Only the positive voltage is routed through the Supervisor on/off switch

circuit breaker. The display is powered any time the power cable is

connected to the SENTRY Supervisor.

• When the Supervisor is turned off, the LCD may display random

characters or lines if the power cable is still connected.

Supervisor Cabling

The SENTRY system is manufactured in CE compliant (“CE”) and non-CE compliant

(“non-CE”) models. Most differences between the two models should be transparent

to the user. However, the two models do not have the same cable connector styles.

The CE compliant model has DB connectors while the non-CE compliant model

maintains the original plastic circular connectors.

Cabling to the Supervisor will depend upon the controller model under installation and

the type of communication interface to be used. Cable drawings for your cable set

have been provided in the drawings section at the end of the controller manual.

Please refer to the controller manual installation and setup section for detailed

instructions on connecting the SENTRY system cabling.

Note:

• In case of over-current situations, the SENTRY system relies upon the tool for

alternating current (AC) disconnect.

12279 Rev 1.0 Page 2of 3

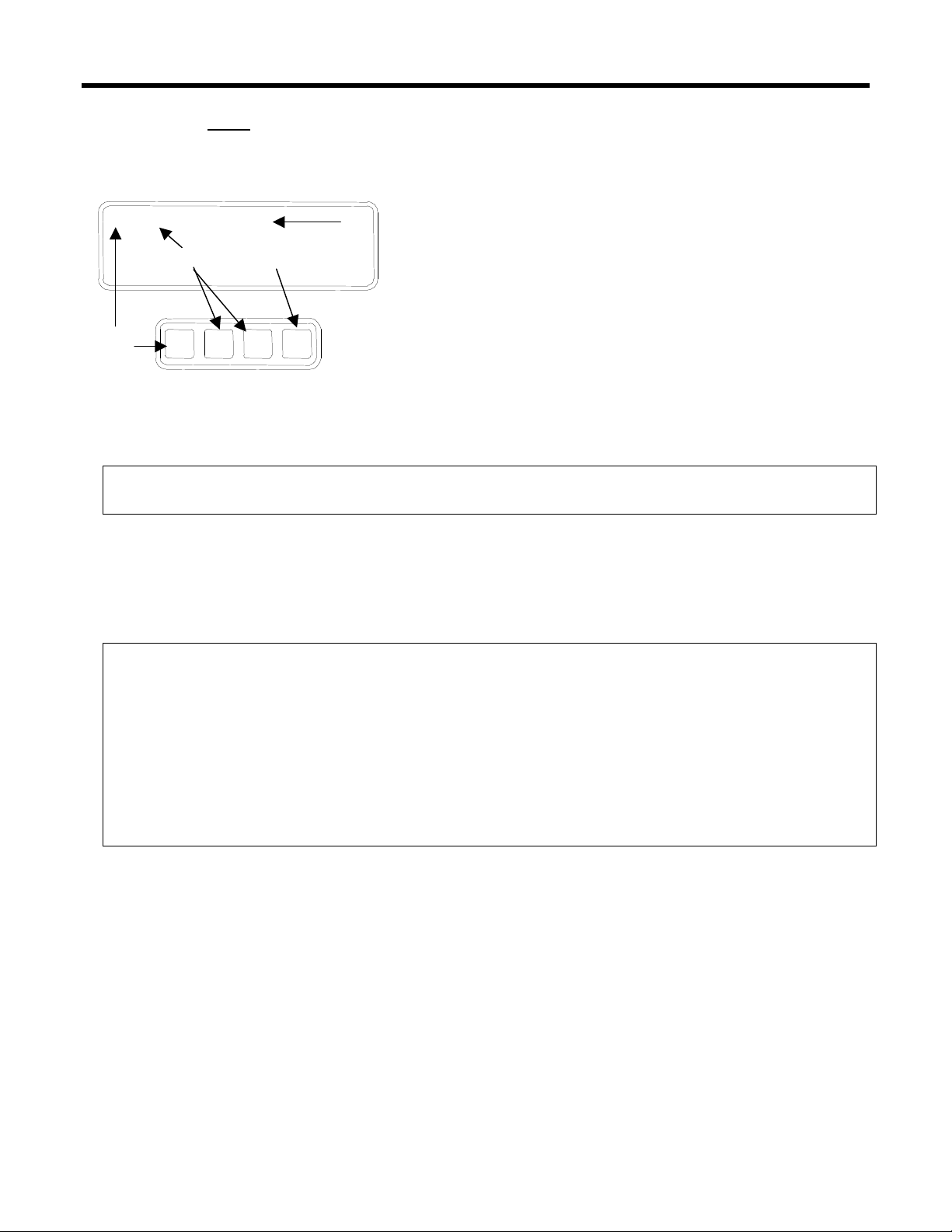

2.1 Installation & Power-Up

Power ON the SENTRY Supervisor

ŒTurn the Supervisor to the ON (1) state.

•Use the contrast knob to adjust the display.

Select Communication Operating Mode

The Supervisor communication operating mode must be selected before set points

can be properly received and interpreted.

ŒUsing the up [á] or down [â] arrow keys on the

SENTRY Supervisor key pad, scroll through the

menu parameters until “STPT MODE” is shown in

the top left corner of the display.

•Choose the menu item by pressing on the star [*]

key.

ŽUsing the up [á] or down [â] arrow keys on the

SENTRY Supervisor key pad, scroll through the

list and choose “SINGLE” if using stand-alone

operation or serial (interface) communication or

choose “ANALOG” if using analog (interface)

communication.

•Press the enter [ENT] key to confirm selection.

Save Operating Parameter Data

Any change made to the menu items is only stored in memory until the power to the

Supervisor is turned off. In order to permanently store selections into memory, the

following steps must be taken.

ŒUsing the up [á] or down [â] arrow keys on the SENTRY Supervisor key

pad, scroll through the menu parameters until “SAVE DATA” is shown in the

top left corner of the display.

•Choose the menu item by pressing on the star [*] key.

ŽPress the down [â] arrow key once (“0” will be displayed).

•Press the up [á] arrow key seven times (“77” will be displayed).

•Press the enter [ENT] key to confirm selection.

Œ

•

Œ

*

↑↑

↓↓

ENT

•

Ž

•

*

↑↑

↓↓

ENT

•

•

Ž

SAVE DATA

77

*

↑↑

↓↓

ENT

Œ

•

*

12279 Rev 1.0 Page 3of 3

2.1 Installation & Power-Up

Serial Communication Tool Interface (RS-422 or Optional RS-485)

The SENTRY Supervisor supports an RS422/485 serial communication link for

communication with a process tool or host computer. The Supervisor can be

configured to operate using either a four-wire RS422 link or a two-wire RS485 link.

This is typically factory configured through the use of a jumper on the Supervisor

circuit board. The communication interface is the same regardless of which

communication link is used.

RS-422 Link (Two Differential Pairs)

The RS-422 communication link uses a four wire (Tx+, Tx-, Rx+, Rx-) connection.

Two wires are used to send from the host; two wires are used to receive by the host.

The serial communication interface cable is a six wire cable. The Supervisor end of

the cable is crimped with a RJ-12, 6-pin male connector. The other end is maintained

with labeled flying leads. Please refer to the controller manual for step-by-step

instructions on connecting the serial communication cable to the Supervisor.

Note:

• There are no functional or CE requirements for connecting the two ground leads

and these may be left unattached.

Pin # Function Comment

1Rx+ Receive from host (Positive)

2Rx-Receive from host (Negative)

3gnd Ground –Not Required

4gnd Ground –Not Required

5Tx+ Transmit to host (Positive)

6Tx-Transmit to host (Negative)

RS-485 Link (Single Differential Pair)

The RS-485 communication link uses a two wire (Tx/Rx+, Tx/Rx-) connection. Two

wires are used for bi-directional data transmission. The serial communication

interface cable is a six wire cable. The Supervisor end of the cable is crimped with a

RJ-12, 6-pin male connector. The other end is maintained with labeled flying leads.

Please refer to the controller manual for step-by-step instructions on connecting the

serial communication cable to the Supervisor.

Note:

• There are no functional or CE requirements for connecting the ground lead which

may be left unattached.

Pin # Function Comment

1Tx/Rx+ Bi-directional data (Positive)

2Tx/Rx-Bi-directional data (Negative)

3gnd Ground –Not Required

4-No connection

5-No connection

6-No connection

1 ü

2 ü

3 ý

4 ý

5 ü

6 ü

1 ü

2 ü

3 ý

4 ý

5 ý

6 ý

Installation, Operation and

Serial Communication Programmer’s Guide

SENTRY™Supervisor

Section 3: Command Menu

12279 Rev 1.0 Page 1of 3

3.1 The Command Menu

The SENTRY Supervisor is common to all of the PTI automated exhaust controllers. As such,

the Supervisor contains a number of command items which may not be applicable to the

specific SENTRY system being installed. The complete menu is listed below. The menu

contains 71 individual entries, 64 of which are directly accessible by the keyboard using the

arrow keys. An explanation is provided for the parameters most commonly used. These

menu items are highlighted in the menu list below.

The Complete SENTRY Supervisor Command Menu

1) Sentry Ver 19) Pos Sp2 37) FiltRate 55) PlotMode

2) Pres Sp 20) Pos Sp3 38) Ctrl Inv 56) Plot Sel

3) Flow Sp 21) Pos Sp4 39) Gain 57) Cycle

4) Pos Sp 22) Alarms 40) GainFine 58) CyclItvl

5) Pres 23) Dev Band 41) Integral 59) StptMode

6) Flow 24) Lo Alarm 42) Intg Sum 60) OperMode

7) Step Cnt 25) Hi Alarm 43) Deriv 61) CtrlMode

8) HouseVac 26) Pres FS 44) Deadband 62) ResetAct

9) Aux In 27) Flow FS 45) Hyster 63) Disp #0

10) Pres Sp1 28) House FS 46) MaxCtlSt 64) Disp #1

11) Pres Sp2 29) Aux FS 47) StepRate 65) Disp #2:

12) Pres Sp3 30) SaveData 48) StepRang 66) "Blank":

13) Pres Sp4 31) BaudRate 49) Step Lim 67) Deviation Alarm Flag

14) Flow Sp1 32) Parity 50) Step Req 68) Low Alarm Flag

15) Flow Sp2 33) HWCtlLck 51) Clk Min 69) High Alarm Flag

16) Flow Sp3 34) Ctl Itvl 52) Clk Hour 70) Control In Band

17) Flow Sp4 35) CtrlLock 53) Clk WDay 71) Step Direction

18) Pos Sp1 36) FlowCoef 54) PlotItvl

Explanation of Commonly Used Menu Entries

Ref. # & Menu Item Function

9) Aux In This indicates the measured voltage from the analog input set point control.

This will reflect the voltage received at the SENTRY Supervisor from the tool.

(5000 = 5.000 V).

10) Pres Sp1 For pressure exhaust controllers, this is the entry that allows the pressure set

point to be reviewed or edited. For the SENTRY 1000, 2000 = 2.000” H2O.

For the SENTRY 1510, 2540 = 25.40 mm H2O.

12279 Rev 1.0 Page 2of 3

3.1 Command Menu

Ref. # & Menu Item Function

14) Flow Sp1 For flow exhaust controllers, this is the entry that allows the flow set point to be

reviewed or edited.

26) Pres FS For pressure exhaust controllers, this indicates the full pressure scale for the

exhaust control device. The full scale must match the pressure transducer

inside the control device.

27) Flow FS For flow exhaust controllers, this indicates the full flow scale achievable by the

control device.

29) Aux FS This indicates the full scale of the analog signal input. When using a 0-5 V

control signal (analog interface), this item must be set to 5000, representing

5.000 V full scale.

30) SaveData This is used to save the Supervisor configuration to nonvolatile memory. Refer

to Section 2, page 2. for instructions on saving parameter changes.

31) BaudRate This is used to set the RS422/RS485 serial port speed rate. The process tool

controller or host computer must use the same baud rate. The Supervisor can

handle up to 9600 baud.

32) Parity This item allows the selection of the following serial data parity: Odd, Even,

One, and Zero. After changing parity, Save Data must be executed first and

then power to the Supervisor must be cycled once (On to Off to On).

40) GainFine This indicates the gain (proportional) coefficient that is used in the PID loop

This indicates the same value as the “Gain” menu item but allows the operator

a finer increment of adjustment.

44) Deadband This indicates the band on either side of the set point, within which the process

variable can move and not cause control loop action.

59) StptMode This is used to define where the controller receives its set point. The selections

are: single, analog, dual and quad. Single indicates a single digital set point

from an RS422/RS485 serial connection or manually set by the user. This set

point is the value under Pres Sp1. Analog indicates a remote set point, through

a 0-5 V analog interface. Dual and Quad are not used.

60) OperMode This indicates the process parameter to be controlled. Pressure is indicated by

Pres, flow is indicated by Flow.

12279 Rev 1.0 Page 3of 3

3.1 Command Menu

Scaling Factors

As indicated previously, the SENTRY Supervisor display and menu items do not show a

decimal point. Depending on the SENTRY controller or menu parameter in question, a

decimal point is implied in the displayed value.

SENTRY

Controller Scaling Factor Description

SENTRY 1510 Pressure set point (Pres Sp1), actual pressure read-back (Pres) and

full scalepressure (Pres FS) have an implied decimal point to the left

of the second digit (from the right). A scaling factor of 100 is used.

The implied units are in millimeters of water column.

Example: The displayed value 2540 equals 25.40 mm H2O.

SENTRY 1000 Pressure set point (Pres Sp1), actual pressure read-back (Pres) and

full scale pressure (Pres FS) have an implied decimal point to the left

of the third digit (from the right). A scaling factor of 1000 is used.

The implied units are in inches of water column.

Example: The displayed value 1150 equals 1.150” H2O.

SENTRY 9000 Flow set point (Flow Sp1), actual flow read-back (Flow) and full scale

flow (Flow FS) have an implied decimal point to the right of the first

digit (from the right). No scaling factor is used. The implied units are

in cubic feet per minute.

Example: The displayed value 12 equals 12 CFM.

Modes of Operation

The Supervisor is configured to operate in Pressure Mode (SENTRY 1000 and SENTRY

1510) or Flow Mode (SENTRY 9000) depending on the type of exhaust controller to be

operated. This must be factory configured to match the specific exhaust controller to be

operated. No user configurable options are available for switching between the two modes.

PID Control Loop

The Supervisor contains a PID closed loop algorithm for controlling the SENTRY controller

stepper motor during a set point change. All the SENTRY controllers used in conjunction with

the SENTRY Supervisor have a patented SENTRY piston regulator. The piston regulator

compensates for fluctuations in facility exhaust to maintain a regulated process exhaust. The

highly responsive nature of the SENTRY controller off loads the PID algorithm such that the

algorithm is only required to change the controller set point. Once the new set point is

reached, the SENTRY piston in the controller performs the corrective control.

Note:

• In most applications, only the gain function of the PID loop is used. This is preset at the

factory and does not typically require adjustment.

Installation, Operation and

Serial Communication Programmer’s Guide

SENTRY™Supervisor

Section 4: Operation

12279 Rev 1.0 Page 1of 3

4.1 Operation

Manual Mode (Stand-Alone)

Manual operation of the SENTRY controller is accomplished through the use of the SENTRY

Supervisor key pad. The key pad is used to enter changes to the menu items available within

the Supervisor. Although there are 71 menu entries available, only one, pressure set point

“PRES SP1” or flow set point “FLOW SP1”, is typically used for operation of the SENTRY

controller. The remaining menu items are preset at the factory with settings that should satisfy

the control requirements of most installations. The default factory settings for each SENTRY

controller are listed in the Appendix of the controller manual. A list of the menu parameters

and an explanation of the most commonly used items is included in Section 1.

Using the Key Pad

The keypad contains four keys used to navigate and change the menu list and parameters.

Refer to the key pad description in Section 1. for a list of the key names and their uses.

Note:

• Any change made to a menu item is only activated after the enter key is pressed.

• Any change made to the menu item is only stored in memory until the next time the

Supervisor is powered off and on. To permanently store values in memory, follow

the steps in Section 2, page 2.

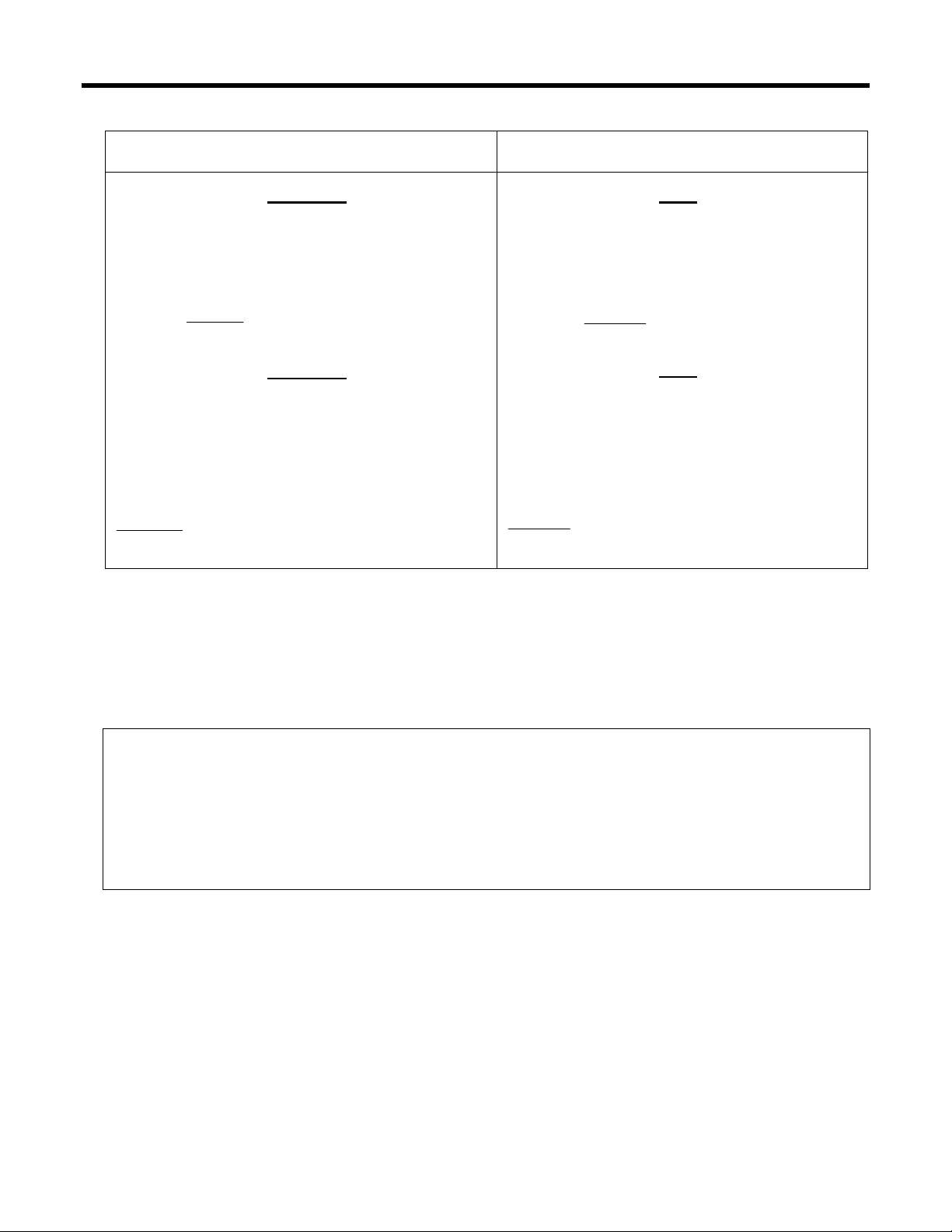

Manual Mode Pressure Set Point Changes

Follow the steps below to change the SENTRY 1000 or SENTRY 1510 set point. The Sentry

system is configured to measure and display pressure set points in units of inches of water

column for the SENTRY 1000 and units of millimeters of water column for the SENTRY 1510.

ŒUsing the up [á] or down [â] arrow keys on the SENTRY

Supervisor key pad, scroll through the menu parameters

until “PRES SP1” is shown in the top left corner of the

display.

•Choose the menu item by pressing on the star [*] key.

ŽUsing the up [á] or down [â] arrow keys on

the SENTRY

Supervisor key pad, change the displayed

value to the

desired value.

•Press the enter [ENT] key to confirm selection.

Note:

• For the SENTRY 1000, there is an implied decimal point to the left of the third digit

(2000 = 2.000” H2O).

• For the SENTRY 1510, there is an implied decimal point to the left of the second

digit (2540 = 25.40 mm H2O).

Œ

*

↑↑

↓↓

ENT

•

Ž

•

12279 Rev 1.0 Page 2of 3

*

•

•

Flow Sp1

12

↑↑

↓↓

ENT

Œ

Ž

*

4.1 Operation

Manual Mode Flow Set Point Changes

Follow the steps below to change the SENTRY 9000 set point. The Sentry system is

configured to measure and display flow set points in units of cubic feet per minute.

ŒUsing the up [á] or down [â] arrow keys on the

SENTRY Supervisor key pad, scroll through the

menu parameters until “FLOW SP1” is shown in

the top left corner of the display.

•Choose the menu item by pressing on the

star [*] key.

ŽUsing the up [á] or down [â] arrow keys on the

SENTRY Supervisor key pad, change the

displayed value to the desired value.

•Press the enter [ENT] key to confirm selection.

Note:

• For the SENTRY 9000, a displayed value of 35 = 35 CFM.

Analog Interfaced Operation

When the SENTRY system is configured for analog operation, the process exhaust pressure

or flow set points are entered through the process tool. The analog interface operates on a

standard 0 to 5 volt full scale command signal.

Note:

• The menu item “STPTMODE” must be set to “ANALOG” in order to use analog

communication. Refer to Section 2, page 2. for details.

• The menu item “AUX IN” will reflect the voltage received at the SENTRY Supervisor.

There is an implied decimal point to the left of the third digit (5000 = 5.000 volts).

• The voltage indicated by the “AUX IN” should be within ±.02 volts of the analog voltage

signal transmitted by the process tool.

• Both the analog and power ground leads must be connected to the Supervisor

and be common on the process tool.

The following table illustrates how the set point and read-back analog voltage signals are

interpreted within the Supervisor.

12279 Rev 1.0 Page 3of 3

4.1 Operation

SENTRY 1000, SENTRY 1510 SENTRY 9000

Process exhaust pressure set point:The

set point voltage transmitted from the tool to

the SENTRY Supervisor will be converted to

a pressure set point using the following

equation:

PresSp Aux In

Aux FS PresFS

= ×

Process exhaust pressure read-back:

The read-back voltage returned by the

SENTRY Supervisor to the tool is

proportional to the actual measured pressure

determined by the following equation:

Measured Process Exhaust Pressure =

Pres

Pres FS Aux FS×

Process exhaust flow set point:The

set point voltage transmitted from the tool

to the SENTRY Supervisor will be

converted to a flow set point using the

following equation:

FlowSp AuxIn

AuxFS FlowFS= ×

Process exhaust flow read-back:

The read-back voltage returned by the

SENTRY Supervisor to the tool is

proportional to the actual measured flow

determined by the following equation:

Measured Process Exhaust Flow =

Flow

Flow FS Aux FS×

Serial Interfaced Operation

When the SENTRY system is configured for serial communication operation, the process

exhaust pressure or flow set points are entered through the process tool. The serial interface

operates on standard RS422/485 serial communication protocol. OEM tool or host

programming of interrogation commands is required in order to operate in serial

communication mode. For complete interface instructions, refer to Section 5.

Note:

• The menu item “STPTMODE” must be set to “SINGLE” in order to use serial

communication. Refer to Section 2, page 2. for details.

• The menu items “BAUD RATE” and “PARITY” must reflect the process tool baud rate

and parity in order to use serial communication.

Installation, Operation and

Serial Communication Programmer’s Guide

SENTRY™Supervisor

Section 5: Serial Communication Interface Programming

12279 Rev 1.0 Page 1of 5

5.1 Serial Communication Interface Programming

In order to configure a tool or host computer to communicate with the SENTRY Supervisor

for adjusting a set point or interrogating a read-back value, the tool or computer must be

programmed to communicate with the SENTRY Supervisor. Although it is possible to

address most of the command menu items identified previously, only three commands are

required for serial interfaced communication. The three commands are: power-up clear,

exhaust (pressure or flow) set point and actual exhaust (pressure or flow) read-back

interrogation. This section describes the communication commands, format and protocol

required in order to allow the tool or computer to adjust the set point and report a read-back

through serial communication.

General Description

A message format and communication protocol have been established for transmitting

commands and receiving acknowledgments from the SENTRY Supervisor. The host

processor and the Supervisor have a master and slave relationship, respectively. That is,

the host processor (master) is responsible for initiating communications with the SENTRY

Supervisor (slave). The communication protocol requires the host to send a command to the

Supervisor. For each command sent, the Supervisor will respond with an acknowledgment

message. The communicated commands and acknowledgments are text strings made up of

characters from the ASCII character set.

Note:

• Up to 64 uniquely addressable SENTRY Supervisors can be connected on a given

network.

• Specification guidelines for RS485 provide for a maximum of 32 units, including the

host, on a single network. A repeater is required to add an additional 32 units for a

maximum total of 64 SENTRY Supervisors.

• Refer to Appendix B for the serial communication specifications.

Command Description

The SENTRY Command messages consist of the following components. For a given

command, some or all of the components may be used.

• Start of message character “>”

• Supervisor address and data bank

• Single character command

• Hexadecimal represented data

• Two character checksum

• Carriage return “↵”

Note:

• The SENTRY Supervisor uses the hexadecimal numbering system to represent

numbers in commands and responses. SENTRY command messages are

transmitted as a series of ASCII characters. Numbers are transmitted as the ASCII

number characters 0 through 9 and the upper-case ASCII characters A through F.

• Appendix E provides a decimal to hex and decimal to binary conversion table.

12279 Rev 1.0 Page 2of 5

5.1 Serial Communication Interface Programming

Start of message

Address of controller to

receive the message

Command

Command qualifiers [position] and [data]

Check sum

>

End of message

↵

Beginning Middle End

Power-Up Clear Using Command “A”

Once power has been applied to the SENTRY Supervisor, a power-up clear command is

required to initialize communications between the host and the SENTRY Supervisor. This

command only functions if it is the first command sent after power-up and prevents the

Supervisor from returning a “power-up clear expected” error.

Note:

• This command has no effect on the SENTRY Supervisor operation.

• After a power up clear command is issued, the SENTRY Supervisor resets to

the last saved menu parameter settings.

Host to Supervisor Command Message: >00AA1↵

Function: This message sends a power-up clear command to the SENTRY

Supervisor at base address 00 (>00AA1↵).

Note:

• If additional Supervisors are connected on the same network, each base address

would be incremented by four. Example: >04AA1↵, >08AA1↵, >0CAA1↵, etc.

Supervisor to Host Response: >A↵

Function: This response indicates an acknowledgement without error.

Set Point Using Command “S”

A set point command must be sent to the SENTRY Supervisor in order to command the

process exhaust controller to a new set point. Depending on whether the exhaust controller

is a pressure or flow controller, one of two memory locations must be addressed for this

command. A mask is used to define the memory location.

Note:

• A set point or read-back can be resolved to a 12-bit value (212) with hexadecimal

representation of 000 to FFF (0 to 4095 decimal). The value represented will vary

based on the pressure or flow full scale value of the SENTRY controller.

12279 Rev 1.0 Page 3of 5

5.1 Serial Communication Interface Programming

Pressure Set Point:

In order to write to the Supervisor a pressure set point, the following command must be

issued:

Host to Supervisor Command Message: >01S0100xxxyy↵

Where: xxx = 000 to FFF representing a 0 to full scale range

yy = two hex character check sum

Function: This message sends a set point to a SENTRY Supervisor configured for

pressure control (i.e. SENTRY 1000 or SENTRY 1510).

Example: For a SENTRY 1000 with a 2” H2O (50.8 mm H2O) full scale range,

>01S010099A28↵changes the set point to 1.2” H2O (Hex 99A based on

2” H2O = Hex FFF).

Note:

• The SENTRY Supervisor addressed is at base address 0, memory bank 1

(>01S0100xxxyy↵).

• Memory location “0100” (Pres Sp1) is being modified (>01S0100xxxyy↵).

• If additional Supervisors are connected on the same network, each base address

would be incremented by four.

Example: >05S0100xxxyy↵

Flow Set Point

In order to write to the Supervisor a flow set point, the following command must be issued:

Host to Supervisor Command Message: >01S1000xxxyy↵

Where: xxx = 000 to FFF representing a 0 to full scale range

yy = two hex character check sum

Function: This message sends a set point to a SENTRY Supervisor configured for

flow control (i.e. SENTRY 9000).

Example: For a SENTRY 9000 with a 35 CFM (990 LPM) full scale range,

>01S100099A28↵changes the set point to 21 CFM (590 LPM) (Hex 99A

based on 35 CFM = Hex FFF).

Note:

• The SENTRY Supervisor addressed is at base address 0, memory bank 1

(>01S1000xxxyy↵).

• Memory location “1000” (Flow Sp1) is being modified (>01S1000xxxyy↵).

• If additional Supervisors are connected on the same network, each base address

would be incremented by four.

Example: >05S1000xxxyy↵

12279 Rev 1.0 Page 4of 5

5.1 Serial Communication Interface Programming

Supervisor Normal Acknowledgment

For both pressure and flow set point commands, the Supervisor responds with the following

acknowledgment.

Supervisor to Host Response: >A↵

Function: This response indicates an acknowledgement without error.

Note:

• Refer to Appendix C for error response codes.

Actual Read-Back Using Command “L”

A read-back command (interrogation) must be sent to the SENTRY Supervisor in order to

request the actual process exhaust value. Depending on whether the exhaust controller is a

pressure or flow controller, one of two memory locations must be addressed for this

command. A mask is used to define the memory location.

Pressure Read-Back

In order to read the current pressure, the following command must be issued to the

Supervisor:

Host to Supervisor Command Message: >01L00016E↵

Function: This message sends an interrogation to read the SENTRY Supervisor

pressure read-back memory location. The Supervisor must be configured

for pressure control (i.e. SENTRY 1000 or SENTRY 1510).

Note:

• The SENTRY Supervisor addressed is at base address 0, memory bank 1

(>01S00016E↵).

• A report on memory location “0001” (Pres) is being requested (>01S00016E↵).

Flow Read-Back

In order to read the current flow, the following command must be issued to the Supervisor:

Host to Supervisor Command Message: >01L00026F↵

Function: This message sends an interrogation to read the SENTRY Supervisor flow

read-back memory location. The Supervisor must be configured for flow

control (i.e. SENTRY 9000).

Note:

• The SENTRY Supervisor addressed is at base address 0, memory bank 1

(>01S00026F↵).

• A report on memory location “0002” (Flow) is being requested (>01S00026F↵).

12279 Rev 1.0 Page 5of 5

5.1 Serial Communication Interface Programming

Supervisor Normal Acknowledgment

For both pressure and flow set point commands, the Supervisor responds with the following

acknowledgment.

Supervisor to Host Response: >A1xxxyy↵

Where: xxx = 000 to FFF representing a 0 to full scale range

yy = two hex character check sum

Function: This response indicates an acknowledgement with data but without error.

Supervisor Error Response

An error response begins with the character “N” followed by the error code and carriage

return “↵”. It does not require a checksum. Error codes are listed in Appendix C.

Calculating End of Message Checksum

All command messages end with two ASCII-hex digits representing the message checksum,

followed by a carriage return. The checksum is computed by (a) adding the decimal values

of all the ASCII characters in the message, excluding the start of command character, ">",

(b) dividing the sum by 256 and (c) converting the integer remainder to a two ASCII-hex

digits.

Example: ŒCommand: >08K012

•Ignore the ">" character

ŽConvert the remaining characters to decimal values

Character Hex Value

Decimal Value

030 48

838 56

K4B 75

030 48

131 49

232 50

SUM 146 326

•Divide the sum by 256: 326/256 = 1 remainder 70

•Convert the remainder to a two ASCII-hex digits:

70 decimal = 46 hex

Note:

• Notice that 46 are only the last two digits in the hex sum.

• Therefore, the checksum in this example is 46.

‘The complete command is written as: >08K01246↵

Note:

• Although not recommended, the checksum can be replaced by the

wildcard symbol “??”.The use of the wildcard symbol does not verify

the message integrity.

Installation, Operation and

Serial Communication Programmer’s Guide

SENTRY™Supervisor

Section 6: Troubleshooting, Specifications, Codes &

Conversion Tables

12279 Rev 1.0 Page 1of 6

6.1 Troubleshooting

Maintenance

No maintenance is required to maintain the SENTRY Supervisor in working order.

Troubleshooting

The following troubleshooting table will assist the user in identifying and correcting some

of the most common problems. Refer to the controller’s installation and operation

manual for a complete guide.

Problem Possible Cause Corrective Action

(Tool Interfaced)

Analog ground and

power ground not

connected or

common

Connect both analog ground and power

ground. Verify that they are common on

the tool.

Set point read-

back is always

zero

Supervisor

parameters

incorrectly configured

Ensure proper parameters are selected for

the controller installed.

Supervisor parameter

“STPT MODE”

improperly set for

installation

Set Supervisor parameter to “Analog” for

analog communication or “Single” for

stand-alone or serial communication.

(Analog Interface)

Analog interface

improperly installed

Properly install analog interface cable.

(Serial Interface)

Serial cable

improperly installed or

address not set

Properly install communication cable.

Adjust Supervisor hex code to match tool

settings.

All set points not

being achieved or

cannot change set

point

Supervisor

parameters

incorrectly configured

Ensure proper parameters are selected for

the model installed.

Power not supplied Connect power.

Both positive and

negative voltage lines

not supplied

The negative voltage (-15 to –24 V @ 50

mA) powers the display. Supply voltage

according to the appropriate cable drawing

in the Drawings section at the end of the

manual.

Supervisor display

not on

Contrast not adjusted Adjust contrast using contrast knob.

12279 Rev 1.0 Page 2of 6

6.2 Specifications

SENTRY Supervisor Specifications

Specifications English Metric

Physical:

SENTRY Supervisor Length

Width

Height

Weight

7.90”

6.00”

1.75”

44.5 mm

200.7 mm

152.4

2 lbs.

0.9 Kg

Power Options DC

(Controller & Supervisor) +15 to +24 VDC, 500 mA and –15 to –24

VDC, 50 mA

AC 90 to 260 VAC, 47 to 63 Hz

Set Point Control Types 0 to 5 Volt Analog Interface

RS422/485 Serial Interface up to 9600

baud

Stand Alone Using Operator Key Pad

Cut-Off & Disconnect Devices:

Safety cut-off device The SENTRY Supervisor on/off switch

functions as a circuit breaker in the event

of over-current. The booster fan includes a

fuse for similar protection.

AC disconnect device The SENTRY Supervisor relies upon the

process tool or house facility for AC mains

disconnect and start/stop device.

Operating environment:

Ambient temperature 40-104° F 4 –40 °C

Relative humidity 30 –90% non-

condensing 30 –90% non-

condensing

Altitude up to 6500 ft

above sea level up to 2000 m above

sea level

12279 Rev 1.0 Page 3of 6

6.2 Specifications

Serial Communication Specifications

Specifications

Serial RS-422 Four wire; two differential pair

Serial RS 485 Two wire; single differential pair. Jumper is required at

location JP6 on circuit board.

Type: Dedicated Network

Length of Network:

Maximum length not to exceed 4000 feet (1200 meters).

RS485 Specification guidelines provide length as a

function of allowable distortion; minimum acceptable

output voltage; terminating resistance; baud rate and

selected cable loop resistance.

Nodes: Up to 64 uniquely addressable SENTRY Supervisors on

a given network. Note: Specification guidelines for

RS485 provide for a maximum of 32 units, including the

host, on a single network. A repeater is required to add

an additional 32 units for a maximum total of 64

SENTRY Supervisors.

Communication Rate:9600 Baud

Data: 8 data bits

Characters: All messages between Host and SENTRY Supervisors

are made up of ASCII characters.

Parity: No parity

Start bit: 1 start bit

Stop bit: 1 stop bit

Protocol: Two-pass with a two character checksum for message

transactions. Host initiates transaction by sending a

command to one of the SENTRY Supervisor units on

the network. The addressed Unit verifies that the

command is valid and then executes the command.

Upon command completion, the SENTRY Supervisor

unit returns an acknowledgment along with any

requested data. Command messages and messages

containing returned data from a Supervisor unit includes

a message checksum to insure secure communications.

Interface Connector: RJ-12, 6 pin female connector on the SENTRY

Supervisor. RS422 two differential pairs, multi-drop

capability.

Table of contents

Popular Recording Equipment manuals by other brands

Talk To Me Technologies

Talk To Me Technologies zuvo PLUS user guide

Bastl

Bastl CASPER SOFTPOP SP2 Reference manual

Ingersoll-Rand

Ingersoll-Rand TRANE BCI-R Application guide

Aeta Audio Systems

Aeta Audio Systems SCOOP STUDIO user manual

Inline

Inline IN2118 Operation manual

Auditronics

Auditronics ALM-12d Technical manual