PTM Cassava Planter User manual

IDENTIFICATION

Dealer:

Owner:

Firm / Farm:

City: State:

No. of the Certificate of Guarantee:

Serial / No.:

Date: Invoice No.:

Product:

Notes:

1

Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

Introduction

The Model PTM Cassava Planter was specially developed for

small and medium properties, makes at once the furrow, fertilizing,

cutting the stems and planting.

With heavy duty main frame and absortion capacity and load

distribution, it’s easy to use. With independent wheels assembled in

the Main Frame side with springs for better flexibility, better following

the ground, avoiding intermittence during the planting.

The PTM are equipped with transversal fertilizer distributer, by

augers screw thread featuring an internal non slip cap, and special

profiles, for better regularity in spreading when used in slopes.

Another differential of this machine is the automatic cut of the

branches, thru the knives driven by tires and with only two operators

to supply the cassava branches guide, with a perfect distribution of

the stalks in the soil.

This Manual Contains the necessary information for the better

planting performance. The operator must be read with attention the

whole manual before operating for the first time, and be aware of the

safety recommendations.

To obtain any information, or in the eventuality of technical

problems, consult the dealer, as well as Marchesan’s customer service,

that will guarantee the planter full operation.

2Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

Index

1. To the owner 3

2. To the operator 4 to 8

3. Technical specifications 9

4. Components 10

5. Assembly 11 and 33

Platform assembly 11

6. Setup instructions 12 and 14

Preparing and Hitching to tractor 12

Spacing between rows and Positioning the row units in chassis 13

Procedures for changing the row spacing 13

To place the planter in transporting position 14

Procedure before planting and Ideal operation spped 14

7. Adjustments and operations 15 and 22

Stalks distribution 15

Prosedures for replace the stalks sprockets 16

Fertilizer distribution and Sprockets changing 17 to 18

Table of fertilizer distribution 18

Practical test of stalks and fertilizer distribution 19

Auxiliary calculation for fertilizer distribution 20

Row articulation and stalks proof 21

Coulter blades 21

Operation - Important points 22

8. Maintenance 23 and 27

Lubrication 23 to 24

Maintenance of the fertilizing metering 25

Maintenance of the openers bearing assemblies 26

How to replace the tires 26

Planter maintenance 27

9. Important 28

3

Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

General information

Important

To the owner

The Right and left sides of the planter are determining by facing in the direction of the

implement will moving forward.

When ordering parts, please be sure to inform the quantity, part number, and the name

of each part wanted. It is also important the mention the machine Serial Number, which is

placed on the chassis.

The acquisition of any TATU product assures to the original purchaser the following

rights:

• Warranty Certificate

• Instructions Manual

• Technical Assistance by the dealer on equipment delivery

The owner has the obligation of inspect the conditions of the product on delivery, as

well as knowing the warranty terms.

Special attention should be given to safety recommendations, operation cares and

maintenance of equipment.

Be sure to read and understand this instructions for adjusting and operating the

equipment as reported in this manual. Check each item referred to obtain an efficient

operation and maximum trouble free performance. Remember an equipment which is

properly lubricated and adjusted saves your time, labor and fuel. This manual should be

read by Operators and Maintenance Personel.

• Only people who own a full knowledge of the tractor and planter,

must operate them;

• Marchesan is not responsible for any damage caused by accident

on transporting, incorrect utilization or inadequate storage;

• After the operating season, clean and inspect your implement,

preventive maintenance pays dividends.

• Your Dealer has original equipment parts, which assure proper fit

and best performance.

The warranty shall not be applied to any equipment, or any part thereof

which has been altered elsewhere than at the place of manufacture, or

which the original purchaser thereof at retail, has used or allowed to be

used parts, not made or supplied by Marchesan S/A.

NOTE

4Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

To the operator

Dear User!

Respect the ecology. Don’t throw trash away. This gesture of

goodwill helps to protect our environment

Don’t spill combustible oil, batteries and filters. These Trashes

in contact with soil reach the sub – layer, which directly damage

the environment. Look for information to delivery this contaminate

elements, to who knows to re- cycle or re-use them.

Operation Safety

• Only with the complete cooperation of the implement operator,

accidents can be prevented.

• This symbols is a warning device which should be kept

in place, always clean and visible, when transporting the

implement during day or night, use accessory lights and other

devices in order to give adequate warning to another vehicles

operators.

Read and understand the information about before realizing

adjustments and maintenance.

Be Careful with environment

The TATU planter are easy to operate, therefore some basic and

indispensable cares are required on their handling.

Always have in mind, the safety requires constant attention,

observation and prudence, during the operation, transport, maintenance

and storage of the planter.

5

Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

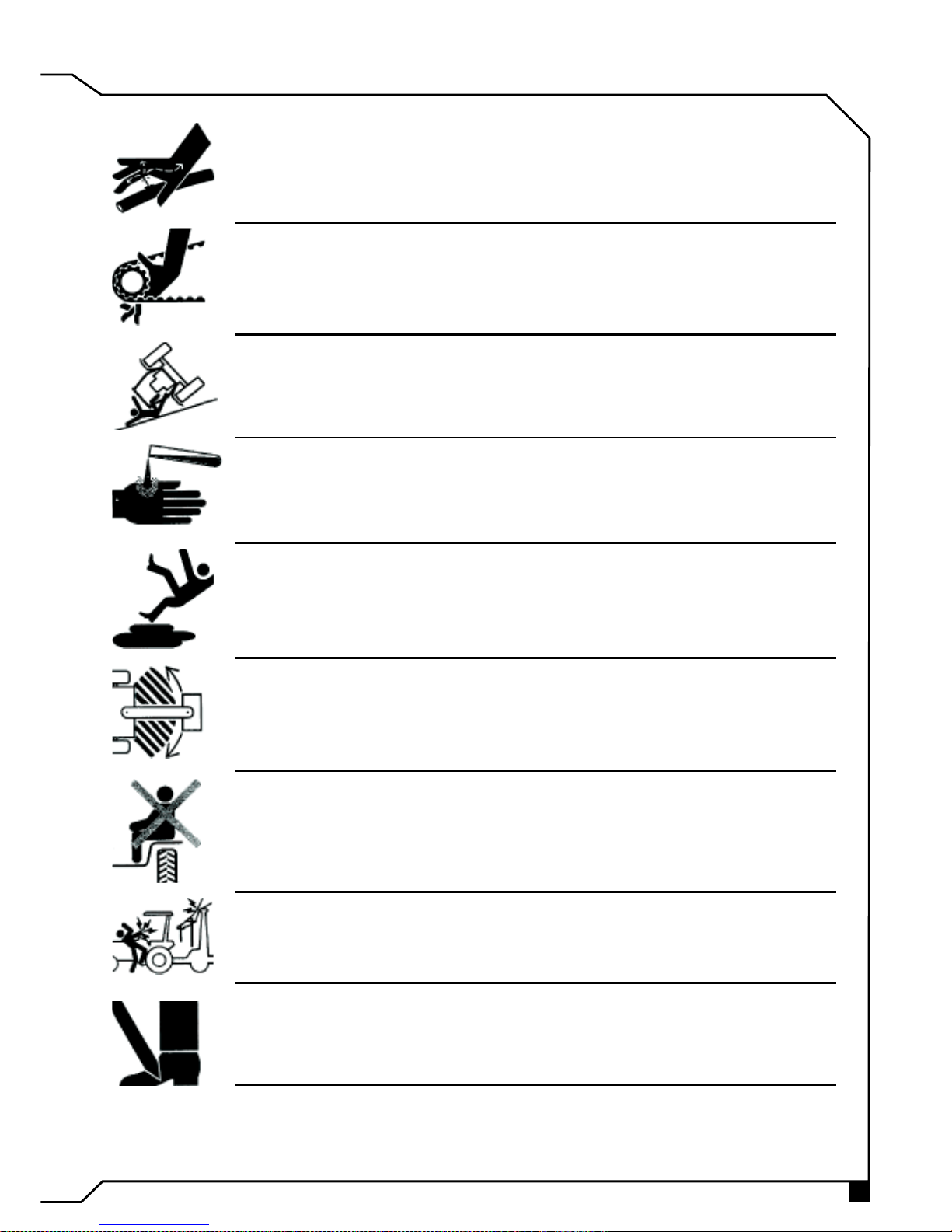

Never use your hands to check hydraulic leaks, escaping oil

under pressure, may have sufficient pressure and may have sufficient

force to penetrate the skin, maybe cause several injuries.

Never attempt to change the adjustments, clean or lubricate the

implement, when the same is turned on or in movement.

Be careful when moving in steep graders. Risk of Overturn.

Be careful about the use of fertilizer or chemicals. These

products in any contact with skin, can be cause any serious injury to

the body.

Keep the entrances and work places clean and safe from oil,

grease. Risk of accidents.

Never transport the implement on rough roads. When operating,

avoid to make sharp turns, that may cause tire contact with the

implement.

Never allow people on the tractor or implement if the additional

seat is not available.

Use extreme caution when circulating with the implement under

electrical power lines, any contact may result severe shocks, injuries

or death.

For your protection and safety, always wear adequate clothes

and shoes during operation of the implement.

To the operator

6Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

• During the operation or transport, don’t allow people on the tractor or in the

planter.

• Never allow children playing near or over the planter, even in operation,

transportation or storing of the equipment.

• Get a full knowledge of the area before starting planting. Delimit the danger

places or obstacles.

• Work and transport with suitable speed according to the local conditions.

• Always wear individual equipments for your own safety.

• Always wear adequate clothes and shoes, avoid large or loose clothes that

may twine on mobile parts.

• Never operate the equipment without the equipment protection devices.

• Be careful when hitching the planter to the tractor, hands and fingers may be

injured when caught between the hitch and the tractor.

• When putting the planter in transport position, verify if there aren’t people or

animals around or over the equipment.

• Never attempt change the adjustments, clean or lubricate with the planter in

movement.

• Please pay attention with transport width in narrow places.

• When disconnecting the planter, move it to a level area, preferably a hard

surface, on the field or in storage warehouse.

• Please look for the general safety instructions on the back cover of this

manual.

When transporting the Implement by Truck or Trailer

To transporting the equipment for long distances use truck or trailer, however,

the safety instructions should be followed carefully.

• Always use an adequate loading dock to load or unload the equipment, never

use a ditch bank, because this practice is very dangerous and could be result

in serious injuries or may causing death.

• Use a suitable Hoist when lifting the equipment to the truck or trailer.

• Use the park standing for correct support the equipment.

• Please Blocking suitable the wheels of the equipment.

• Use sufficient fastenings (cables, ropes, chains, cord, etc.) to immobilize the

equipment during transportation.

• After 8 to 10 kilometers of transporting, please inspect the cargo conditions.

Always Repeat this procedure for every 80 to 100 kilometers of transporting.

Give more attention when transporting on rough roads, steep graders, and

other adverse conditions.

• Be careful with transport height, specially when passing under electrical power

lines and bridges. Risk of shock and serious injuries.

• Observe all the laws and regulations about the height and width limits of cargo.

When transporting the implement by truck or trailer. If necessary, use banners,

lights and other devices to give the adequate warning for the drivers/operators

of another vehicles.

To the operator

7

Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

The safety stickers are a warning of some

points that require more attention in the equipment.

The safety stickers always should be kept in good

conditions. If they are damaged or become illegible,

should be replaced. Marchesan supplies this stickers

upon indication of the respective part numbers.

0 5 0 3 0 3 1 4 2 8

Leia o manual ante s d e i n i c i a r o

uso do equipamento.

Read the manual before attempting

to work with the equipment.

Lea el manual antes de iniciar el

uso del equipo.

Safety Stickers

Safety Stickers 05.03.06.1949

LUBRIFICAR E REAPERTAR DIARIAMENTE

LUBRICAR Y REAPRETAR DIARIAMENTE

L U B R I C AT E A N D T I G H T E N D A I L Y

0503031827

To the operator

P T M

Um adesivo

cada por jogo

Dois adesivos

cada por jogo

na lateral

Dois adesivos

cada por jogo

na lateral

P T M

Um adesivo

cada por jogo

8Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

To the operator

TABLE OF ADJUSTMENTS OF DISTANCE

BETWEEN STALKS

30 16 310

28 16 330

26 16 360

24 16 400

20 16 440

26 20 470

30 24 500

24 20 530

20 18 580

26 24 600

30 28 660

26 28 730

20 22 760

26 30 810

22 26 840

24 30 900

20 26 960

22 30 1000

Sprockets

Drive Shaft Driven Shaft Spacings (mm)

NOTE: For obtain another spaces, replace the sprockets according the list

above by drive shaft (wheel axle) x driven shaft (cutting system).

TABLE OF FERTILIZER DISTRIBUTION

NOTE: We suggest to make a practical test on the fertilizer distribution along of 50 linear

meters and compare with the 3rd column of the table. (Grams by 50 meters).

14 38 169 42 37

14 34 189 47 42

14 30 214 53 47

18 38 217 54 48

18 34 242 61 54

14 26 247 62 55

22 38 265 66 59

18 30 275 69 61

14 22 291 73 65

22 34 296 74 66

26 38 313 78 70

18 26 317 79 70

22 30 336 84 75

26 34 350 88 78

14 18 356 89 79

30 38 362 90 80

18 22 375 94 83

22 26 387 97 86

26 30 397 99 88

30 34 404 101 90

34 38 410 102 91

22 22 458 114 102

Sprocket

Drive

Shaft

Driven

Shaft

Grams

by 50

meters

Space between

row lines (mm)

Tabl e of distrib ution o f commerci al granula ted fer tilizer - Qu antity in kg /Hecta re

with screw thread for 1" (25,4 mm) STANDARD.

800 900

Sprocket

Drive

Shaft

Driven

Shaft

Grams

by 50

meters

Space between

row lines (mm)

800 900

38 34 512 128 114

34 30 519 130 115

30 26 528 132 117

26 22 541 135 120

22 18 560 140 124

38 30 580 145 129

18 14 589 147 131

34 26 599 150 133

30 22 624 156 139

26 18 661 165 147

38 26 669 167 149

34 22 708 177 157

22 14 720 180 160

30 18 763 191 170

38 22 791 198 176

26 14 850 213 189

34 18 865 216 192

38 18 967 242 215

30 14 981 245 218

34 14 1112 278 247

38 14 1243 311 276

9

Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

Technical specifications

PTM

02

800 - 900

223 liters - 250 kg

2700

1800

2077

1525

6,50 x 16 (60 psi)

580

60

Model

Number of rows

Row spacings (mm)

Fertilizer capacity

Working width (mm)

Transporting height (mm)

Transporting width (mm)

Total length (mm)

Tires

Net height (kilograms)

Tractor required (hp)

10 Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

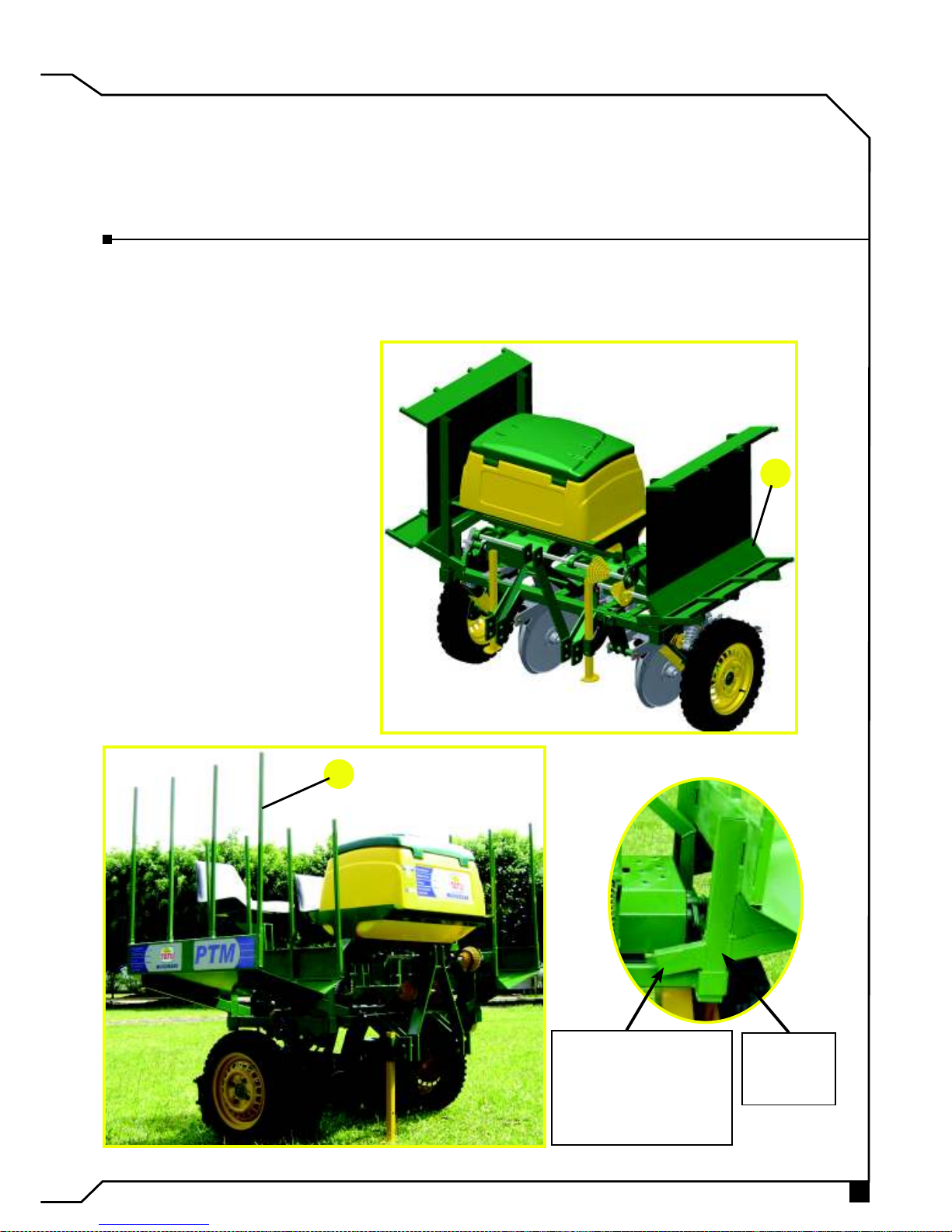

Components

01 - Main frame

02 - Drawbar (three point hitch - category I and II)

03 - Fertilizer hooper

04 - Sprockets

05 - Branches deck

06 - Park standing

07 - Covering discs (notched)

08 - Operator's seat

09 - Branches conductor

10 - Wheels and tires

07

01

02

03

04

05

06

08

10

09

Detail of

stalk guide

11

Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

Assembly

For easy transport, the planter are assembled at factory, just remaining change the

branches platform of the transporting position for working position and placing the cassava

branches protect tubes in conformity with the information below.

Platform assembly

The branches platform (A), have a articulation system for easy transporting in narrow

roads or to storage the equipment. To place the platform in working position, just turn the

platform and fit in the main frame, for last, place the tubes(B), as showed below.

Detail of

working

position.

Transport position,

just turn the

platform and fits

in the front part of

main frame.

B

A

12 Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

Preparing the tractor

If necessary, add fill up with water or counterweights to the front of the tractor or in

rear wheels for better traction and better stability.

Please be careful with the instructions below, what should be followed to obtain better

working efficiency.

Hitching to the tractor

Setup instructions

For Hitching to the tractor, choose and taking the planter to a flat and leveling

place.

Come on with the tractor in slowly reverse gear to the planter, and be ready to push

the brake. So close, use the lever for hydraulic position control. So the lower left side arm

at the couple bolt planter same level.

1) Coupling the left and right side arms, what have up and down movements, with the

adjust of lower arm, and placing the cotter pins. At this time, the extension screw thread

of the high arm of the tractor can be used for nearing or move away the planter, facilitate

the coupling.

Third point

high arm with

extended

screw thread.

2) Putting the High Arm (third point) and putting the cotter

pin.

For a better coupling, the planter should be centralized with

the tractor, how do it of the follow maner.

• Align the planter drawbar with third point of the tractor.

• Raise up totally the planter.

• Verify if the distance of the lower arms and tires are the same

(measure “A”), and leveling in the both sides (measure “B”).

A

B

B

A

13

Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

IMPORTANT

Mark the center of chassis, from this mark you have to measure half spacing to right

and half spacing to left, installing in these points the rows.

For making the row spacing change, make this in a clean, plane and stable place.

The planter always should be coupled properly to the tractor.

1 – Lower the parking stands (A), and blocking the planter chassis, to prevent accidents

and several injuries.

2 – Loosen the Nuts (B), from the row lines front fixing, the nuts(C), what fixing the

back of the rows, loosen the bushing bolt (D), what hold the axle close to bearing to displace

whole components of the chassis. Note that these items work aligned, to procedure the

change, the whole assembly moves (See the pictures below).

Spacing between rows

The PTM are delivered with a row spacing to the request number of rows, with flexibility

for several row spacings, sure, if necessary.

Positioning the row units in chassis

Procedures for changing the row spacing

Makes the retighten of the assemblies, with a special attention:

• The retighten of the nuts that hold the rows on main frame should

be maid gradually, avoiding to tight totally at once each nut.

• Between these operations of tightening the nuts of one row and

passing to another row, should be lean the bushing (D), on the

bearing, and just enough tight to the correct align to avoid blocking

the axle.

Setup instructions

B

D

C

A

14 Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

- Raise the park standings (A).

- Never transport the planter only supported on the

tires.

- Be sure, always maintain the branches platform

in transporting position, to allow transporting in tight

places.

- Before planting, makes a general inspection on the planter, retighten all bolts and

nuts, also check all cotter pins and clamps, to avoid premature maintenance for better yield

of the planter. Please, repeat this operation after the first day of operation.

- Look for the tires calibration, always use the same inflation for both tires (60 psi).

- Please also verify if have any strange object inside the hoopers, that can damage

the fertilizer distribution system.

The TATU PTM Planter operate with larger efficiency at 5km/hour speed, never exceed

this speed for better efficiency.

Setup instructions

To place the planter in transporting position

Procedure before planting

Ideal operation speed

- We suggest fill the planter only at work place,

to avoid loading excess during the transport,

and for a good operation of the tractor and

planter.

- Warning, never transit with loading excess, risk

of accidents and serious personal injuries.

NOTE

A

15

Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

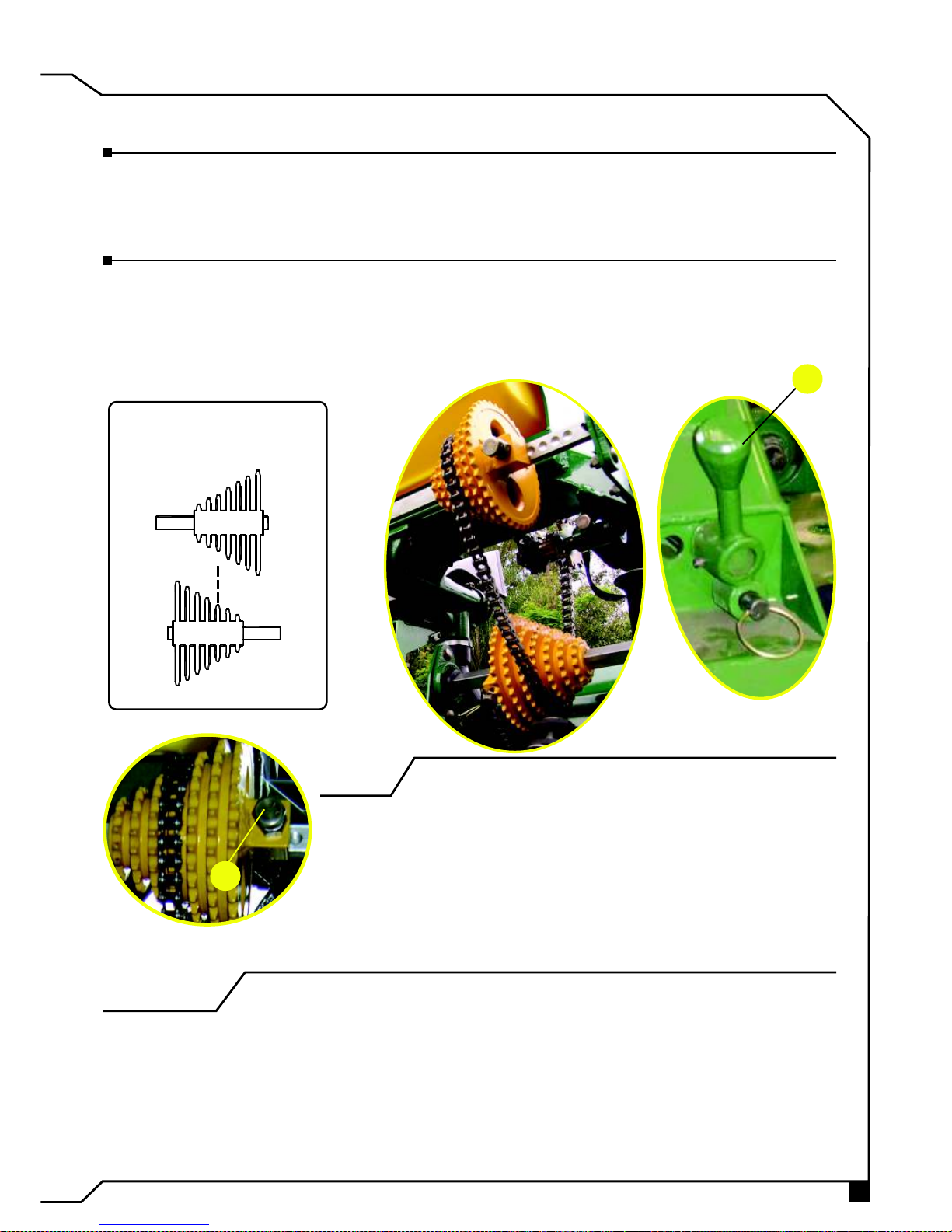

Adjustments and operations

The spacing between stalks are made through the sprockets change (drive) wheel

shaft and (driven) shaft of cutting system, that is placed in the planter side. The stalks

distribution also depends on the operation speed, that never should be faster than 5 km/

hour.

The planter are manufactured

with 2 sprockets of 20 teeth each one,

and goes with two sets of sprockets

of 18,22,24,26,28 and 30 Teeth. (See

picture below).

For adjusting of stalks distance,

take a look on the table and see the

number of sprockets for desired distance

(See the instructions on page 16).

This table is only reference for starting adjustments of the planter.

External factors like as slippage index of the planter carrying

wheels(skidding), working speed more than recommended (5

Km/hour), Tires inflation (Less than recommended), and field

conditions, can result in values a bit different from those indicated

in the table above.

Therefore, It is always indispensable to make the practical

distribution tests, as indicated in page 19 of this manual.

Stalks distribution

IMPORTANT

TABLE OF ADJUSTMENTS OF DISTANCE

BETWEEN STALKS

30 16 310

28 16 330

26 16 360

24 16 400

20 16 440

26 20 470

30 24 500

24 20 530

20 18 580

26 24 600

30 28 660

26 28 730

20 22 760

26 30 810

22 26 840

24 30 900

20 26 960

22 30 1000

Sprockets

Drive Shaft Driven Shaft Spacings (mm)

NOTE: For obtain another spaces, replace the sprockets according the list

above by drive shaft (wheel axle) x driven shaft (cutting system).

Detail of the

sprockets

16 Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

Adjustments and operations

- For replacing the sprockets, choose one and proceed according to the instructions

below:

• Take off the cotter pin (A), and safely move with the hands the chain tighter for

changing the sprocket of wheel axle.

• Loosen the bushing bolt (B), displace the axle, for making the changing of the

sprocket of cutting system, see the picture below.

• This procedure should be done on the both sides of the machine. As they are

independent system.

Procedures for replace the stalks sprockets

Detail of cotter pin

B

A

17

Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

Adjustments and operations

Fertilizer distribution

Procedure for sprockets changing

The fertilizer distribution is done through the steel auger and the different dosage

rates of fertilizer, by changing the sprocket of drive shaft {C} (14,18,22,26,30,34 and 38

teeth) and driven shaft {D} (14,18,22,26,30,34 and 38 teeth).

RECÂMBIO DE ENGRENAGENS

SPROCKET COMBINATIONS

CAMBIO DE ENGRANAJES

ADUBO FERTILIZER ABONO

EIXO MOVIDO

DRIVEN SHAFT

EJE MOVIDO

EIXO MOTOR

DRIVE SHAFT

EJE MOTOR

D

C

• Move the lever (A) to alleviate the chain tighter and lock with the locker pin in the

hole.

• Displace Manually the sprockets combination cone on the axle and align the choosing

sprocket with the chain.

• Loosen the lever for liberating the lock pin.

• The bolts (B) on the sprockets combination

cone of “TRA”, are calibrated in the factory,

allowing the sprockets change without use of any tool.

• In case of any sliding motion on cone shaft, just loose the

counter nut and made only once turn around the bolt, and

re-lock.

• In order to avoid damage to the spring and shafts, never

apply excessive torque when tightening the bolts and

nuts.

IMPORTANT

NOTES

B

A

Look in the following pages the different quantities of fertilizer,

according with the sprockets combination.

The fertilizer distribution table of this manual, should be used just like a reference to

start the planter calibration. Factors as slippage index of the planter carrying wheels

(skidding), work speed more than the recommended (5 km/Hour), tires inflation less

than recommended and field conditions, can introduce values a bit different from

those indicated in the tables. Therefore, it is always indispensable make the practical

distribution tests as indicated in page 19 of this manual.

18 Marchesan Implementos e Máquinas Agrícolas “TATU” S.A.

• The table Below indicates the obtained amount of the auger of

2”(Standard). This auger transports approximately 35 grams of

fertilizer per turn.

Auger of 1” coil

pitch optional

Auger of 2” coil

pitch standard

Table of fertilizer distribution

Adjustments and operations

ATTENTION

TABLE OF FERTILIZER DISTRIBUTION

NOTE: We suggest to make a practical test on the fertilizer distribution along of 50 linear

meters and compare with the 3rd column of the table. (Grams by 50 meters).

14 38 169 42 37

14 34 189 47 42

14 30 214 53 47

18 38 217 54 48

18 34 242 61 54

14 26 247 62 55

22 38 265 66 59

18 30 275 69 61

14 22 291 73 65

22 34 296 74 66

26 38 313 78 70

18 26 317 79 70

22 30 336 84 75

26 34 350 88 78

14 18 356 89 79

30 38 362 90 80

18 22 375 94 83

22 26 387 97 86

26 30 397 99 88

30 34 404 101 90

34 38 410 102 91

22 22 458 114 102

Sprocket

Drive

Shaft

Driven

Shaft

Grams

by 50

meters

Space between

row lines (mm)

Table of distribution of commercial granulated fertilizer - Quantity in kg/Hectare

with screw thread for 1" (25,4 mm) STANDARD.

800 900

Sprocket

Drive

Shaft

Driven

Shaft

Grams

by 50

meters

Space between

row lines (mm)

800 900

38 34 512 128 114

34 30 519 130 115

30 26 528 132 117

26 22 541 135 120

22 18 560 140 124

38 30 580 145 129

18 14 589 147 131

34 26 599 150 133

30 22 624 156 139

26 18 661 165 147

38 26 669 167 149

34 22 708 177 157

22 14 720 180 160

30 18 763 191 170

38 22 791 198 176

26 14 850 213 189

34 18 865 216 192

38 18 967 242 215

30 14 981 245 218

34 14 1112 278 247

38 14 1243 311 276

Table of contents

Other PTM Farm Equipment manuals

Popular Farm Equipment manuals by other brands

CORN

CORN MACDON C HARVESTEC 6000 installation manual

Roxell

Roxell Dozit user guide

MASSEY FERGUSON

MASSEY FERGUSON RB 4160 V Workshop service manual

Poettinger

Poettinger TOP 692 A Operator's manual

Dhollandia

Dhollandia DH-RK 33 installation manual

GREAT PLAINS

GREAT PLAINS MC5109 Max-Chisel Assembly manual