3

Operator’s Manual JM 2640 EX PD

1 -INTRODUCTION ......................................................................................... 4

2 -PRODUCTPRESENTATION ........................................................................ 5

2 -SAFETYSTANDARDS .............................................................................. 6

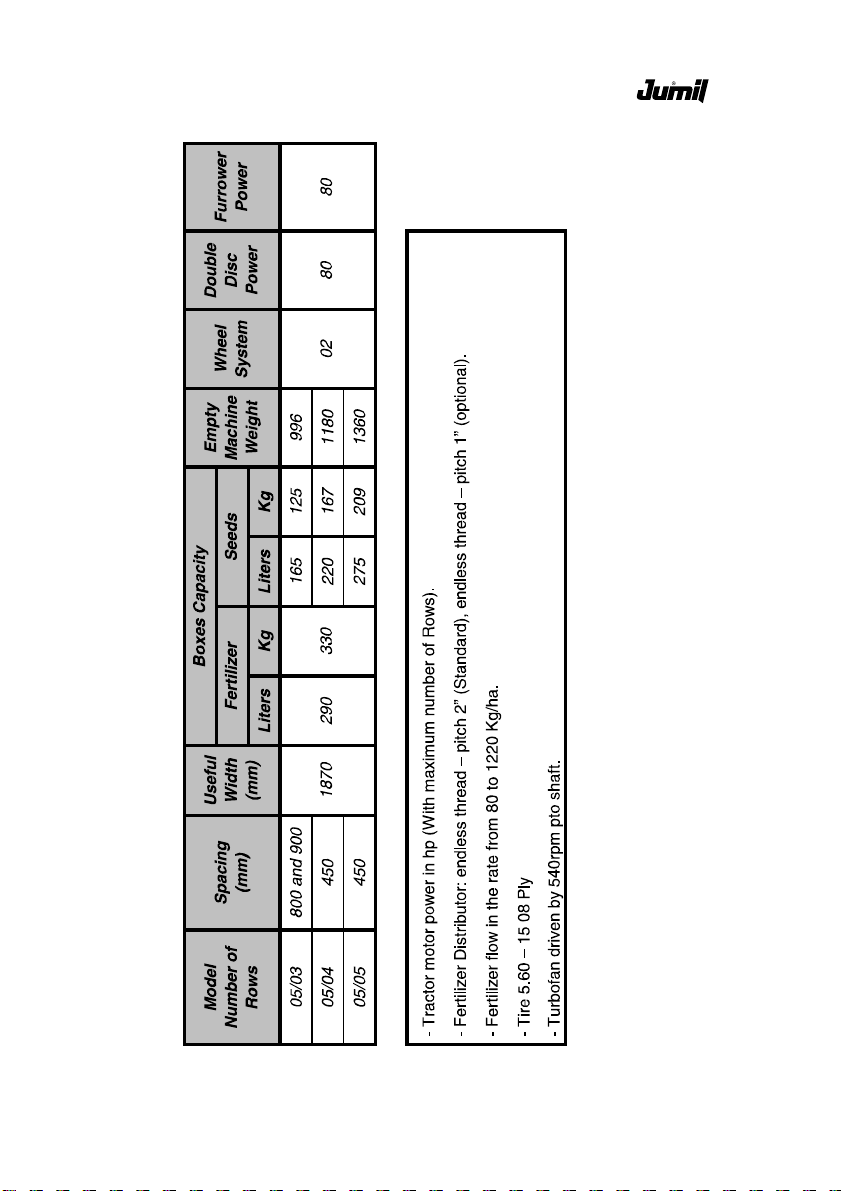

4 -TECHNICALSPECIFICATIONSJM2640PDEX .......................................... 8

5 -OPTIONAL ................................................................................................. 9

5.1 - OPTIONALDISCS .................................................................................... 10

6 -PRODUCTCOMPOSITION ........................................................................11

7 -PRODUCTASSEMBLY..............................................................................11

8 -PREPARETOUSE ................................................................................... 12

8.1 -SEEDSDISTRIBUTION ............................................................................. 12

8.1.1 -SELECTOR .............................................................................................. 12

8.1.2 -DISTRIBUTORBODY............................................................................... 12

8.1.2.1 -DISCSUPPORTINSERT .......................................................................... 13

8.1.3 -COVEROFTHEDISTRIBUTOR ............................................................... 14

8.1.4 -ADJUSTMENTS INTHEDISTRIBUTION .................................................... 15

8.1.5 -CHANGEOFTHEDISCSFORSEED. ...................................................... 16

8.2 -DIRECT(NOTILL)OR CONVENTIONALPLANTING .............................. 17

8.2.1 -CUTTINGDISCOFTHEDIRECTPLANTING ............................................ 17

8.3 -APPLICATORSOFFERTILIZERS ............................................................. 18

8.3.1 -OFFSETDOUBLEDISCOFFERTILIZERS ............................................... 18

8.3.2 -FURROWER ............................................................................................. 18

8.4 -ADJUSTMENTOFFERTILIZERPLACEMENTAND SEED. ........................ 19

8.4.1 -RODSOFDOUBLESPRINGS.................................................................. 21

8.4.2 -SEEDSDEPTHCONTROL ....................................................................... 21

8.5 -PRESSINGANDCOVERINGOFTHESEEDS .......................................... 22

8.6 -SEEDERDOUBLEDISC ........................................................................... 22

8.7 -FERTILIZERANDSEEDAPPLICATION ..................................................... 23

8.8 -COUPLINGTOTHETRACTOR ................................................................ 24

8.8.1 -TRACTORPREPARATION ....................................................................... 25

8.9 -DRIVING .................................................................................................. 26

8.9.1 -HOMOCINETICPTOSHAFT. .................................................................... 27

8.9.1.1 -PTOSHAFTSPECIFICATIONS................................................................. 28

8.9.1.2 -MAXIMUMANGLEOFTHEJOINTS ......................................................... 29

8.9.1.3 -LUBRICATION .......................................................................................... 30

8.9.1.4 -COUPLEROFTHE PTOSHAFT............................................................... 30

8.9.1.5 -PINOFFASTCOUPLER .......................................................................... 30

8.9.1.6 -LENGTHADJUSTMENT ........................................................................... 31

8.9.1.7 -CHAINS ................................................................................................... 32

9 -ADJUSTMENTS ....................................................................................... 33

9.1 -ADJUSTMENTOFTHEAMOUNTOF SEEDS ........................................... 33

9.2 -FERTILIZERSDISTRIBUTION ................................................................... 35

9.2.1 -DETERMINATIONOFFERTILIZERDISTRIBUTION .................................... 35

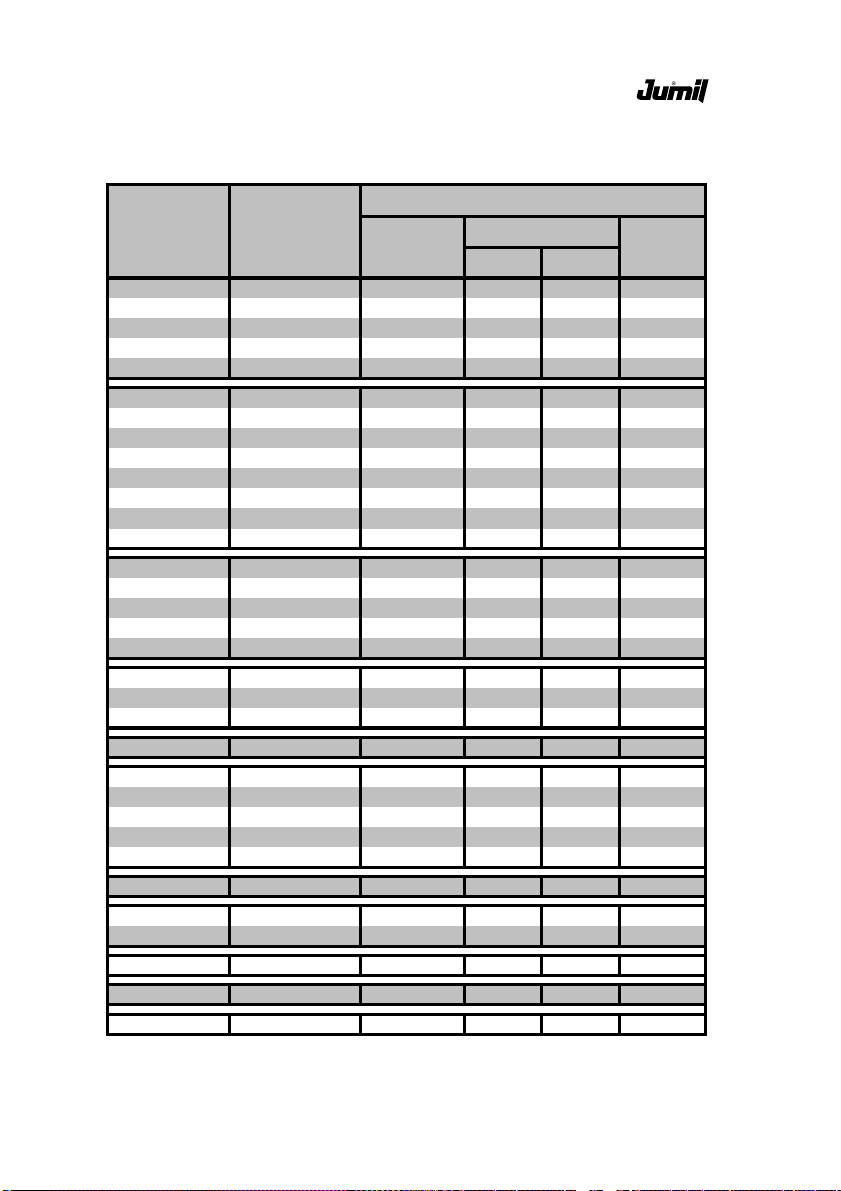

10 -SCHEMEOFASSEMBLYANDSPACINGS .............................................. 39

11 -LUBRICATION .......................................................................................... 43

11.1 -OBJECTIVESOFLUBRICATION .............................................................. 43

11.2 -SYMBOLSOFLUBRICATION.................................................................. 43

11.3 - CHARTOF LUBRICANTS ........................................................................ 44

11.4 -LUBRICATIONPOINTS............................................................................. 45

12 -INCIDENTS,POSSIBLECAUSESANDSOLUTIONS ................................ 49

INDEX