Puhui MT-60 User manual

User Manual

MT-60 User Manual

全自动贴片机

Auto Chip Mounter

泰安普惠电气科技有限公司

Tai'an Puhui Electric Technology CO., LTD.

Http://www.tech168.cn

Installation instructions

1 Ready to install

A : Installation Preparation

1 Choose flat on the ground in order to guarantee the machine level

2 Enough operation space

3 Avoid high temperature and high humidity environment

4 Check whether there is any damage on the power cord

B: Considerations

1 Electrical considerations

a:Use the voltmeter to check the power supply voltage is correct,connection

is reliable

b: Please confirm is safely grounded

c:Please confirm the hardware connection is firm and reliable

2 Air supply matters needing attention

a:Please make sure the external air trachea and the machine connection is

normal

b:Please make sure the vacuum mechanical and electrical source connected

with the machine to normal

3 Security considerations

a:Before moving to the machine, shut off the power, disconnect cables.

b:Handling personnel, pay attention to personal safety.

c:Before power on, confirm there is no foreign body in the machine

d:Before power on, manual review agencies operating normally, without

obstacles.

E: An emergency, press the red stop switch, system power is disconnected.

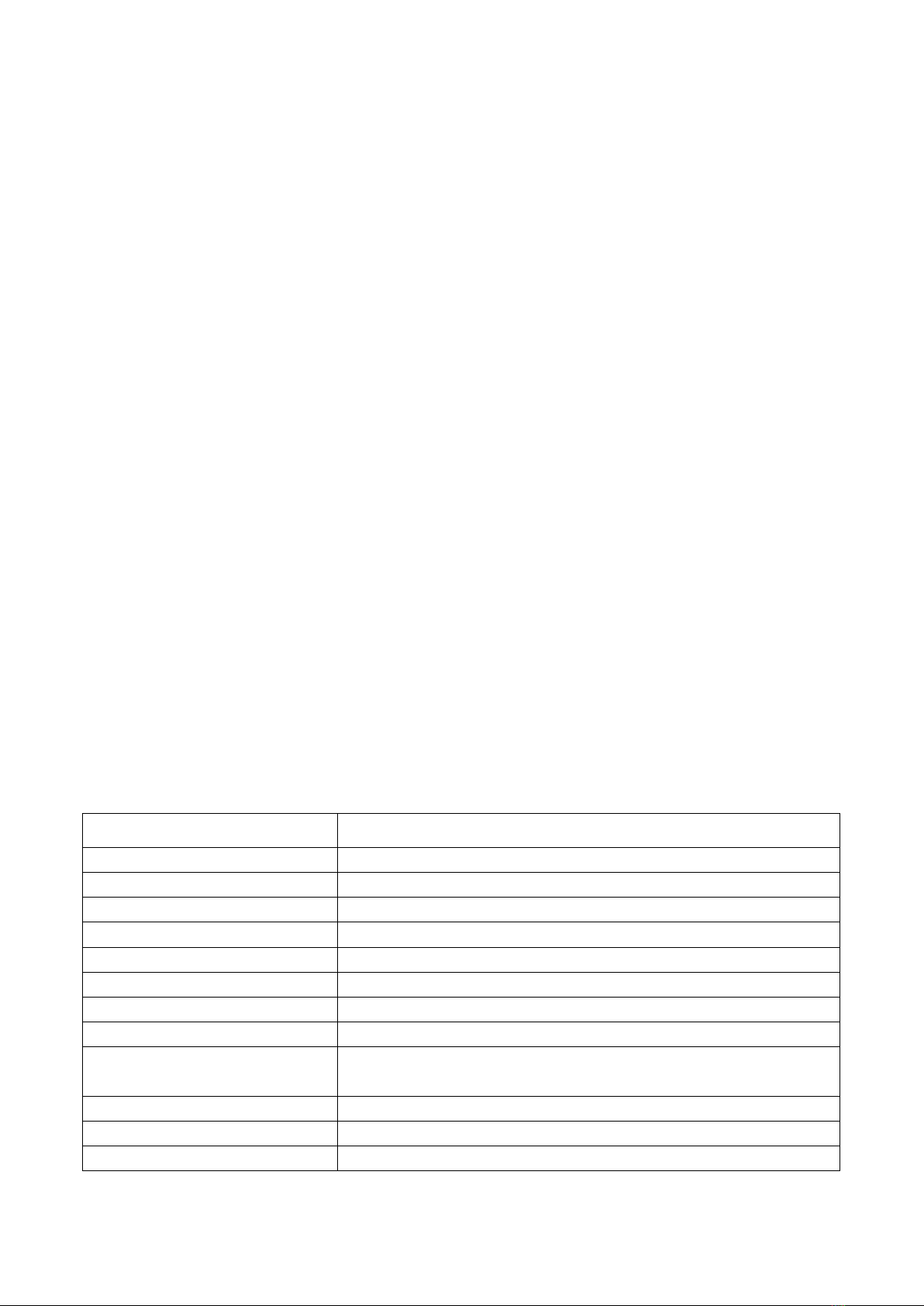

Technical Parameters

Item

Specification

Name

Multi-axis automatic placement machine

Model

MT-60

Placement head quantity

1

Speed

<6200CPH

Positioning accuracy

0.025mm

Feeders number

56(8mm=50,12mm=4,16mm=2),

Applicable Components

0603-1206,diode, triode, capacitance, resistance, chip, etc

Feeders

8mm=50,12mm=4,16mm=2

Offline store the number of

files

20

Applicable PCB

300mm×400mm

Power supply

220V,50/60Hz,350W

Vacuum pump

0~30Kpa(Low vacuum), 20L/min

Operating system

Windows XP/ Win 7/ Win8

External Dimension

1566mm×884mm×367mm

Weight

110Kg

Fault detection

Leak detection、Congestion detection、Pressure detection

Machine Appearance

Suction Mechanism

Pushing Mechanism

Spindle motor -S

Control cabinet

Emergency stop switch

Power switch

Circuit board tray

Stents

The Motor of X-axis

Vacuum pump

Waste recycling gear

Idler pulley

Take-up motor driver board

The Motor of Y-axis

Adapter plate

The Reed for press the feed

Vacuum suction nozzle solenoid valve

Take-up gear box

Take-up motor C

Pushing motor CAM mechanism

Pushing feed motor T

Pushing to adjust seat

Pushing feed adjustment bolts

Leak hunting base

A rotary motor Q

Pick and place motor Z

Circuit board tray

Absorb feed skeleton

The overall structure

Spindle

motion

components

1The spindle drive motor S

2The mounting plate for S-axis motor

3The limit switch for S-axis motor

4The main orbital axis

5The bearing of S-axis

6The bearing pedestal of S-axis

7The casing of S-axis

8The slab of S-axis

9Synchronous belt

10Synchronous belt clamp mechanism

Suction

Mechanism

1Absorb feed skeleton

2Pick and place mechanism

3Rotating mechanism

4The limit switch for Z-axis

5The pick and place drive motor Z

6Rotate the drive motor Q

7Suction nozzle component

Pushing

Mechanism

1Pushing feed motor T

2Pushing CAM mechanism components

3The limit switch T

4Pushing the needle

5Pushing feed motor install L plate

6Eccentric shaft sleeve

7Rack

8Gear shaft

The X-axis

motion

mechanism

1The pallet drive motor X

2 Circuit board positioning bracket

3The pallet track bearing

4The pallet slider

5Pallet orbit X -axis

6The limit switch for X-axis

7Synchronous belt for X-axis

8Synchronous belt clamp mechanism

9 Spring retaining seat

10 Compression spring

11 Fastening bolts

Waste

recovery

mechanism

1Closed with gear box

2Take up gear assembly

3Take up motor

4Take up motor drive circuit board

Rack

1 Tray tora

2 Tray pin

3Wast recycling gear

4Guide wheel

SMD

pressure

seat

1SMD pressure seat

2Binder reed

3Discharging pressure rod

Installation

1 Select the appropriate operating space for placing mounter.

2 Place it in a dedicated support shelf

3 -Access to the power supply and gas supply

-Access to the power supply on the INPUT socket labeled

-Access to the vacuum pump power on the socket labeled

-Access to the gas pump source from the interface success of auxiliary

control cabinet

The Test and Operation security essentials

1Don’t hinder the moving parts when the machine is moving

2Don’t push the moving parts when the machine stop

3Make sure that the terminal connection is good

4After power off, please again after boot in 20 seconds

5Don’t insert the other equipment into the power socket

6An emergency,press the red stop switch,system power is disconnected

Operation panel

1Front panel

A: Emergency stop switch

Press the switch, the machine stop any ongoing action.

Press the switch clockwise, button pop-up, machine resets, the shaft back to

the origin position

B: Power switch

Control the electrical source on and off

2Main panel

A:Liquid crystal display

B:Keys

Software panel

The mouse pointer

move up

Continue

The mouse pointer

move up

Pause

Confirm

The tray in and out

Return

Main menu

tab

Element list

Toolbar

Plot area

Status bar

Unit manager panel/ Parameter Interface

System Parameters Setting Interface

Backup

recovery

zone

Shelf

parameter

Shelf

landing

Shelf

location

Other

parameter

adjustment

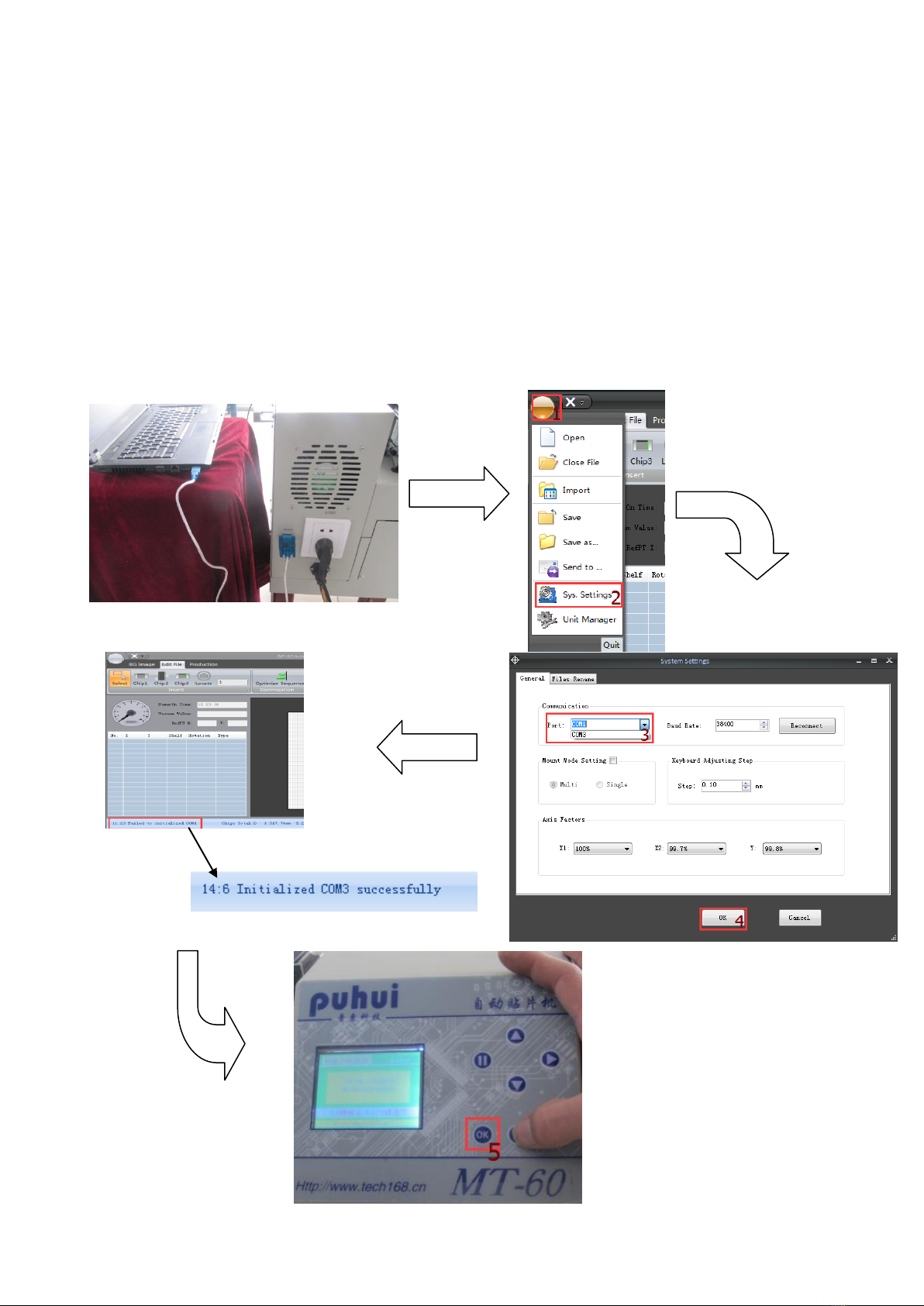

Operation 1 —— Connect with computer

1. Connect MT-60 with computer by using RS232wire,open the control software, turn on the

power of MT-60.

2. Click “main menu”- “system parameter, you will see “system parameter setting dialog box”,

click serial port, you will see the current name of the serial port.

3. Select the serial port which match with RS232 wire.

4. Click OK, you will see the notice information in the bottom left corner of page。

5. At this time, Press “OK”at MT-60 operation panel, start to connect with computer, it

connect successfully when MT-60 operation page show “already connected with computer”

Operation 2 —— Parameter Adjustment

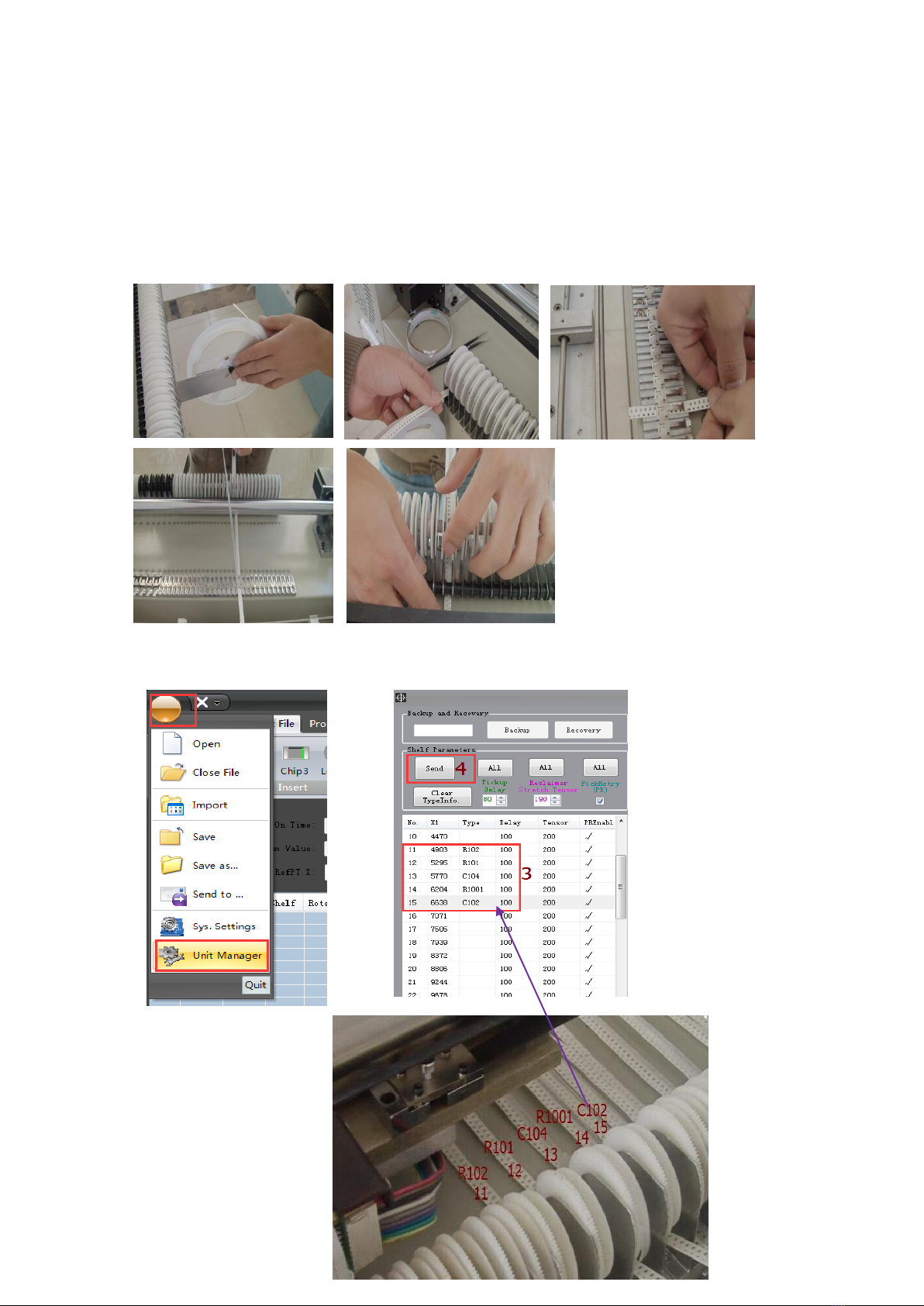

1.Install Feeders

Feeders NO 1-10 suit for diode, triode with plastic feeders. 31-34 suit for

12mm components,35-36 suit for 16mm components. The others suit for 8mm

components.

2.entryformation of feeders

Click main menu- Unit manager, entry the information of feeders.

3. Check feeders coordinate

Checking purpose: make nozzle locate in the middle of component

between left and right.

Click ―main menu‖–―Unit manager‖, click the number of checked feeder,

click , the nuzzle will move to the feeder, click and

, check whether the nuzzle locates in the middle of component.

If not, click and , then click , click again, the nuzzle wiil

move the new coordinate, check again to confirm the position. Click

after adjusted.

check pick- Ysteps

Checking purpose:make nozzle locate in the middle of component

between before and after.

Select any a feeder number, click , then click to push a

component, coil the skin manually. Then copy the data of Ysteps.

Click , the nuzzle will be moved over the component. Click , the

nuzzle lands on the component, check whether the nuzzle locates in the

middle of component. Copy the data to entry the pick Y steps., click to

save data.

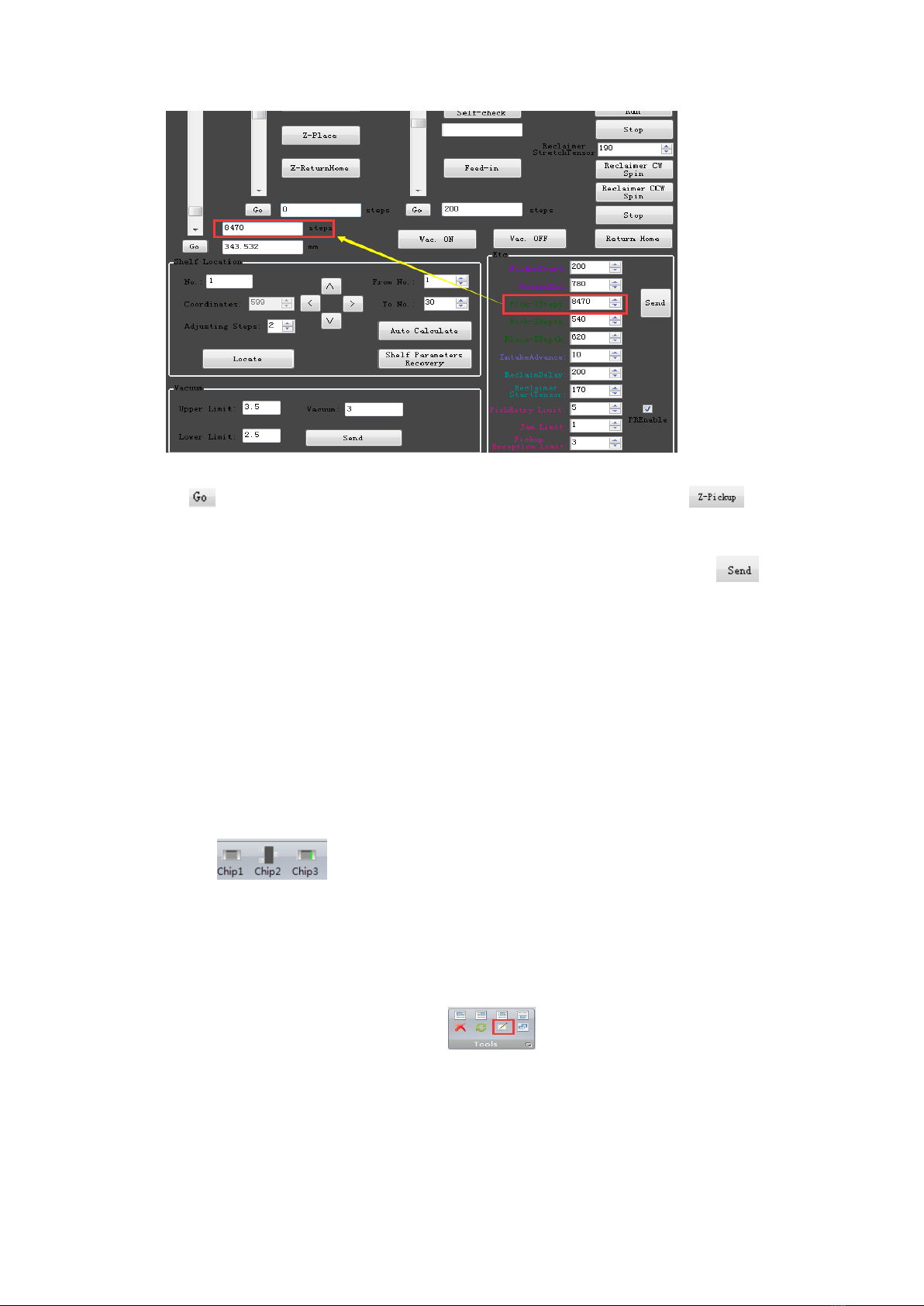

Operation 3 —Create placement data document

(Create coordinate )

1. Basic Operation

a. components edit

1). Place component

Click to choose a component type, click on the left side of

the mouse for placing component in the plot area.

Tips: press the space bar to change the direction of rotation before placing;

press F2 bar to change 90 degree of rotation. Click on the right side of mouse

for quitting placing components state.

2) Copy and paste

Select the copy components, click , select any component as the

aim point, then move mouse to the paste point, click mouse to finish.

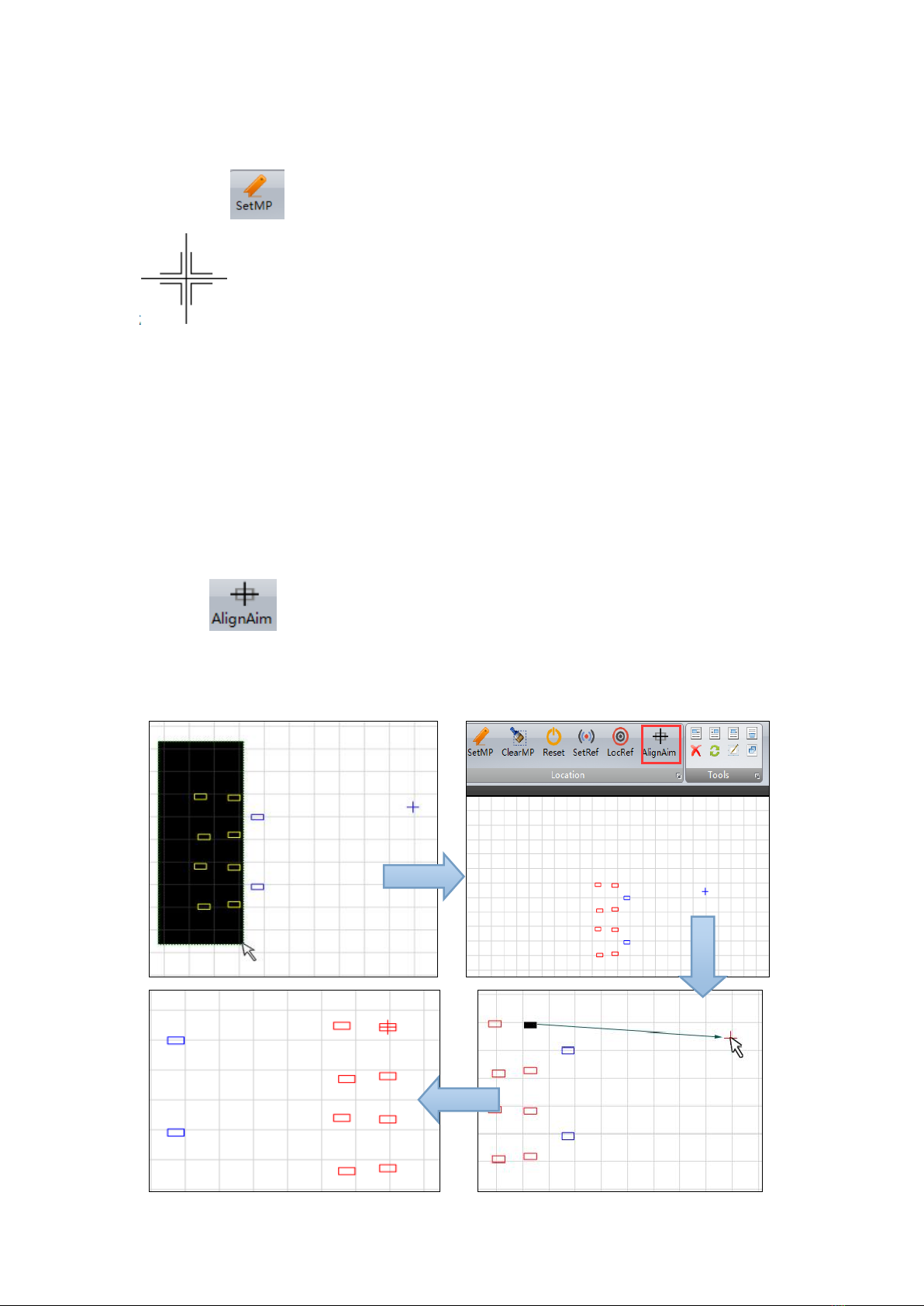

b. Set mark point

Purpose: find the corresponding coordinate, which corresponds to one point of

PCB in the plate.

Steps:

1. Place PCB in the plate;

2. Click , move mouse to the plot area, the mouse pointer changes

.

3.When move mouse or arrow keys, the nuzzle will be moved. Push the

space bar, the nuzzle lands on the PCB. Loosen the space bar, the nuzzle

rises.

4. Select a component as aim component, move mouse to make nozzle land

in the center of aim component. Press Enter bar, the mouse pointer changes

blue.

5. Press ESC bar to quit Mark state.

c. Align aim

1. Select all need to move components.

2. Click , click the aim component, it changes black.

3.Click the blue mark point, all the need to move components will be moved

to the new area.

4.Press ESC to quit align aim state.

2.Create placement data document

There are 3 types to create placement data document. Mark every point,

import PCB coordinate document, Mark printer scan.

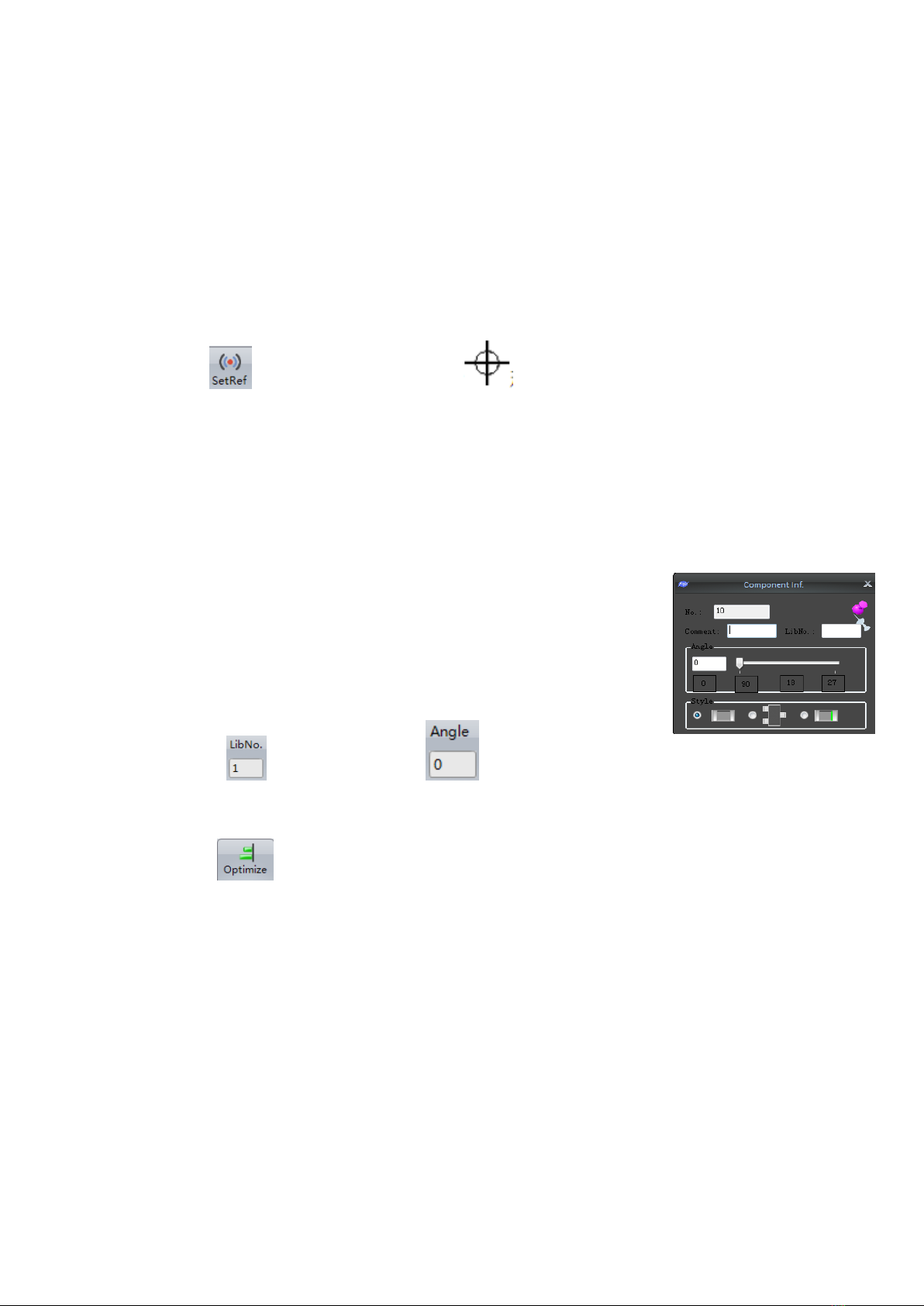

Operation 4—Set reference point

a. Mark point as the reference point of PCB in the plot area (via hole, pad holes,

etc)

b. Click , mouse pointer changes ,click on the left side of mouse to

set reference point.

c. Select the reference point, move to the mark point by align aim.

Operation 5—Entry information of component

1. Basic operation

a. edit a single component

In the edit file tab, double-click the component to bring up a

formula bar of component. Left-click on any whitespace to quit.

b. edit multicomponent

Select all the same type components, fill in the feeder number

then click to edit type. Click to edit angle.

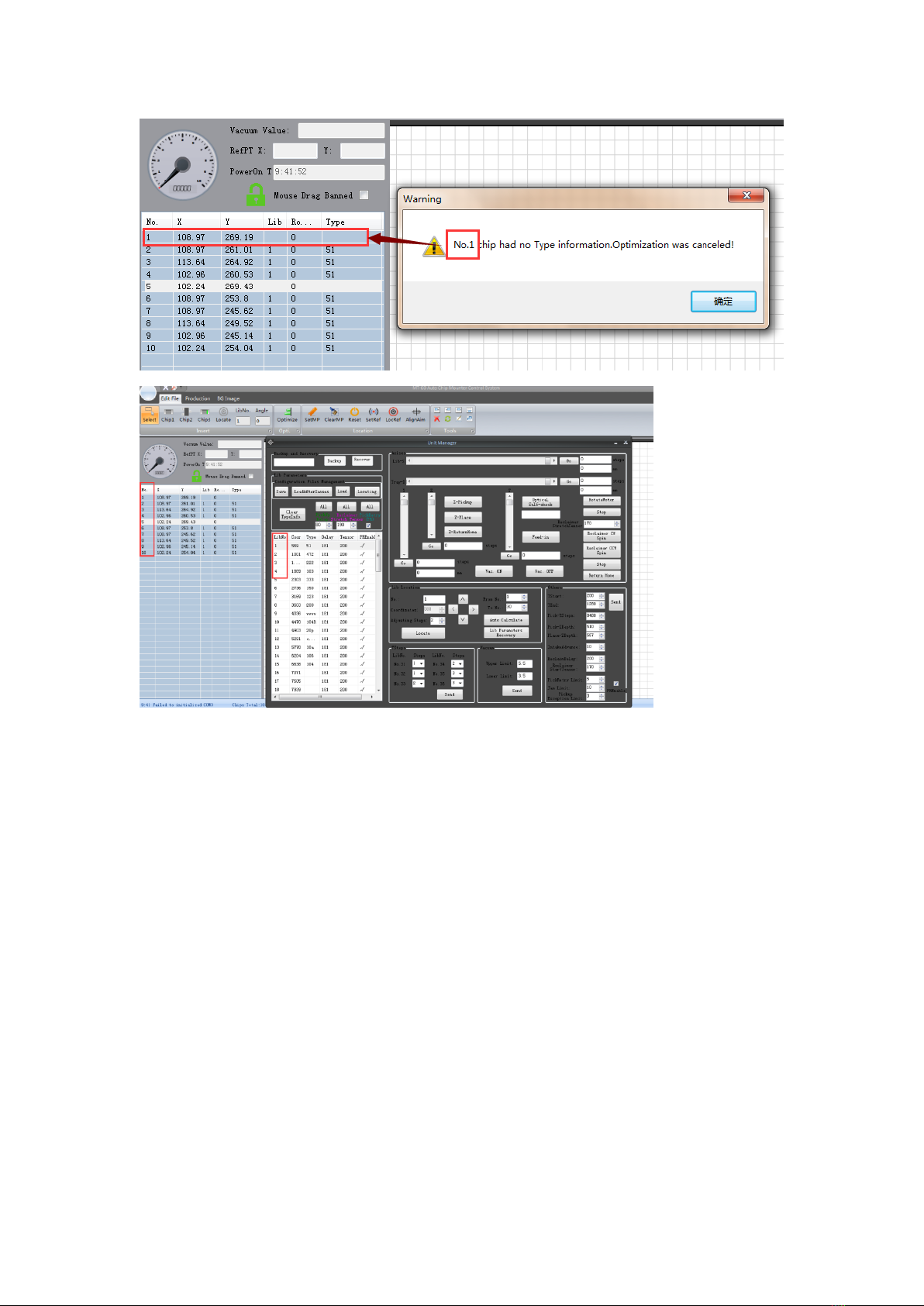

2.Optimize mounting sequence

1. Click after finishing edition to check whether the document is

correct. It there is tip as below, please check the component number. It need

you to fill type in the Shelf parameter.

2. After optimizing, click main menu—save, the placement document is saved

on computer.

3.click main menu—transform, select the block number to save in the machine.

Fast learning how to operate

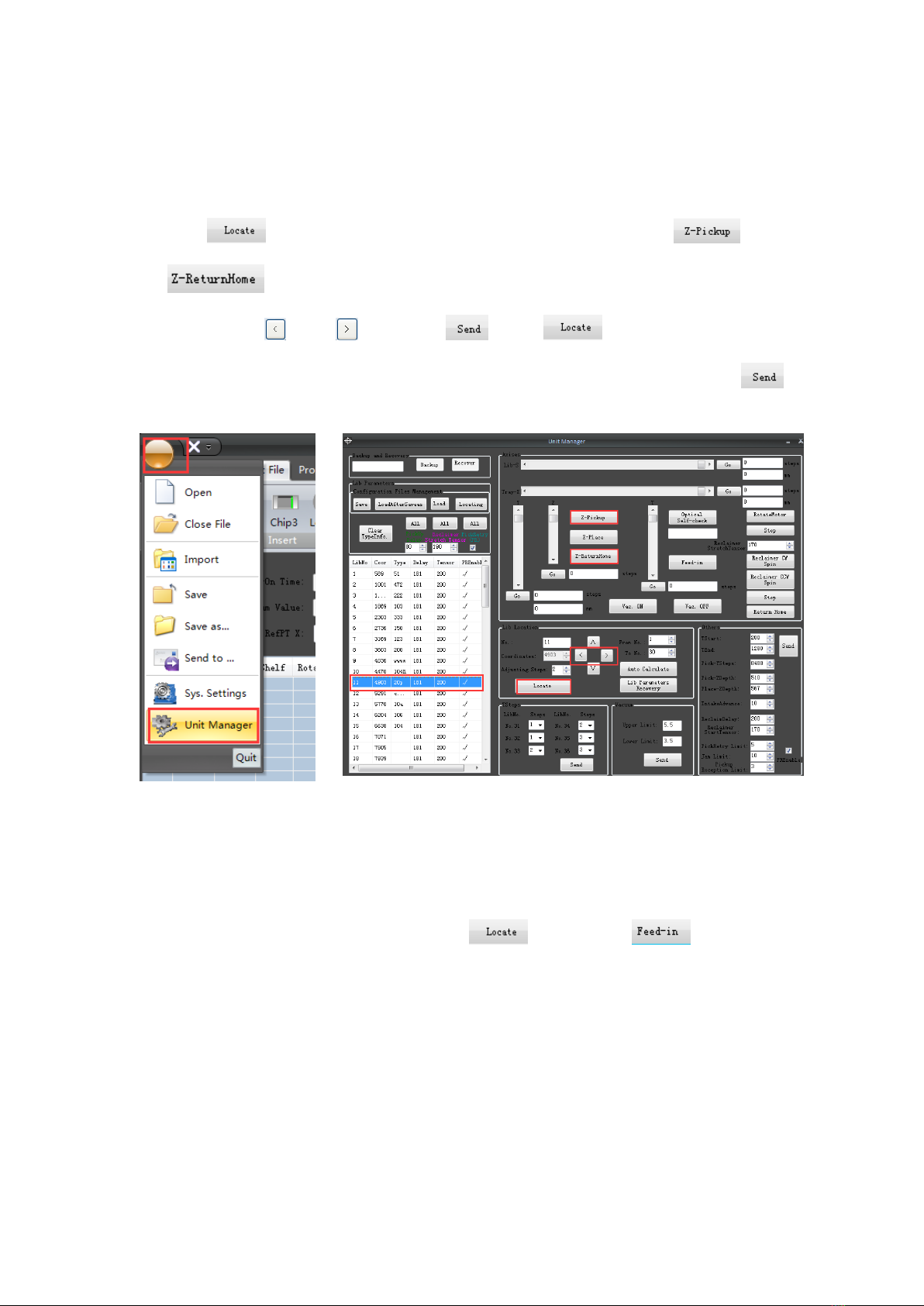

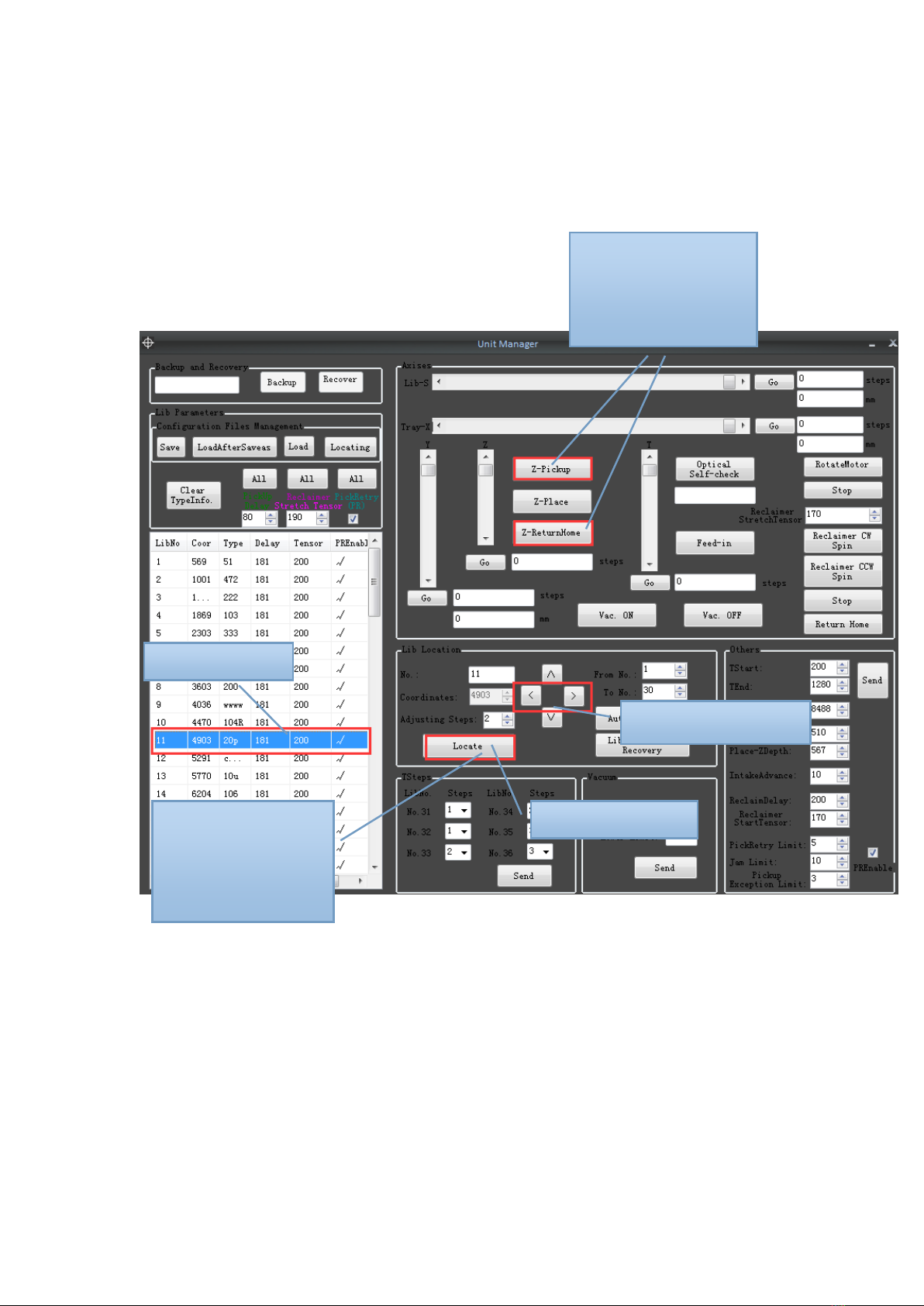

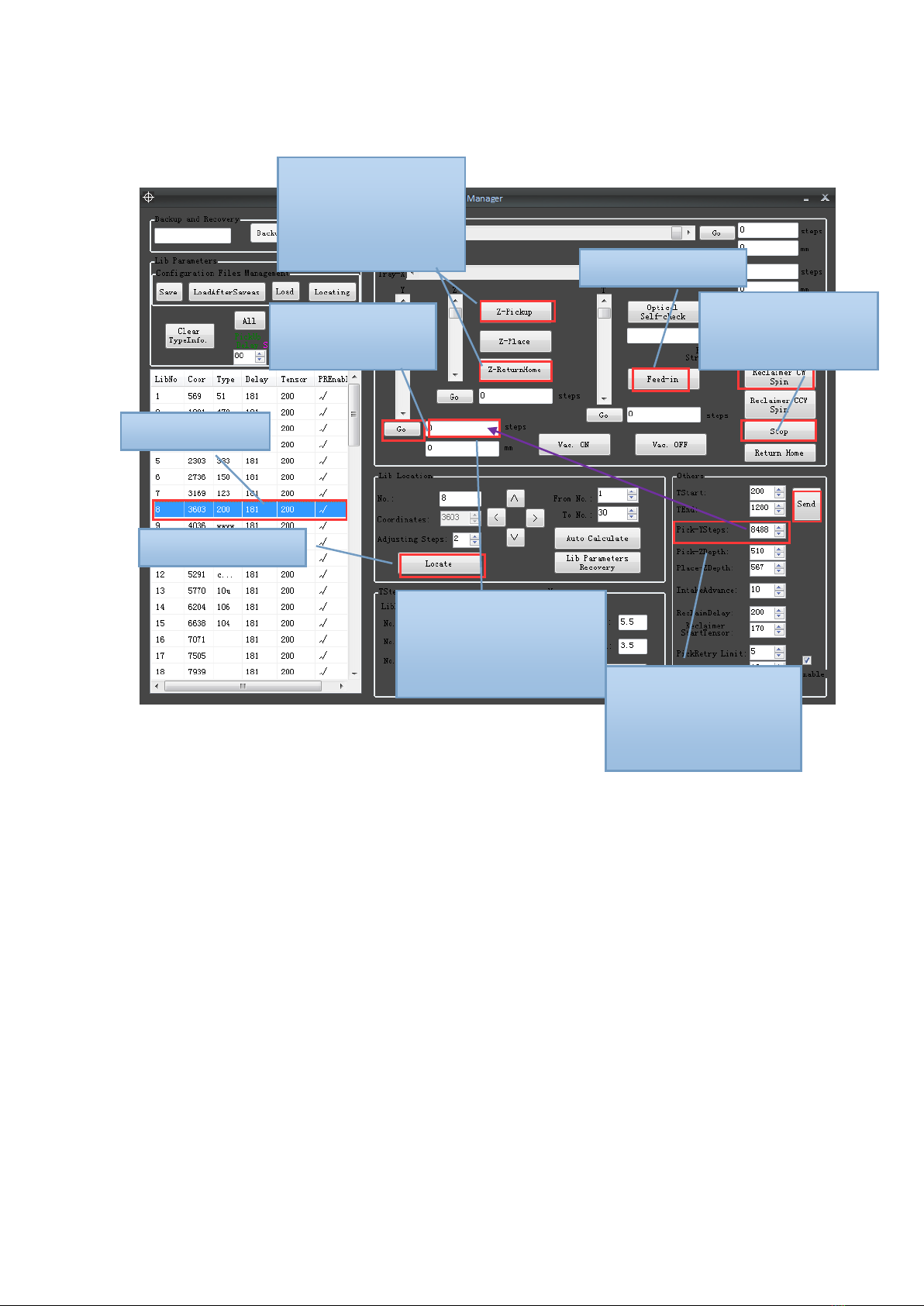

Unit Manager

1、Shelf Location

① Select Shelf

②click ―locate‖

③click ‖Z-pickup‖&

―Z-ReturnHome‖, see

the nozzle position on

chip

④adjust ―coordinates‖

⑤click ―locate‖,

repeat③④,until the

nozzle is in the centre

2、Pick-Y adjustment

MT-60 operation (not connect with computer)

Feeders in reserve

1. MT-60 has ten feeders in reserve.

⑧add/reduce the step

numbers, make sure the

nozzle in the centre of

chip

①Select Shelf

②click ―locate‖

③click ―Feed-in‖

④click ―Reclaimer

CW Spin‖ then ―Stop‖

⑤copy pick-ysteps

here ,then click “go”

⑦click ‖Z-pickup‖&

―Z-ReturnHome‖, see

the nozzle position on

chip

⑨Put the new step

numbers back to this

―Pick-YSteps‖, then

click ―send‖

Feeders

Main feeders number

Feeders in reserve number

8mm

9

49

10

50

11

51

12

52

13

53

14

54

15

55

16

56

12mm

31

33

32

34

2. Put same components at main feeder and feeder in reserve, when the

components at main feeder run out, MT-60 will continue to pick same

components from feeders in reserve.

Production (Pick and Place)

一、Turn on the power

二、Press to Offline operation ,press ,select placement file

三、press ,select file,press ,press ,check if nozzle is in the

center of reference point,if not,press adjust nozzle in the center,

press ,start mounting。

四、When mounting, press to stop mounting ,press continue

mounting,press return home。

If display ―blockage",please check machine as below.

State of machine

Operation

Run out of components

No

reserve

feeders

Change new components stack, then

press

Reserve

feeders

Press to continue place in

reserve feeder

There are still many

components.

Check whether there is something wrong with

machine, then press to continue

8mm/12mm/16mm Multi place

1. There are 2 models to mounting. They are multi and single to place.

In the multi model, It can be mounted 8/12/16mm once, not need to change

nuzzle.

In the single model, It need to change nuzzle.

2. The process of single model:

a. MT-60 will be pause when it

mounting all 8mm components, It will

move to open area at this time.

b. adjust bolt(8mm is in A,12mm is in

B,16mm is in C)

c. change the suitable nuzzle

d. press continue mounting.

Table of contents