1

Table of Contents

Introduction Safety Warnings and Notices

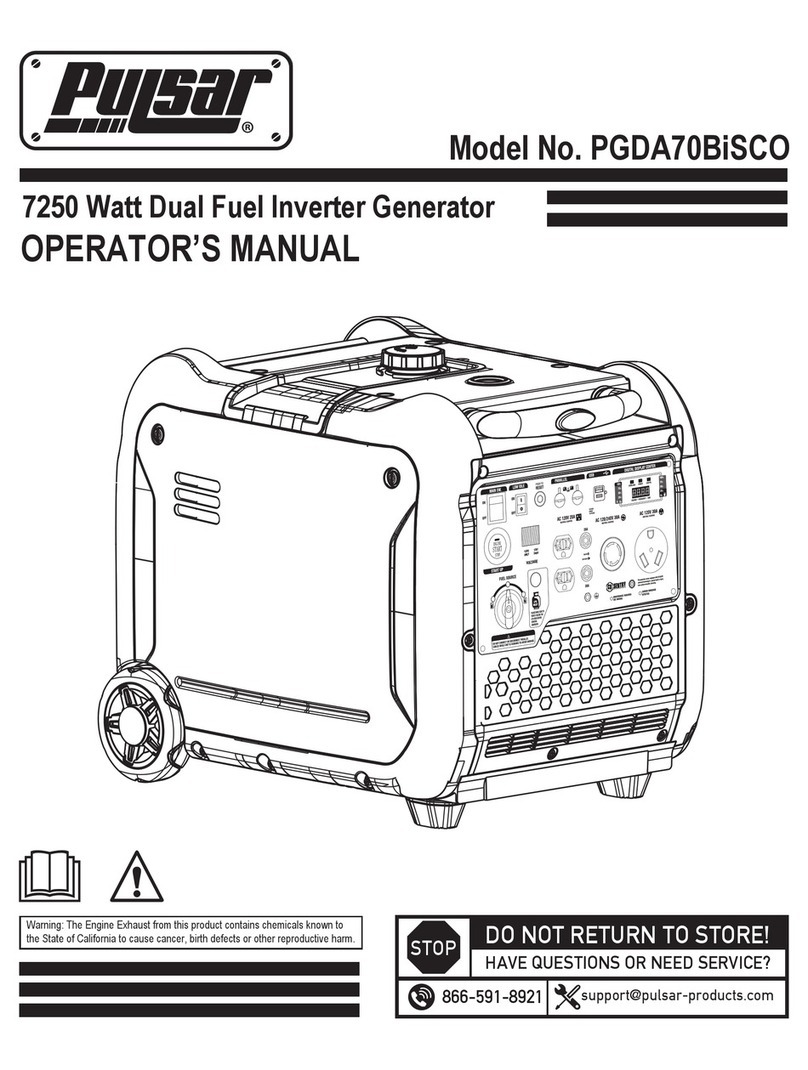

Thank you for choosing Pulsar Products!

This manual provides instruction on how to operate and use your

generator safely and correctly; be sure to read and understand

this manual before using your generator. If you have ANY

questions, please phone 866.591.8921 M-F or email

All details and images in this Operator’s Manual are believed to be

accurate at the time of publication.

Pulsar Products reserves the right to make updates to this manual

at any time.

Please contact Pulsar Support at 866.591.8921 M-F or email

This manual is a permanent part of the generator set. If the

generator is resold, kindly include this manual with the generator.

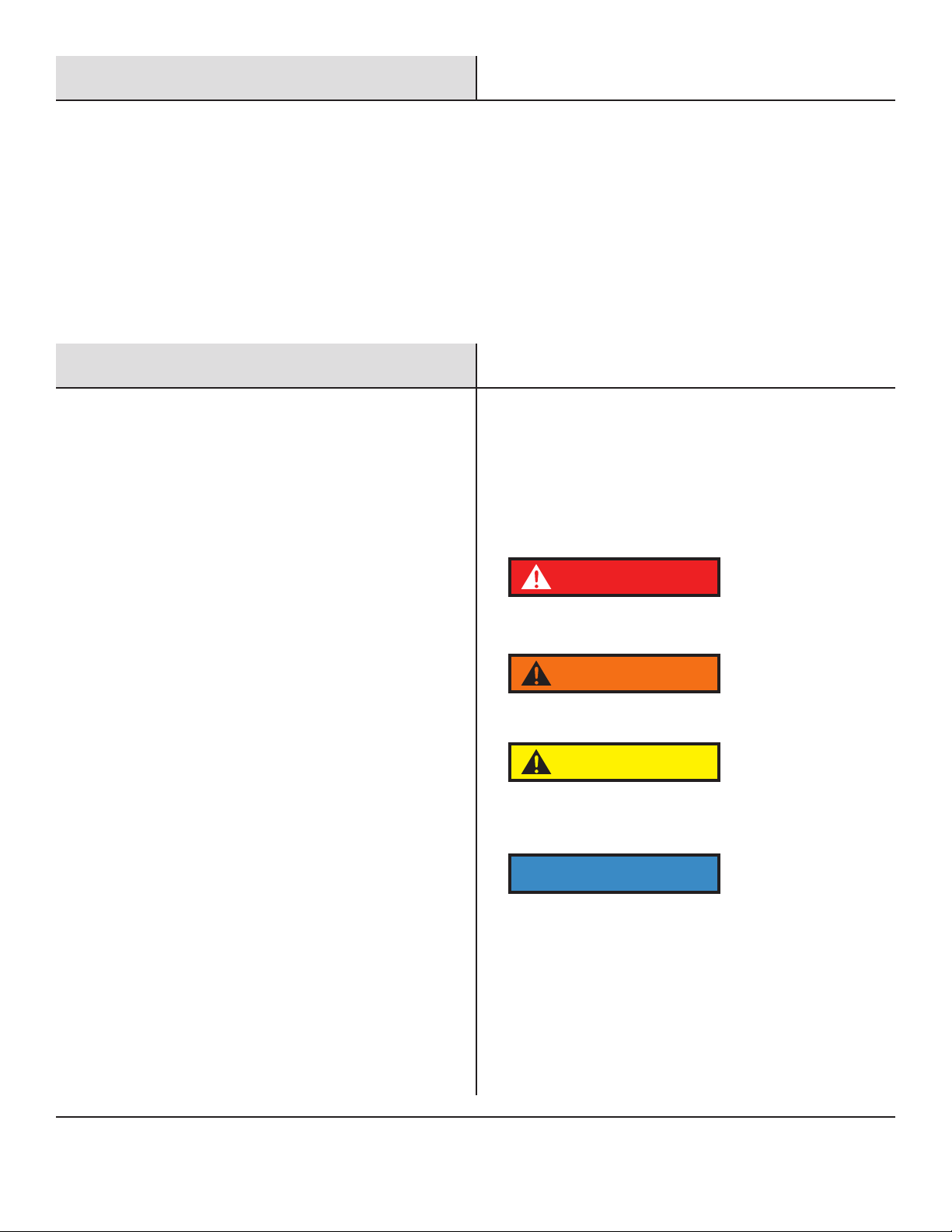

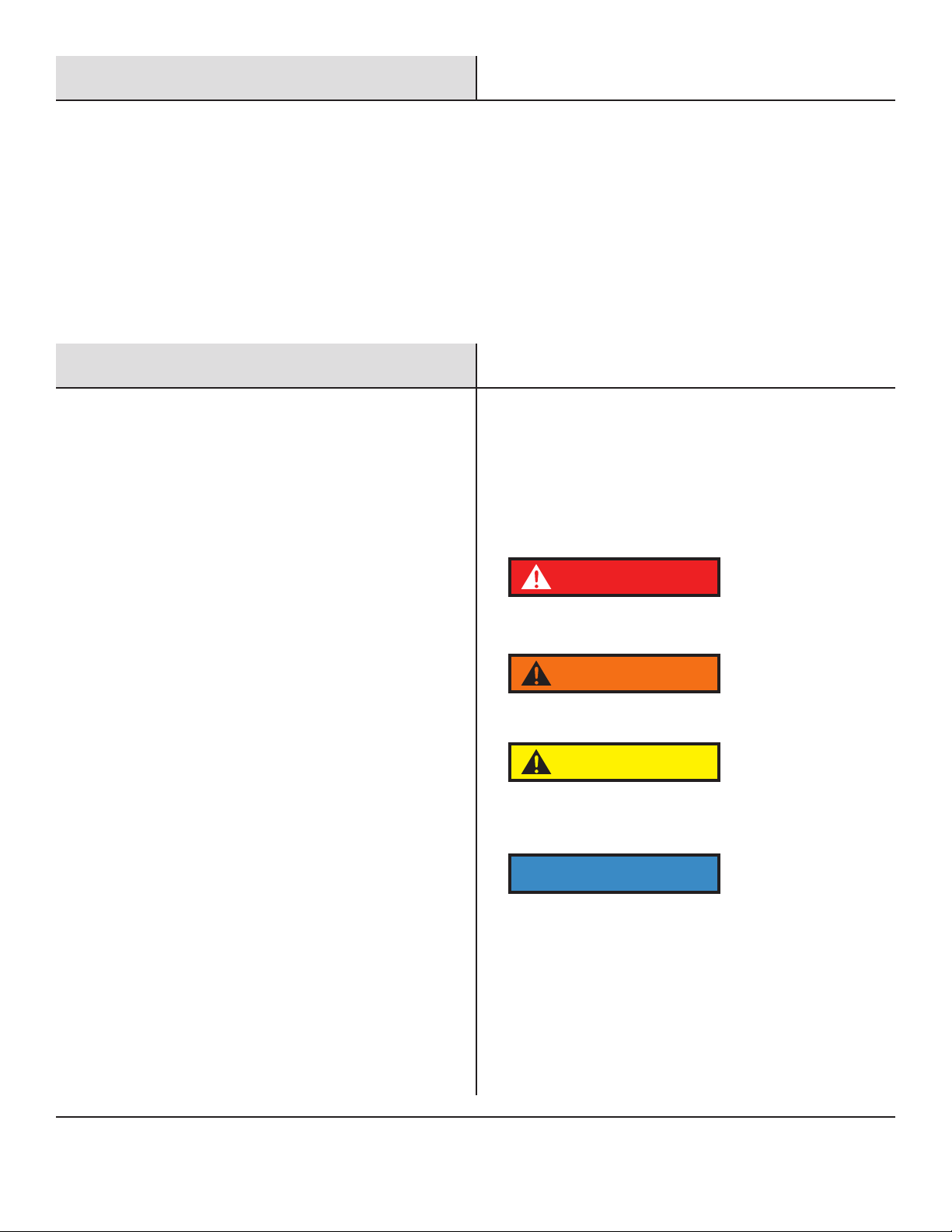

Throughout this manual and on generator decals you may see

one or more of the notices below. Safety Warnings alert you to

potential hazards that could cause death, injury, or damage to

property. The decals show one of four words "DANGER",

"WARNING", "CAUTION", and "NOTICE". Definitions are

as follows:

DANGER indicates an imminently hazardous situation which,

if not avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury. It

may also be used to alert against unsafe practices.

Failure to follow the instruction may result in the damage

to your generator and other property.

Safety Warning.........................1

Safety Instructions......................2

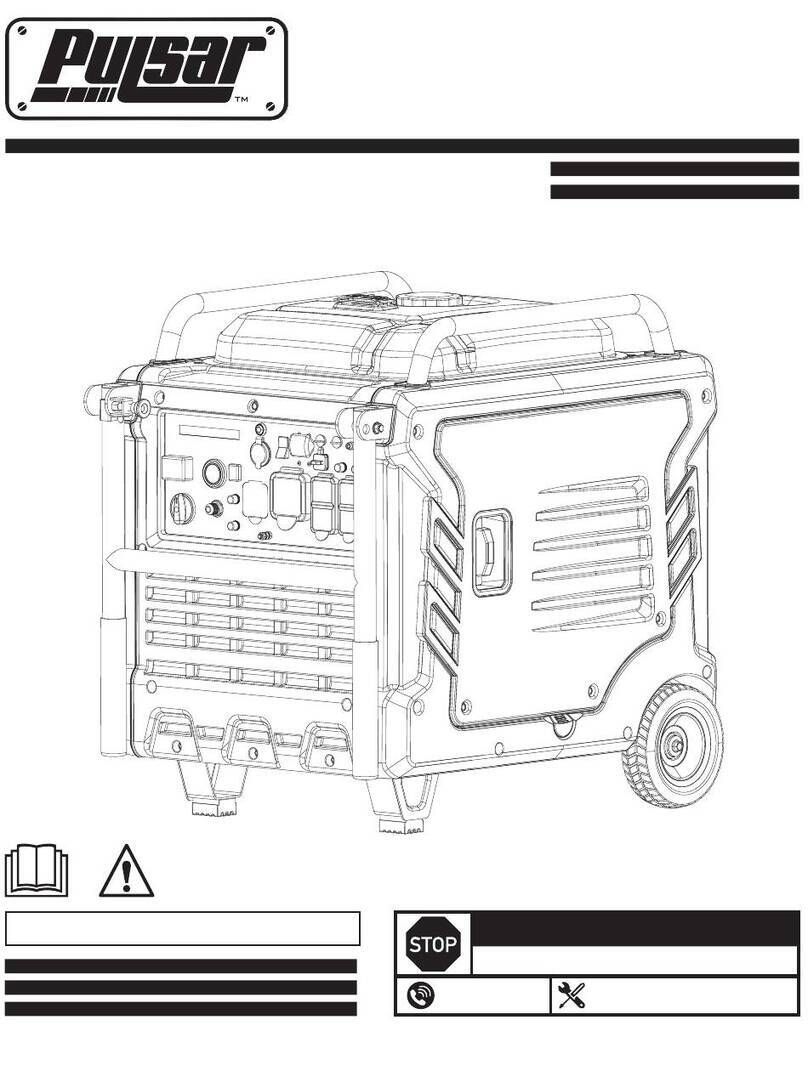

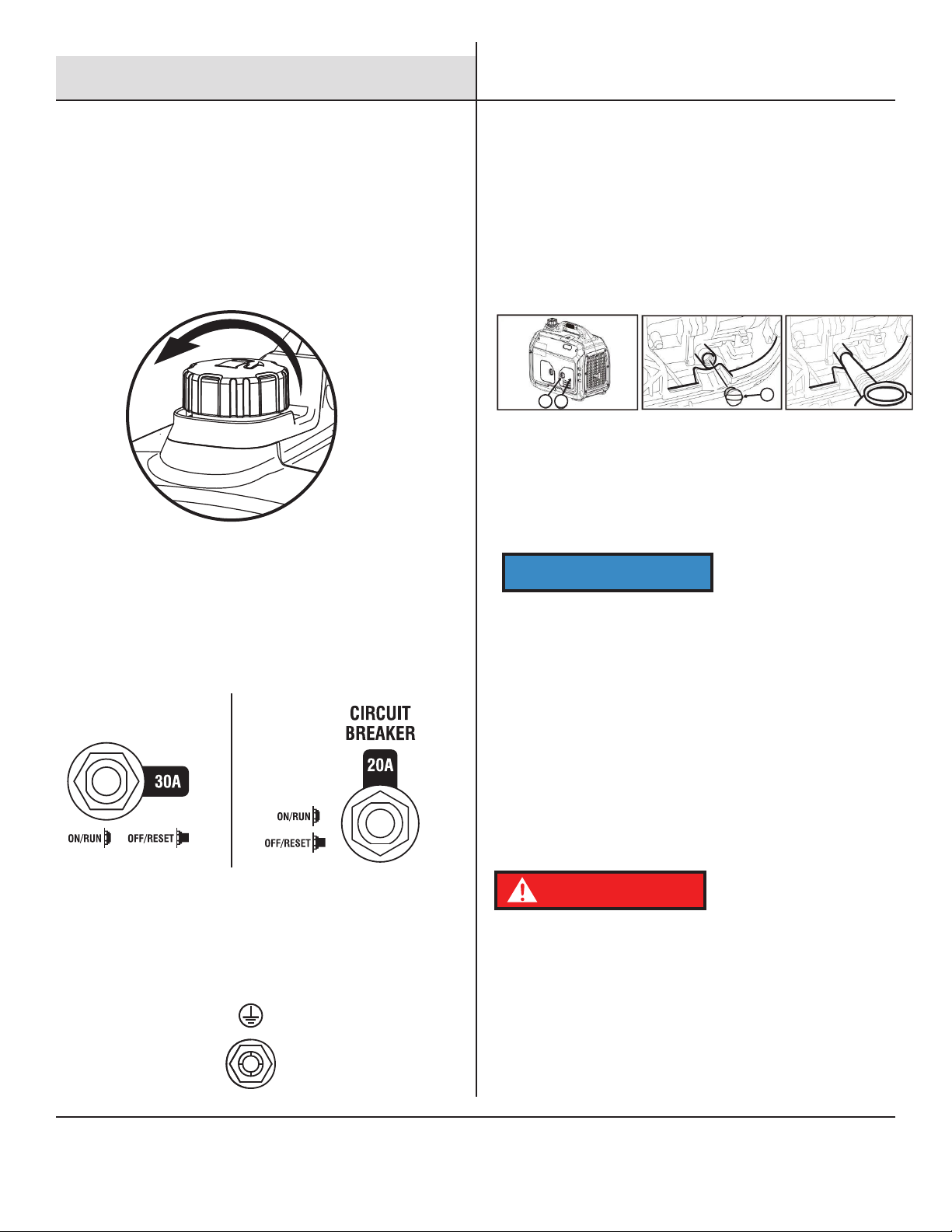

Names of Components...................3

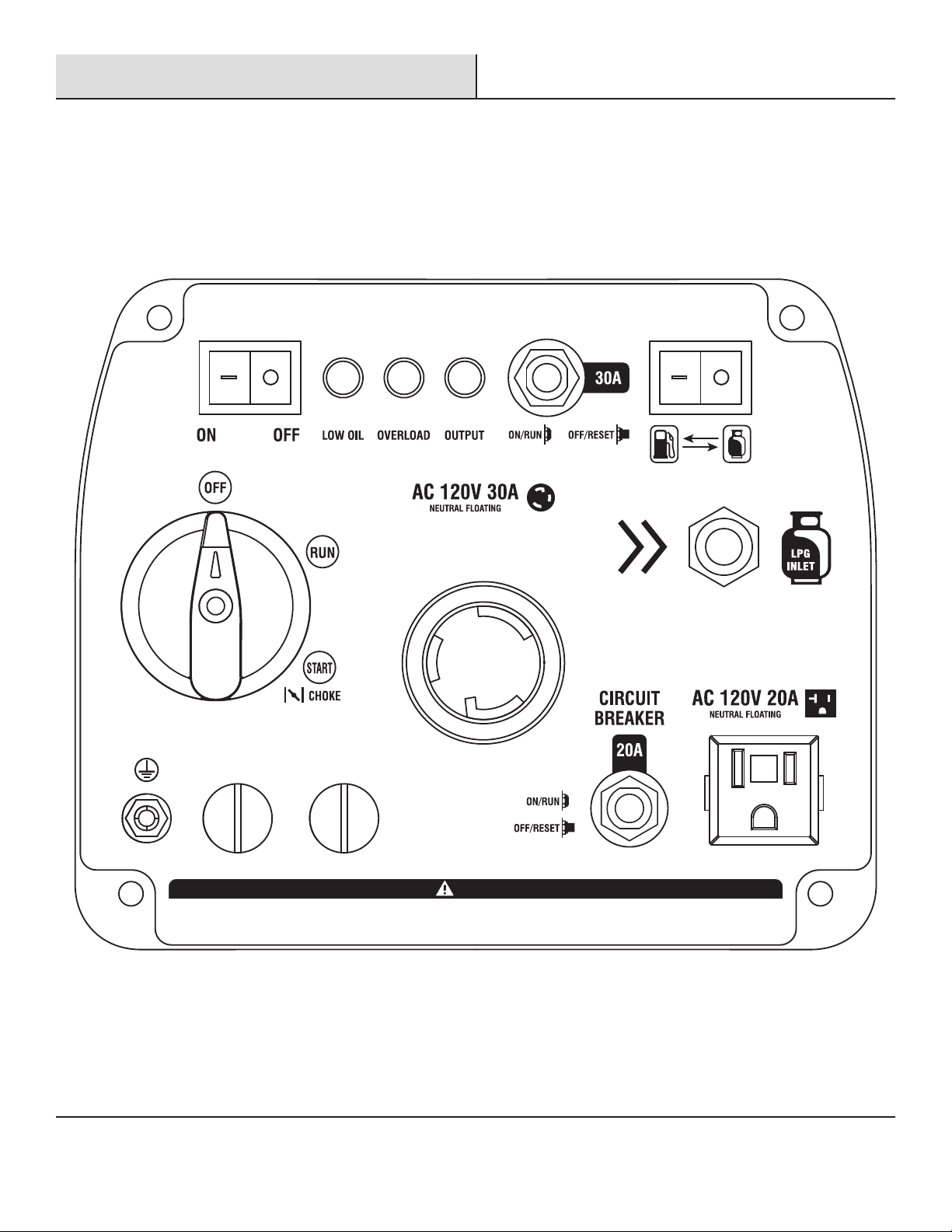

Control Panel ..........................4

Control Functions.......................5

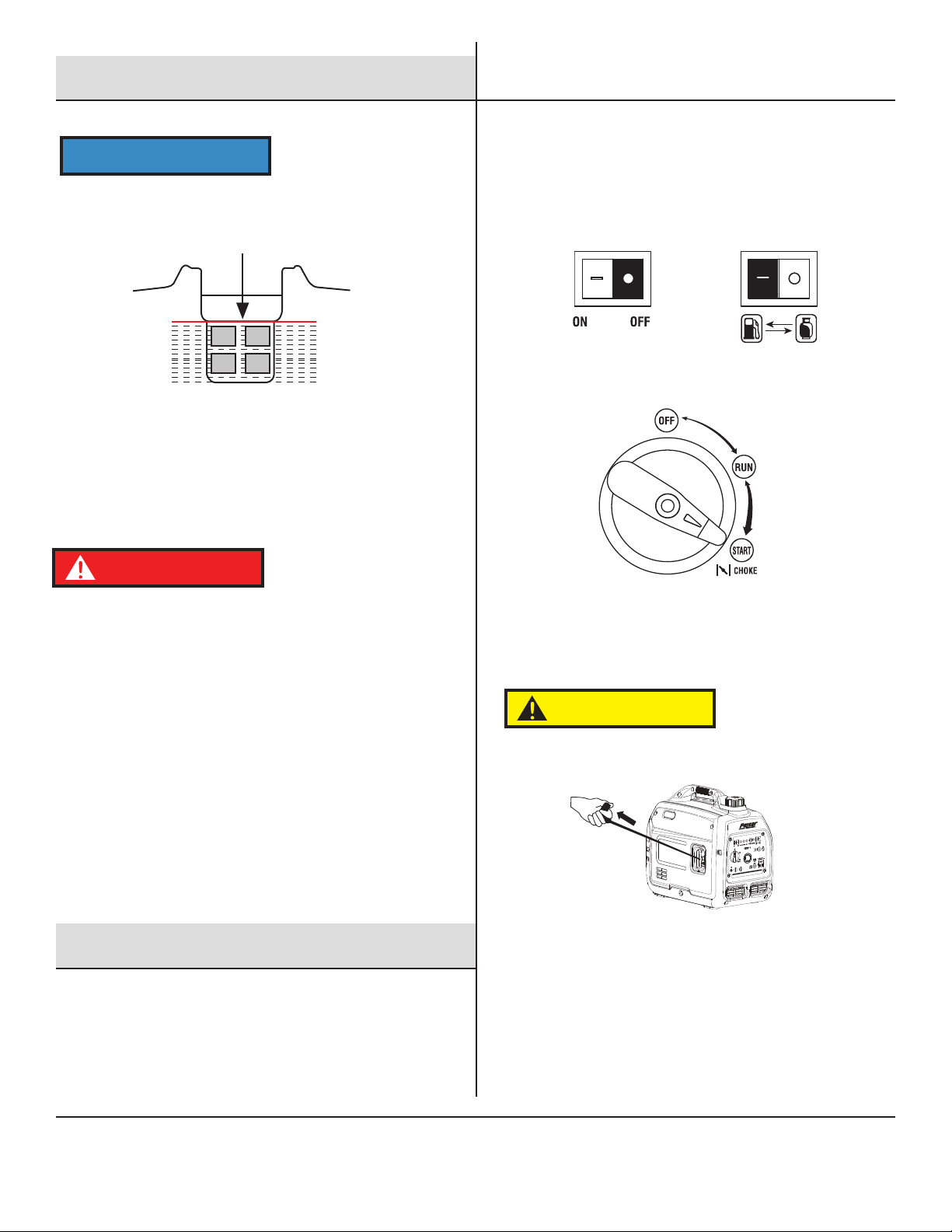

Preparing Your Generator.................6

Starting up the Generator.................7

Shutting Down the Generator .............10

Using the Generator.....................10

Service and Maintenance................ 11

Storage and Transport ................. 13

Troubleshooting....................... 14

Technical Parameters .................. 15

Electrical Schematic ................... 16

DANGER

WARNING

CAUTION

NOTICE