It is required to install an installation switch with a nominal current of 6 A in power supply circuits outside

power supply unit.

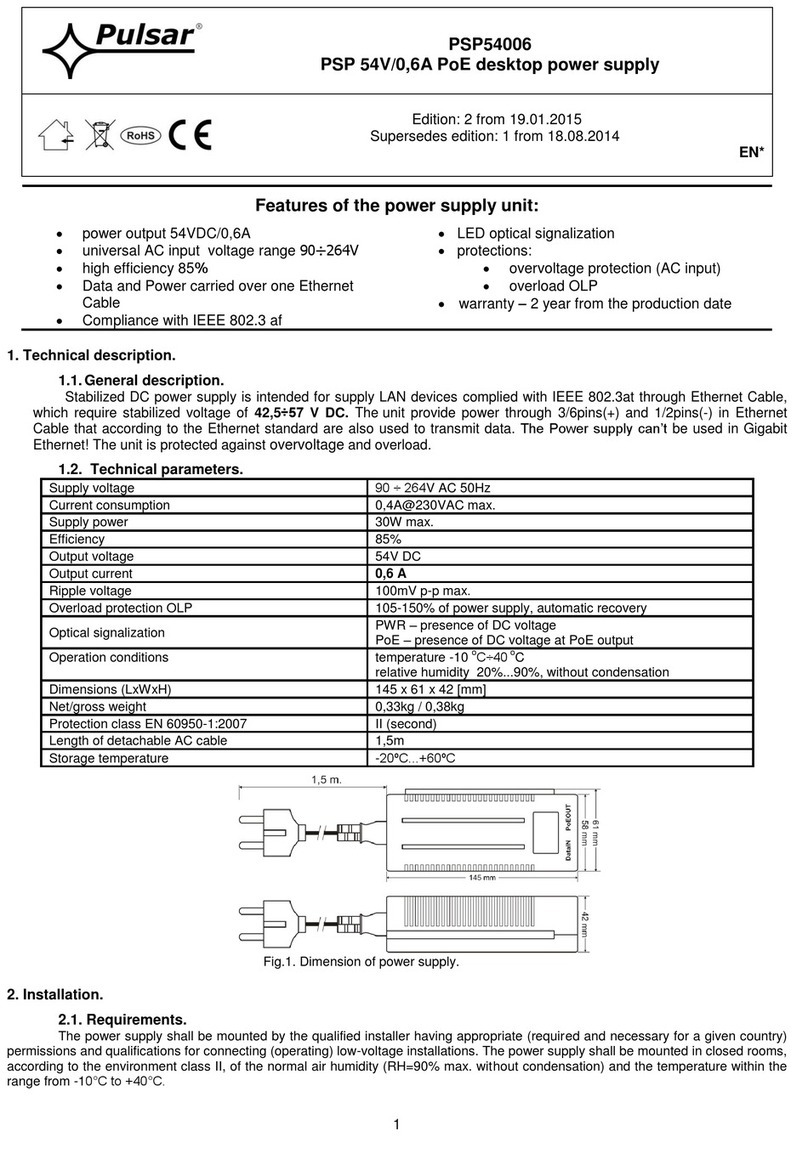

1. Mount the PSU in a selected location and connect the wires.

2. Connect power cables (~230 V) to L-N clips of PSU. Connect ground wire to clip marked by earth symbol . Use a

three-core cable (with a yellow and green protection wire) to make connection ). Lead the cables to the appropriate

clips through the insulating bushing of the PSU.

Shock protection circuit shall be done with a particular care: yellow and green wire coat of power cable

should be connected to terminal marked with the grounding symbol on PSU enclosure. Operation of PSU

without the properly made and fully operational shock protection circuit is UNACCEPTABLE! It can cause

damage to equipment or an electric shock.

3. Switch on 230 V supply. LEDs on power supply PCB should be ON.

4. Check output voltage and adjust if necessary using right potentiometer.

5. Disconnect the PSU from the mains and make the rest of the connections - connect wires to the AUX1...AUX4

connectors.

6. Once the tests and control operation have been completed, close the enclosure/cabinet.

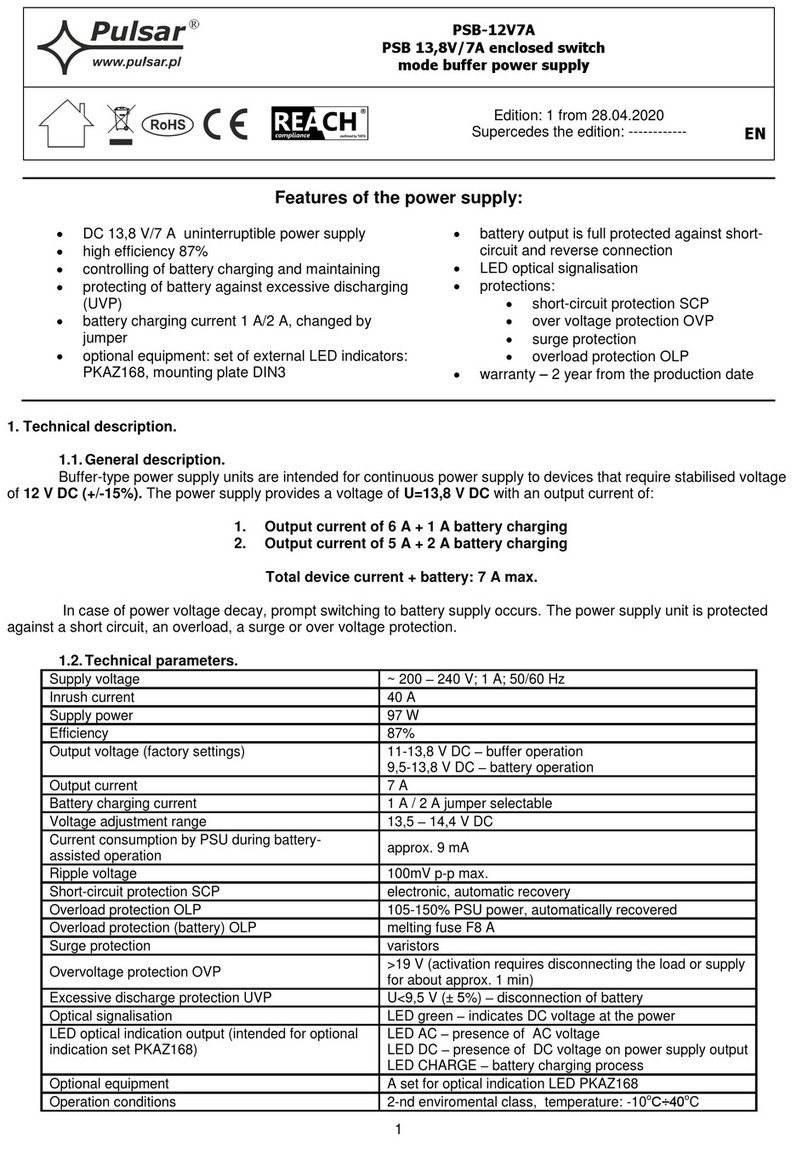

3. Operating status indication.

The power supply unit features LED status indication. Presence of voltage at each output of the PSU is indicated by the

green LED nearby each outputs fuse. Failure (fuse damage) is indicated by shutting down green LED nearby appropriate

outputs fuse on the PSU module.

4. Operation and use.

4.1. Overload or short circuit of the PSU module output.

The AUX1÷AUX4PSU outputs are protected against short circuit by glass fuses. Activation of the protection (glass fuse

blowing) is indicated by shutting down green LED nearby appropriate outputs fuse on the PSU module. In case of damage,

replace the fuse (compatible with the original).

4.2. Operation of the PSU OVP system.

If the OVP system is activated, the output voltage is automatically cut off. Operation is resumed automatically.

5. Maintenance.

Any and all maintenance operations may be performed following the disconnection of the PSU from the power

supply network. The PSU does not require performing any specific maintenance measures, however, in the case of

significant dust rate, its interior is recommended to be cleaned with compressed air.

WEEE MARK

According to the EU WEE Directive –It is required not to dispose of electric or electronic waste as

unsorted municipal waste and to collect such WEEE separately

Pulsar sp. j.

Siedlec 150, 32-744 Łapczyca, Poland

Tel. (+48) 14-610-19-40, Fax. (+48) 14-610-19-50

http:// www.pulsar.pl, www.zasilacze.pl