2

1Contents

1CONTENTS..................................................................................................................................2

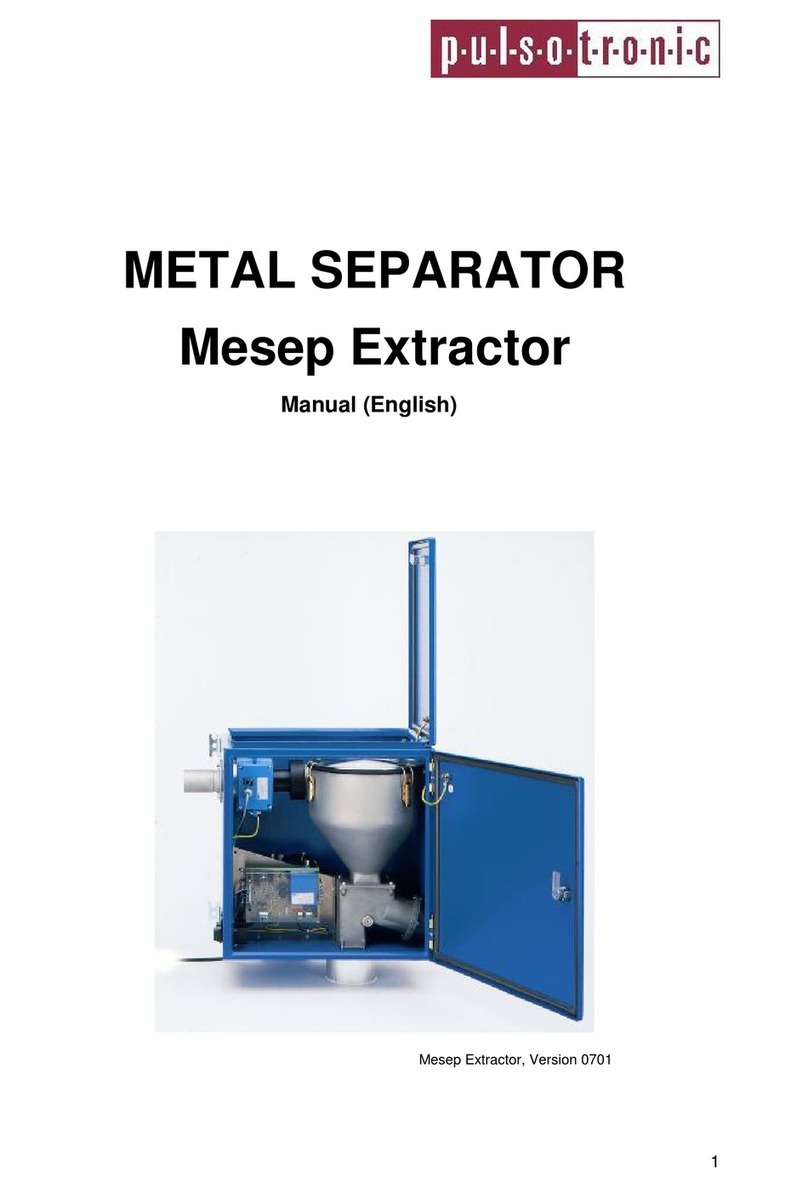

2GENERAL....................................................................................................................................3

2.1 INSTRUCTIONS FOR USE OFTHIS MANUAL..............................................................................3

2.2 GENERAL SAFETY INSTRUCTIONS...........................................................................................4

2.2.1 Explanation of the Symbols Used......................................................................................4

2.2.1 BASIC SAFETY MEASURES......................................................................................................5

3APPLICATION AND QUALIFICATION................................................................................6

3.1 USE FOR INTENDED PURPOSE..................................................................................................6

3.2 EXAMPLES OF APPLICATION ...................................................................................................7

3.3 OPERATING PRINCIPLE............................................................................................................7

3.3 MISUSE...................................................................................................................................7

3.4 OWNERS DUTY OF CARE.........................................................................................................8

3.5 FUNCTION .....................................................................................................................................8

3.5.1 Keypad...................................................................................................................................8

3.5.2 Key Functions......................................................................................................................10

3.5.3 Selection of Operation Variants..........................................................................................11

3.6 SENSITIVITY TABLE.....................................................................................................................12

3.7 THESEPARATINGDRUM ..............................................................................................................13

4OPERATING INSTRUCTIONS FOR THE METAL SEPARATORS................................14

4.1 Erection Instructions.......................................................................................................14

4.2 Connection Instructions..................................................................................................14

4.3 Operation Instructions....................................................................................................15

4.4 Failure Protection of the Metal Separator......................................................................15

5TECHNICAL CHARACTERISTICS......................................................................................16

6TECHNICAL DESCRIPTION.................................................................................................17

6.1 FRONT PLATE........................................................................................................................17

6.2 SELECTION OF OPERATION VARIANTS..................................................................................18

6.3 NOTES FOR THE VALUES OFSENSITIVITY ..............................................................................19

6.4 SORTING GATE .....................................................................................................................19

6.5 FUNCTION AND LIMITATIONS ................................................................................................19

6.5 PRODUCT EFFECTS - DISTURBING PRODUCT PROPERTIES.....................................................20

7. TRANSPORT.............................................................................................................................22

7.2 SAFETY INSTRUCTIONS FOR TRANSPORT AND ERECTION ......................................................22

8INSTRUCTIONS FOR ERECTION........................................................................................22

8.1 ERECTION AIDS ....................................................................................................................22

8.2 CONNECTORS........................................................................................................................23

8.3 SAMPLE OFAPPLICATION ......................................................................................................24

8.4 ELECTRICAL CONNECTION....................................................................................................25

8.5 PRINTED CIRCUIT BOARD .....................................................................................................28

8.6 FACTORY SETUP ...................................................................................................................29

8.7 QUICK REFERENCE ...............................................................................................................29

9. MAINTENANCE.......................................................................................................................30

9.1. GENERAL MAINTENANCE .....................................................................................................30

9.1.1 Repairs and Wearing parts - Important Notice...................................................................31

9.1.2 Removal of the Laminated-Paper Protective Tube..............................................................32

9.2 REGULAR INSPECTIONS.........................................................................................................32