5

Location

The location selected must provide for electrical service,

cold or hot water supply, and sanitary drain.

When selecting a location, try to keep the humidifier

within 10 feet (305 cm) of the duct to avoid unnecessary

heat losses, condensation within the steam supply line

and excessive pressure buildup in the reservoir.

Visible “fog” will saturate and condense when it contacts

objects such as turning vanes, filters, fans, elbows, or

take-offs. The warmer the air, the more easily it will

dissipate the visible steam. The most active and warmest

portion of the duct will provide better mixing of the steam

and air. The injection tube should be mounted a

minimum of 2 feet (61 cm) downstream from an elbow or

other uneven air flow area.

Avoid mounting single-style injection tube(s) closer than 8

-10 feet (244-305 cm) upstream of objects that could

become saturated and condense the steam (reference

paragraph above). If the duct layout does not provide a

straight, unobstructed run of 8-10 feet (244-305 cm), a

multiple injection tube system should be considered to

reduce the visible steam travel distance.

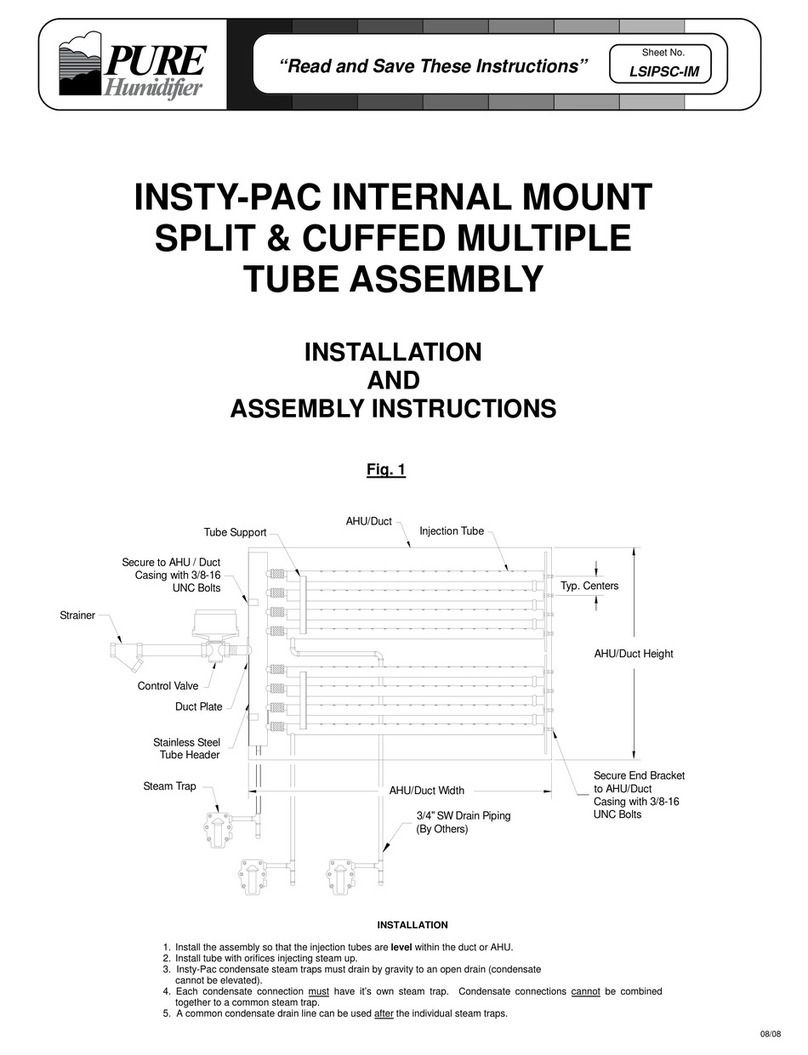

For Fast-Pac and Insty-Pac multiple tube assemblies

please consult factory for job specific non-wetting

distances.

Reference Fast-Pac or Insty-Pac O&M’s for full

installation details.

CAUTION: Do not humidify upstream of filters. Consult

factory.

CAUTION: Smoke detectors should not be located

downstream of injection tube assemblies.

Location of Control Sensors

It is important to avoid mounting any control sensors

within the visible steam. The control sensors should be

mounted a minimum of 8-10 feet (244-305 cm)

downstream from the humidifier injection tube. Due to the

temperature rise that exists within the visible steam

dissipation area, thermostats should not be mounted near

the injection tube. High-limit humidistats should be

installed before any duct obstruction to make sure the

humidifier is interrupted before saturation can occur on

the object. The high-limit should be mounted a minimum

of 8-10 feet (244-305 cm) downstream from the injection

tube. Installing the high-limit closer than 8 feet (244 cm)

from the humidifier may cause erratic control.

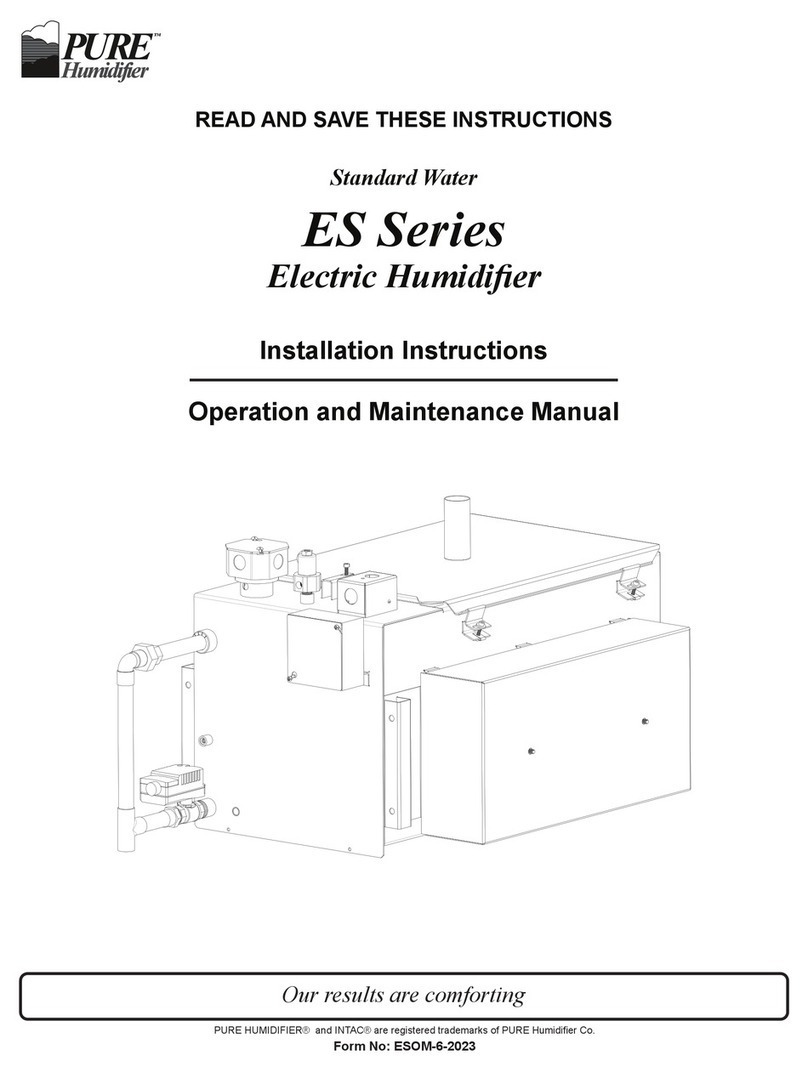

Mounting

Mounted from the wall. The humidifier should be mounted

dead level in both directions. PURE Humidifier Co.

supplies the wall mounting bracket. Bracket is mounted to

wall studs first. The bracket must be mounted to wall

studs or additional support must be provided in the field.

ECDDR cabinet is then hung on the slip-fit bracket.

Drain Pan Mounting

A drain pan is an additional safety feature which may be

required to be supplied in the field. In a proper humidifier

installation, a drain pan is not required. However, if the

humidifier and injection tube are located in an area that

contains valuable equipment or is a water sensitive area,

PURE Humidifier Co. recommends the addition of a drain

pan under the humidifier and under the injection tube. The

drain pan should extend past all edges of the humidifier

and if installed in the duct, it should extend a minimum of 3

feet (91 cm) downstream from the injection tube. The pan

should be of a size which is sufficient to retain sudden

drainage of the humidifier’s contents. The pan should be

drained to a sanitary drain.

Injection Tube Installation

Single tube units should have the injection tube installed in

the center of the duct. Multiple tube units should have the

tubes staggered within the duct. See Injection Tube and

Flexible Hose Installation on page 8 for details.

Injection tube should be pitched 2 inches (5 cm) per foot

(31 cm), back to the humidifier. If proper pitch cannot be

maintained, or the injection tube is mounted lower than the

humidifier, a drain “tee” will be required.

Install the tube with the steam ports injecting steam up.

NOTE: If narrow ducts (6”/15 cm or less, in height) are

utilized, install the tube with the steam ports injecting with

the air flow slightly (2 o’clock position).

Galvanized steel duct plates are provided to seal the

opening where the tube enters the duct.

Multiple Injection Tube Assemblies

See page 9 for details.

Location & Mounting