© Pure Processing, Inc. 2015. All rights reserved. FlexiPump™Independent Flushing System User Manual; April 2015

OPERATION (continued)

Set-up: tube sets

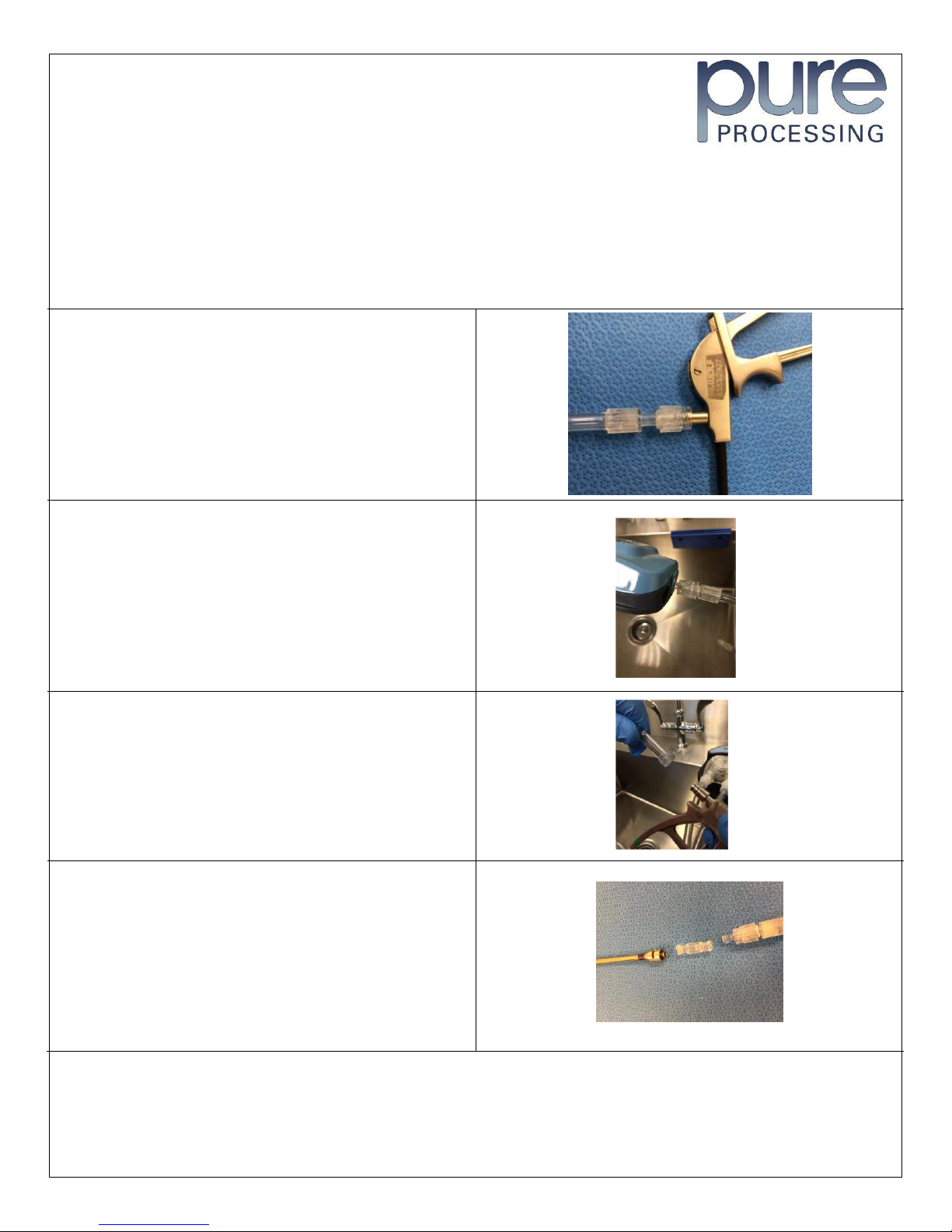

The drop-down tube on each new tube set is 30 inches long. If the tube is too long for your sink, it can be cut

to shorten it. If you cannot position it so it is submerged under the cleaning solution, use a tissue clip or other

medical device to add weight and rest it at the bottom of the sink where solution is drawn from. A ceramic

weight can also be purchased from Pure Processing.

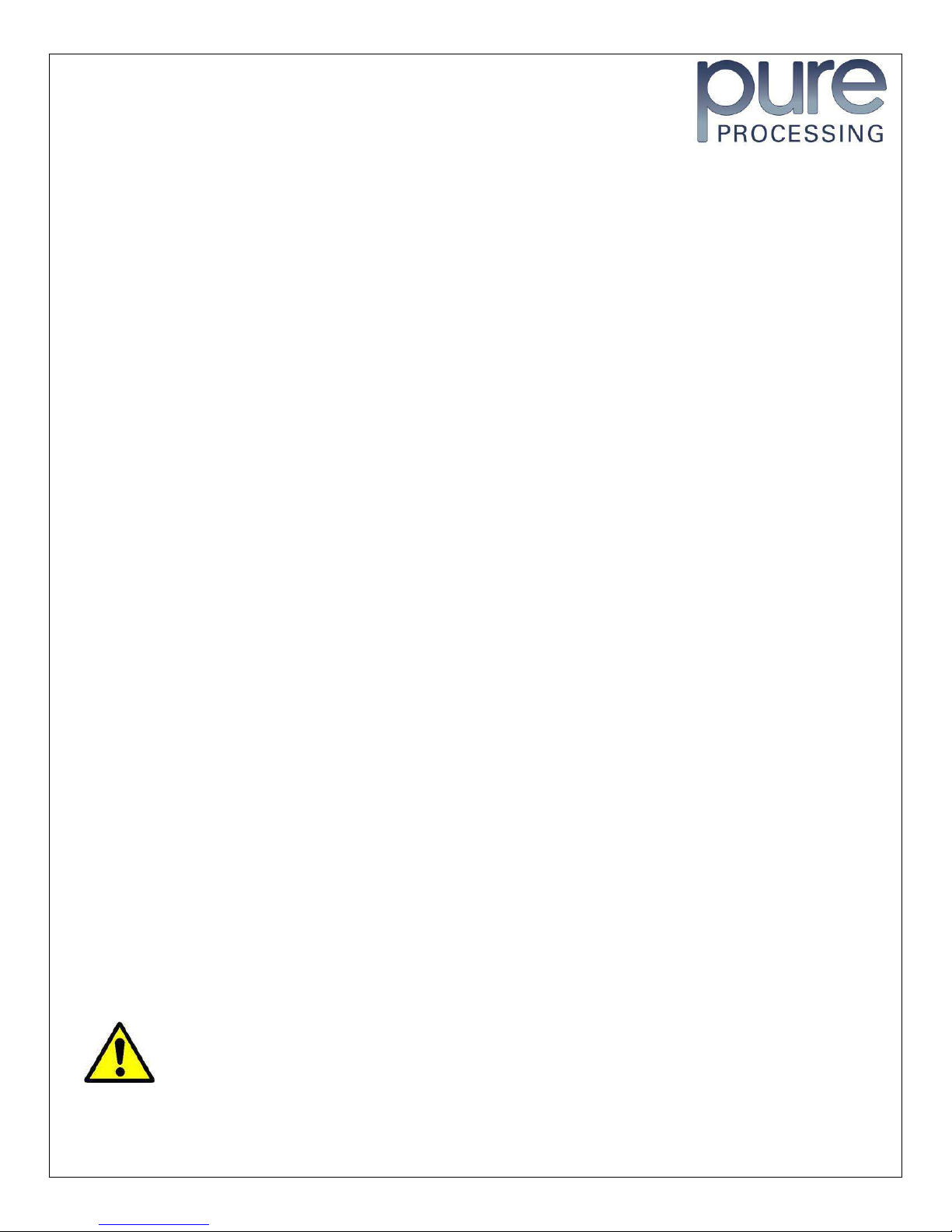

Each FlexiPump tube set comes with three (3) leads, each of which can be attached to an instrument. You

can use all three at once. If you have fewer than three devices to flush, you can cap off the unused lead(s) to

ensure appropriate pressure into the lead(s) with attached devices. Use the luer end cap provided with your

tube set. You may also re-use end caps from other FlexiPump tube sets.

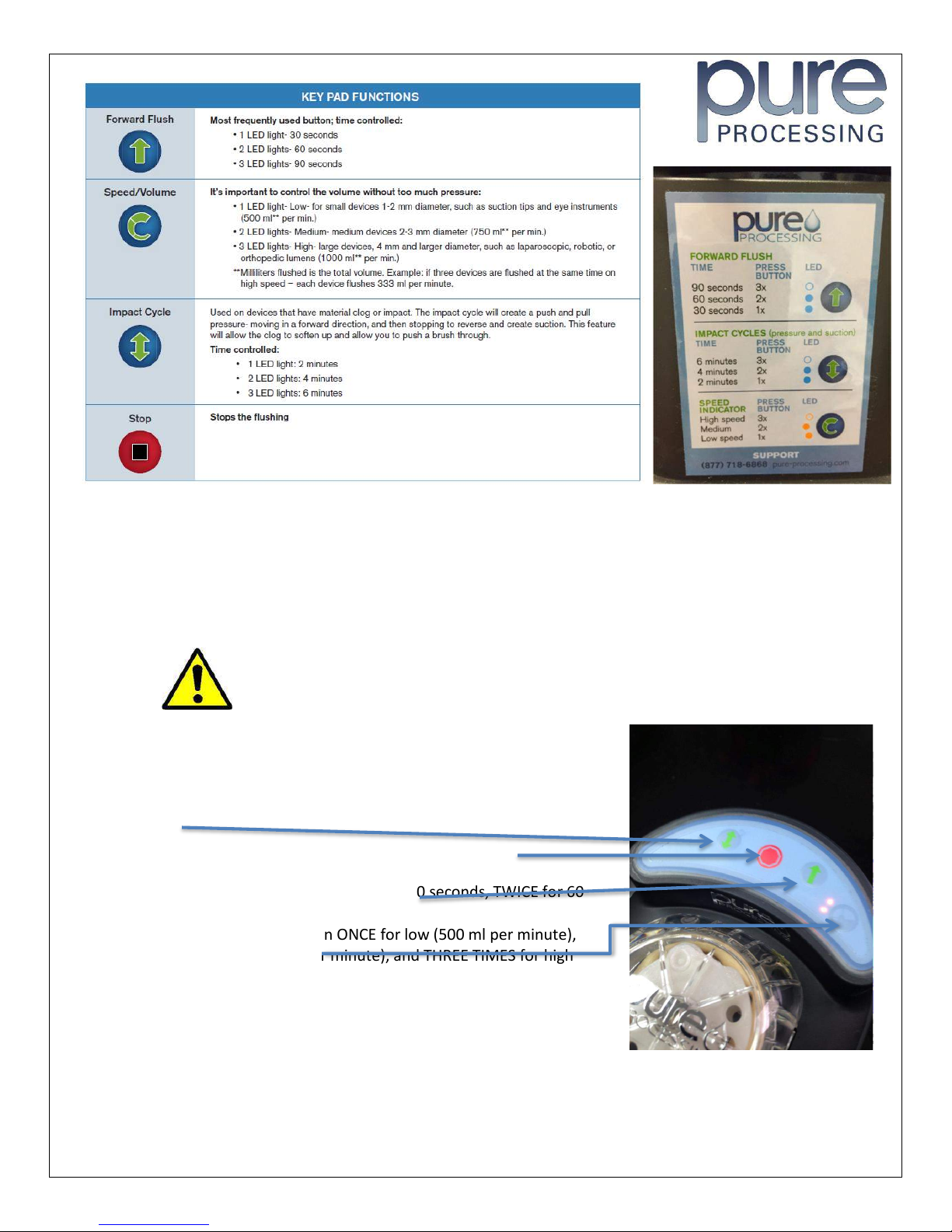

General guidelines for speed control

Because fluid will take the path of least resistance, it is important that instrument channels attached to a

FlexiPump system are approximately the same diameter, to assure consistent flushing into all the devices.

DO NOT ATTACH A LARGE-DIAMETER LUMEN TO ONE LEAD AND A SMALL-DIAMETER LUMEN TO ANOTHER

ON THE SAME PUMP SYSTEM.

Low speed: this setting is designed for small channels, 1 to 3 millimeters (mm) in size. This setting

will flush 500 milliliters (ml) of fluid in one minute into all three channels (166 ml through each

lead). DO NOT TURN UP THE SPEED when you hear the motor slowing down. The smaller channels

cannot accommodate any higher flow volume. Trying to force it to go faster will cause back up in

the motor and will make the pressure release valve drain fluid.

Medium speed: This setting is designed for channels that are 2 to 3 mm in diameter. This setting

will flush 750 ml of fluid in one minute into all three channels (250 ml through each lead). DO NOT

TURN UP THE SPEED if you hear the motor slowing down. However, if there is fluid draining from

the pressure relief valve, you can consider slowing the pump speed.

High Speed: This setting will flush 1,000 ml of fluid in one minute into all three channels (333 ml

through each lead). This is used for channels larger than 4 mm in diameter.

Too much pressure and speed for small devices can result in tube set damage.