Speeds

Low speed

This setting is designed for small channels, 1 to 3 millimeters (mm) in size. This

setting will flush a total of 200 mL of fluid in 30 seconds. Do not turn up the

speed when you hear the motor slowing down. The smaller channels cannot

accommodate any higher flow volume. Trying to force it to go faster will cause a

back-up in the motor and will make the pressure release valve drain fluid.

Medium speed

This setting is designed for channels that are 2 to 3 mm in diameter. This setting

will flush a total of 375 mL of fluid in 30 seconds. Do not turn up the speed if you

hear the motor slowing down. However, if there is fluid draining from the pressure

relief valve, you can consider slowing the pump speed.

High Speed

This setting will flush a total of 500 mL of fluid in 30 seconds. This is used for

channels larger than 4 mm in diameter.

FlexiPump™ Independent Flushing System User Manual © Pure Processing, LLC. 2023. All rights reserved.

6

Too much pressure and speed

for small devices can result in

tube set damage.

Because fluid will take the path of least resistance, it is important that instrument channels attached to a FlexiPump

system are approximately the same diameter, to assure consistent flushing into all the devices. For this reason, do

not attach a large-diameter lumen to one lead and a small-diameter lumen to another on the same pump system.

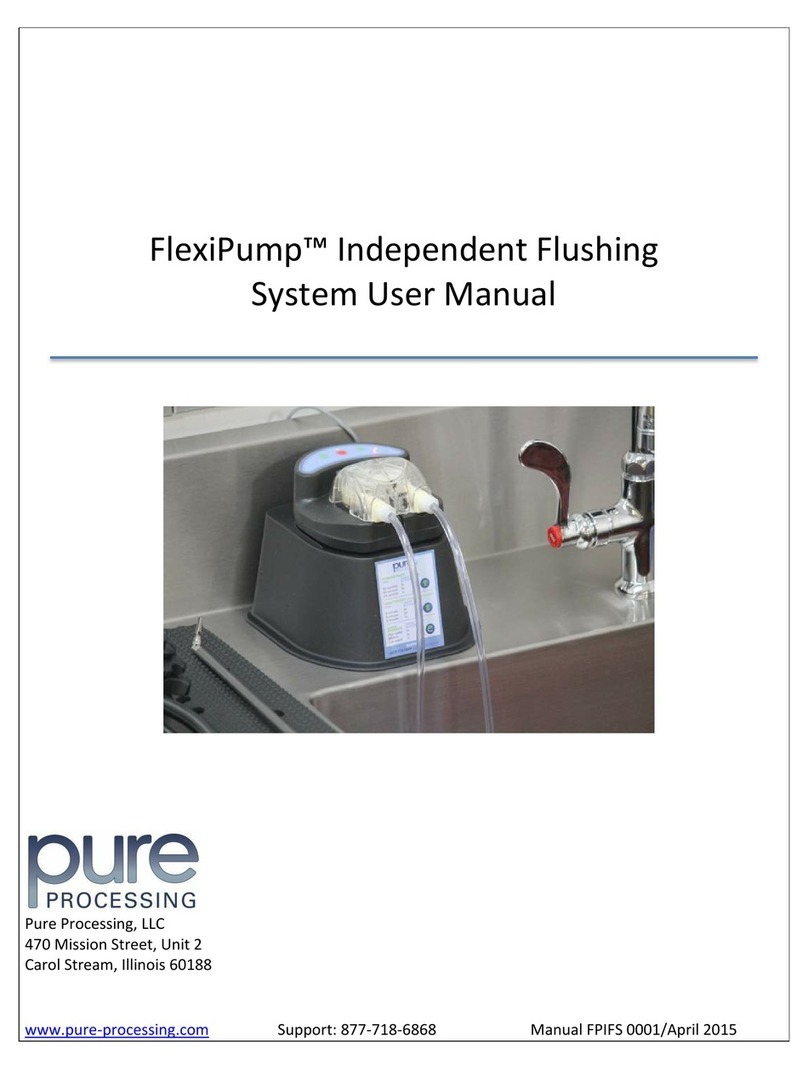

OPERATION

Keypad Settings

Key Pad Operation

Speed Control

Push the button ONCE for low (500 ml per minute), TWICE for

medium (750 ml per minute), and THREE TIMES for high speed

(1,000 ml per minute).

Forward Flush

Press the button ONCE for 30 seconds, TWICE for 60 seconds

and THREE TIMES for 90 seconds.

Stop

Press to stop all pump action and cancel any cycle.

Impact

Press for clogged devices. Press the button ONCE for two (2)

minutes, TWICE for four (4) minutes, and THREE TIMES for six

(6) minutes.

For a video demonstration, visit our

YouTube page at:

youtube.com/user/pureprocessing