PUREGAS INSTRUCTION MANUAL

MODEL P05860-GLTG

TABLE OF CONTENTS

SECTION 1 -GENERAL .............................................................................................1

SECTION 2 - INSPECTION AND INSTALLATION..............................................2

2.1 Initial Inspection................................................................................... 2

2.2 Installation............................................................................................. 2

2.3 Electrical Requirements....................................................................... 2

SECTION 3 - PRINCIPLES OF OPERATION........................................................3

3.1 Air System ............................................................................................. 3

3.2 Air Compressor..................................................................................... 3

3.3 Pressure Switch, and Safety Relief Valve........................................... 3

3.4 Air Buffering Dryer.............................................................................. 3

3.5 Manual Drain Valve ............................................................................. 3

3.6 Water Drain Instructions..................................................................... 3

SECTION 4 - GENERAL MAINTENANCE.............................................................4

4.1 Nitrogen Bottle Replacement Module................................................. 4

4.2 Air Compressor Safety Valve.............................................................. 5

4.3 Air Compressor Pressure Switch........................................................ 5

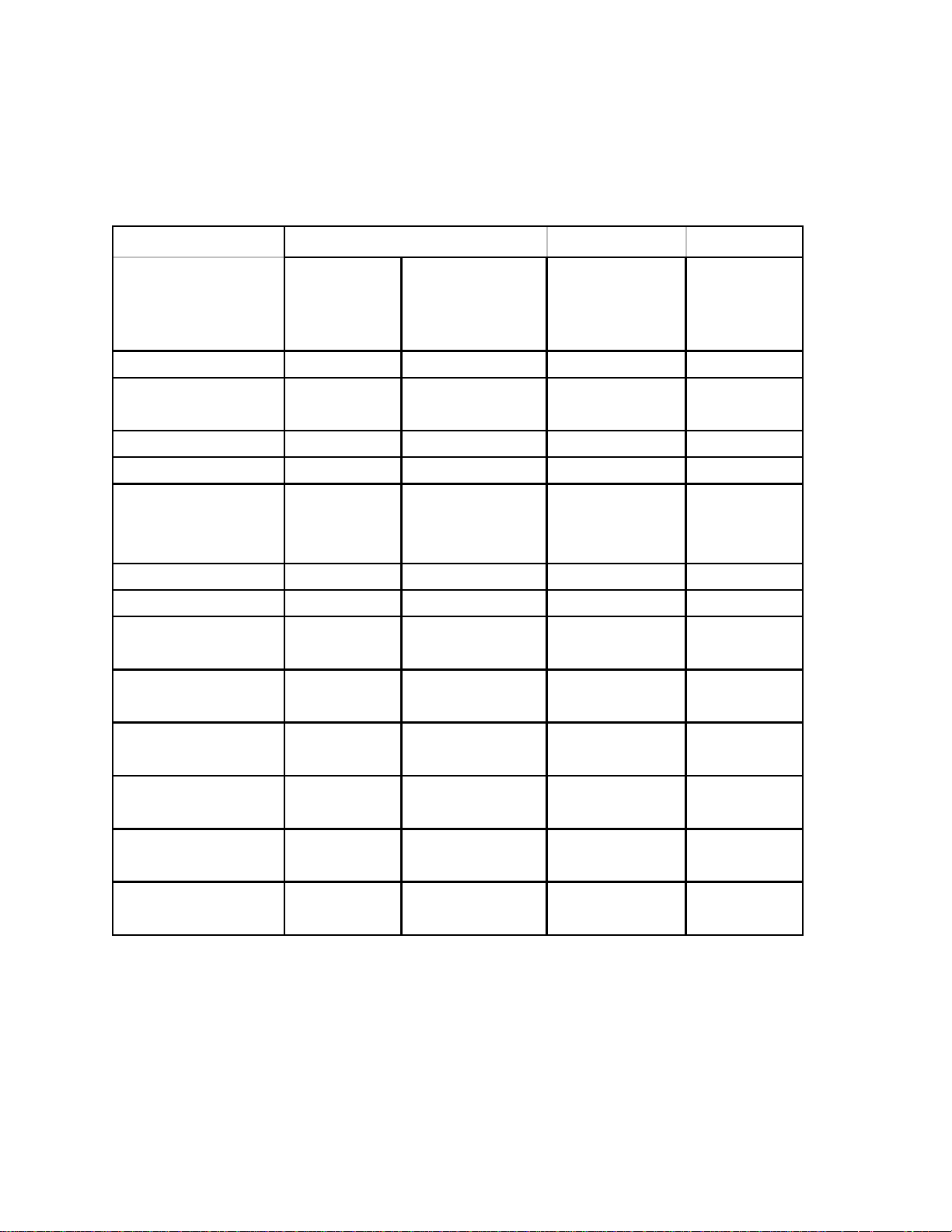

4.4 Air Compressor Troublshooting Chart.............................................. 6

4.5 Air Compressor Maintenance ............................................................. 7

4.6 Air Compressor Disassembly............................................................... 8

4.7 Air Compressor Assembly................................................................... 8

4.7 Air Compressor Assembly (continued)............................................... 9

4.8 Air Buffering Dryer.............................................................................. 9

4.9 Recommended Spare Parts List............................................................ 9

SECTION 5 – TROUBLESHOOTING INFORMATION GUIDE.......................13

FIGURES

WIRING DIAGRAM ...........................................................................................2

FLOW DIAGRAM ...............................................................................................4

AIR COMPRESSOR PRESSURE SWITCH ....................................................5

EXPLODED VIEW OF COMPRESSOR AND MOTOR ASSEMBLY.........10

AIR DRYER..........................................................................................................11

NBRM PARTS IDENTIFICATION...................................................................12

CHARTS

MODULE SPECIFICATIONS............................................................................1

AIR COMPRESSOR TROUBLESHOOTING CHART..................................6