5

P: 479.419.4800 | F: 479.419.4801 | www.purkeys.net

TAPS INSTALLATION GUIDE

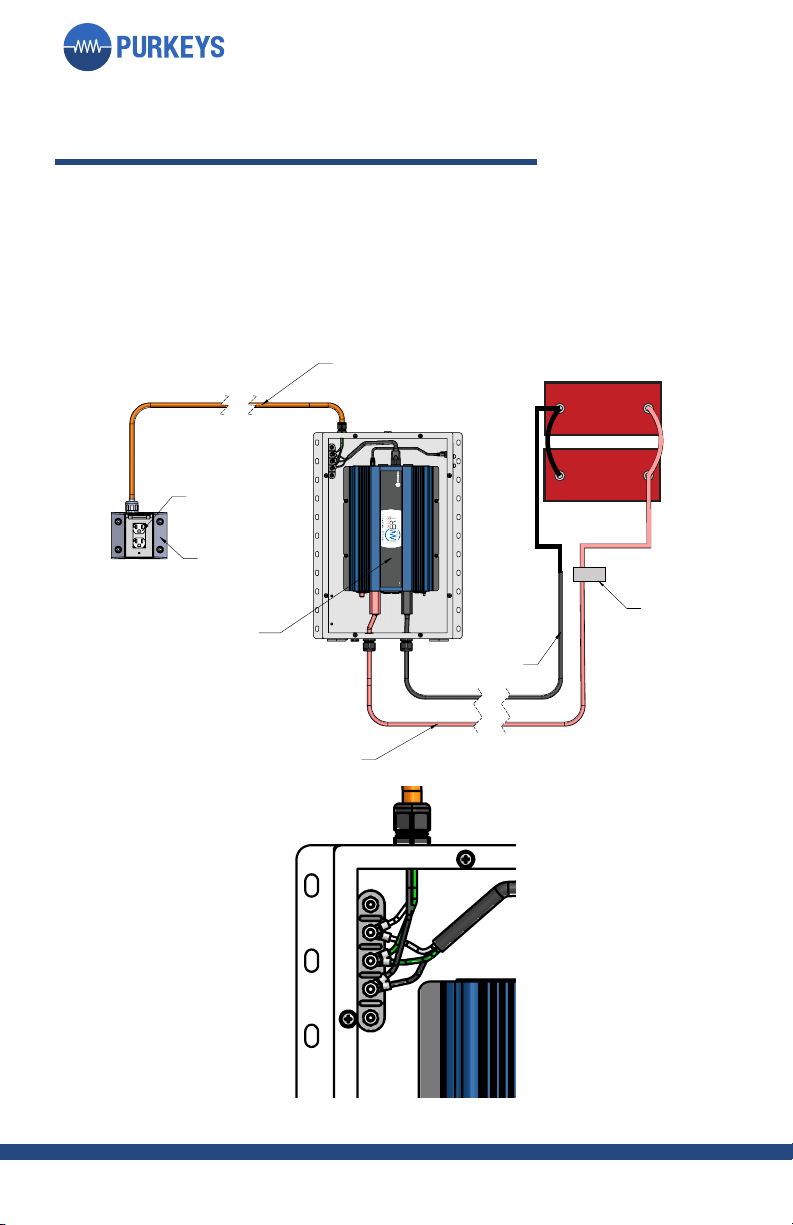

DUAL POLE CONFIGURATION

STRAIGHT TRUCK CONFIGURATION

'XDOSROH

QHJDWLYHFDEOH

'XDOSROH

SRVLWLYHFDEOH

:DWWSXUH

VLQHLQYHUWHU

/LTXLGWLJKW9$&KDUQHVV

5HLQIRUFHGQ\ORQ

UHFHSWDFOHER[

9$&UHFHSWDFOH

ZLWK/('LQGLFDWLRQ

'XDOSROHQRVHER[

[

,17(535(77+,6'5$:,1*,1$&&25'$1&(:,7+$60(

<

6((6(3$5$7(3$576/,67)253$576

5(029($//%8556

%5($.6+$53&251(56

:(,*+7

0$7(5,$/

0$7(5,$/),1,6+

0$7(5,$/&2/25

72/(5$1&(681/(6627+(5:,6(63(&,),('

,)(1*/,6+$1'0(75,&63(&,),('(1*/,6+>0(75,&@

35235,(7$5<$1'&21),'(17,$/

7+(,1)250$7,21&217$,1(',17+,6'5$:,1*,67+(62/(

3523(57<2)385.(<6$1<5(352'8&7,21,13$5725$6$:+2/(

:,7+2877+(:5,77(13(50,66,212)385.(<6,6352+,%,7('

(1*/,6+

;

;;

;;;

0(75,&

;

;;

;;;

/2:(//$5.$16$6

5'$1*/(

WĞĞƌZĞǀŝĞǁŚĞĐŬůŝƐƚ

ĞĐĂů;ƐͿ;ƵLJ^ƚŝĐŬĞƌͿ

ͻ

ĞĐĂů;ƐͿŝŶĐůƵĚĞĚ

ͻ

EŽŽǀĞƌůĂƉ

ͻ

ŽƌƌĞĐƚƚŽůĞƌĂŶĐŝŶŐ

ͻ

>ĂďĞů;ƐͿ;DĂŬĞ^ƚŝĐŬĞƌͿ

ͻ

>ĂďĞů;ƐͿŝ/ŶĐůƵĚĞĚ

ͻ

EŽŽǀĞƌůĂƉ

ͻ

ŽƌƌĞĐƚƚŽůĞƌĂŶĐŝŶŐ

ͻ

^ĞƌŝĂůη;ŝĨŶĞĞĚĞĚͿ

ͻ

ƉƉƌŽƉƌŝĂƚĞůŽĐĂƚŝŽŶ

ͻ

ŽƌƌĞĐƚƚŽůĞƌĂŶĐŝŶŐ

ͻ

ŽƌƌĞĐƚƐƚŝĐŬĞƌƚLJƉĞ

ͻ

tŽƌŬKƌĚĞƌĂƌĐŽĚĞ

ͻ

ƉƉƌŽƉƌŝĂƚĞůŽĐĂƚŝŽŶ

ͻ

ŽƌƌĞĐƚƚŽůĞƌĂŶĐŝŶŐ

ͻ

ŽƌƌĞĐƚƐƚŝĐŬĞƌƚLJƉĞ

ͻ

KǀĞƌĂůůĚŝŵĞŶƐŝŽŶƐ

ͻ

ƌŝƚŝĐĂůĚŝŵĞŶƐŝŽŶƐ

ͻ

tŝƌĞůĞŶŐƚŚƐ

ͻ

ƉƉƌŽƉƌŝĂƚĞƚŽůĞƌĂŶĐĞƐŽŶĞĂĐŚƐŚĞĞƚ

ͻ

ŽƌƌĞĐƚƵŶŝƚƐĂƌĞƐĞůĞĐƚĞĚ

ͻ

dŽůĞƌĂŶĐĞƐĂƌĞĂƉƉƌŽƉƌŝĂƚĞ

ͻ

tĞŝŐŚƚ

ͻ

tĞŝŐŚƚŝŶĐůƵĚĞƐĞǀĞƌLJƚŚŝŶŐŝŶĚƌĂǁŝŶŐ

ͻ

hŶŝƚƐĂƌĞƐŚŽǁŶ

ͻ

/ŵƉŽƌƚĂŶƚĨĞĂƚƵƌĞƐ

ͻ

ŽŵƉůĞƚĞƚŝƚůĞďůŽĐŬ;ĂƐĞĚŽŶWDĚĂƚĂĐĂƌĚͿ

ͻ

ĞƐĐƌŝƉƚŝŽŶŝƐĂĐĐƵƌĂƚĞ

ͻ

WĂƌƚŶƵŵďĞƌŝƐĐŽƌƌĞĐƚ

ͻ

WƌŽũĞĐƚŶĂŵĞŝƐĐŽƌƌĞĐƚ

ͻ

ƌĂǁŝŶŐŶƵŵďĞƌŝƐĐŽƌƌĞĐƚ

ͻ

ZĞǀŝƐŝŽŶŝƐĐŽƌƌĞĐƚ

ͻ

ƌĂǁŶLJ

ƐŚŽǁƐĐŽƌƌĞĐƚŶĂŵĞĂŶĚĚĂƚĞ

ͻ

ƉƉƌŽƉƌŝĂƚĞŶŽƚĞƐĂƌĞŝŶĐůƵĚĞĚ

ͻ

&ŝƌƐƚƉĂŐĞƐŚŽǁƐĞŶƚŝƌĞƉĂƌƚ

ͻ

KDƉĂŐĞ;ƐͿĂƌĞĐŽŵƉůĞƚĞĂŶĚƌĞĨůĞĐƚ

ͻ

ŵĂŶƵĨĂĐƚƵƌŝŶŐƉƌŽĐĞƐƐ

>ĂƐƚƉĂŐĞƐŚŽǁƐĐŽŵƉůĞƚĞƌĞǀŝƐŝŽŶŚŝƐƚŽƌLJ

ͻ

7(&+1,&$/'5$:,1*

dĞĐŚŶŝĐĂůƌĂǁŝŶŐŚĞĐŬůŝƐƚƐ

ͲϮϬϭϴϭϮϭϭ

7$36385(6,1(

352-(&7

3$57

&$*(

'5$:1%<

5(9,(:('%<

(1*$335

4$$335

'$7(

1$0(

'(6&5,37,21

6,=(

%

':*12

5(9

6&$/(

6+((72)

3'

3$57'(6&5,37,21),//6

)520'$7$&$5'

$ $

% %

& &

' '

( (

) )

YƉƉƌŽǀĂůŚĞĐŬůŝƐƚ

KǀĞƌĂůůĚŝŵĞŶƐŝŽŶƐ

ͻ

tŝƌĞůĞŶŐƚŚƐ

ͻ

ŽŵƉůĞƚĞƚŝƚůĞďůŽĐŬ

ͻ

ĞƐĐƌŝƉƚŝŽŶŝƐĂĐĐƵƌĂƚĞ

ͻ

WĂƌƚŶƵŵďĞƌŝƐĐŽƌƌĞĐƚ

ͻ

WƌŽũĞĐƚŶĂŵĞŝƐĐŽƌƌĞĐƚ

ͻ

ƌĂǁŝŶŐŶƵŵďĞƌŝƐĐŽƌƌĞĐƚ

ͻ

ZĞǀŝƐŝŽŶŝƐĐŽƌƌĞĐƚ

ͻ

ƌĂǁŶLJ

ZĞǀŝĞǁĞĚLJ

ĂŶĚ

ŶŐƉƉƌ

ƐŚŽǁ

ͻ

ĐŽƌƌĞĐƚŶĂŵĞƐĂŶĚĚĂƚĞƐ

dŽůĞƌĂŶĐĞƵŶŝƚƐŝƐƐĞůĞĐƚĞĚŽŶĞĂĐŚƐŚĞĞƚ

ͻ

&ŝƌƐƚƉĂŐĞƐŚŽǁƐĞŶƚŝƌĞƉĂƌƚ

ͻ

KDĐŽŵƉůĞƚĞ

ͻ

>ĂƐƚƉĂŐĞƐŚŽǁƐĐŽŵƉůĞƚĞƌĞǀŝƐŝŽŶŚŝƐƚŽƌLJ

ͻ

tĂƚĞƌŵĂƌŬŚĂƐďĞĞŶƌĞŵŽǀĞĚ

ͻ

ŶŐŝŶĞĞƌŝŶŐƉƉƌŽǀĂůŚĞĐŬůŝƐƚ

ŽƌƌĞĐƚĞĐĂů;ƐͿĂŶĚ>ĂďĞů;ƐͿ

ͻ

ŽƌƌĞĐƚŐƌĂƉŚŝĐ

ͻ

ůůůĂďĞůƐŶĞĞĚĞĚĂƌĞƐŚŽǁŶ

ͻ

^ĞƌŝĂůη;ŝĨŶĞĞĚĞĚͿ

ͻ

ƉƉƌŽƉƌŝĂƚĞůŽĐĂƚŝŽŶ

ͻ

ŽƌƌĞĐƚƚŽůĞƌĂŶĐŝŶŐ

ͻ

ŽƌƌĞĐƚƐƚŝĐŬĞƌƚLJƉĞ

ͻ

tŽƌŬKƌĚĞƌĂƌĐŽĚĞ

ͻ

ƉƉƌŽƉƌŝĂƚĞůŽĐĂƚŝŽŶ

ͻ

ŽƌƌĞĐƚƚŽůĞƌĂŶĐŝŶŐ

ͻ

ŽƌƌĞĐƚƐƚŝĐŬĞƌƚLJƉĞ

ͻ

KǀĞƌĂůůĚŝŵĞŶƐŝŽŶƐ

ͻ

ƌŝƚŝĐĂůĚŝŵĞŶƐŝŽŶƐ

ͻ

tŝƌĞůĞŶŐƚŚƐ

ͻ

tĞŝŐŚƚ

ͻ

tĞŝŐŚƚŝŶĐůƵĚĞƐĞǀĞƌLJƚŚŝŶŐŝŶĚƌĂǁŝŶŐ

ͻ

hŶŝƚƐĂƌĞƐŚŽǁŶ

ͻ

/ŵƉŽƌƚĂŶƚĞŶŐŝŶĞĞƌŝŶŐŵĂŶƵĨĂĐƚƵƌŝŶŐĐƵƐƚŽŵĞƌ

ͻ

ĨĞĂƚƵƌĞƐ

ƉƉƌŽƉƌŝĂƚĞŶŽƚĞƐĂƌĞŝŶĐůƵĚĞĚ

ͻ

&ŝƌƐƚƉĂŐĞƐŚŽǁƐĞŶƚŝƌĞƉĂƌƚ

ͻ

>ĂƐƚƉĂŐĞƐŚŽǁƐĐŽŵƉůĞƚĞƌĞǀŝƐŝŽŶŚŝƐƚŽƌLJ

ͻ

ZĞǀŝĞǁĞĚLJ

ƐŚŽǁƐĐŽƌƌĞĐƚŶĂŵĞĂŶĚĚĂƚĞ

ͻ

KDƉĂŐĞƐƌĞĨůĞĐƚĐŽƌƌĞĐƚŵĂŶƵĨĂĐƚƵƌŝŶŐƐƚĞƉƐ

ͻ

127(6

ηηηĞƐƵƌĞƚŽƉƌĞƐƐ&ϳƚŽĐŽŵƉůĞƚĞĂƐƉĞůůĐŚĞĐŬďĞĨŽƌĞLJŽƵƐƵďŵŝƚĨŽƌWĞĞƌZĞǀŝĞǁηηη

Fuse

150 amp

Fuse Cube

and

Bracket

x

INTERPRET THIS DRAWING IN ACCORDANCE WITH ASME

1.

Y14.100-2004

SEE SEPARATE PARTS LIST FOR PARTS

2.

REMOVE ALL BURRS

3.

BREAK SHARP CORNERS

4.

WEIGHT: -

5.

MATERIAL:

6.

MATERIAL FINISH:

7.

MATERIAL COLOR:

8.

TOLERANCES UNLESS OTHERWISE SPECIFIED:

IF ENGLISH AND METRIC SPECIFIED - ENGLISH [METRIC]

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE

PROPERTY OF PURKEYS. ANY REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF PURKEYS IS PROHIBITED.

ENGLISH

.X

.030

.XX

.010

.XXX

.005

METRIC

.X

.25

.XX

.13

.XXX

.013

LOWELL, ARKANSAS 72745

DRAFT

3RD ANGLE

Peer Review Checklist:

Decal(s) (Buy Sticker)

•

Decal(s) included

•

No overlap

•

Correct tolerancing

•

Label(s) (Make Sticker)

•

Label(s)iIncluded

•

No overlap

•

Correct tolerancing

•

Serial # (if needed)

•

Appropriate location

•

Correct tolerancing

•

Correct sticker type

•

Work Order Barcode

•

Appropriate location

•

Correct tolerancing

•

Correct sticker type

•

Overall dimensions

•

Critical dimensions

•

Wire lengths

•

Appropriate tolerances on each sheet

•

Correct units are selected

•

Tolerances are appropriate

•

Weight

•

Weight includes everything in drawing

•

Units are shown

•

Important features

•

Complete title block (Based on PDM data card)

•

Description is accurate

•

Part number is correct

•

Project name is correct

•

Drawing number is correct

•

Revision is correct

•

Drawn By

shows correct name and date

•

Appropriate notes are included

•

First page shows entire part

•

BOM page(s) are complete and reflect

•

manufacturing process

Last page shows complete revision history

•

TECHNICAL DRAWING

Technical Drawing Checklists

- 2018/12/11

10111 - TAPS PURE SINE

PROJECT

PART #

CAGE:

DRAWN BY

REVIEWED BY

ENG APPR.

Q.A. APPR.

DATE

NAME

DESCRIPTION:

SIZE

B

DWG. NO.

REV

SCALE: 1:8

4/9/2019

SHEET 1 OF 6

PD009868

PART DESCRIPTION FILLS

FROM DATA CARD

A A

B B

C C

D D

E E

F F

10

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

Q.A. Approval Checklist:

Overall dimensions

•

Wire lengths

•

Complete title block

•

Description is accurate

•

Part number is correct

•

Project name is correct

•

Drawing number is correct

•

Revision is correct

•

Drawn By

,

Reviewed By

, and

Eng. Appr

show

•

correct names and dates

Tolerance units is selected on each sheet

•

First page shows entire part

•

BOM complete

•

Last page shows complete revision history

•

Watermark has been removed

•

Engineering Approval Checklist:

Correct Decal(s) and Label(s)

•

Correct graphic

•

All labels needed are shown

•

Serial # (if needed)

•

Appropriate location

•

Correct tolerancing

•

Correct sticker type

•

Work Order Barcode

•

Appropriate location

•

Correct tolerancing

•

Correct sticker type

•

Overall dimensions

•

Critical dimensions

•

Wire lengths

•

Weight

•

Weight includes everything in drawing

•

Units are shown

•

Important engineering/manufacturing/customer

•

features

Appropriate notes are included

•

First page shows entire part

•

Last page shows complete revision history

•

Reviewed By

shows correct name and date

•

BOM pages reflect correct manufacturing steps

•

NOTES:

### Be sure to press F7 to complete a spell check before you submit for Peer Review. ###

x

INTERPRET THIS DRAWING IN ACCORDANCE WITH ASME

1.

Y14.100-2004

SEE SEPARATE PARTS LIST FOR PARTS

2.

REMOVE ALL BURRS

3.

BREAK SHARP CORNERS

4.

WEIGHT: -

5.

MATERIAL:

6.

MATERIAL FINISH:

7.

MATERIAL COLOR:

8.

TOLERANCES UNLESS OTHERWISE SPECIFIED:

IF ENGLISH AND METRIC SPECIFIED - ENGLISH [METRIC]

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE

PROPERTY OF PURKEYS. ANY REPRODUCTION IN PART OR AS A WHOLE

WITHOUT THE WRITTEN PERMISSION OF PURKEYS IS PROHIBITED.

ENGLISH

.X

.030

.XX

.010

.XXX

.005

METRIC

.X

.25

.XX

.13

.XXX

.013

LOWELL, ARKANSAS 72745

DRAFT

3RD ANGLE

Peer Review Checklist:

Decal(s) (Buy Sticker)

•

Decal(s) included

•

No overlap

•

Correct tolerancing

•

Label(s) (Make Sticker)

•

Label(s)iIncluded

•

No overlap

•

Correct tolerancing

•

Serial # (if needed)

•

Appropriate location

•

Correct tolerancing

•

Correct sticker type

•

Work Order Barcode

•

Appropriate location

•

Correct tolerancing

•

Correct sticker type

•

Overall dimensions

•

Critical dimensions

•

Wire lengths

•

Appropriate tolerances on each sheet

•

Correct units are selected

•

Tolerances are appropriate

•

Weight

•

Weight includes everything in drawing

•

Units are shown

•

Important features

•

Complete title block (Based on PDM data card)

•

Description is accurate

•

Part number is correct

•

Project name is correct

•

Drawing number is correct

•

Revision is correct

•

Drawn By

shows correct name and date

•

Appropriate notes are included

•

First page shows entire part

•

BOM page(s) are complete and reflect

•

manufacturing process

Last page shows complete revision history

•

TECHNICAL DRAWING

Technical Drawing Checklists

- 2018/12/11

10111 - TAPS PURE SINE

PROJECT

PART #

CAGE:

DRAWN BY

REVIEWED BY

ENG APPR.

Q.A. APPR.

DATE

NAME

DESCRIPTION:

SIZE

B

DWG. NO.

REV

SCALE: 1:8

4/9/2019

SHEET 1 OF 6

PD009868

PART DESCRIPTION FILLS

FROM DATA CARD

A A

B B

C C

D D

E E

F F

10

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

Q.A. Approval Checklist:

Overall dimensions

•

Wire lengths

•

Complete title block

•

Description is accurate

•

Part number is correct

•

Project name is correct

•

Drawing number is correct

•

Revision is correct

•

Drawn By

,

Reviewed By

, and

Eng. Appr

show

•

correct names and dates

Tolerance units is selected on each sheet

•

First page shows entire part

•

BOM complete

•

Last page shows complete revision history

•

Watermark has been removed

•

Engineering Approval Checklist:

Correct Decal(s) and Label(s)

•

Correct graphic

•

All labels needed are shown

•

Serial # (if needed)

•

Appropriate location

•

Correct tolerancing

•

Correct sticker type

•

Work Order Barcode

•

Appropriate location

•

Correct tolerancing

•

Correct sticker type

•

Overall dimensions

•

Critical dimensions

•

Wire lengths

•

Weight

•

Weight includes everything in drawing

•

Units are shown

•

Important engineering/manufacturing/customer

•

features

Appropriate notes are included

•

First page shows entire part

•

Last page shows complete revision history

•

Reviewed By

shows correct name and date

•

BOM pages reflect correct manufacturing steps

•

NOTES:

### Be sure to press F7 to complete a spell check before you submit for Peer Review. ###

'XDOSROH

QHJDWLYHFDEOH

'XDOSROH

SRVLWLYHFDEOH

:DWWSXUH

VLQHLQYHUWHU

/LTXLGWLJKW9$&KDUQHVV

5HLQIRUFHGQ\ORQ

UHFHSWDFOHER[

9$&UHFHSWDFOH

ZLWK/('LQGLFDWLRQ

'XDOSROHQRVHER[

[

,17(535(77+,6'5$:,1*,1$&&25'$1&(:,7+$60(

<

6((6(3$5$7(3$576/,67)253$576

5(029($//%8556

%5($.6+$53&251(56

:(,*+7

0$7(5,$/

0$7(5,$/),1,6+

0$7(5,$/&2/25

72/(5$1&(681/(6627+(5:,6(63(&,),('

,)(1*/,6+$1'0(75,&63(&,),('(1*/,6+>0(75,&@

35235,(7$5<$1'&21),'(17,$/

7+(,1)250$7,21&217$,1(',17+,6'5$:,1*,67+(62/(

3523(57<2)385.(<6$1<5(352'8&7,21,13$5725$6$:+2/(

:,7+2877+(:5,77(13(50,66,212)385.(<6,6352+,%,7('

(1*/,6+

;

;;

;;;

0(75,&

;

;;

;;;

/2:(//$5.$16$6

5'$1*/(

WĞĞƌZĞǀŝĞǁŚĞĐŬůŝƐƚ

ĞĐĂů;ƐͿ;ƵLJ^ƚŝĐŬĞƌͿ

ͻ

ĞĐĂů;ƐͿŝŶĐůƵĚĞĚ

ͻ

EŽŽǀĞƌůĂƉ

ͻ

ŽƌƌĞĐƚƚŽůĞƌĂŶĐŝŶŐ

ͻ

>ĂďĞů;ƐͿ;DĂŬĞ^ƚŝĐŬĞƌͿ

ͻ

>ĂďĞů;ƐͿŝ/ŶĐůƵĚĞĚ

ͻ

EŽŽǀĞƌůĂƉ

ͻ

ŽƌƌĞĐƚƚŽůĞƌĂŶĐŝŶŐ

ͻ

^ĞƌŝĂůη;ŝĨŶĞĞĚĞĚͿ

ͻ

ƉƉƌŽƉƌŝĂƚĞůŽĐĂƚŝŽŶ

ͻ

ŽƌƌĞĐƚƚŽůĞƌĂŶĐŝŶŐ

ͻ

ŽƌƌĞĐƚƐƚŝĐŬĞƌƚLJƉĞ

ͻ

tŽƌŬKƌĚĞƌĂƌĐŽĚĞ

ͻ

ƉƉƌŽƉƌŝĂƚĞůŽĐĂƚŝŽŶ

ͻ

ŽƌƌĞĐƚƚŽůĞƌĂŶĐŝŶŐ

ͻ

ŽƌƌĞĐƚƐƚŝĐŬĞƌƚLJƉĞ

ͻ

KǀĞƌĂůůĚŝŵĞŶƐŝŽŶƐ

ͻ

ƌŝƚŝĐĂůĚŝŵĞŶƐŝŽŶƐ

ͻ

tŝƌĞůĞŶŐƚŚƐ

ͻ

ƉƉƌŽƉƌŝĂƚĞƚŽůĞƌĂŶĐĞƐŽŶĞĂĐŚƐŚĞĞƚ

ͻ

ŽƌƌĞĐƚƵŶŝƚƐĂƌĞƐĞůĞĐƚĞĚ

ͻ

dŽůĞƌĂŶĐĞƐĂƌĞĂƉƉƌŽƉƌŝĂƚĞ

ͻ

tĞŝŐŚƚ

ͻ

tĞŝŐŚƚŝŶĐůƵĚĞƐĞǀĞƌLJƚŚŝŶŐŝŶĚƌĂǁŝŶŐ

ͻ

hŶŝƚƐĂƌĞƐŚŽǁŶ

ͻ

/ŵƉŽƌƚĂŶƚĨĞĂƚƵƌĞƐ

ͻ

ŽŵƉůĞƚĞƚŝƚůĞďůŽĐŬ;ĂƐĞĚŽŶWDĚĂƚĂĐĂƌĚͿ

ͻ

ĞƐĐƌŝƉƚŝŽŶŝƐĂĐĐƵƌĂƚĞ

ͻ

WĂƌƚŶƵŵďĞƌŝƐĐŽƌƌĞĐƚ

ͻ

WƌŽũĞĐƚŶĂŵĞŝƐĐŽƌƌĞĐƚ

ͻ

ƌĂǁŝŶŐŶƵŵďĞƌŝƐĐŽƌƌĞĐƚ

ͻ

ZĞǀŝƐŝŽŶŝƐĐŽƌƌĞĐƚ

ͻ

ƌĂǁŶLJ

ƐŚŽǁƐĐŽƌƌĞĐƚŶĂŵĞĂŶĚĚĂƚĞ

ͻ

ƉƉƌŽƉƌŝĂƚĞŶŽƚĞƐĂƌĞŝŶĐůƵĚĞĚ

ͻ

&ŝƌƐƚƉĂŐĞƐŚŽǁƐĞŶƚŝƌĞƉĂƌƚ

ͻ

KDƉĂŐĞ;ƐͿĂƌĞĐŽŵƉůĞƚĞĂŶĚƌĞĨůĞĐƚ

ͻ

ŵĂŶƵĨĂĐƚƵƌŝŶŐƉƌŽĐĞƐƐ

>ĂƐƚƉĂŐĞƐŚŽǁƐĐŽŵƉůĞƚĞƌĞǀŝƐŝŽŶŚŝƐƚŽƌLJ

ͻ

7(&+1,&$/'5$:,1*

dĞĐŚŶŝĐĂůƌĂǁŝŶŐŚĞĐŬůŝƐƚƐ

ͲϮϬϭϴϭϮϭϭ

7$36385(6,1(

352-(&7

3$57

&$*(

'5$:1%<

5(9,(:('%<

(1*$335

4$$335

'$7(

1$0(

'(6&5,37,21

6,=(

%

':*12

5(9

6&$/(

6+((72)

3'

3$57'(6&5,37,21),//6

)520'$7$&$5'

$ $

% %

& &

' '

( (

) )

YƉƉƌŽǀĂůŚĞĐŬůŝƐƚ

KǀĞƌĂůůĚŝŵĞŶƐŝŽŶƐ

ͻ

tŝƌĞůĞŶŐƚŚƐ

ͻ

ŽŵƉůĞƚĞƚŝƚůĞďůŽĐŬ

ͻ

ĞƐĐƌŝƉƚŝŽŶŝƐĂĐĐƵƌĂƚĞ

ͻ

WĂƌƚŶƵŵďĞƌŝƐĐŽƌƌĞĐƚ

ͻ

WƌŽũĞĐƚŶĂŵĞŝƐĐŽƌƌĞĐƚ

ͻ

ƌĂǁŝŶŐŶƵŵďĞƌŝƐĐŽƌƌĞĐƚ

ͻ

ZĞǀŝƐŝŽŶŝƐĐŽƌƌĞĐƚ

ͻ

ƌĂǁŶLJ

ZĞǀŝĞǁĞĚLJ

ĂŶĚ

ŶŐƉƉƌ

ƐŚŽǁ

ͻ

ĐŽƌƌĞĐƚŶĂŵĞƐĂŶĚĚĂƚĞƐ

dŽůĞƌĂŶĐĞƵŶŝƚƐŝƐƐĞůĞĐƚĞĚŽŶĞĂĐŚƐŚĞĞƚ

ͻ

&ŝƌƐƚƉĂŐĞƐŚŽǁƐĞŶƚŝƌĞƉĂƌƚ

ͻ

KDĐŽŵƉůĞƚĞ

ͻ

>ĂƐƚƉĂŐĞƐŚŽǁƐĐŽŵƉůĞƚĞƌĞǀŝƐŝŽŶŚŝƐƚŽƌLJ

ͻ

tĂƚĞƌŵĂƌŬŚĂƐďĞĞŶƌĞŵŽǀĞĚ

ͻ

ŶŐŝŶĞĞƌŝŶŐƉƉƌŽǀĂůŚĞĐŬůŝƐƚ

ŽƌƌĞĐƚĞĐĂů;ƐͿĂŶĚ>ĂďĞů;ƐͿ

ͻ

ŽƌƌĞĐƚŐƌĂƉŚŝĐ

ͻ

ůůůĂďĞůƐŶĞĞĚĞĚĂƌĞƐŚŽǁŶ

ͻ

^ĞƌŝĂůη;ŝĨŶĞĞĚĞĚͿ

ͻ

ƉƉƌŽƉƌŝĂƚĞůŽĐĂƚŝŽŶ

ͻ

ŽƌƌĞĐƚƚŽůĞƌĂŶĐŝŶŐ

ͻ

ŽƌƌĞĐƚƐƚŝĐŬĞƌƚLJƉĞ

ͻ

tŽƌŬKƌĚĞƌĂƌĐŽĚĞ

ͻ

ƉƉƌŽƉƌŝĂƚĞůŽĐĂƚŝŽŶ

ͻ

ŽƌƌĞĐƚƚŽůĞƌĂŶĐŝŶŐ

ͻ

ŽƌƌĞĐƚƐƚŝĐŬĞƌƚLJƉĞ

ͻ

KǀĞƌĂůůĚŝŵĞŶƐŝŽŶƐ

ͻ

ƌŝƚŝĐĂůĚŝŵĞŶƐŝŽŶƐ

ͻ

tŝƌĞůĞŶŐƚŚƐ

ͻ

tĞŝŐŚƚ

ͻ

tĞŝŐŚƚŝŶĐůƵĚĞƐĞǀĞƌLJƚŚŝŶŐŝŶĚƌĂǁŝŶŐ

ͻ

hŶŝƚƐĂƌĞƐŚŽǁŶ

ͻ

/ŵƉŽƌƚĂŶƚĞŶŐŝŶĞĞƌŝŶŐŵĂŶƵĨĂĐƚƵƌŝŶŐĐƵƐƚŽŵĞƌ

ͻ

ĨĞĂƚƵƌĞƐ

ƉƉƌŽƉƌŝĂƚĞŶŽƚĞƐĂƌĞŝŶĐůƵĚĞĚ

ͻ

&ŝƌƐƚƉĂŐĞƐŚŽǁƐĞŶƚŝƌĞƉĂƌƚ

ͻ

>ĂƐƚƉĂŐĞƐŚŽǁƐĐŽŵƉůĞƚĞƌĞǀŝƐŝŽŶŚŝƐƚŽƌLJ

ͻ

ZĞǀŝĞǁĞĚLJ

ƐŚŽǁƐĐŽƌƌĞĐƚŶĂŵĞĂŶĚĚĂƚĞ

ͻ

KDƉĂŐĞƐƌĞĨůĞĐƚĐŽƌƌĞĐƚŵĂŶƵĨĂĐƚƵƌŝŶŐƐƚĞƉƐ

ͻ

127(6

ηηηĞƐƵƌĞƚŽƉƌĞƐƐ&ϳƚŽĐŽŵƉůĞƚĞĂƐƉĞůůĐŚĞĐŬďĞĨŽƌĞLJŽƵƐƵďŵŝƚĨŽƌWĞĞƌZĞǀŝĞǁηηη

Fuse

150 amp

Fuse Cube

and

Bracket