FGT400 User Manual Page 4 UK

INSTALLATION (CONT.)

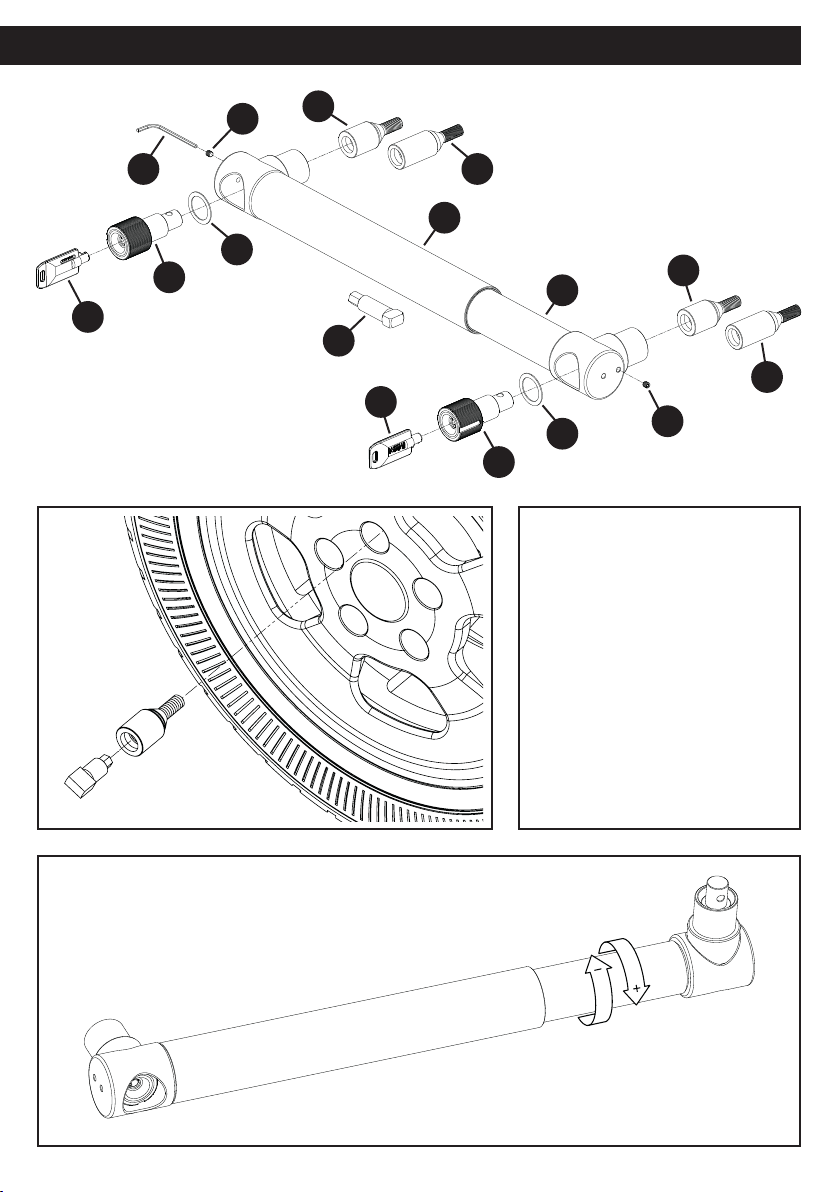

2. To prepare the Gemini for tting, the required length must rst be determined and adjusted accordingly.

To do this, both Locking Portions (3) will need installing for use as guides. Using Fig.A for reference, install

the Locking Portions (3) into apertures in the head of both the Outer (1) and Inner Tubes (2). Each Locking

Portion (3) can then be secured in place by tightening the Locking Portion Hex Screw (5) using the supplied

3mm Hex Key (6) (see Fig.A for reference).

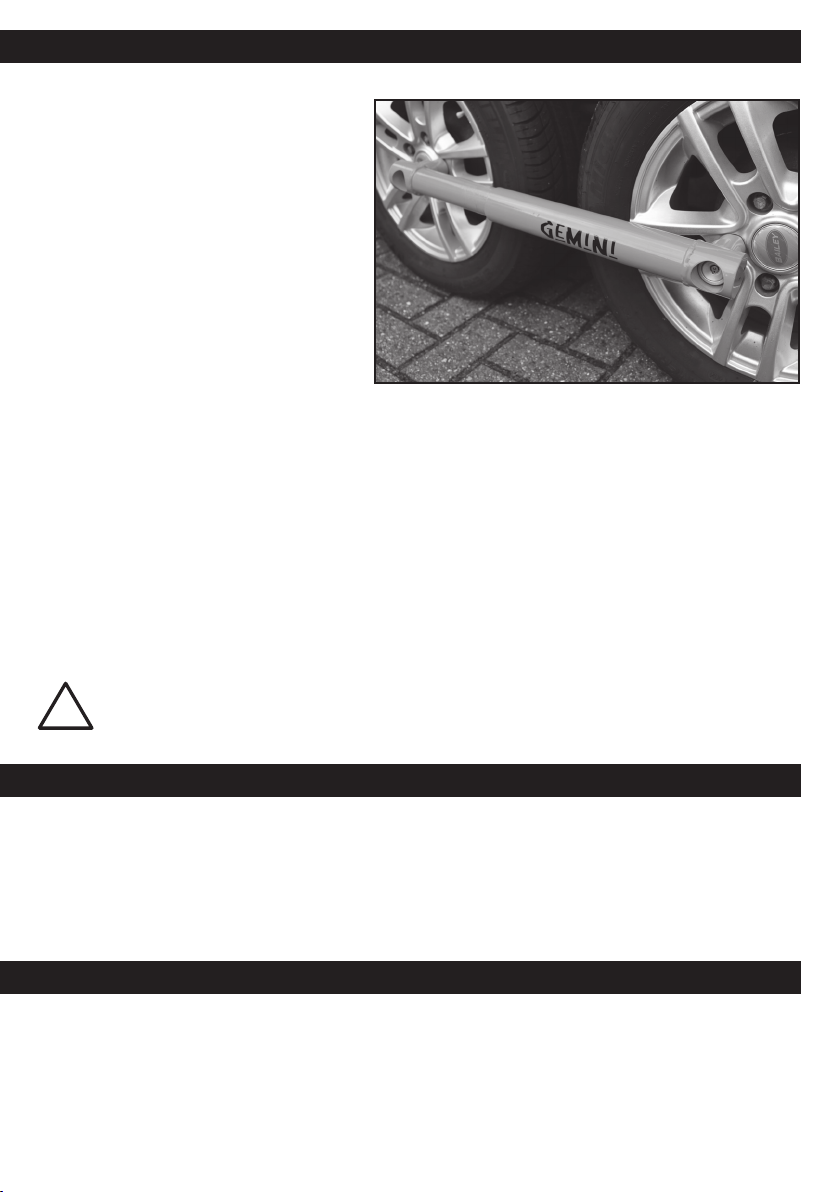

Next, hold the device up to the wheels, and line the Locking Portion (3) in the head of the Outer Tube (1) up

with the Receiver Bolt (9,10) in one of the wheels. From here, gauge whether the length of the Gemini needs

to be longer or shorter to allow the Locking Portion (3) in the head of the Inner Tube (2) to line up correctly

with the Receiver Bolt (9,10) in the second wheel (see Fig.F for guidance).

To adjust the length of the Gemini Wheel Lock to suit your vehicle, grip the Outer Tube (1) in one hand,

and proceed to rotate the Inner Tube (2) in the disired direction (see Fig.C). Use the arrow graphic on the

product for reference. Whilst adjusting the length of the Gemini, periodically oer the assembly up to the

Receiver Bolts (9,10) in order to correctly judge the required length. Each 360°rotation of the Inner Tube (2)

is approximately equal to 1.5mm of length adjustment.

NOTE: When shortening the length of the Gemini,

ensure that if resistance is met, you do not continue

to attempt shortening. This has likely occurred as

the minimum length has been met. If in this state the

assembly is too long, consider relocating the position

of your Receiver Wheel Bolts (9,10) to allow for a wider

installation length.

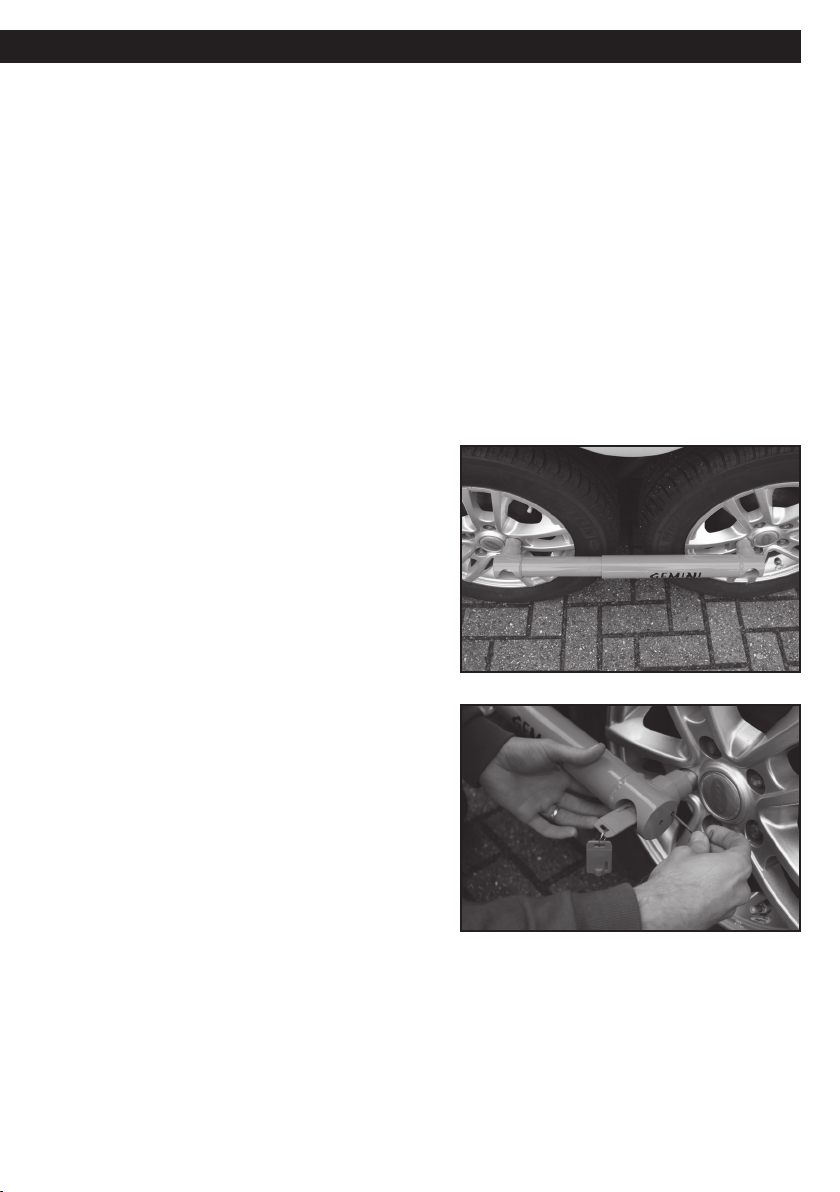

3. Before using the device it may be necessary to add

Spacer Rings (4) to ensure that, when tted, the ends of

the locking portion tubes are as tight as possible to the

face of the wheel when the Locking Portion (3) is locked

into a Receiver Bolt (9,10). To check this, rst t both

sets of keys (7) into their respective Locking Portions (3)

and rotate them through 90° clockwise to release the

locking ball bearings.

Oer up the assembly to the Receiver Bolts (9,10),

guiding the end of the Locking Portions (3) in as far as

they will go. Lock them together by rotating the keys (7)

anti-clockwise through 90°, then remove both keys (7).

The aim at this stage is for the heads of both the Inner

(2) and Outer Tubes (1) to be as tight as possible to the

face of the wheels, when the Locking Portions (3) are

locked into the Receiver Bolts (9,10). Acheiving this will

mean that the Gemini will be most eective; protecting

and preventing acess to the Receiver Bolts (9,10) when

locked in place.

Fig. H

Fig. G

If there is a gap, or the asembly can be pulled away from the face of the wheel, making the Receiver Bolts

(9,10) visible, then Spacer Rings (4) must be used. Try to gauge the amount of gap and add the necessary

amount of 1mm thickness Spacer Rings (4) between each Tube (1,2) and respective Locking Portion (3) as

shown in Fig.A. Always add an equal sum of spacer rings (4) to each Tube (1,2) .To x these in place, use the

supplied 3mm Hex Key (6) and tighten the Locking Portion Hex Screws (5) into the most applicable of the

two avilable holes in each Tube (1,2) (see Fig.H). The Hex Screws (5) should be tightened to the bodies of the

Locking Portions (3) to correctly secure the spacer rings (4) in place.