Sheet: 2 of 11

PRODUCT NAME

MODEL NO.

Date: 7/26/2017

Rev: A

1201-10

Drawn: BDYE

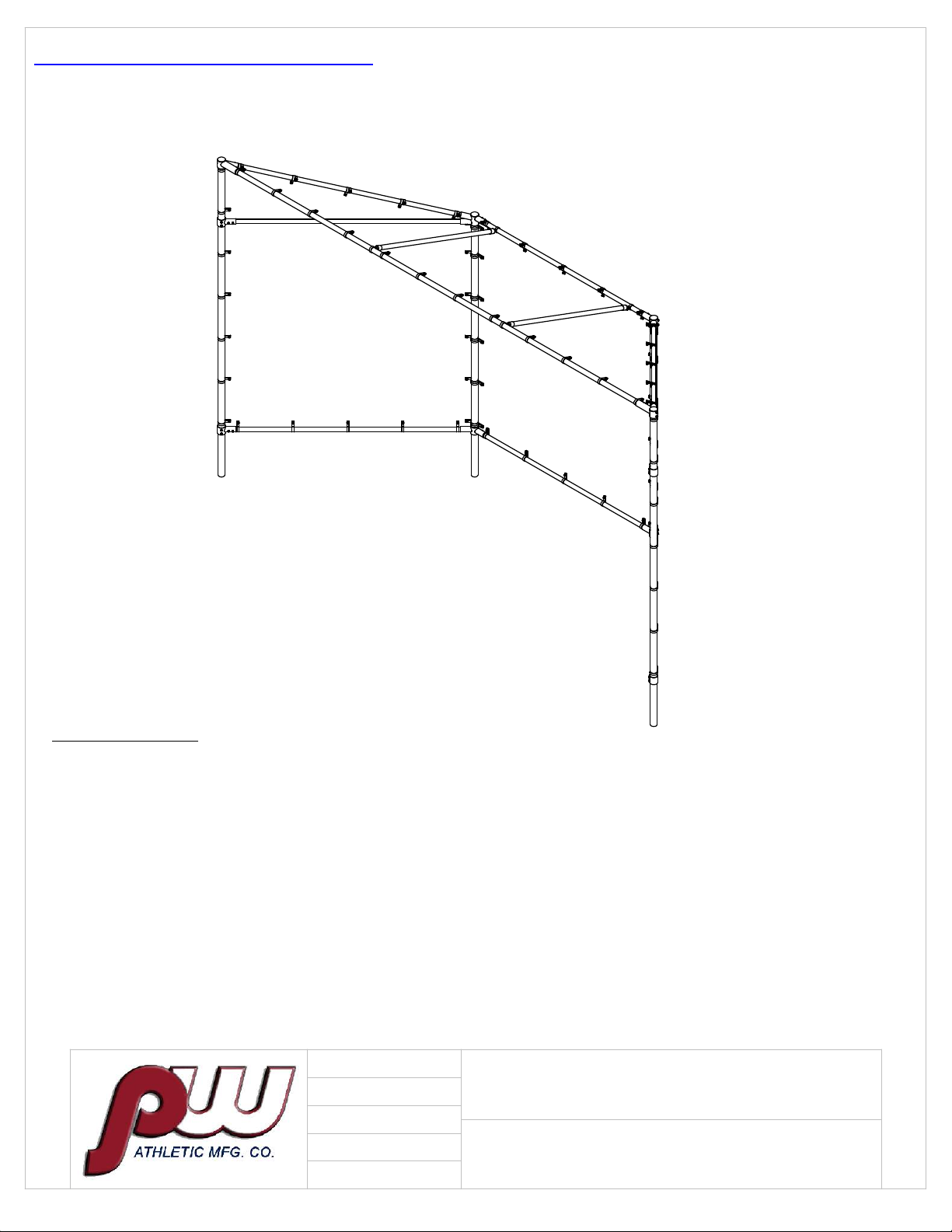

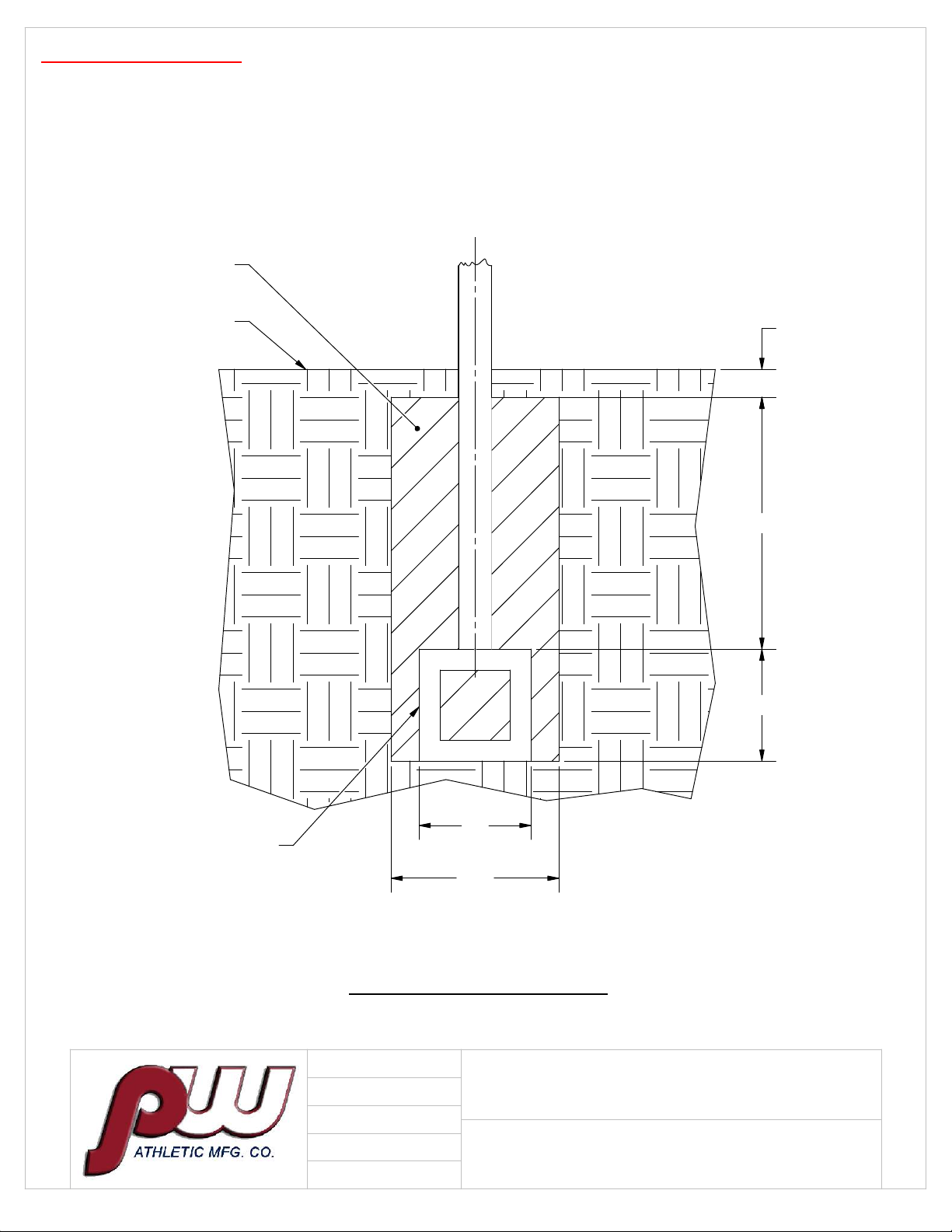

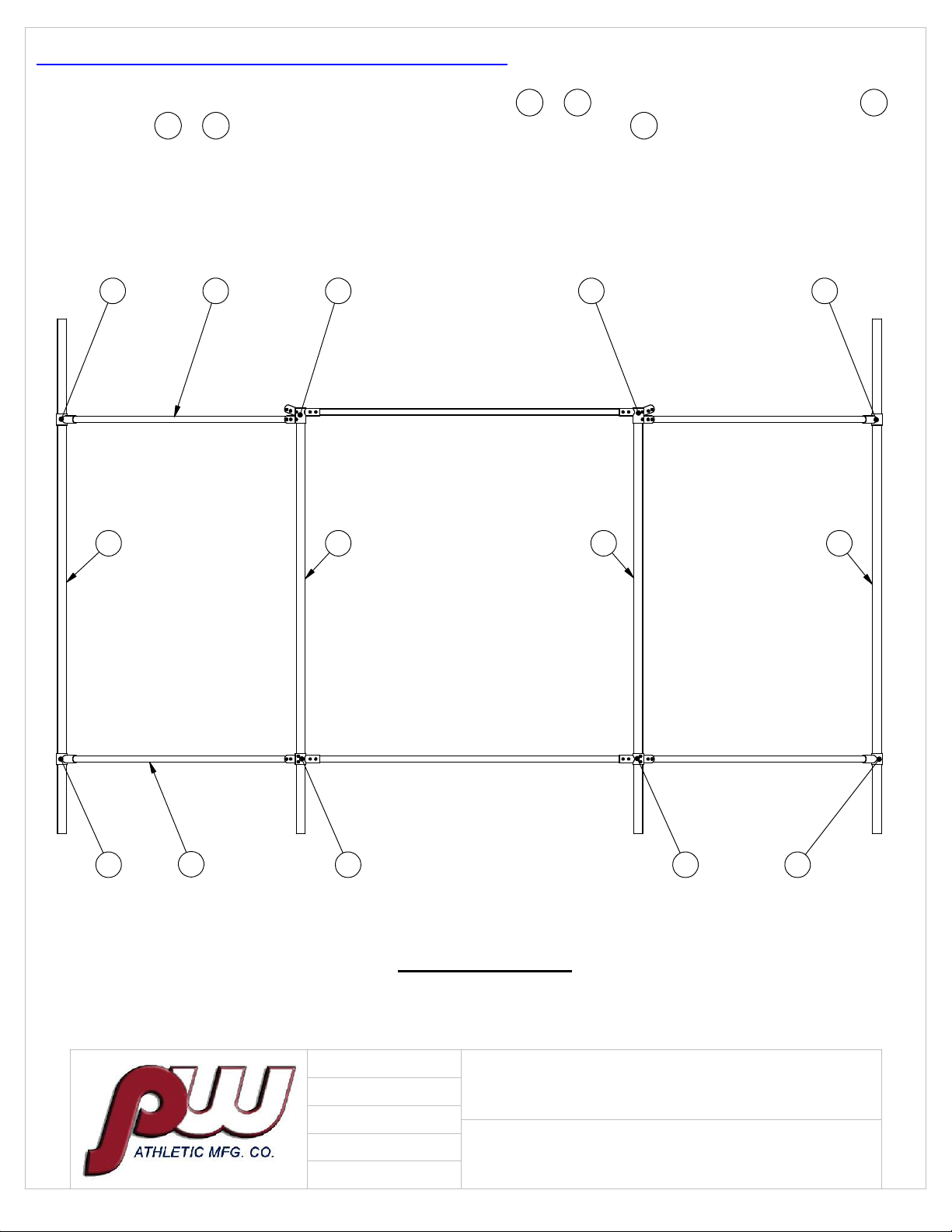

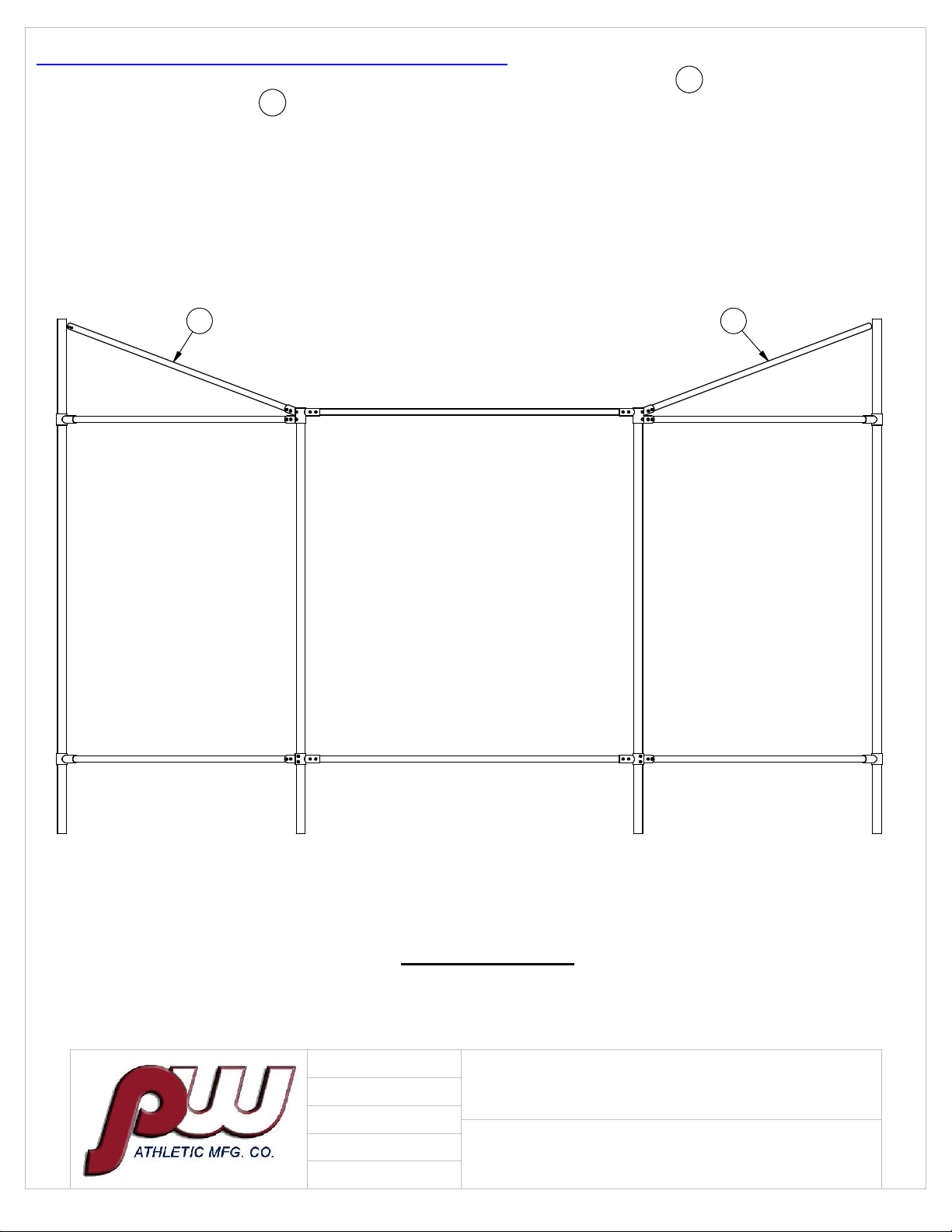

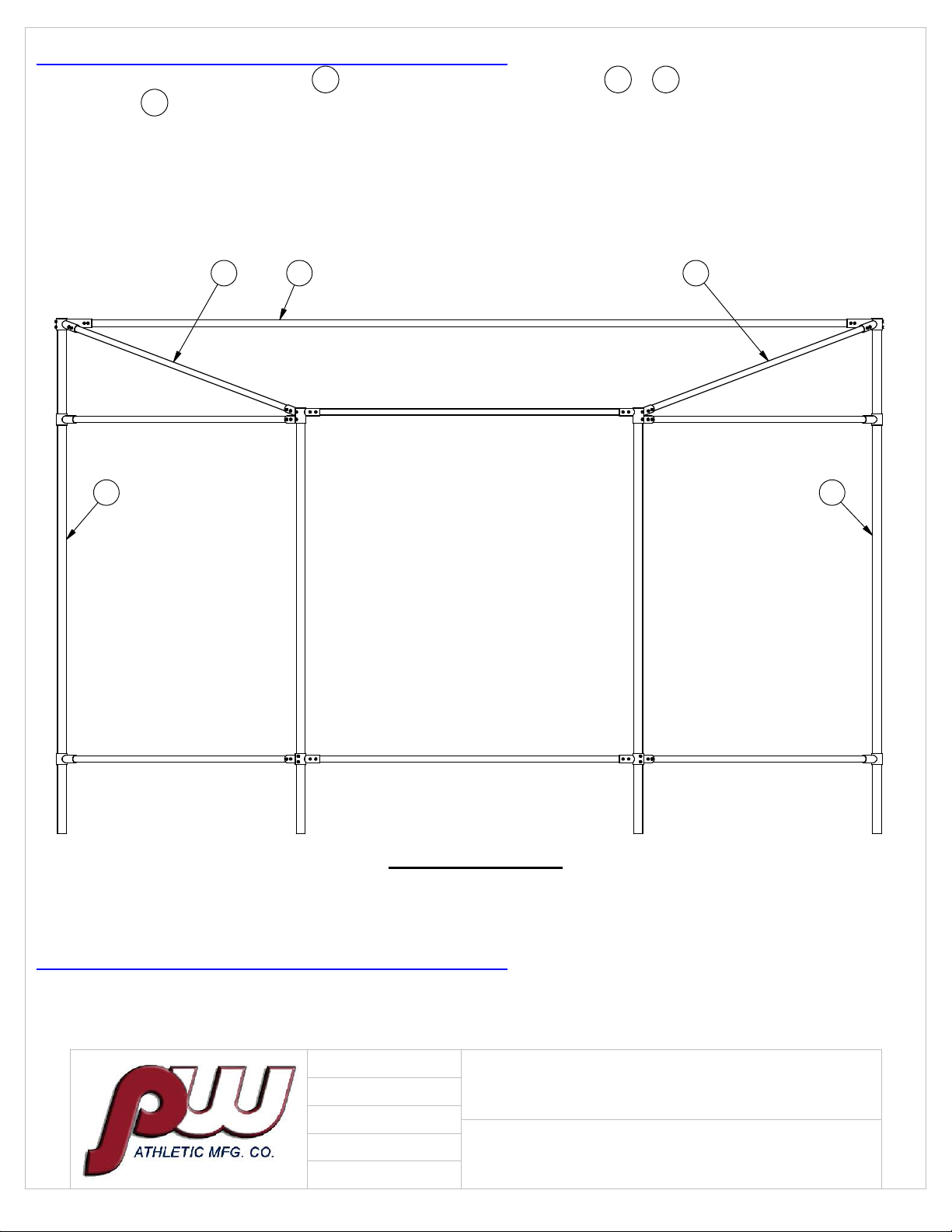

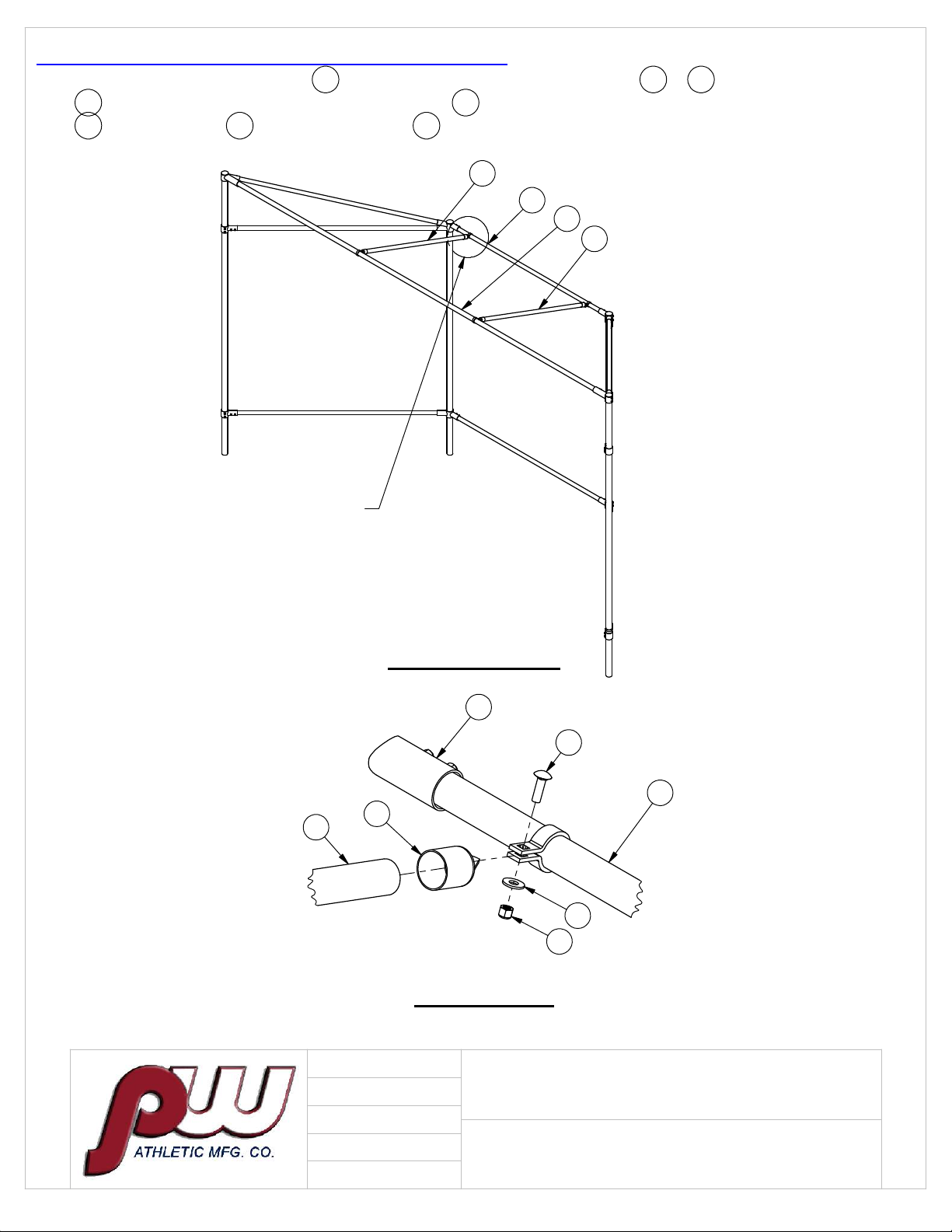

ECONOMY BACKSTOP

BOM

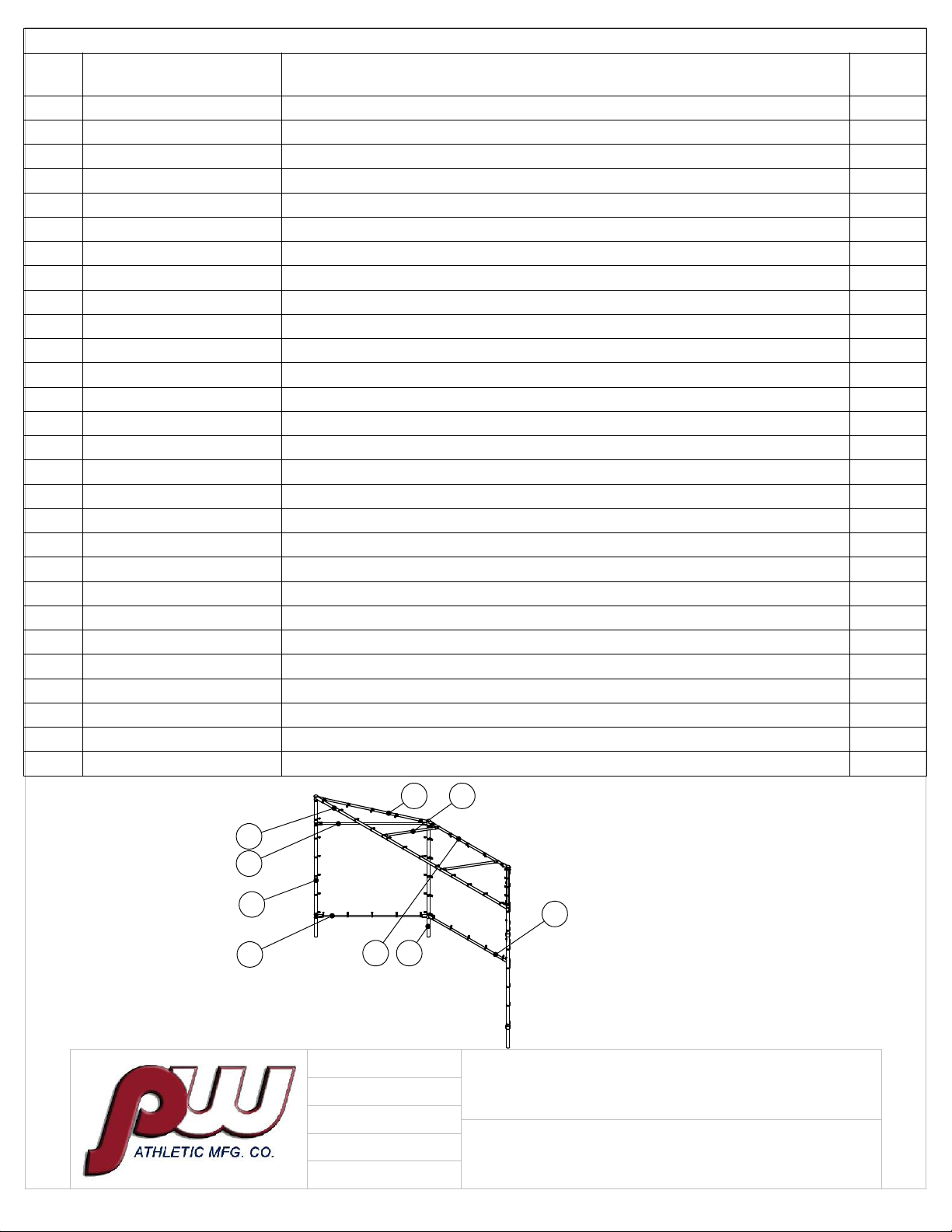

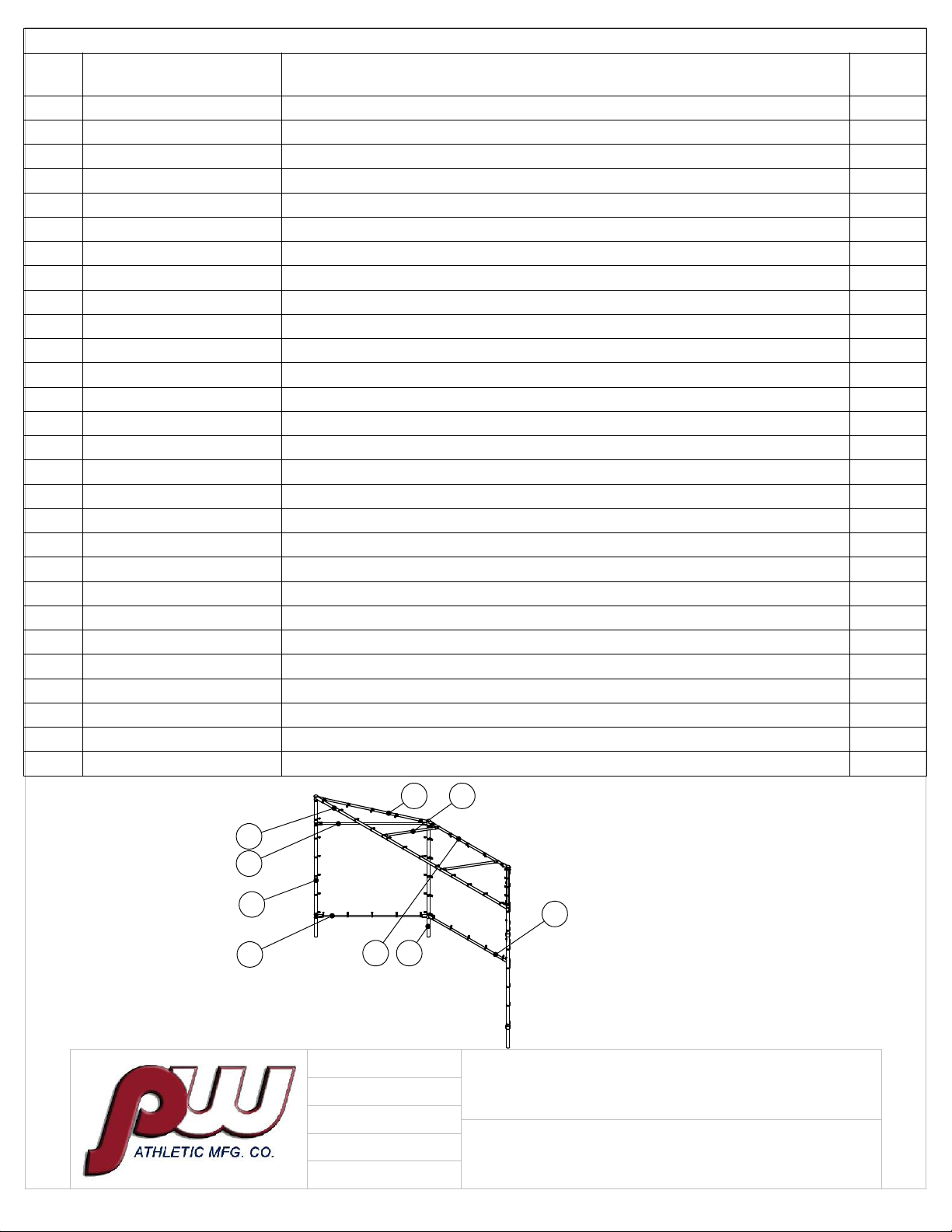

ITEM

NO. PART NUMBER DESCRIPTION QTY.

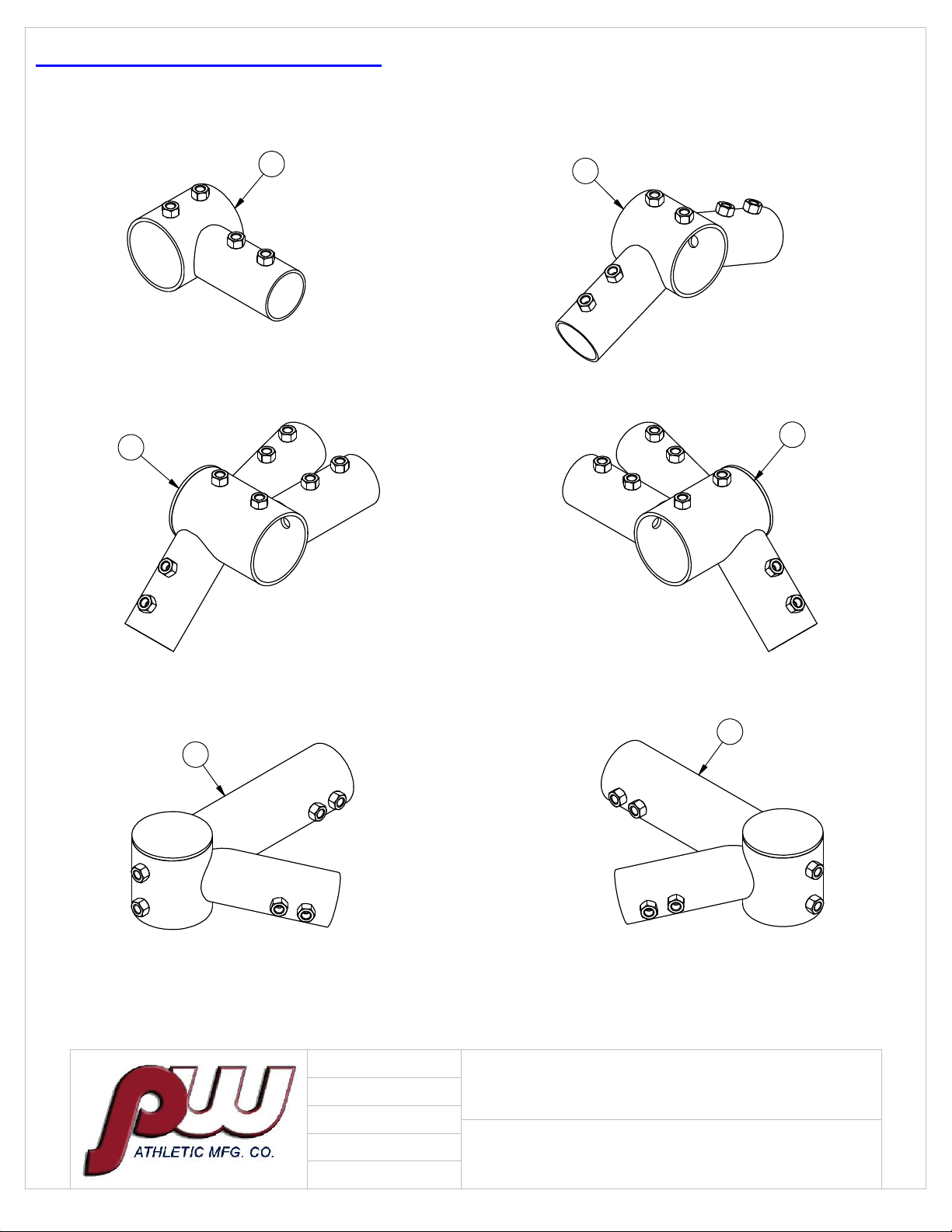

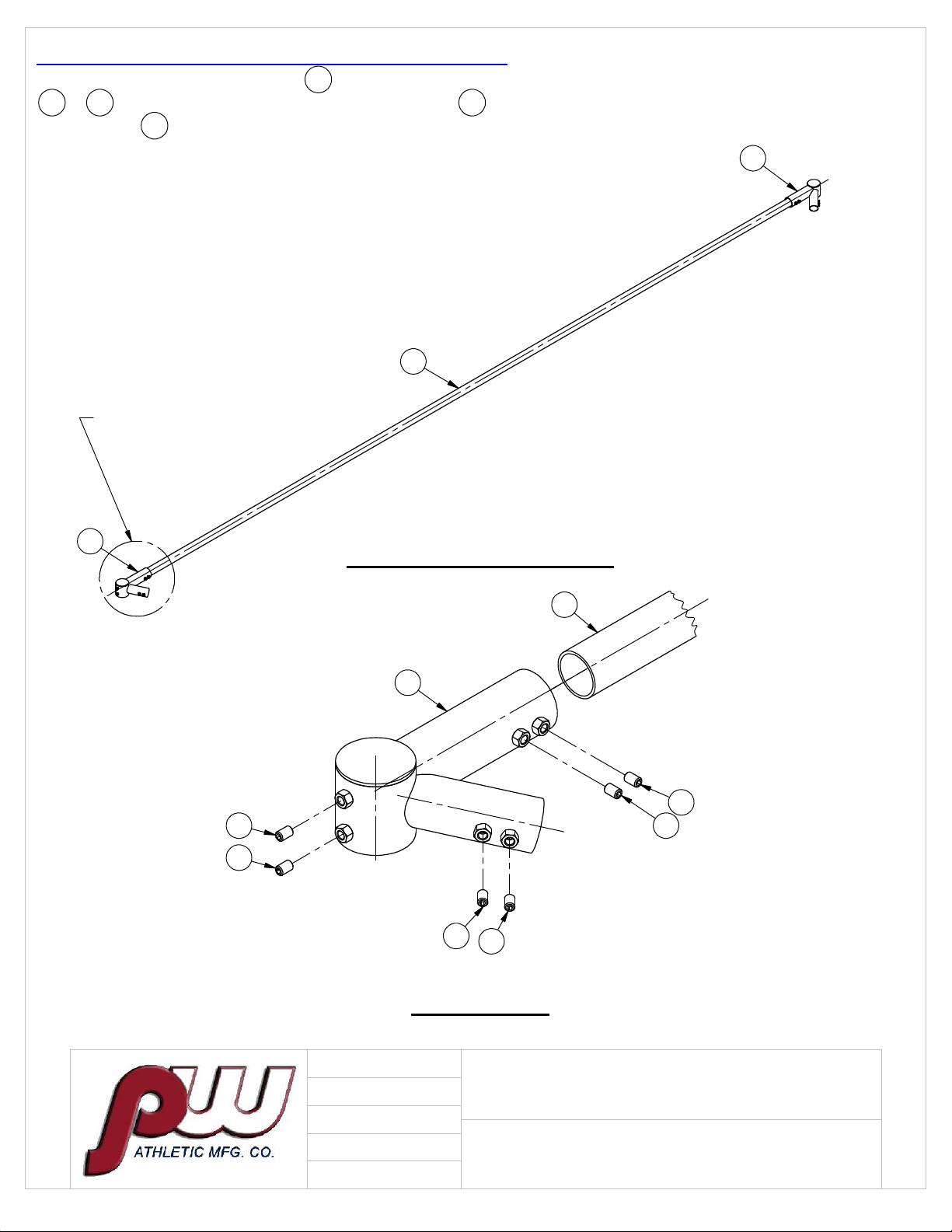

1 ASA-500-12AD-A1 12AD-A1 FITTING 4

2 ASA-502-12AD-A3 12AD-A3 FITTING 2

3 ASA-503-12AD-A4 12AD-A4 FITTING 1

4 ASA-504-12AD-A5 12AD-A5 FITTING 1

5 ASA-505-12AD-Z1 12AD-Z1 FITTING 1

6 ASA-506-12AD-Z2 12AD-Z2 FITTING 1

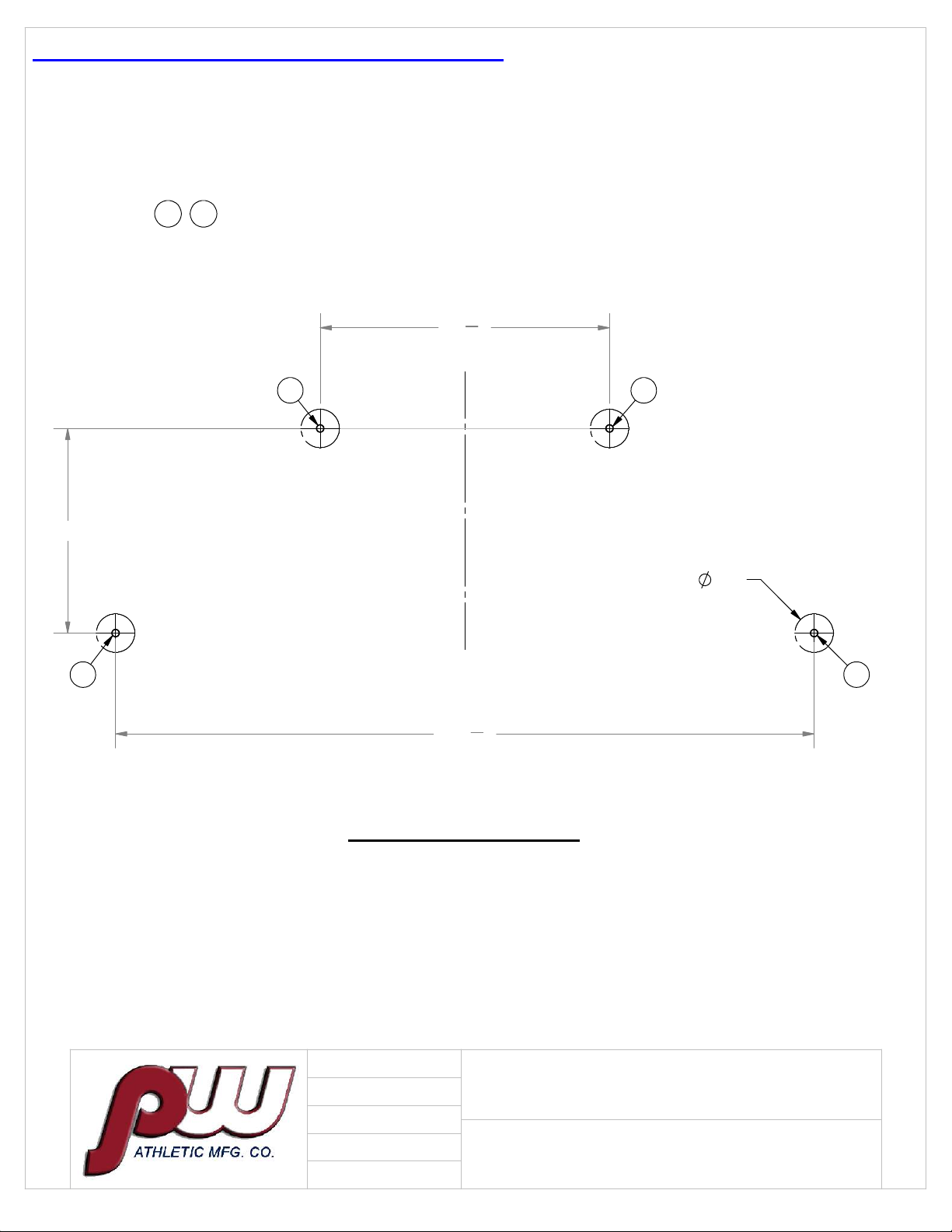

7 RT-003-1210-138-G FRONT VERTICAL POSTS 2-3/8" DIA. 2

8 RT-001-1210-114-G REAR VERTICAL POSTS 2-3/8" DIA. 2

9 RT-002-1210-87-G BOTTOM HORIZONTAL RAILS 1-5/8" DIA. 6

10 RT-004-1210-88.5-G TOP SIDE HOOD RAILS 1 7/8"DIA. 2

11 RT-005-1210-212.5-G HOOD CROSSBAR 1 7/8" DIA. 1

12 RT-006-1210-62.25-G CENTER HOOD SUPPORT 1 5/8"DIA. 2

13 HWSC3858 3/8 X 5/8 SET SCREW ZINC 56

14 HWFLWA38 3/8" USS FLAT WASHER 4

15 HWLN38 3/8"-16 LOCK NUT 4

16 HWCB38114 3/8-16 X 1 1/4 CARRIAGE BOLT ZINC (5-9/16 BRACE BANDS) 4

17 HWCB5161 5/16-18 X 1 CARRIAGE BOLT GRADE 2 ZINC 96

18 HWFLWA516 5/16 FLAT WASHER 96

19 HWLN516 5/16 NYLOK NUT ZINC 96

20 VCIRAILEND158 1 5/8 ID RAIL END 4

21 VCIBB163 1 5/8" BRACE BAND 2

22 VCIBB178 1 7/8" BRACE BAND 2

23 VCITEN238 2 3/8" TENSION BAND 38

24 VCITEN158 1 5/8" TENSION BAND 47

25 VCITEN178 1 7/8" TENSION BAND 11

26 8' TENSION BAR 4

27 10' TENSION BAR 2

28 #10 X 1/2 RD HD U - DRIVE SCREW ZINC 30

VCITBAR8

VCITBAR10

HWDS1012HWDS1012

9

10

7

12

9

11

9

9

8