Troubleshooting

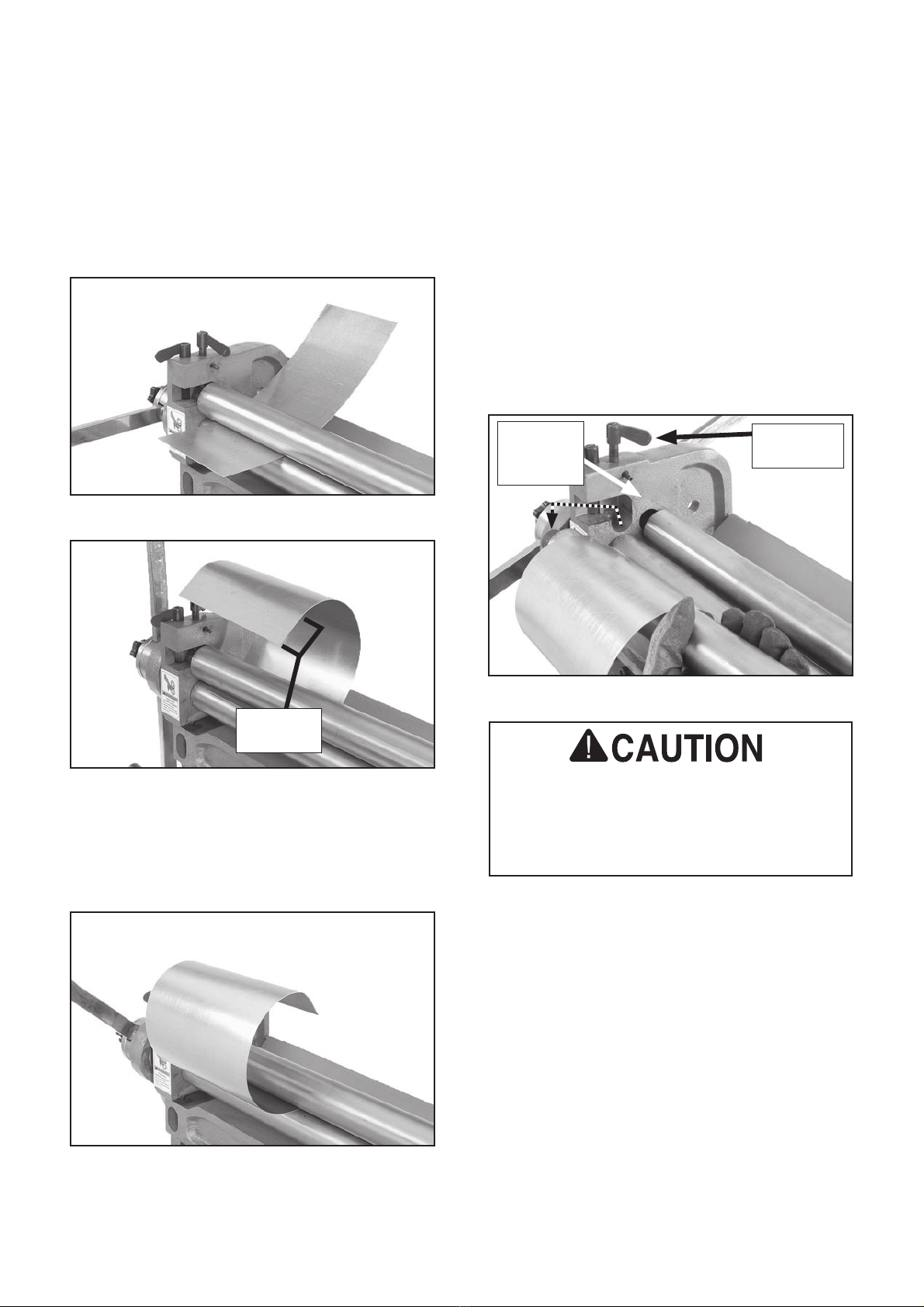

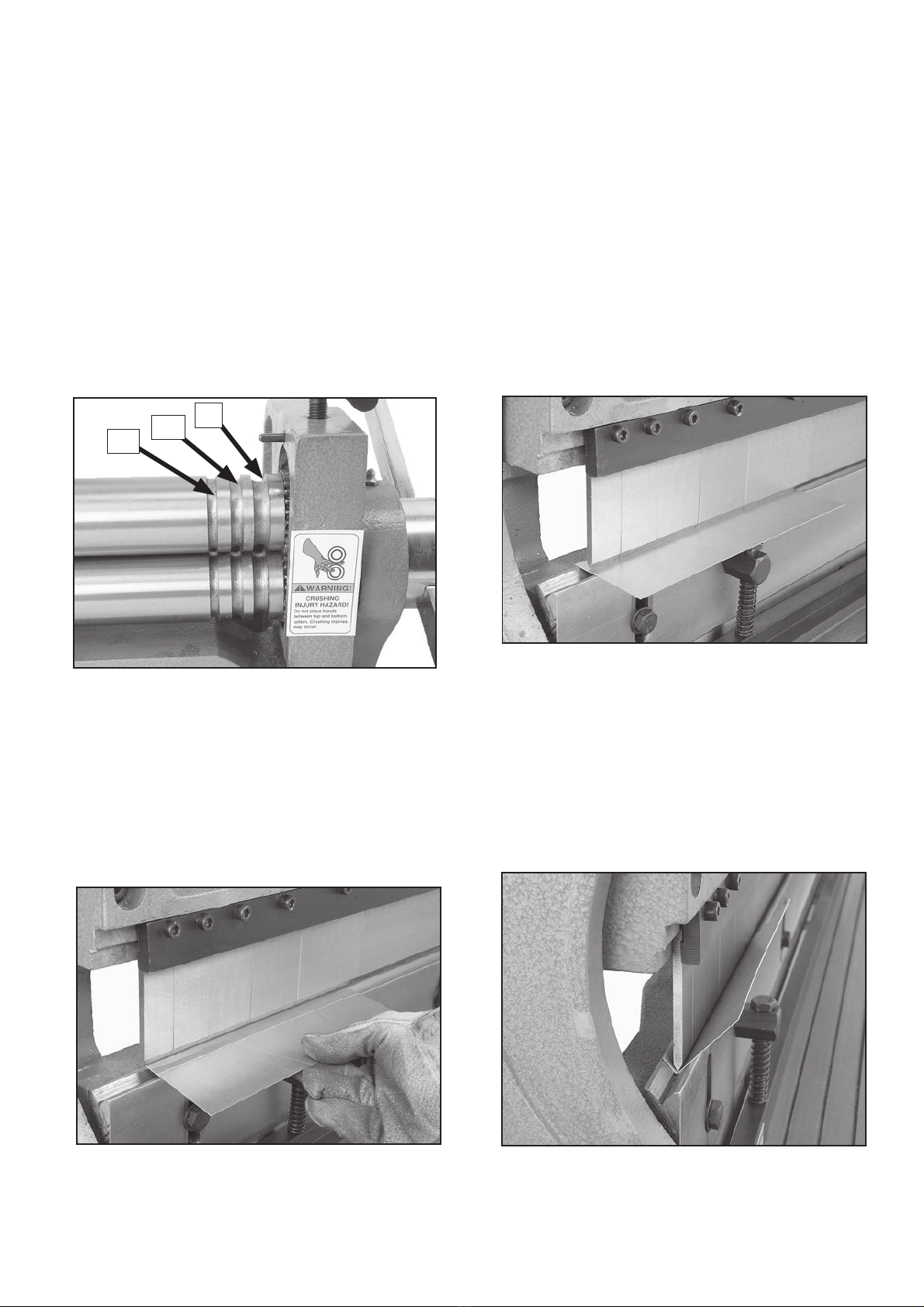

Slip Roll Operation

Symptom Possible Cause Possible Solution

Slip roll creates

cones when trying

to create cylinders.

1. Rollers are not parallel. 1. Adjust rear roller adjustment knobs as necessary to

be sure the rear roller and top roller are parallel.

A noticeable crease

is formed in the

workpiece.

1. Excessive pressure applied in one spot. 1. Reduce the radius and perform the bend in several

passes.

Workpiece is pitted. 1. Workpiece is dirty, roller is damaged. 1. Clean workpiece, polish out any nicks in the rollers.

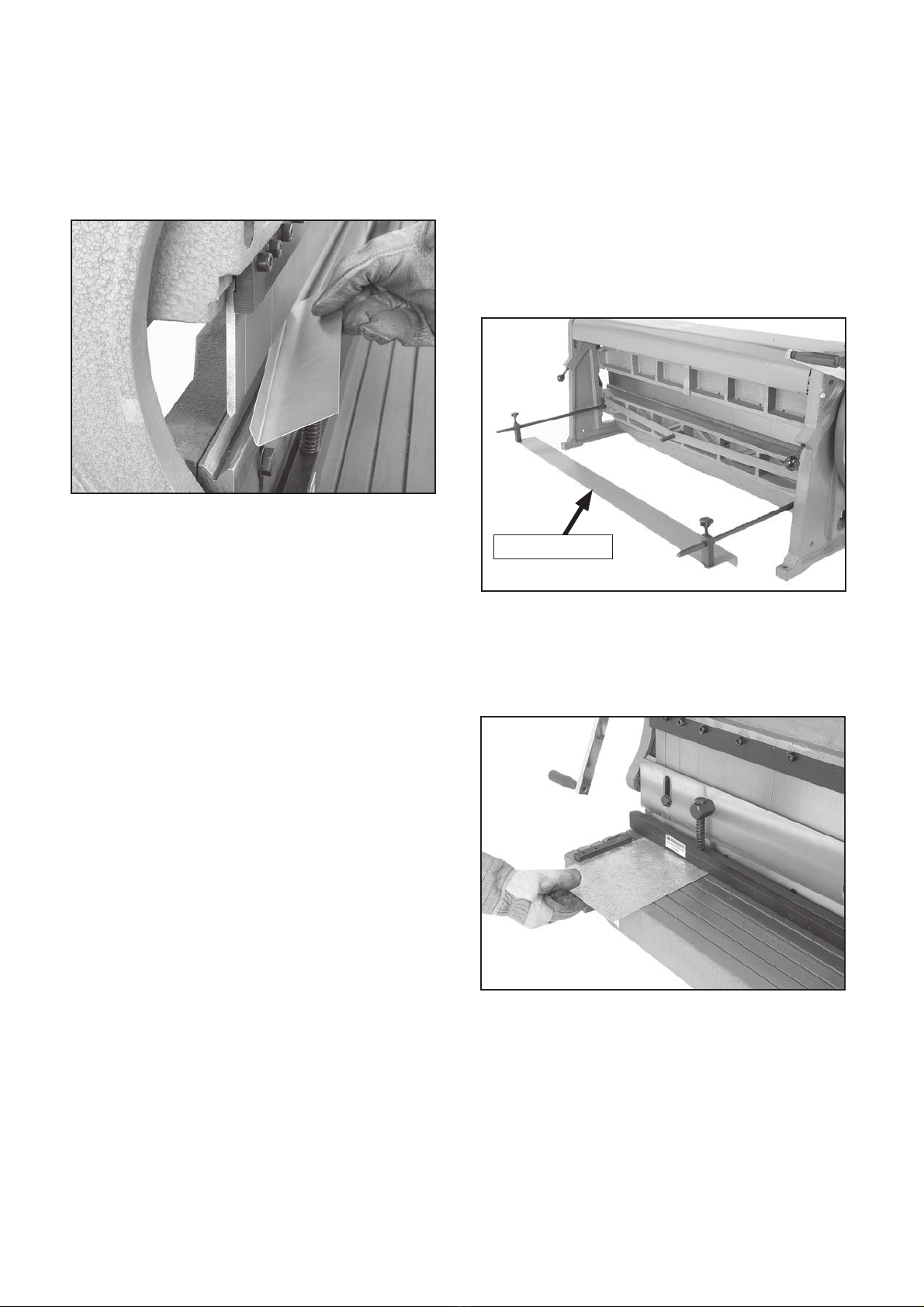

Brake Operation

Symptom Possible Cause Possible Solution

Heavy resistance

during bends.

1. Machine capacities are exceeded. 1. Use materials within the capacity of the machine.

Bend radius is not

consistent across

workpiece.

1. Machine capacities are exceeded.

2. Fingers and finger receiver not aligned.

1. Use materials within the capacity of the machine.

2. Adjust brake alignment.

Point of fingers are

chipping or rolling.

1. Fingers and finger receiver not aligned.

2. Workpiece is too thick.

1. Adjust brake alignment.

2. Use materials within the capacity of the machine.

Workpiece shows

scoring marks after

bend.

1. Fingers or finger receiver has scratches. 1. Polish out scratches, and apply tape at the bend

locations for protection.

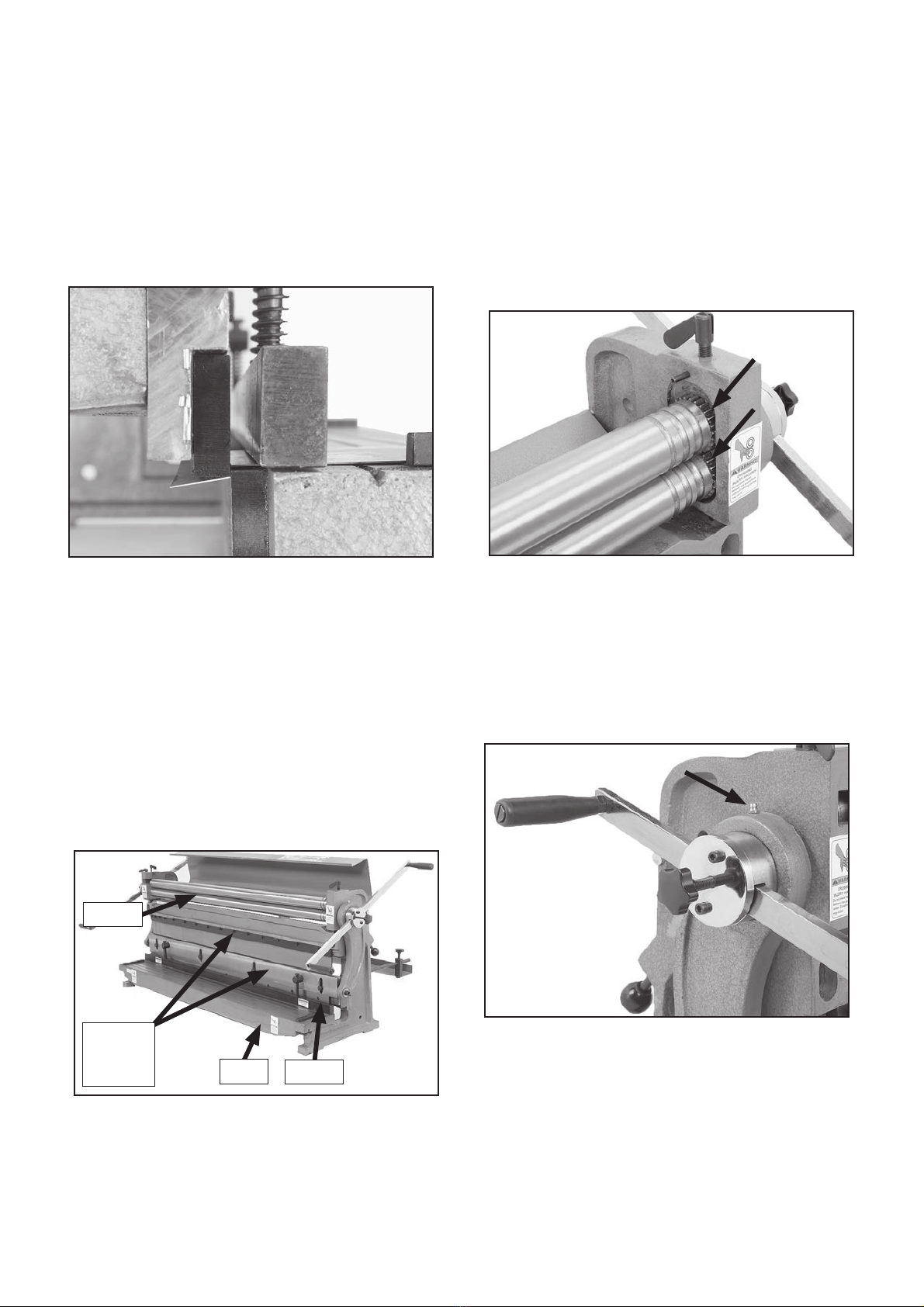

Shear Operation

Symptom Possible Cause Possible Solution

Won't cut

material.

1. Improper blade gap distance.

2. Cut exceeds machine capacities.

1. Widen gap to accommodate thicker gauge material.

2. Make cuts within the capacity of the machine.

Cuts aren't

square. 1. Blade gap unequal across length.

2. Too much bow in blade.

3. Inadequate hold-down pressure.

4. Uneven contact with guides.

1. Adjust blade gap to be equal across length.

2. Adjust blade bow.

3. Adjust gap of hold-down.

4. Maintain consistent contact with guides.

Poor quality of

cuts, ripping or

tearing.

1. Dull blades.

2. Poor blade gap set up.

3. Loose blade.

1. Replace or sharpen blades.

2. Adjust blade gap

3. Remove blade, clean blade mounting, and reinstall.