Section 2. Safety Information

5

2. Safety Information

Q-Lab accepts no responsibility for the consequences if the user fails to comply with the instructions in this operating

manual. Q-Lab will accept responsibility for defective parts or components only if the machinery was defective at the time

that the tester was shipped.

●This manual does not claim to address potential safety issues, if any, associated with the use of this product.

●It is the responsibility of the user of this manual to establish appropriate safety and health practices, and to

determine the applicability of regulatory limitations prior to use.

●If the equipment is used in a manner not specied by the manufacturer, the protection provided by the equipment

safety devices may be impaired.

●The Q-SUN meets the European Low Voltage Directive 2014/35/EU and complies with the requirements of

EN 61010-1: 2010 (Third Edition), “Safety of Electrical Equipment for Measurement, Control and Laboratory Use”.

●The Q-SUN meets the European Electromagnetic Directive 2014/30/EC and complies with the requirements of

EN 55011:2007 Radiated and Conducted Emissions – class A.

●Use only parts that have been supplied or recommended by Q-Lab.

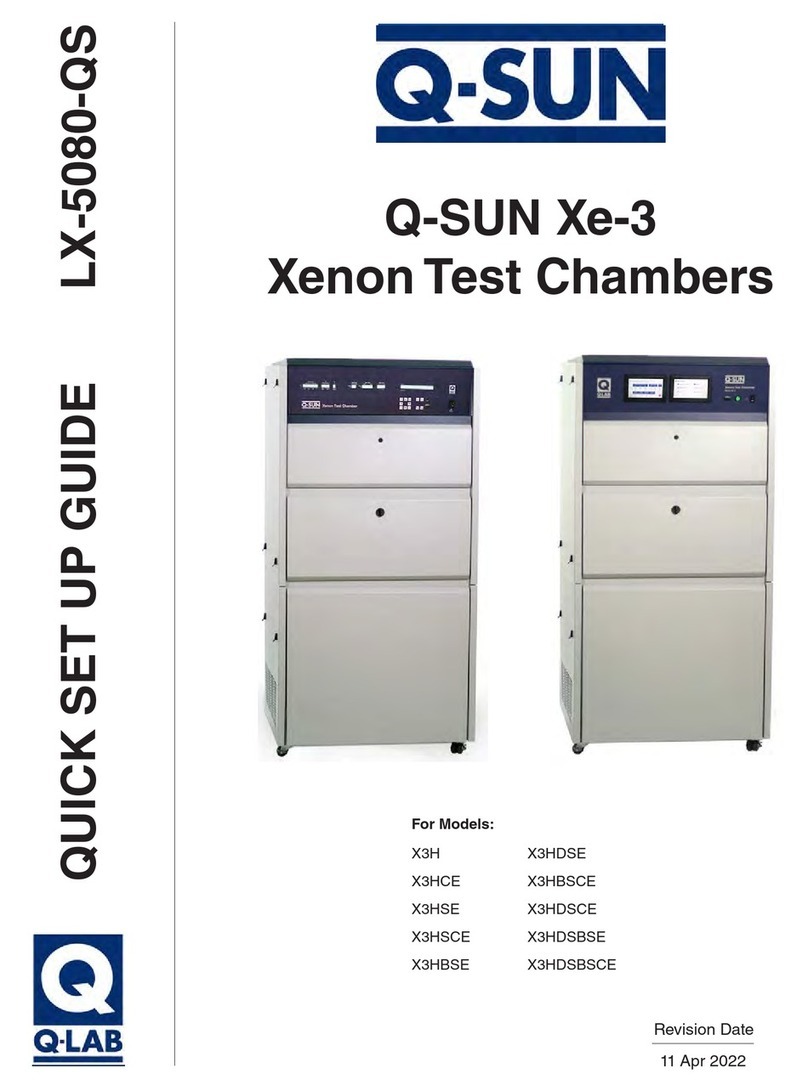

2.1 Heat and Electrical Shock Hazards (Jun 2022)

Warning Labels

●Warning: If the equipment is used in a manner not specied by the manufacturer, the protection provided by the

equipment may be impaired.

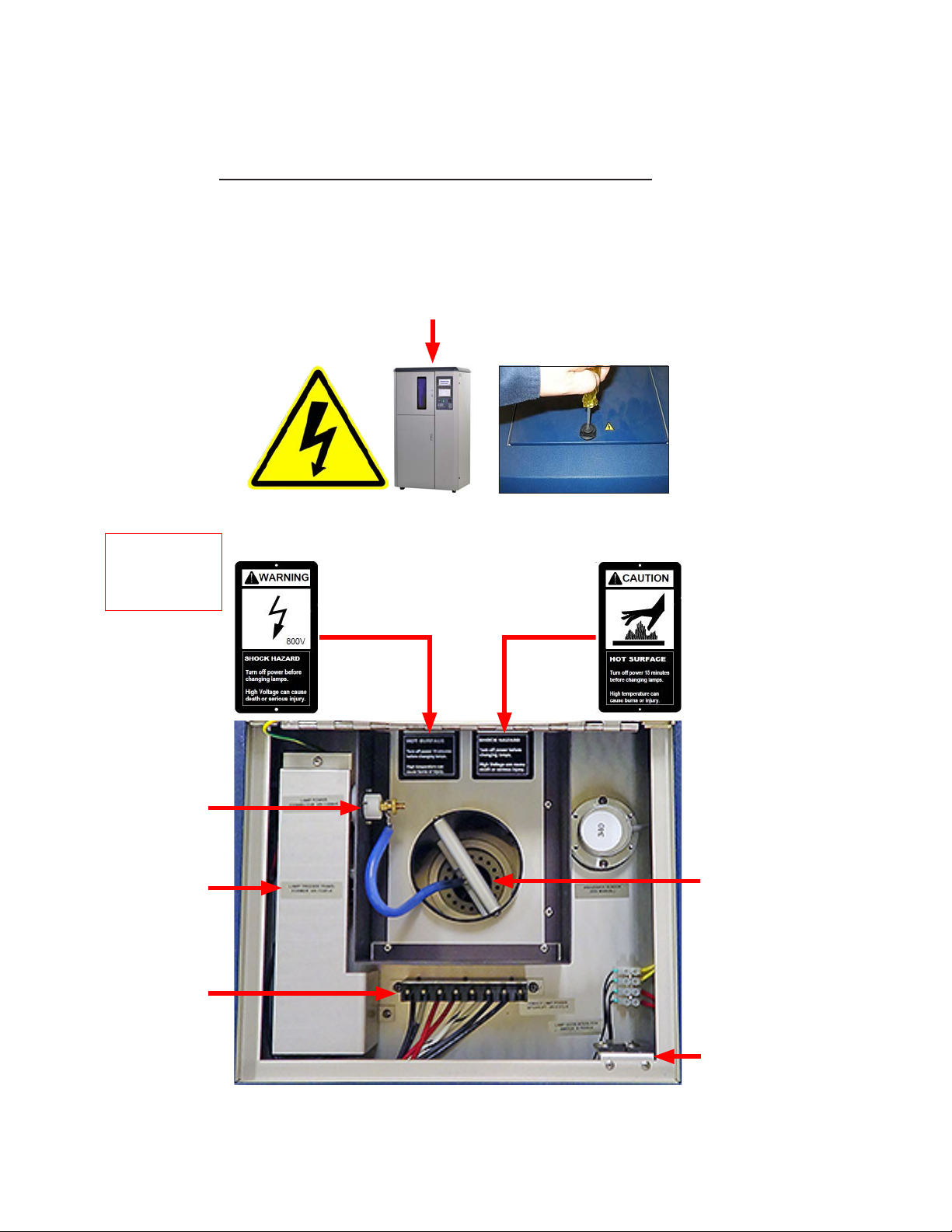

●Doors (Figure 2.1a) provide access to tester interior spaces containing heat generating and/or electrical

components.

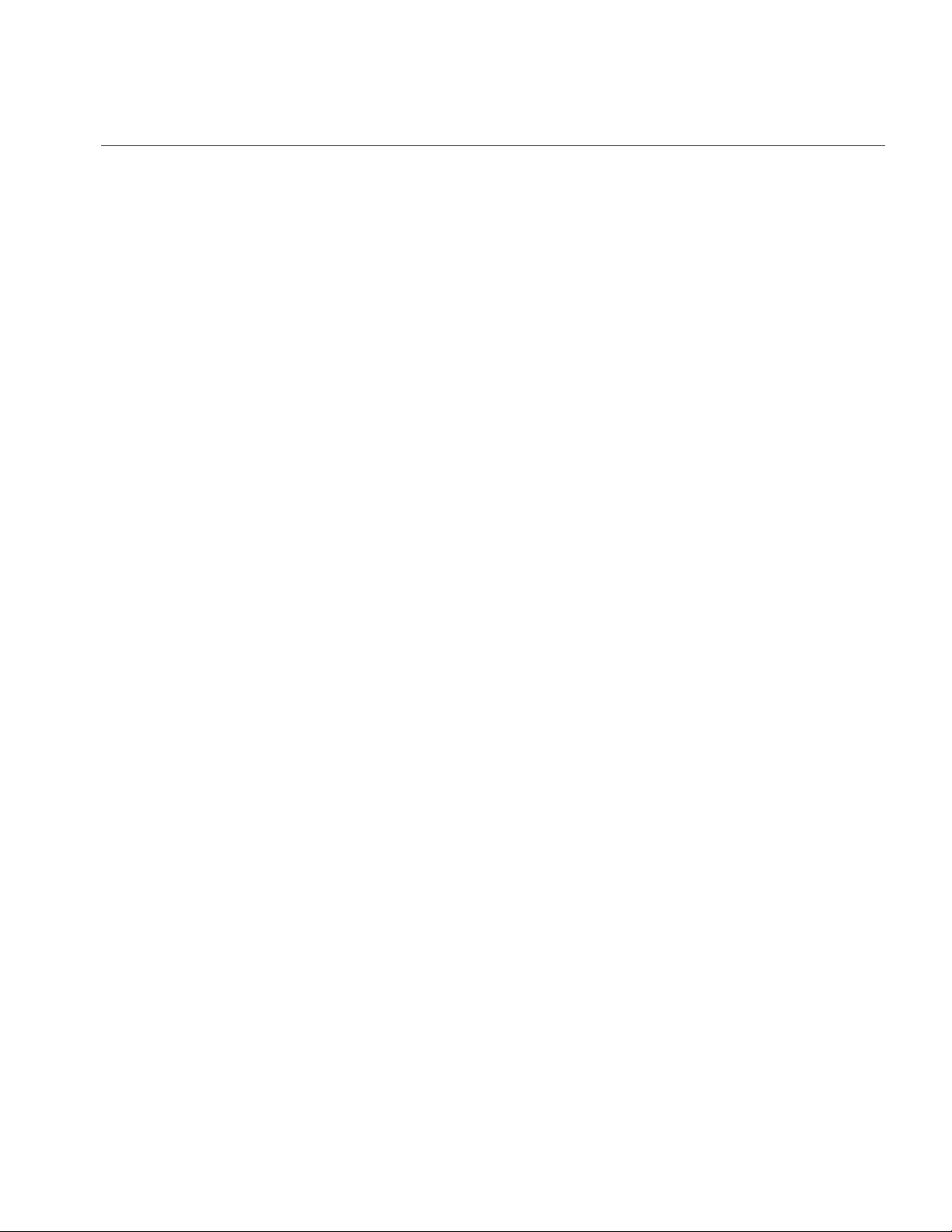

●Warning labels indicate heat and electric shock hazards inside the Q-SUN tester (Figure 2.1a and Figure 2.1b).

Figure 2.1a: Tester access door locations. Figure 2.1b: Hot surface and shock hazard warning labels.

Lower

Front Door

Left Side

Access Door

Right Side

Access Door

Test Chamber

Door

Lamp Door