6 7

INSTALLATION AND OPERATION MANUAL SOLAR MODULES Q.PEAK DUO XL-G11.2 – Q CELLS INSTALLATION AND OPERATION MANUAL SOLAR MODULES Q.PEAK DUO XL-G11.2 – Q CELLS

Installation Site

Please note the following guidelines that apply to the installation site:

• Solar modules are not explosion-proof and are not suitable for

use in explosive environments.

ÄDo not operate solar modules near highly flammable gas and

vapors (e.g. gas tanks, gas stations).

ÄDo not install modules in enclosed space.

ÄDo not install modules in locations where they may be submerged

in water (e.g. floodplains).

ÄDo not use modules as a substitute for the normal roofing (e.g.

modules are not watertight).

ÄDo not install modules in close proximity to air conditioning

systems.

ÄDo not install modules above 13,120ft (4,000m) altitude above

sea level.

ÄContact with saline water (e.g. spray water from the sea) and

salt aggregation on the modules must be avoided.

ÄDo not bring any chemical substance (e.g. oil, solvent etc.) into

contact with any part of the panel. Only substances, which are

released by Q CELLS, are allowed to be used during installation,

operation and maintenance.

ÄAny installation of modules on surfaces of water is prohibited.

This includes installations on floating as well as pile-based

platforms. Q CELLS may extend the coverage of its warranty

to such installations, based on a case by case assessment of

the system design and location. A prior written consent by the

warrantor is required in any case.

Prevention of Shadowing Effects

Optimal solar irradiation leads to maximum energy output:

ÄFor this reason, install the modules so that they face the sun.

ÄAvoid shadowing (due to objects such as buildings, chimneys

or trees).

ÄAvoid partial shading (for example through overhead lines,

dirt, snow).

Limitations

The solar modules are designed for the following applications:

• Operating temperatures from –40°F to +185 °F.

• Pull loads and push loads according to chapter „2.3 Mounting

Options“ (‘Test Load’ in accordance with IEC 61215 and ‘Design

Load ×1.5’ in accordance with UL 61730).

• Installation using a mounting structure for solar modules.

Mounting Structure Requirements

Requirements for the mounting structure:

• Conform to the necessary structural requirements.

• Compliant with local snow and wind loads.

• Properly fastened to the ground, the roof, or the façade.

• Forces acting on the module are relayed to the mounting sub-

structure.

• Ensures sufficient rear ventilation of the module.

•

Avoid the usage of different metals to prevent contact corrosion.

• Allows for stress-free expansion and contraction due to tem-

perature fluctuations.

ÄEnsure that no additional forces are applied through the mounting

system into the module except for the wind and snow loads.

Additional forces and moments of torque at the mounting

positions caused by torsions, displacements or vibrations in

the mounting system are not allowed.

ÄEnsure that the clamps and the mounting frame are compatible.

Clamp System Recommendations

Use customary clamps that satisfy the following requirements:

• Clamp width: ≥1.5in (38 mm).

• Clamp height compliant with a 1.38in (35 mm) frame height.

•

Clamp depth: 0.2-0.47in (5-12mm). (applicable for all CL and TC

clamping mounting options at section „2.3 Mounting Options“)

• Clamps are not in contact with the front glass.

• Clamps do not deform the frame.

• Clamps that satisfy the structural requirements based on the

conditions of the installation site according to the applicable

regulations and technical standards.

• Long-term stable clamps that securely affix the module to the

mounting frame.

Module Orientation Requirements

• Vertical or horizontal installation is permitted.

ÄEnsure that rain and melting snow can run off freely. No water

accumulation.

ÄEnsure that the drainage holes in the frame are not covered.

No sealing.

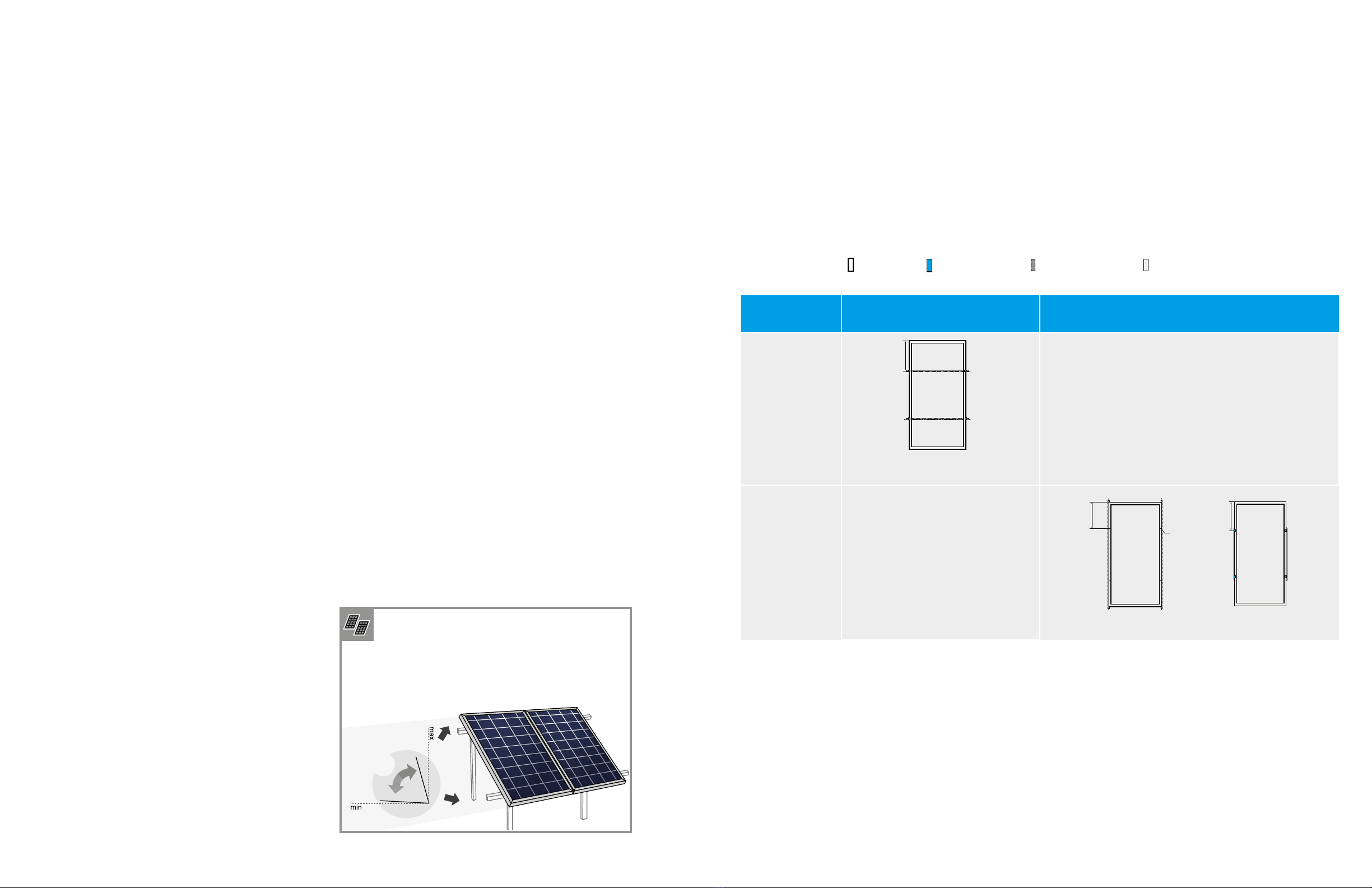

75°

3°

ÄMaintain the permissible angle of inclination.

• Minimum angle of inclination: 3°

• Inclination angles above 75° may be limited by

local regulations

ÄStanding water on the modules glass needs to be

avoided.

2 PLANNING

2.2 REQUIREMENTS

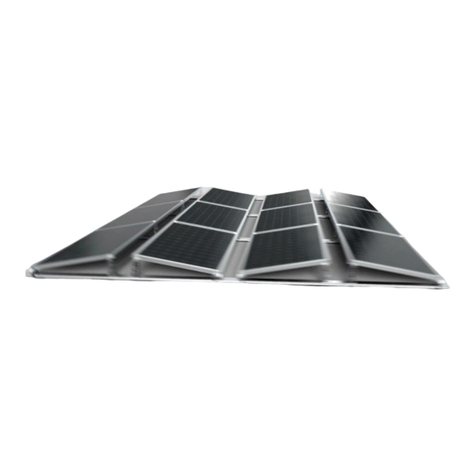

Fig. 2: Installation options for crystalline Q CELLS modules. All dimensions are given in inch (mm in brackets). Also observe

the maximum test loads and clamping range as specified on page 9.

The illustrated installation options apply for both horizontal and vertical module orientation.

Module Clamp Subconstruction Mounting profile

2 PLANNING

2.3 MOUNTING OPTIONS

The module is considered to be in compliance with UL 61730 only when the module is either mounted in the manner specified by

the mounting instructions, or when the mounting means has been evaluated with this PV module to UL 2703. A module with exposed

conductive parts is considered to be in compliance with UL 61730 only when it is either electrically grounded in accordance with the

manufacturer’s instructions and the requirements of the National Electrical Code, ANSI/ NFPA 70 (2014-2017), or when the bonding

means has been evaluated with this module to UL 2703.

TYPE OF

INSTALLATION

POINT MOUNTING SYSTEM LINEAR MOUNTING SYSTEM

INSTALLATION

WITH CLAMPS

INSTALLATION

ON MOUNTING

POINTS

FB2

4 ×mounting

slots

20

(508)