Table of Contents

1 About this manual

1.1 Introduction...............................................................................................................................6

1.2 Product documentation............................................................................................................ 6

1.3 Source language...................................................................................................................... 7

1.4 Drawings.................................................................................................................................. 7

1.5 Symbols used in the manual.................................................................................................... 7

1.6 Terminology list.........................................................................................................................7

1.7 Further support and information............................................................................................... 8

2 General

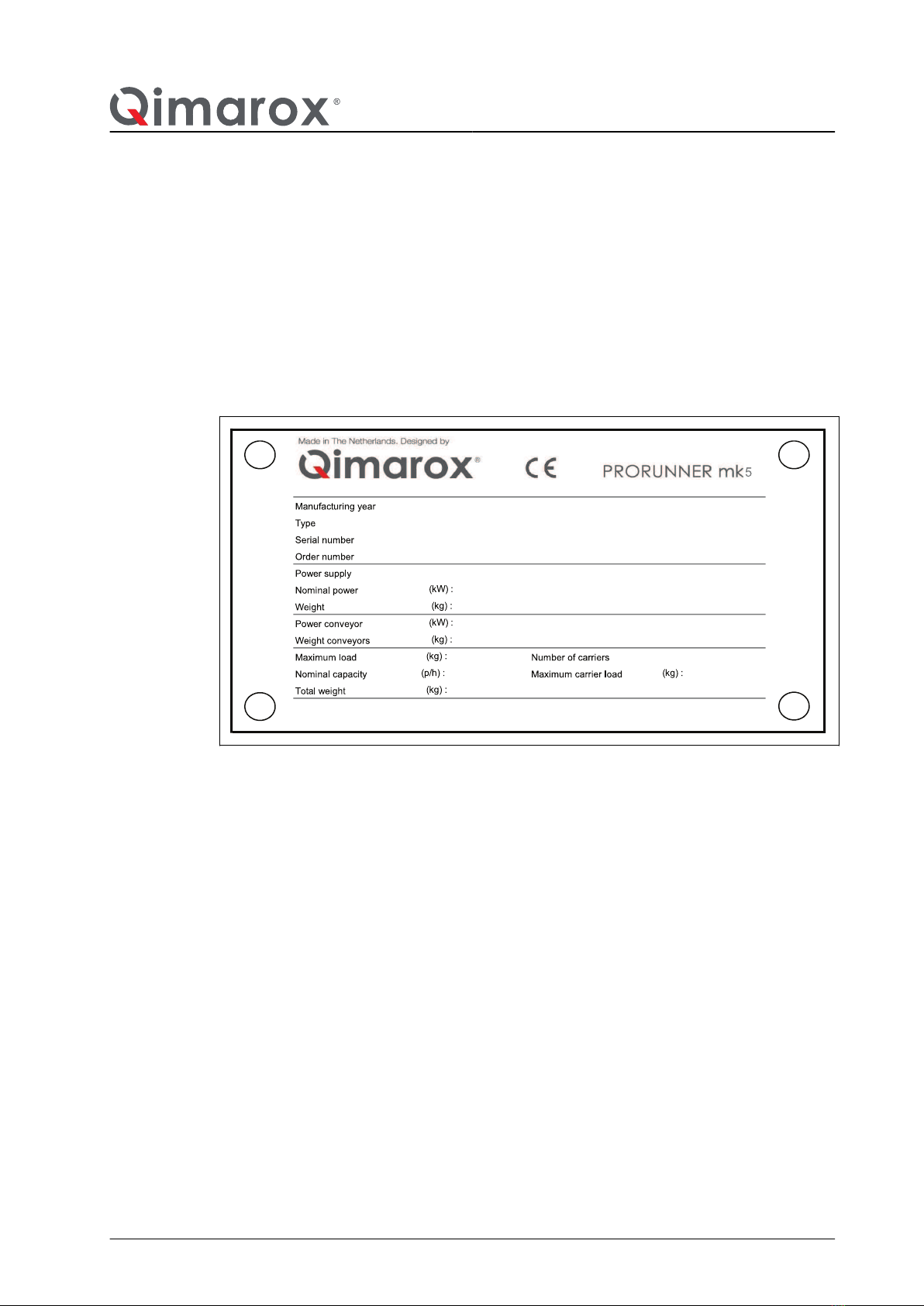

2.1 Machine identification...............................................................................................................9

2.2 Machine layout drawing and specifications............................................................................ 10

2.3 Warranty................................................................................................................................. 11

2.4 Liability....................................................................................................................................11

2.5 CE Declaration of Conformity.................................................................................................12

2.6 Patent..................................................................................................................................... 12

3 Safety

3.1 Intended use of the machine.................................................................................................. 13

3.2 User types and qualifications................................................................................................. 13

3.3 Safety instructions.................................................................................................................. 13

3.4 Safety provisions.................................................................................................................... 15

3.5 Sound level.............................................................................................................................17

3.6 Personal safety.......................................................................................................................17

3.7 Potential risks......................................................................................................................... 19

3.8 Machine end of life and environment disposal....................................................................... 19

4 Description

4.1 General overview................................................................................................................... 21

4.2 Working principles.................................................................................................................. 21

4.3 Sensors.................................................................................................................................. 23

4.4 Motor...................................................................................................................................... 26

4.5 Control system....................................................................................................................... 27

4.6 Guiding of the carriers............................................................................................................ 28

4.7 Machine in a system...............................................................................................................28

4.8 Specifications......................................................................................................................... 31

Table of Contents

UM-Prorunner mk5-2.0-EN 3