4

• (1) AD-DWL.180, AD-DWL.360, or AD-DWL.SUB

• (1) collar

• (4) collar Torx M6 screws

• (1) Torx bit

• (1) installation template

• (1) paint mask for AD-DWL.180, (2) paint masks for

AD-DWL.360*

* Paint mask not required for AD-DWL.SUB. For painting

instructions, see the Self Help Portal.

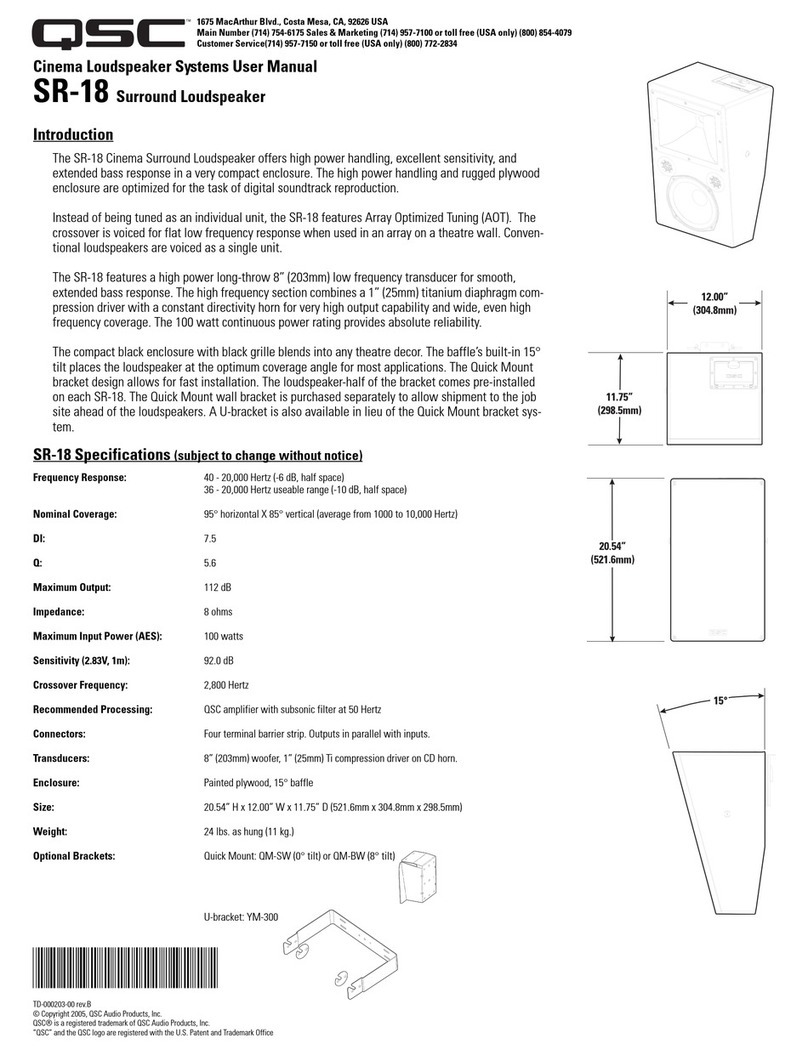

Four M10 or 3/8” bolts

on 120mm (4.72”) diameter circle

— Figure 1 —

Installation on Concrete or Other Hard Surfaces

Hard surface installation requires four M10 or 3/8" drop-in anchor

bolts, eight nuts, and eight washers (not supplied). The bolts must be

long enough to provide 65mm (2.5") of usable thread above the

surface level.

Prepare the surface

NOTE:

Before proceeding, be aware of the location of

conduit under the loudspeaker location and the intended

orientation of the loudspeaker – for example, facing

parallel to another hard surface, such as a sidewalk or

patio.

1. Use the supplied installation template to mark the location for the

four drop-in anchor bolts as close to the center of each arc as

possible, as shown in Figure 1.

2. Install the anchor bolts (not supplied) into the mounting surface.

Mount the collar

The rotational orientation of the collar determines the

aim of the loudspeaker. The collar can rotate ± 26°

from the arc center.

1. On each anchor bolt, place a bottom nut and

washer. These are used to level the collar.

2. Place the collar on the bottom washers. Using a

bubble level, adjust the nuts so that the collar is

horizontal and that all washers are in contact with

the collar flange. See Figure 2.

NOTE:

There must be no gap between the

washers and the collar flange.

3. Rotate the collar to the exact desired position,

verify levelness, and then secure the collar by

attaching a top washer and nut for each bolt. See

Figure 3.

4. Tighten all top nuts to a recommended torque of

81 kgf.cm (70 lbf.in).

Hard Surface

Flange

Nut Washer

— Figure 2 —

Hard Surface

Flange

Nut

Washer

— Figure 3 —

What's in the Box