LA-KIT-I Quick Start Guide

IMPORTANT SAFETY INSTRUCTIONS

WARNING!: TO PREVENT FIRE OR ELECTRIC SHOCK, DO NOT EXPOSE THIS EQUIPMENT TO RAIN OR

MOISTURE.

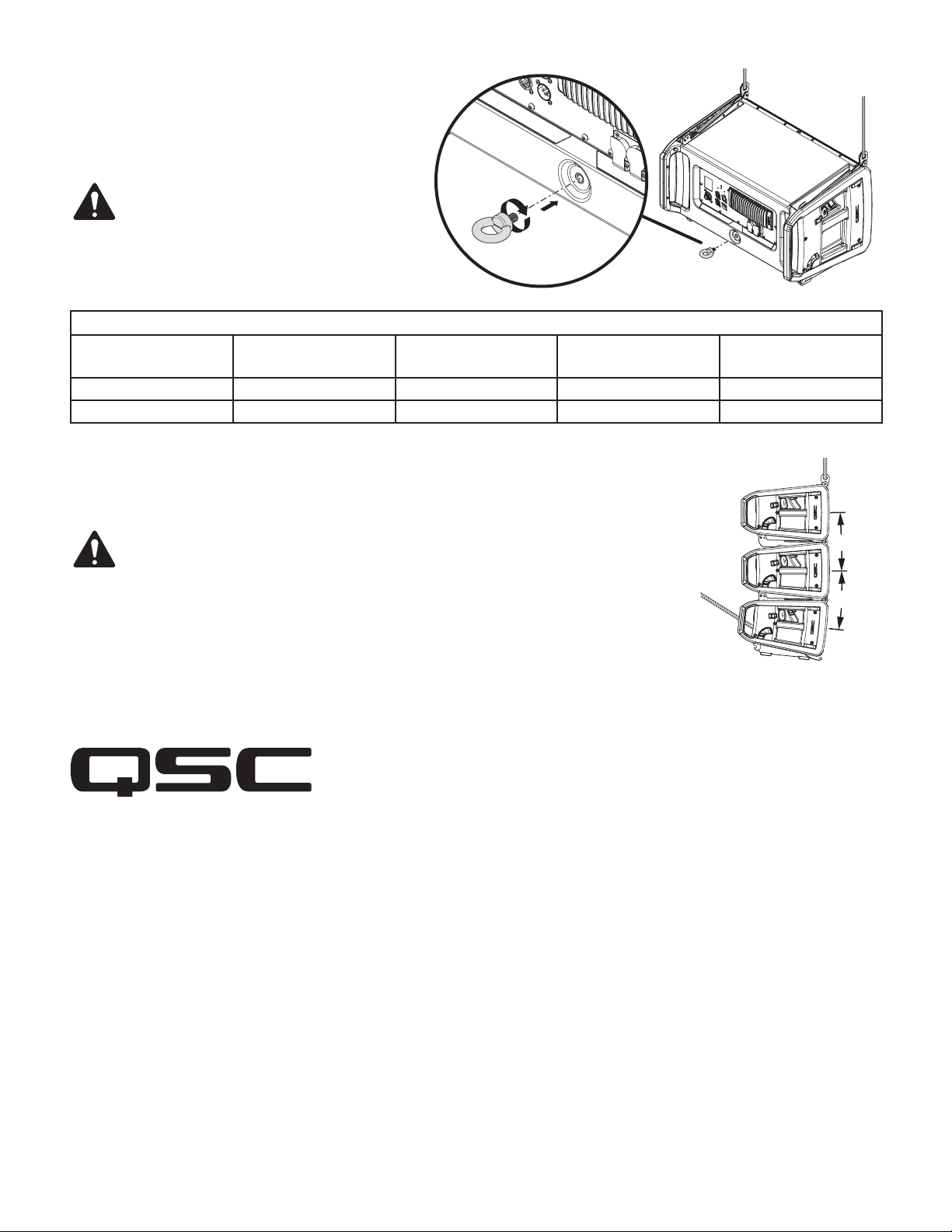

WARNING!: Before placing, installing, rigging, or suspending any loudspeaker product, inspect all hardware,

suspension, cabinets, transducers, brackets and associated equipment for damage. Any missing, corroded, deformed, or

non-load rated component could significantly reduce the strength of the installation or placement. Any such condition

severely reduces the safety of the installation and should be immediately corrected. Use only hardware which is rated for

the loading conditions of the installation and any possible short-term, unexpected overloading. Never exceed the rating of

the hardware or equipment. Consult a licensed, professional engineer regarding physical equipment installation. Ensure

that all local, state and national regulations regarding the safety and operation of loudspeakers and related equipment are

understood and adhered to.

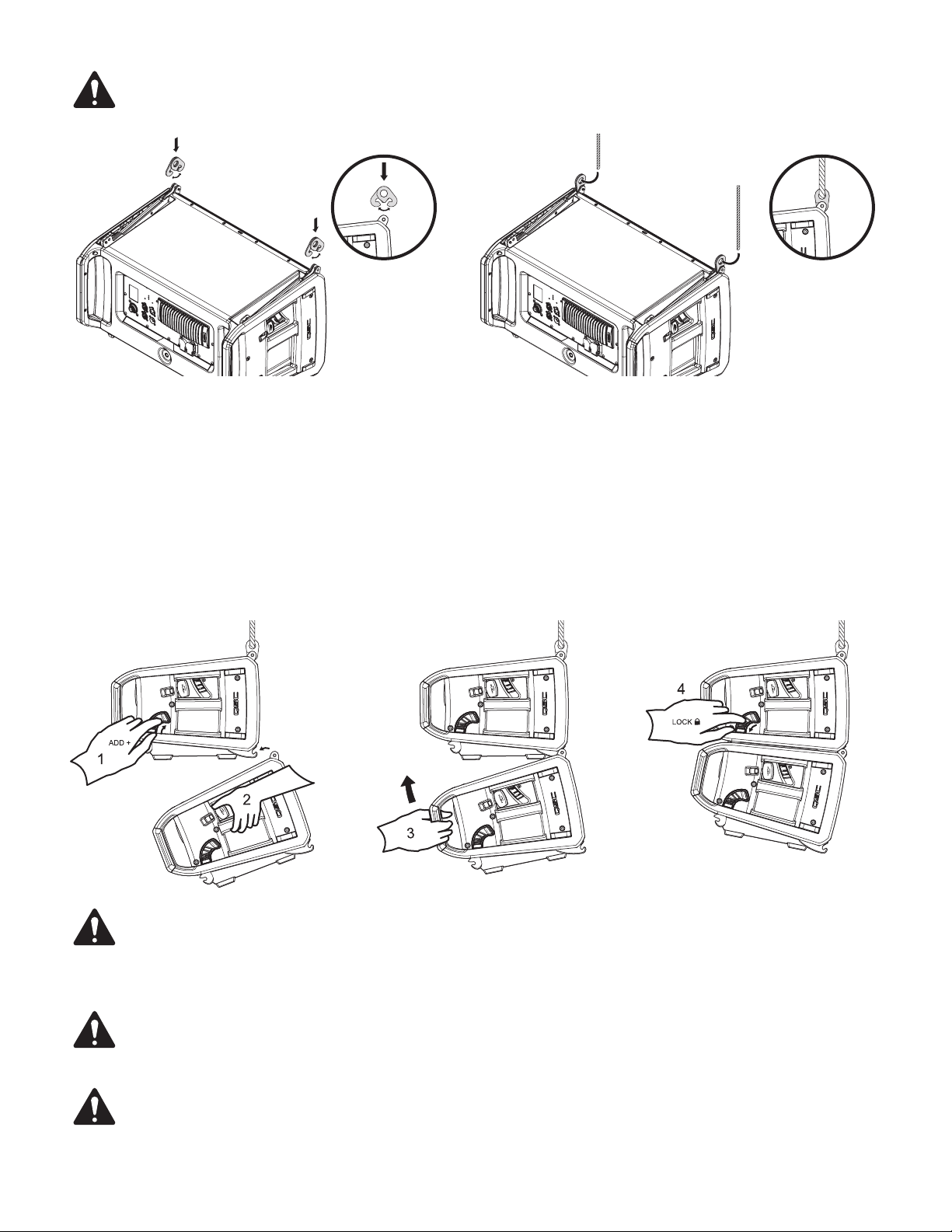

WARNING!: The LA108 loudspeaker weighs 13.7 kg (30.1 lb), and the LA112 loudspeaker weighs 21.4 kg (47.2 lb).

Use proper precautions when lifting or moving. During assembly and disassembly, make sure the loudspeakers are

properly, physically supported throughout the entire process. While it is possible for one person to lift a LA108 or LA112

loudspeaker, it is important to use proper lifting techniques. Suggested reading: OSHA Technical Manual on Back

Disorders and Injuries.(http://www.osha.gov/dts/osta/otm/otm_vii/otm_vii_1.html#app_vii:1_2).

1. Keep these instructions.

2. Heed all warnings.

3. Follow all instructions.

4. Do not use this apparatus near water.

5. Clean only with a dry cloth.

6. Install in accordance with the manufacturer's instructions.

7. Do not install near any heat sources such as radiators, heat

registers, stoves, or other apparatus (including amplifiers) that

produce heat.

8. This apparatus shall not be exposed to dripping or splashing

water, and no object filled with liquids such as cups or vases

shall be placed on the apparatus.

9. To reduce the risk of electric shock, the power cord shall

be connected to a mains socket with a protective earthing

connection.

10. Protect the power cord from being walked on or pinched,

particularly at plugs, convenience receptacles, and the point

where they exit from the apparatus.

11 . Only use attachments/accessories specified by the

manufacturer.

12. Unplug this apparatus during lightning storms or when

unused for long periods of time.

13. Refer all servicing to qualified service personnel. Servicing

is required when the apparatus has been damaged in

any way, such as when the power-supply cord or plug is

damaged, liquid has been spilled or objects have fallen into

the apparatus, and/or the apparatus has been exposed to

rain or moisture, does not operate normally, or has been

dropped.

14. The appliance coupler (AC Mains plug) is the AC mains

disconnect device and shall remain readily operable after

installation.

15. Adhere to all applicable, local codes.

16. Consult a licensed, professional engineer when any doubt or

questions arise regarding a physical equipment installation.

17. Suspension of this product should be done by qualified

persons following safe rigging practices. Other limitations

may apply.

18. Use only the recommended system components and

suspension hardware intended for use with this product as

directed by this manual.

TD-001648-01-A

*TD-001648-01*