6

2a: Preparing your Locomotive: Pre-Install Precautions

We've already covered a few of the things that you don't want to do when installing your decoder. Now let's

look at some things you do want to do to get your locomotive ready to roll.

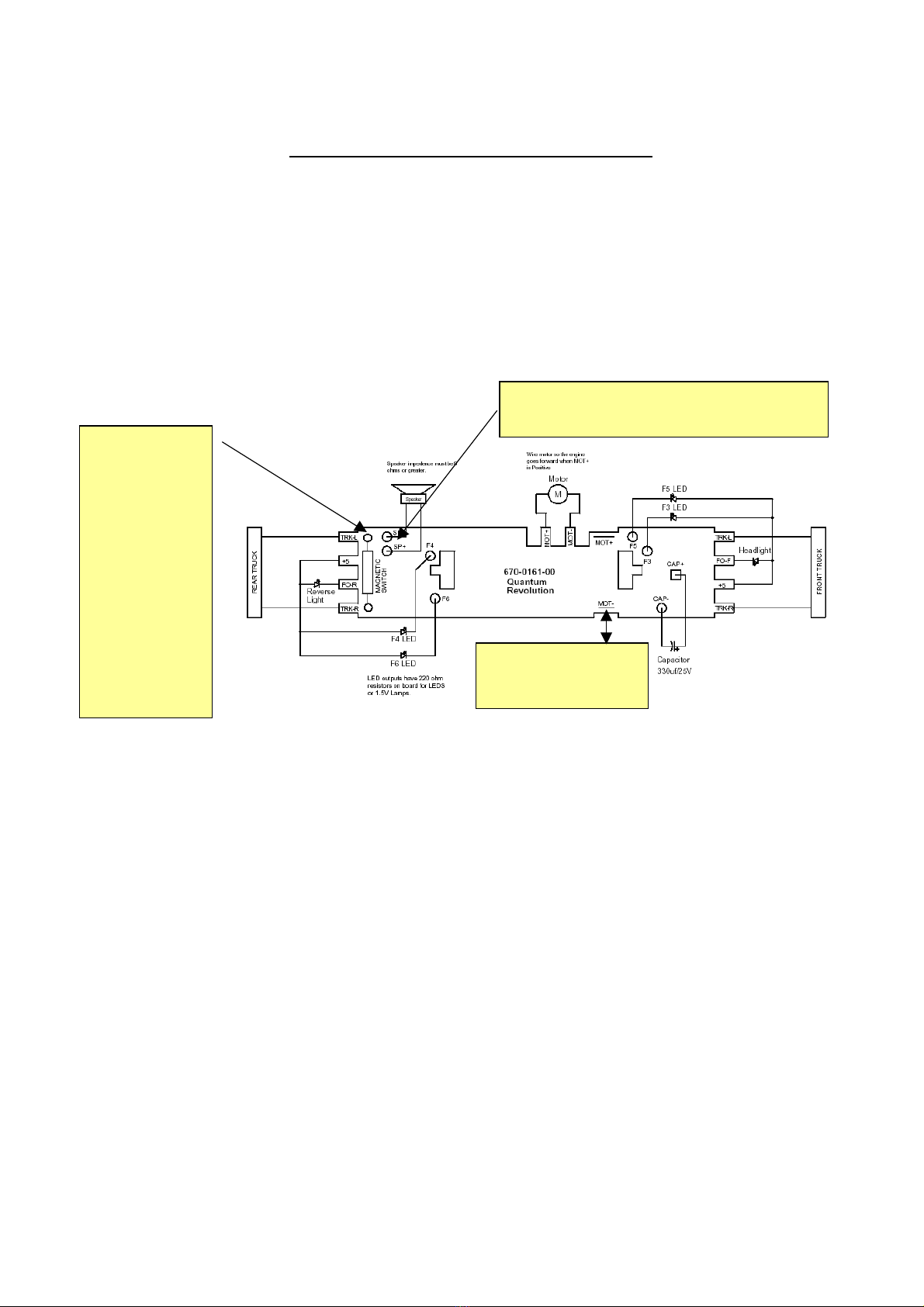

1st: Isolate the motor.This is one of the most critical aspects of any DCC decoder installation, regardless

of make or model. You MUST make sure your motor no longer receives ANY power directly from the track. In other

words, if you can find pick-up wires going directly from one side of your wheels/trucks to the motor terminals, you'll

want to disconnect them where they connect to the motor not from the trucks. Disconnecting them will keep the DCC

from “backfeeding” into the decoder and burning it up (see Step 5 of Section 2 regarding “smoke”!).

Note that on certain locomotives the motor draws power directly from 2 sides of a split frame, which the

motor is enclosed inside. Isolating this type of motor can be more difficult, and can require insulation of the

inner parts of the frame. If you have any doubt about the type of motor set-up you have, please contact QSI

Solutions for clarification before proceeding with the installation.

Most modern models already have the motor isolated. If the locomotive instructions say anything about it

being “DCC Ready,” then your model already has the motor isolated.

2nd: Trace your wires. By identifying which wire goes where, you'll make things a lot easier. We

recommend you devise some method of marking the wires once you have them traced out. That way, when

you want to reconnect that headlight, you won’t be left sitting there, looking at a bundle of wires, thinking

uhhhhhhh..... Hint: On the Revolution-

, move ONE wire at a time from the circuit board to the new decoder.

2b: Pre-Installation Loco Modifications

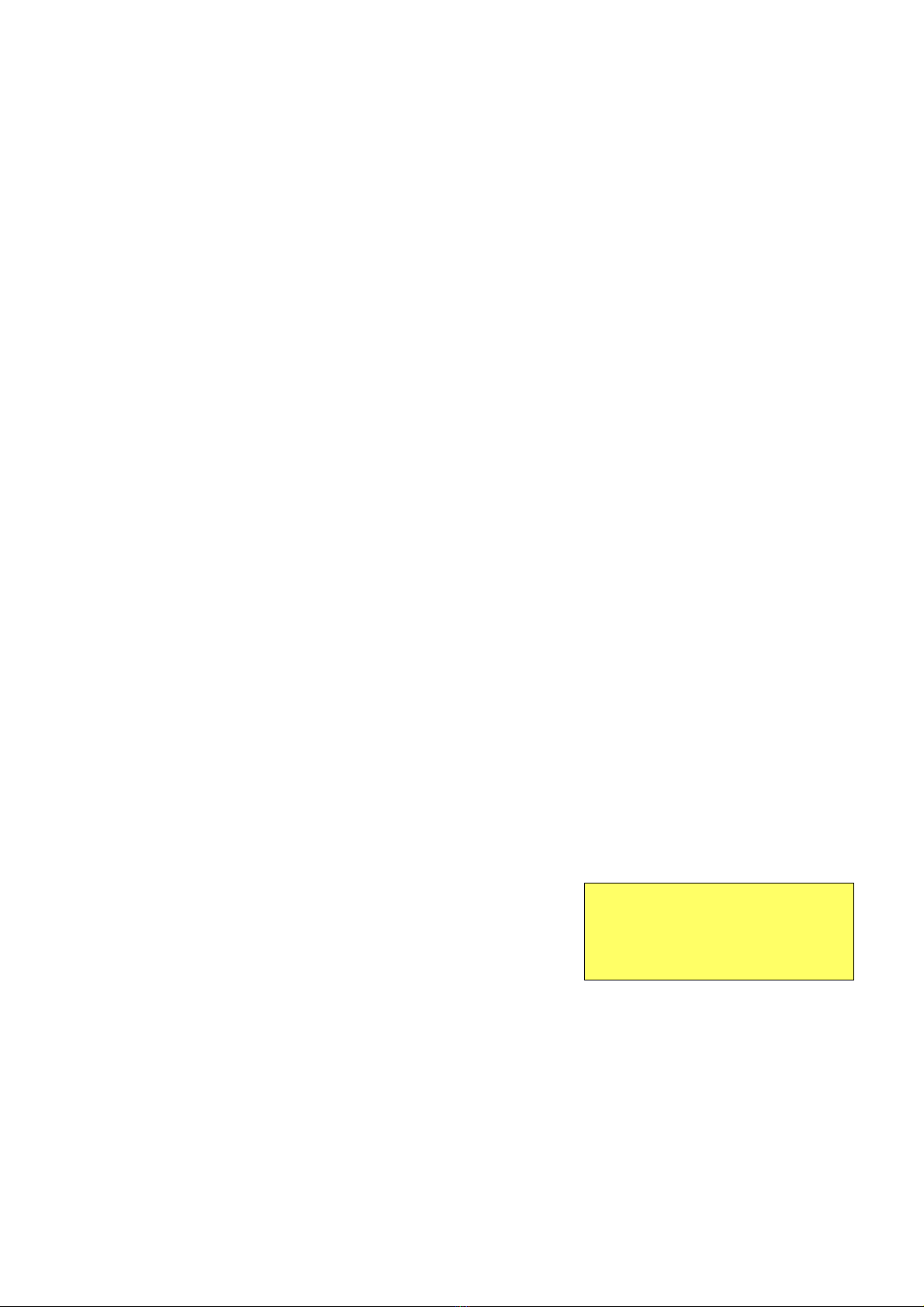

Now that you've isolated your motor and traced your wires, it is time to figure out where to put that speaker.

In steam locomotives, this is often pretty easy since most tenders are reasonably open inside. In diesels, it

tends to be a bit more difficult. We'll outline a couple ideas and let you decide.

2c: Speaker Selection

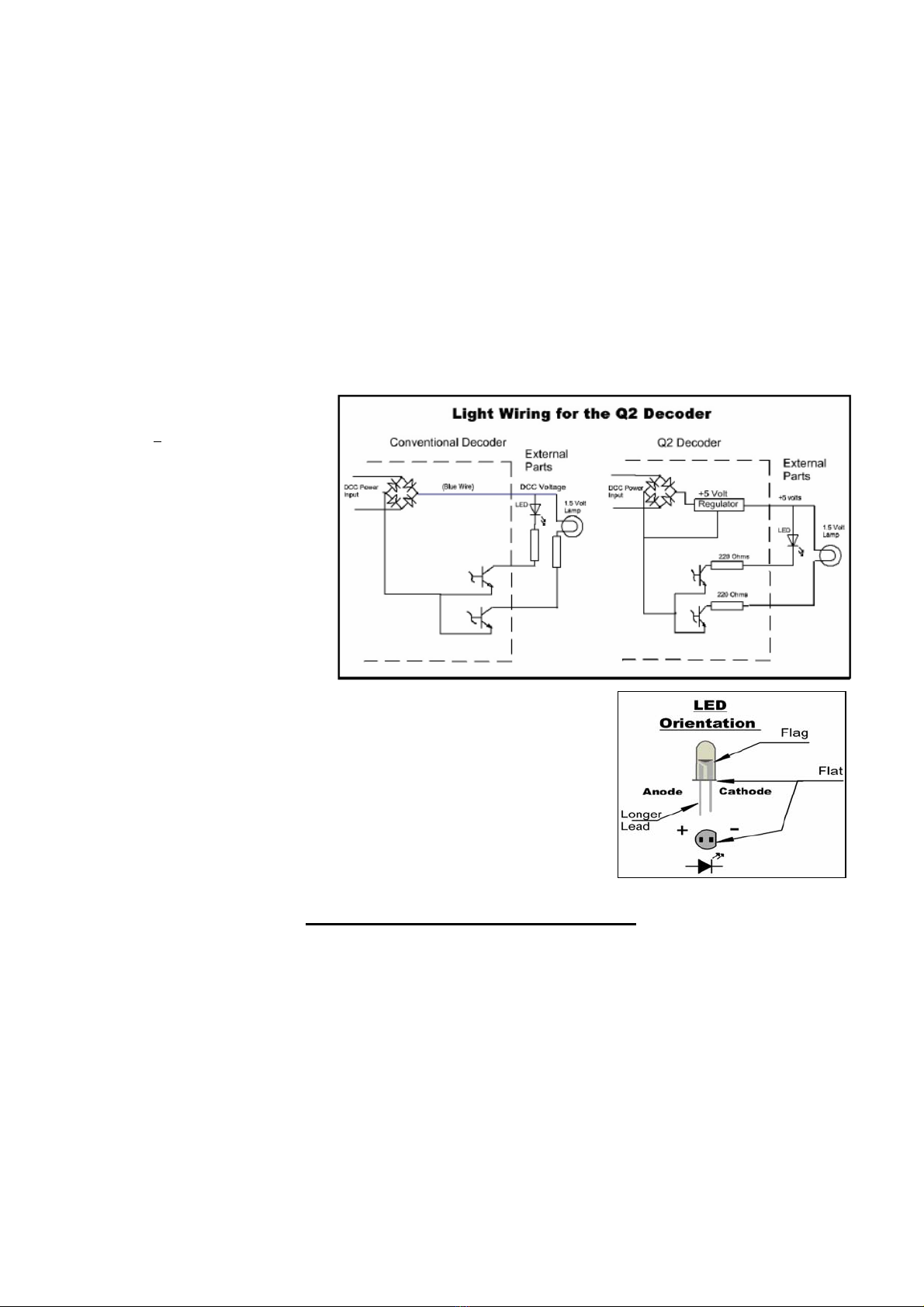

Since we've talked about where you're going to put the speaker, let's take a step back and talk about which

speaker you're going to use. QSI offers a plethora of new speakers with varying frequency responses

which means you now have many options. We recommend you experiment, so that you can decide how

much modification you’re willing to do to accommodate a particular speaker. Hint: Be sure to use some type

of baffle (enclosure) with your speakers. You can either use one of the available speaker enclosures, or with

appropriate “sealing,” the body shell itself. If you're unsure about what kind of speaker you're going to need,

feel free to call QSI Solutions for recommendations.

Next, make the final decision on where you'll put your speaker(s). Some locomotives have a cover on the

fuel tank that, when removed, reveals a weight that can also be removed. This is actually one of the better

configurations, because it accommodates the largest speaker. Another option includes: removing weight

from the top of the frame and broadcasting the sound out, quite prototypically, through the exhaust fan grills.

The last (and possibly most common) configuration is to remove any cab detailing and locate your speaker

in the remaining open space.