QUADBOSS UTV STRAIGHT PUSH TUBE

TROUBLESHOOTING GUIDE

Below are some tips to help you resolve any problems and keep your Quadboss plow system in proper working order. After reviewing, if you still need

technical assistance please call 877-847-1558.

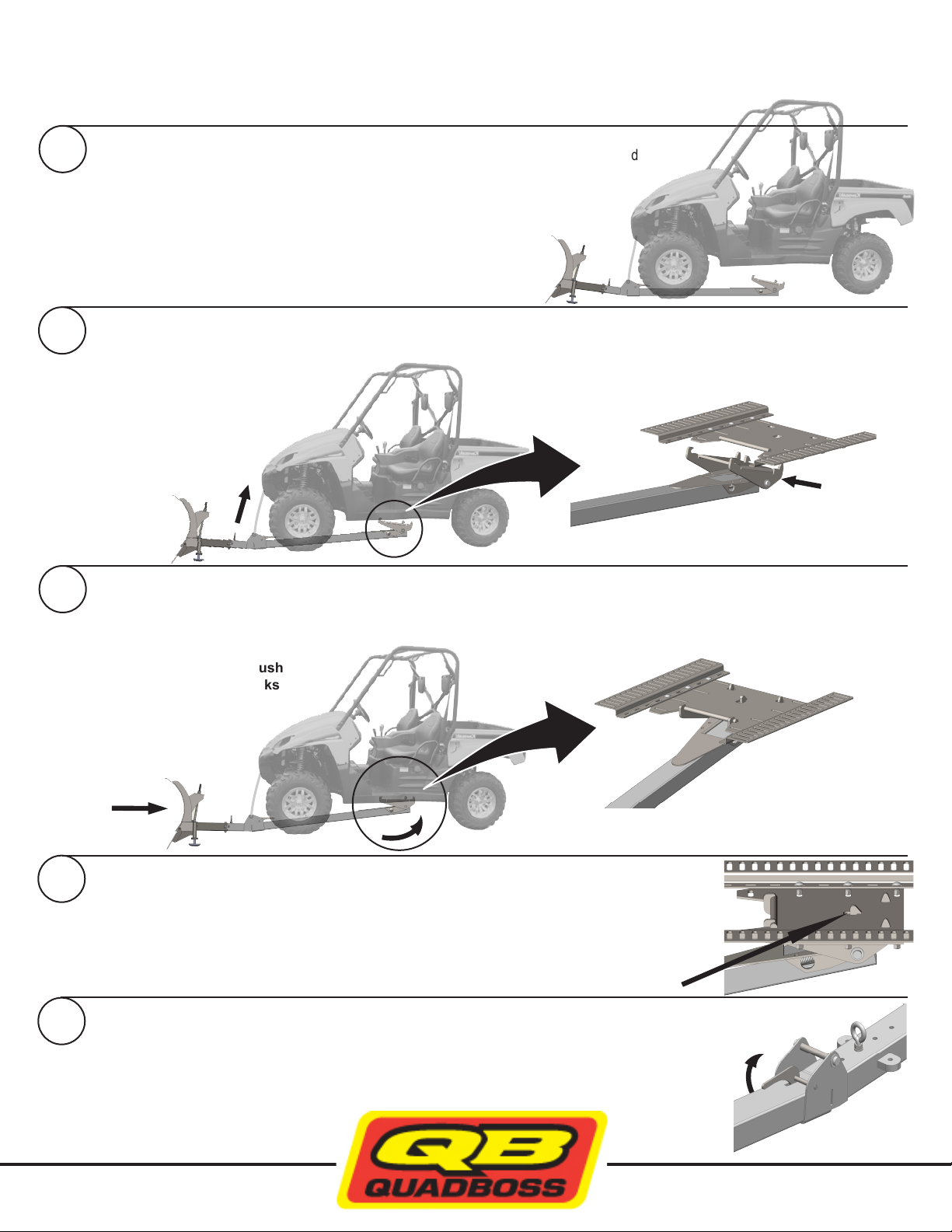

PLOW ASSEMBLY WILL NOT ATTACH OR DISCONNECTS FROM THE BOTTOM MOUNT ON THE ATV.

1. Plow is not positioned properly. Lift the plow with the winch until the pivot plate of the push tube hits the bottom of the machine and the blade

is a couple inches off the ground. Now look under the machine to verify the hooks on the pivot plate are centered and in front of the bottom

mount. If not, re-position the winch lifting position or bottom mount until the plow is properly positioned. Using a firm swift motion push the

plow back until it engages into the mount.

2. Spring for the pivot plate on the push tube is worn or broken. The pivot plate needs to be angled upwards for the hooks to engage the bottom

mount. Replace the spring.

3. Linkage rod is bent or disconnected. Inspect to determine the problem and repair or replace the linkage rod.

4. Pivot plate is bent or damaged. The ears of the pivot plate must be straight. Straighten if possible or replace the pivot plate.

5. Latch pawl is worn or bent. Replace pawl.

6. Release lever is in the open position. Close lever which will position the pivot plate at the proper angle. If the lever will not close, inspect the

linkage rod, pivot plate, spring, and latch pawl for any damage.

7. Ice or snow buildup on either the pivot plate or bottom mount.

8. Bottom mount is bent or damaged. Inspect for any bending, shifting, warping, twisting or any other damage. The welded on rod must be straight.

Replace the bottom mount if damage is found.

9. Bottom mount plate is installed upside down. The rod is welded to the plate off center and must be facing upwards. The bottom of the mount

should be flush for the pivot plate to attach to.

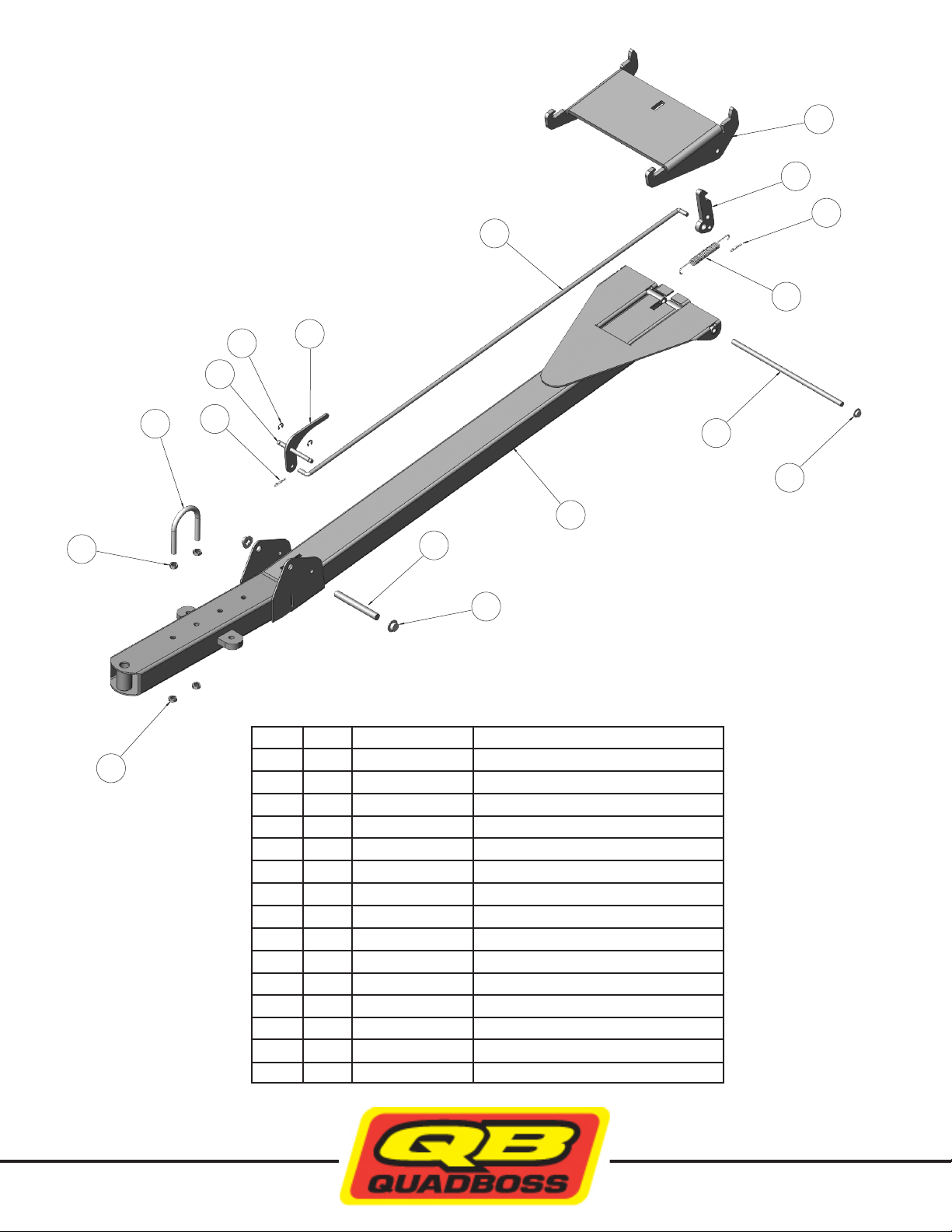

BLADE IS STUCK OR IS DIFFICULT TO SWIVEL SIDE TO SIDE.

1. Pivot pin is still in the plow. Remove pin to swivel plow.

2. Ice, snow, dirt or other debris packed in the back channel of the blade. Thoroughly clean out any debris.

3. One or both struts broke. Carefully inspect both struts as the ends may tear open without coming loose from the plow. Replace as necessary.

4. Strut bolts bent or washers missing. Inspect for bent bolts or missing washers. See illustration for correct washer orientation.

5. Sliding lock plates inside back channel of blade are bent. Inspect for damage and replace where applicable.

6. Back channel of the blade is bent or the slots are pulled open. Repair or replace blade.

WEARBAR WILL NOT TRIP PROPERLY.

1. Wearbar, blade, or trip rod bent or damaged. Inspect for any bending, twisting, denting of the components and repair or replace. If there is no

obvious sign of damage, remove both trip spring assemblies and move the wear bar back and forth by hand to help pinpoint the problem area.

2. Rocks or other debris caught between the blade and wear bar. Remove the springs or VERY CAREFULLY force the wearbar open with a

prybar to let the debris fall out. NEVER pull it out using your hands!

3. Springs not installed correctly. Refer to the blade diagram to confirm all spring and spring rod parts are in the proper location. Verify the top

1/2” nuts on the spring rod are tightened most of the way down.

4. Springs broke or worn out. Replace if necessary.

WEARBAR TRIPS TOO EASILY OR CHATTERS DURING OPERATION.

1. Depending upon surface type and snow conditions some chatter is normal with this system to quickly hop over packed snow/ice. Simply make

one or two more passes to help clear the snow/ice. This chatter helps you keep plowing where the competitors plows trip forward forcing you

to stop, back up, and try again.

2. Springs are too loose or worn out. Verify the top 1/2” nuts on the spring rod are tightened most of the way down. Replace springs if worn.

08/09/2011 Rev. 1.1

PAGE 5 of 6

PART #9382

Tech Line 877-847-1558 www.quadboss.com