11

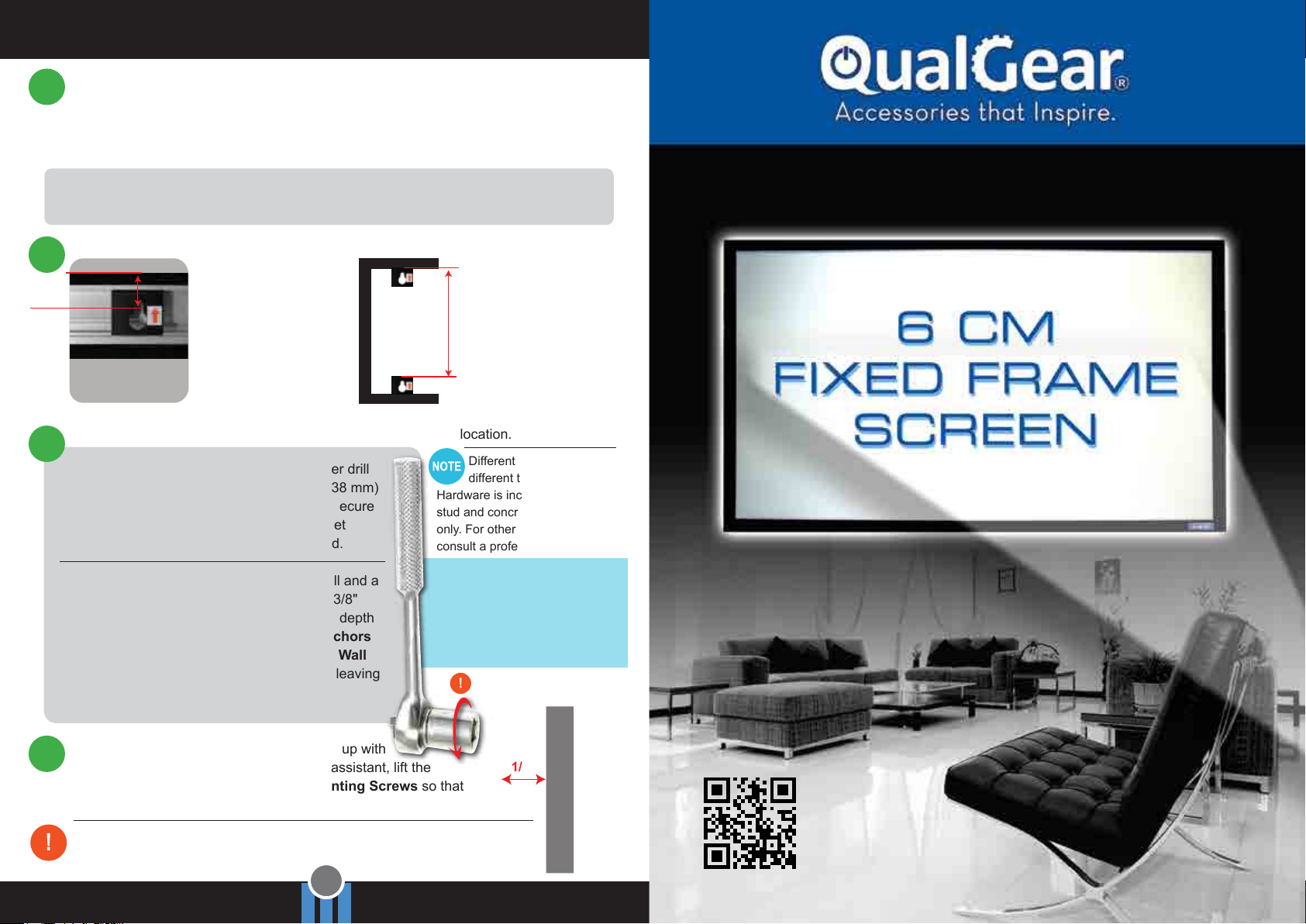

Mount to the Wall

Slide the Hanging Brackets until they line up with

the secured mounting hardware. With an assistant, lift the

screen gently onto the secured Wall Mounting Screws so that

the keyholes on the Hanging Brackets fit over the screws.

18

INSTALLATION MANUAL

www.qualgear.com | 2 Year Limited Warranty | Version: December 2015

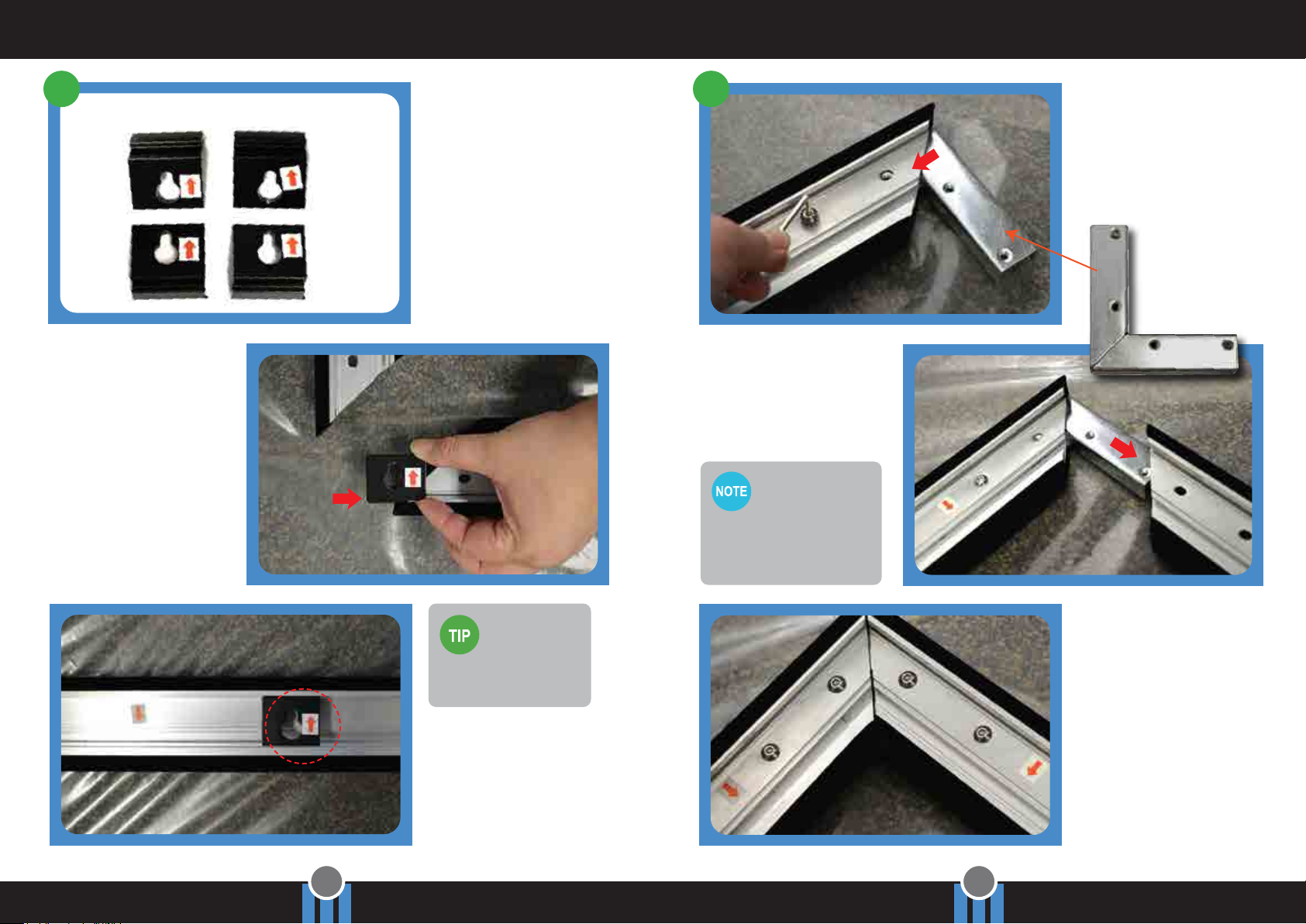

16 Top Hanging Brackets:

on the wall, measure

and mark 3/4" down

from the top edge of the

desired frame location.

IMPORTANT make sure

they are marked on the

center of the studs and

verify they are level.

Bottom Hanging

Brackets: measure and

record the distance from

the top of the bracket to

the top of the matching

bottom bracket on the

assembled frame. Mark

this distance on the wall

from the top marked

location.

approx. 3/4"

Record

Distance

17

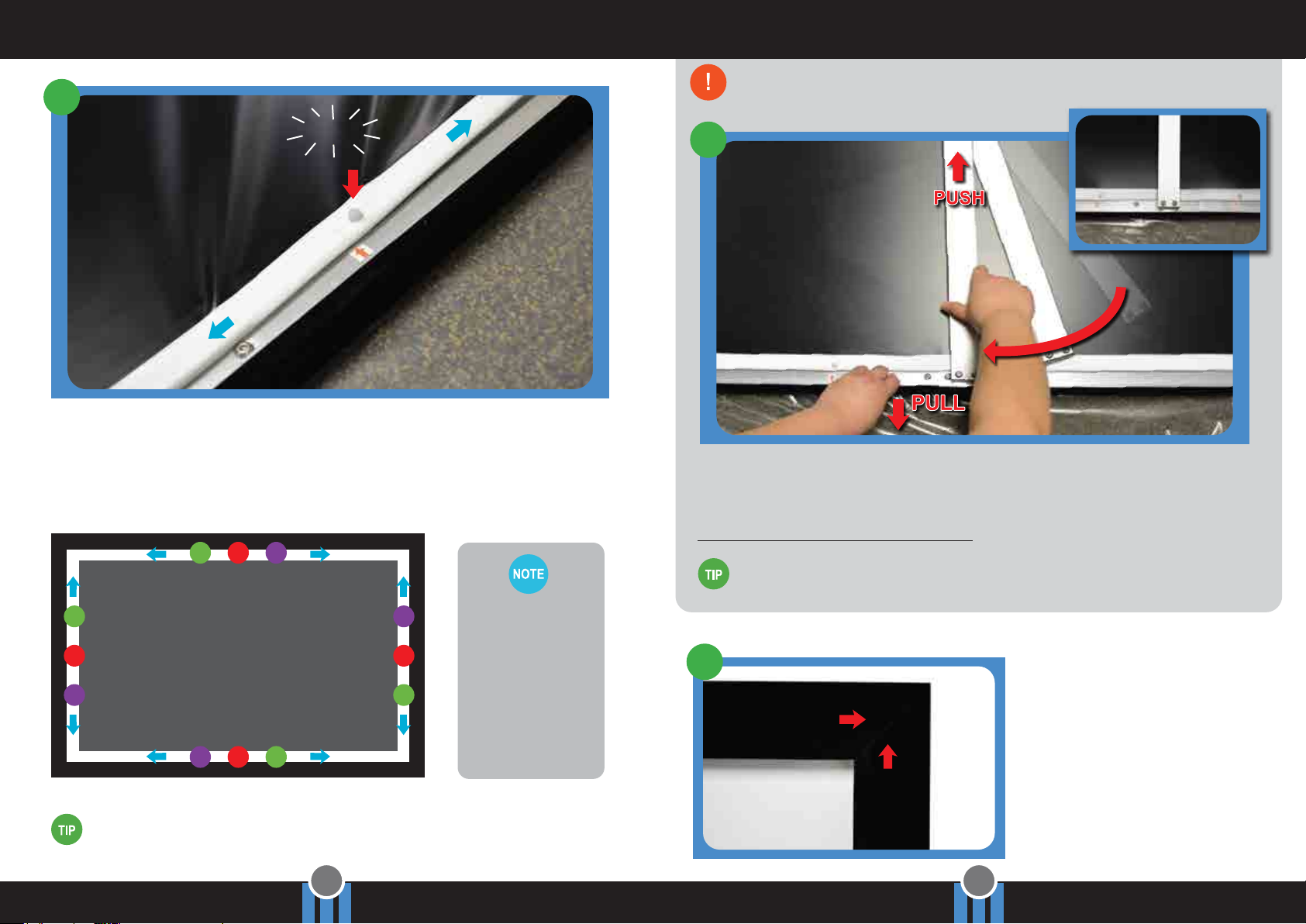

Locate the Wooden Studs

This step applies to wooden stud wall installation only. Determine and mark the exact

locations of two stud centers on the wall. Wooden studs should be spaced so that the

weight of the screen is distributed evenly. In order to achieve this, mark the studs that

are separated by at least one-third to one-half of the projector screen’s total width.

15

For example: if the projector screen is 100" wide, look for two studs that are spaced

between 33" to 50" apart. Stud spacing 48" apart would be ideal in this case.

1/4"

IMPORTANT Verify that each Hanging Bracket is properly secured before releasing

the projector screen to avoid injuries and property damages.

Mark the Drill Locations for the Hanging Brackets

Different wall types require

different types of hardware.

Hardware is included for wooden

stud and concrete wall mounting

only. For other wall types, please

consult a professional.

Wooden Stud Wall Mounting: using a power drill

and 3/32" drill bit, drill pilot holes of 3/32" (2.38 mm)

diameter and approx. 1.18" (30 mm) depth. Secure

each Wall Mounting Screw by using a socket

wrench, leaving about 1/4" of thread exposed.

Concrete Wall Mounting: using a power drill and a

3/8" masonry drill bit, drill mounting holes of 3/8"

(10 mm) diameter and approx 1.18" (30 mm) depth

at the marked locations. Insert Concrete Anchors

and hammer them into the wall, secure each Wall

Mounting Screw by using a socket wrench, leaving

about 1/4" of thread exposed. Socket

Wrench

Do not use power drill to

fasten the Mounting Screws.

Use the anchors provided

for concrete wall mounting only.

Do not use them for drywall.

Also, use socket wrench for Wall

Mounting Screws to prevent

damages to the screw heads.