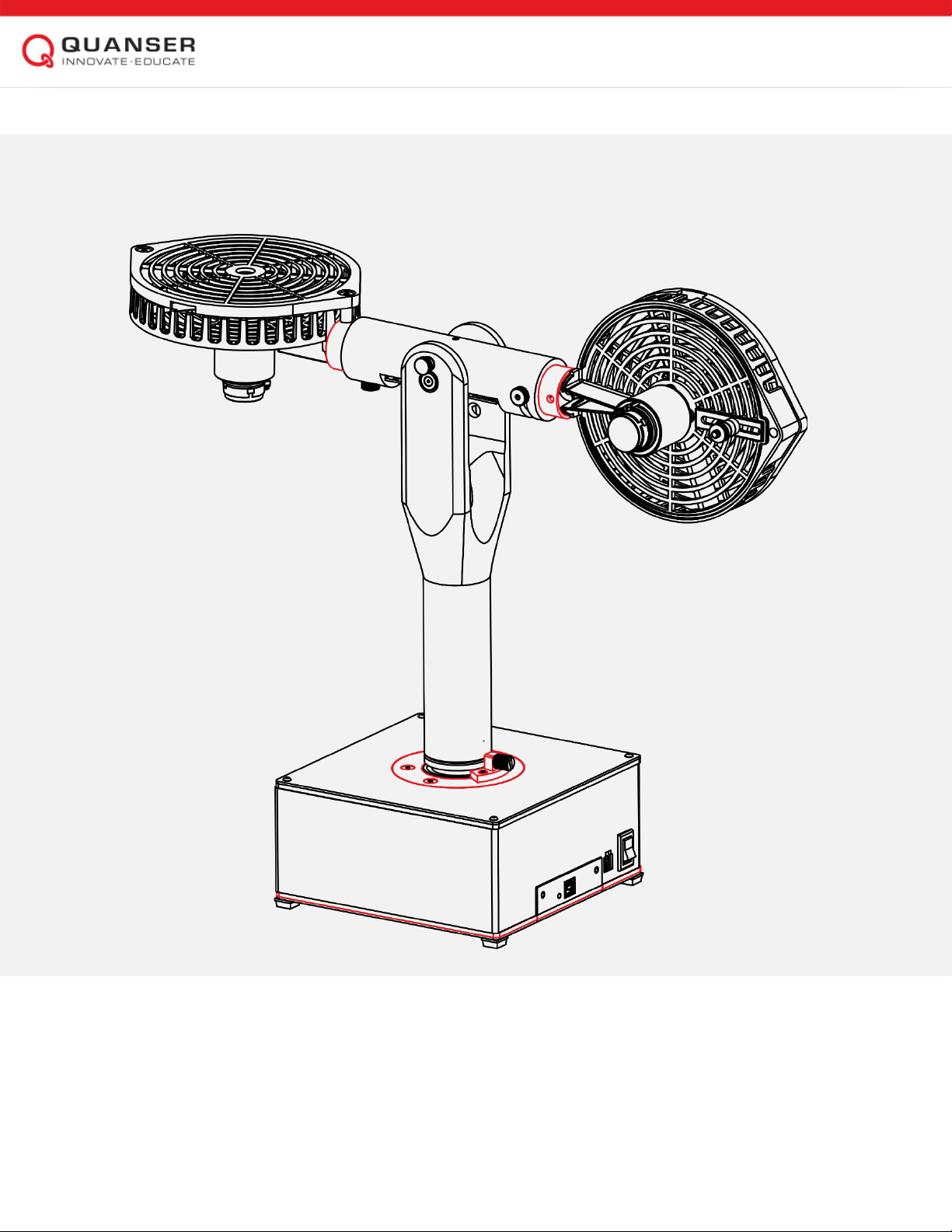

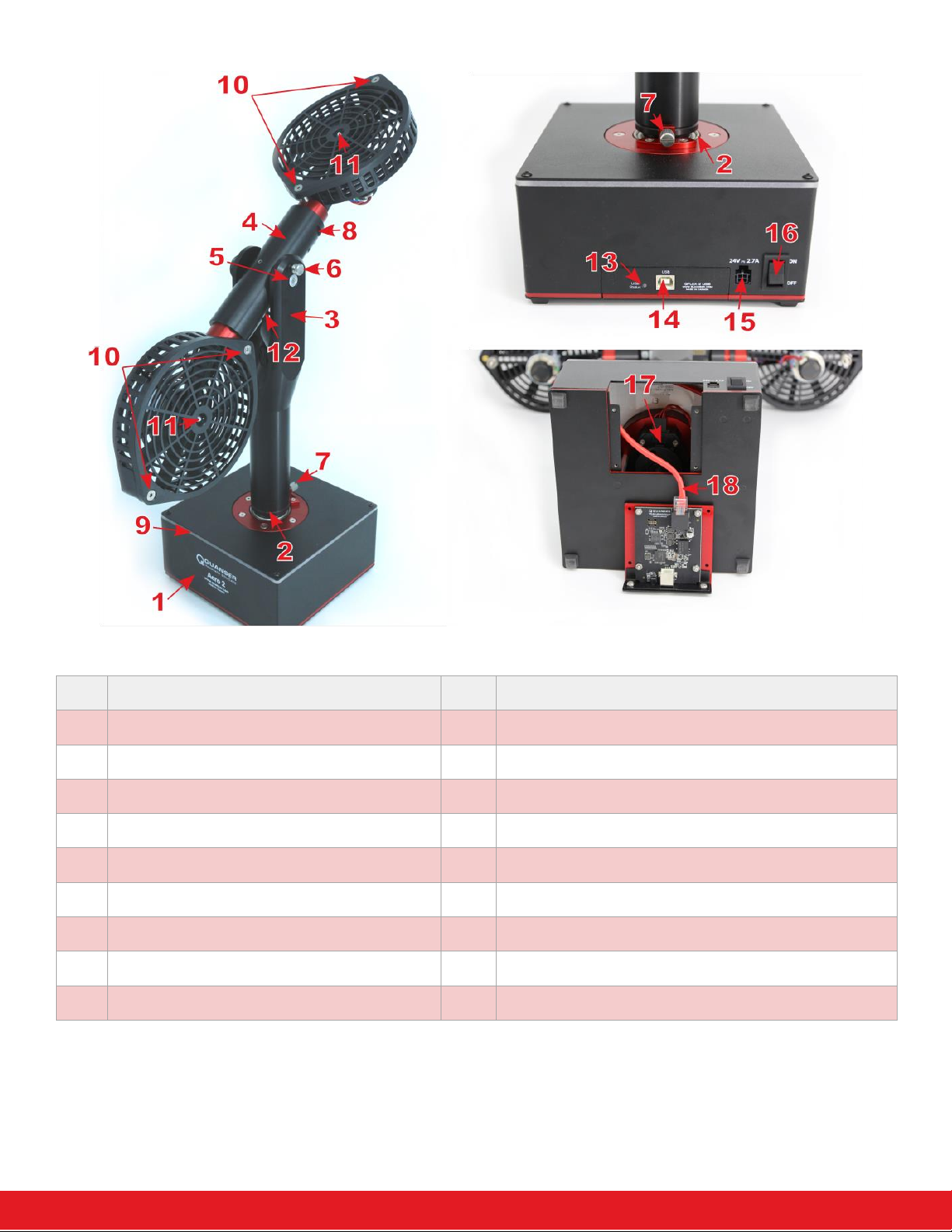

Hardware Components

i. DC Motors

The Quanser Aero 2 includes two direct drive 18V brushed DC motors. The motor specifications are given in Table 2.2.

The Quanser Aero 2 contains two Allied Motion CL40 Series Coreless DC Motors, model 16705. The complete

specification sheet of the motor is available at: http://alliedmotion.com/Products/Series.aspx?s=29.

ii. Propellers

The Quanser Aero 2 ships with two eight-vane counter-rotating 3D printed propellers. These propellers have been

specially designed to have high dynamic coupling. As such they will apply a strong cross-torque during thrust. These

propellers are manufactured custom for Quanser and can be replaced by contacting your local Quanser distributor.

If a more efficient, but less coupled configuration is desired, the Aero 2 also ships with high-efficiency propellers. The

high-efficiency propellers are APC 5.0x4.6 propellers, models LP05046E/EP. More information on the propellers can

be found on the Advanced Precision Composites website (www.apcprop.com).

Both propeller types are mounted to the thruster motors using aluminum prop adapters with collets. The propeller

adaptors are E-flite part number EFLM1922.

iii. Encoders

There are three different types of encoders on the Quanser Aero 2.

The encoders used to measure the pitch of the Aero body and the angular position of the DC motors on the Quanser

Aero 2 are single-ended optical shaft encoders. The motor encoders output 2048 counts per revolution in quadrature

mode (512 lines/rev). This encoder is the US Digital E8P-512-118 single-ended optical shaft encoder. While the pitch

encoder is 2880 counts per revolution in quadrature mode (720 lines/rev) consisting of a US Digital E8P-720-118 single-

ended optical shaft encoder.

The final encoder is used to measure the yaw position of the support yolk is the US Digital E3-1024-984 optical encoder,

which outputs 4096 counts per revolution in quadrature (1024 lines/rev)

iv. Inertial Measurement Unit (IMU)

The Quanser Aero 2 includes an integrated IMU mounted on the Aero core board. This module allows for real-time

measurement of the angular position and velocity about all three of the primary axes of the Aero body. The

accelerometer has a 16-bit, +/-8g range and the gyroscope has a 16 bit, +/-500 deg/s range.

The IMU incorporated into the Quanser Aero 2 is the TDK IIM-42652 inertial module.

v. Power Supply

The Quanser Aero is equipped with an external DC power supply which provides 24.0 V power at up to 2.71 A for the

sensors and motors. This supply is intended for use with 100-240 VAC at 50-60 Hz.

Only the provided power supply and AC cord should be used with the Quanser Aero 2. The included supply is a

TRUMPower model TTA65-24E-M4SG.