1 PRESENTATION

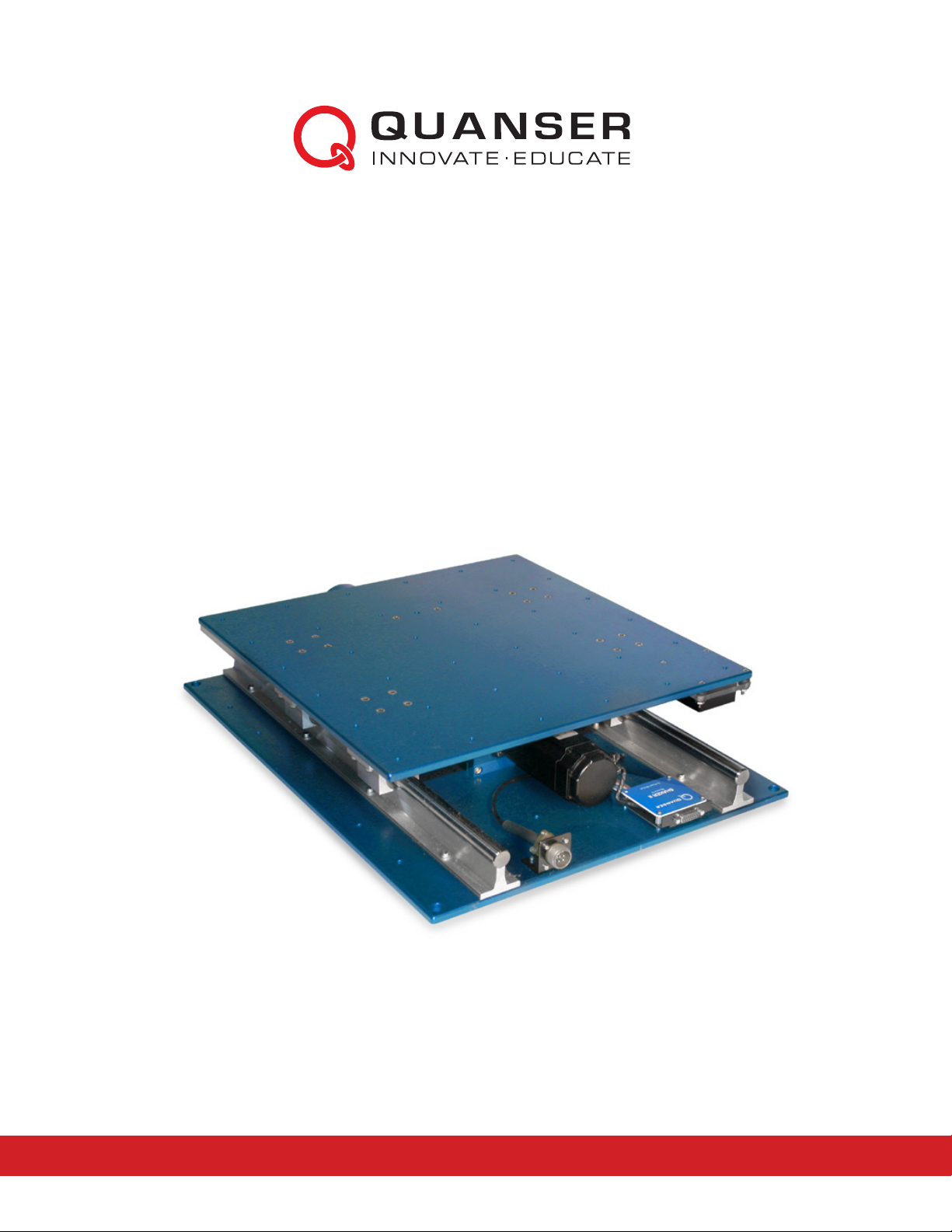

The Quanser Shake Table II (STII) shown in Figure 1.1 is an instructional shake table device that was originally

developed for the University Consortium on Instructional Shake Tables (UCIST). It can be used to teach structural

dynamics, vibration isolation, feedback control, and various other topics for mechanical, aerospace, and civil engi-

neers.

The shake table is rated to drive a 7.5 kg load at 2.5 g. The stage rides on two ground-hardened metal shafts

using linear bearings which allows for smooth linear motions with low path deflection. When starting from center the

stage is capable of moving ±7.62 cm, or ±3-inches (i.e., total travel of 15.24 cm). The 400 Watt 3-phase brushless

DC actuator is connected to a robust ball-screw assembly. The motor has an embedded high-resolution encoder

used to measure stage position with a resolution of 3.10 µm. An analog accelerometer is mounted to measure the

acceleration of the stage directly.

Figure 1.1: Quanser Shake Table II

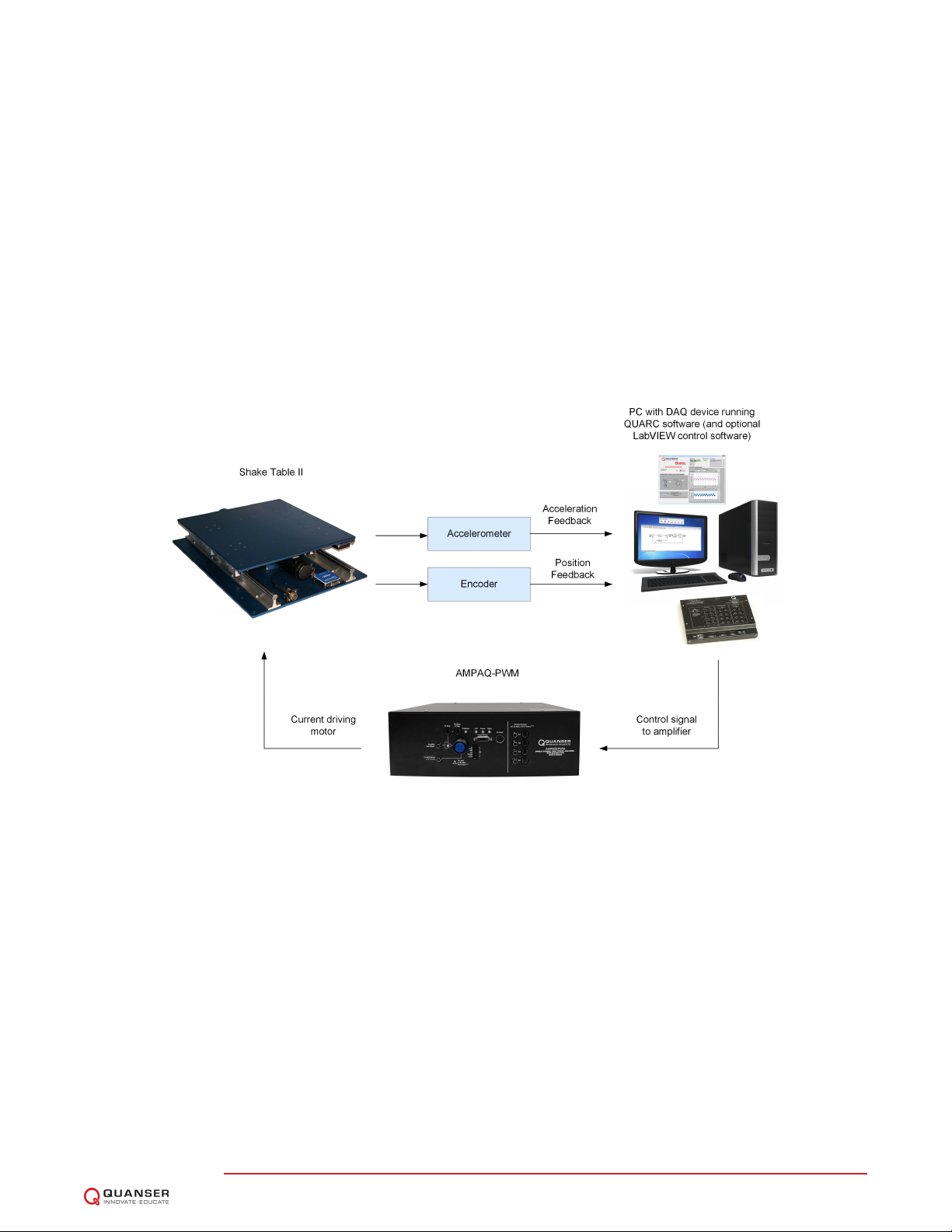

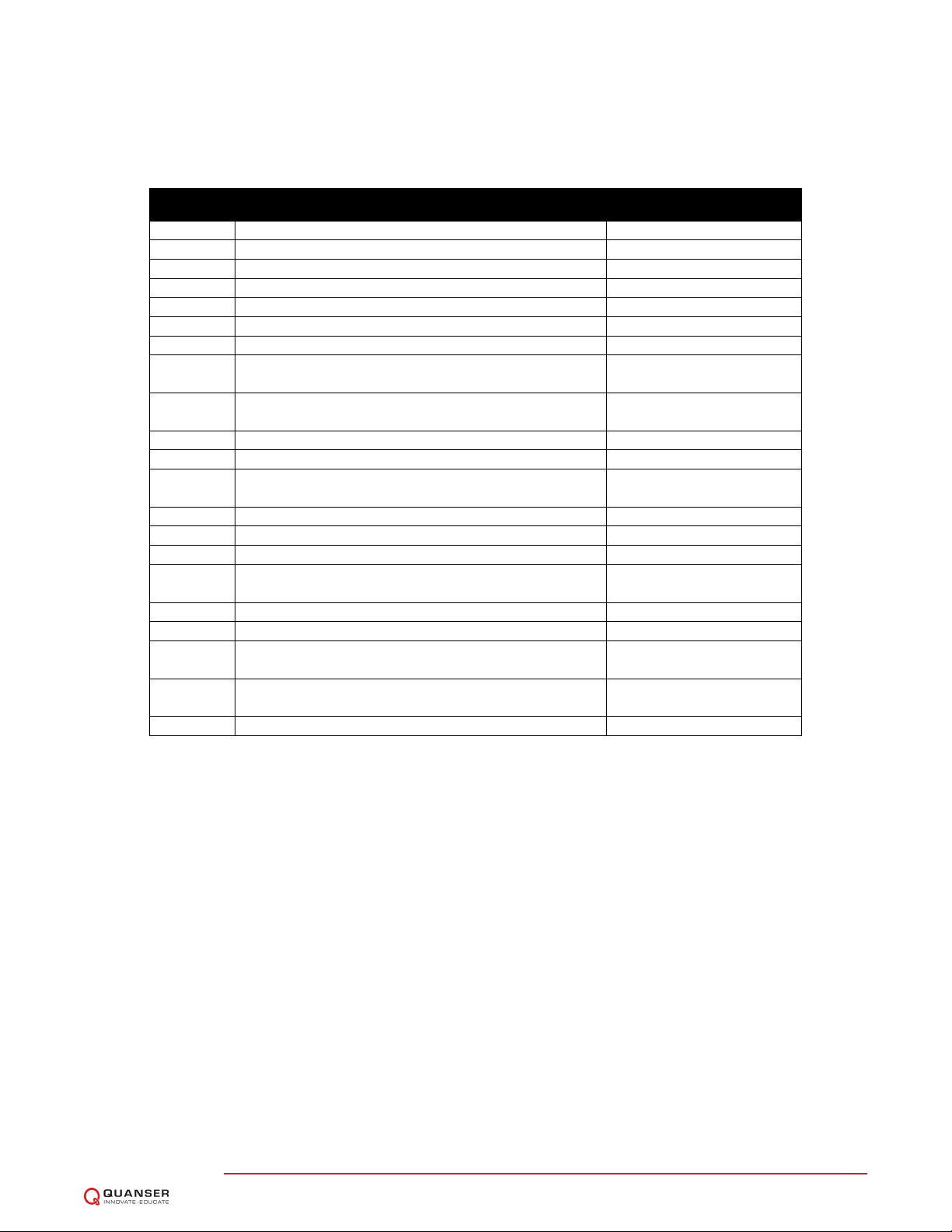

The main devices used to run the shake table is depicted in Figure 1.2. The entire system is comprised of:

1. Quanser Shake Table II

2. Power amplifier: Quanser AMPAQ-PWM

3. Data acquisition (DAQ) device: Quanser Q2-USB, Q8-USB, or QPIDe.

4. PC running QUARCrsoftware (optional: LabVIEW™ -based STII Control Software)

The interaction between the different system components is shown in Figure 1.2. Using QUARCror the optional

LabVIEW™ -based Control Software on the PC/laptop, the user specifies a command signal to the shake table (e.g.,

sine wave, earthquake). The current needed to move the stage to the desired position is calculated in QUARCr

and sent through the analog output channel of the DAQ device to the power amplifier. The amplifier applies the

current and drives the motor on the Shake Table II. The table tracking the commanded signal and the resulting

displacement and acceleration of the stage are measured by the on-board encoder and the accelerometer sensors.

The encoder and accelerometer are connected to the DAQ and their signals can be displayed and processed further

in QUARCror the optional LabVIEW™ -based Control Software. Plotted data can be also be saved for later analysis.

Caution: This equipment is designed to be used for educational and research purposes and is not

intended for use by the general public. The user is responsible to ensure that the equipment

will be used by technically qualified personnel only.

Caution: The Shake Table II is very loud when in operation. Please use ear protection when working in close

proximity to the shake table, or isolate the shake table in a sound proof enclosure where available.

STII User Manual 4