Wel ome to Quill Fal on 3

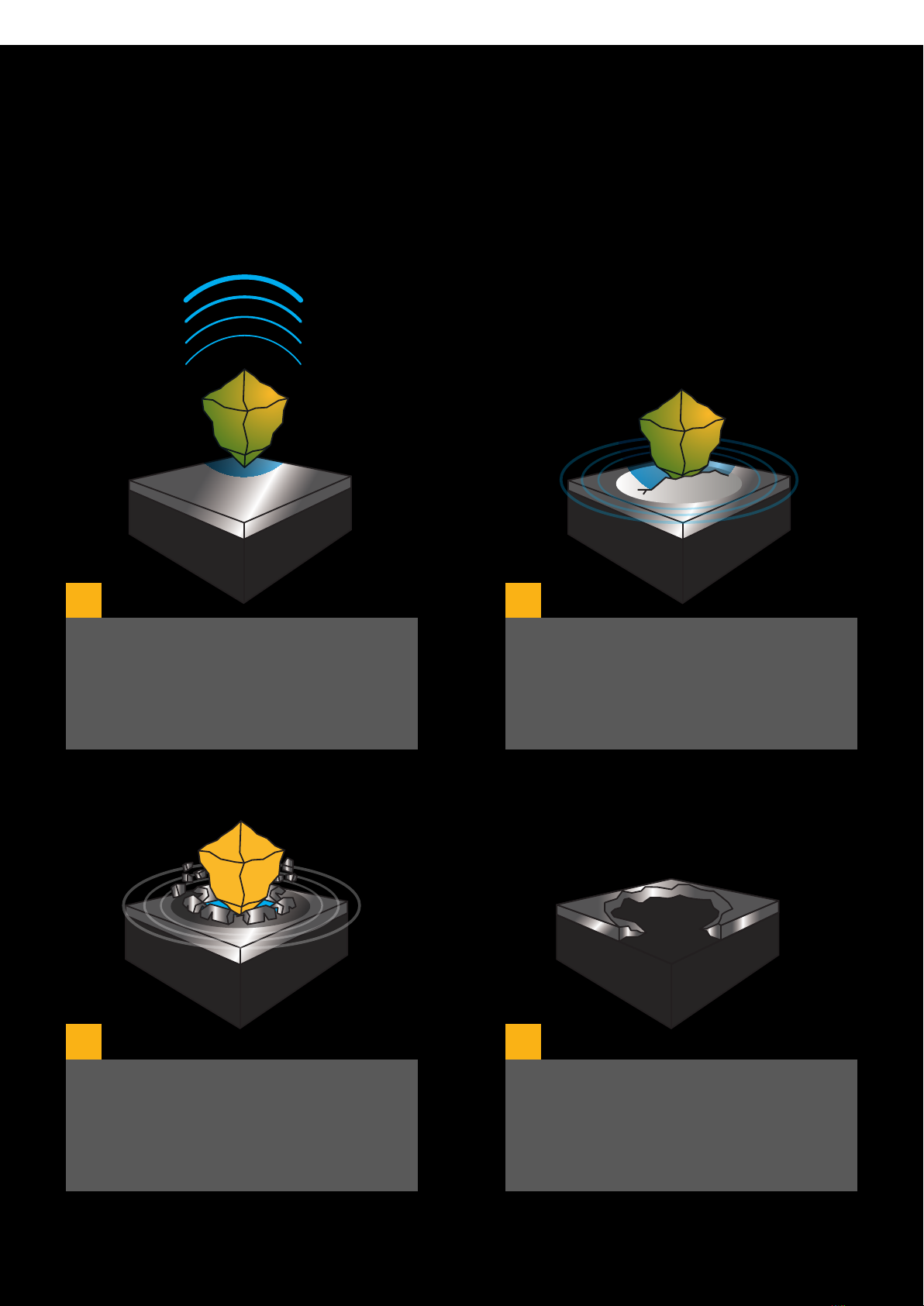

How does the Quill Fal on Cy lone work? 4

Why is the Quill Fal on Cy lone better than a wet or dry blaster? 5

Quill Fal on Cy lone appli ations 6

Quill Fal on Cy lone produ t range 8

Getting started with the Quill Fal on Cy lone 12

Additional produ ts 14

Quill Fal on Cy lone safety guidelines 16

Quill Fal on Cy lone Complete safety guidelines 17

Operating the Quill Fal on Cy lone System 18

Quill Fal on Cy lone - Setting up 20

Quill Fal on Cy lone - Filling & refilling 21

Quill Fal on Cy lone - Starting & stopping 22

The Quill Fal on Cy lone Complete Air Breathing operative instru tions 23

Quill Fal on Cy lone troubleshooting 25

Quill Fal on Cy lone daily he k list 26

Quill Fal on Cy lone ordering spares 27

S ott RAS mask and airline breathing harness set 28

S ott RAS mask daily 10 step he k list 29

Quill Fal on Mobile 4 Man Air Breathing Unit 30

Quill Fal on Mobile 4 Man Air Breathing Unit Safety Guidelines 31

Quill Fal on Mobile 4 Man Air Breathing Unit - Setting up 32

Quill Fal on Mobile 4 Man Air Breathing Unit - Getting started 33

Quill Fal on Mobile 4 Man Air Breathing Unit - Shutting down 34

Quill Fal on Mobile 4 Man Air Breathing Unit - Daily he ks 35

Quill Fal on Cy lone bespoke solutions 36

How to hire or buy a Quill Fal on System 37

CONTENTS

Quill_Falcon_Ope ato s_Manual_v18.qxp_Layout 1 24/07/2019 15:58 Page 2