Troubleshooting

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

ElectricalProblems.....................3-2

ElectronicProblems.....................3-3

Error Codes . . . . . . . . . . . . . . . . . . . . . . . 3-3

ServiceMode......................3-5

FirmwareRevision ...................3-5

ControllerKeys.....................3-5

Dislays ........................3-6

Tri-colorDislay ....................3-6

S eed/Grade (O en-Loo Mode) . . . . . . . . . . . . 3-6

HR ClubTrack Plus

™

LCDDislayTest.........3-7

TestingPinSignals...................3-7

HeartRateMonitoringOtion ...............3-8

TestingHeartRateAccuracy ..............3-9

MechanicalProblems....................3-9

WalkBelt........................3-9

DriveBelt....................... 3-10

TreadmillNoise.................... 3-10

FlowCharts........................ 3-10

Repair/Replacement and Calibration

Cautions/Warnings.....................4-1

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

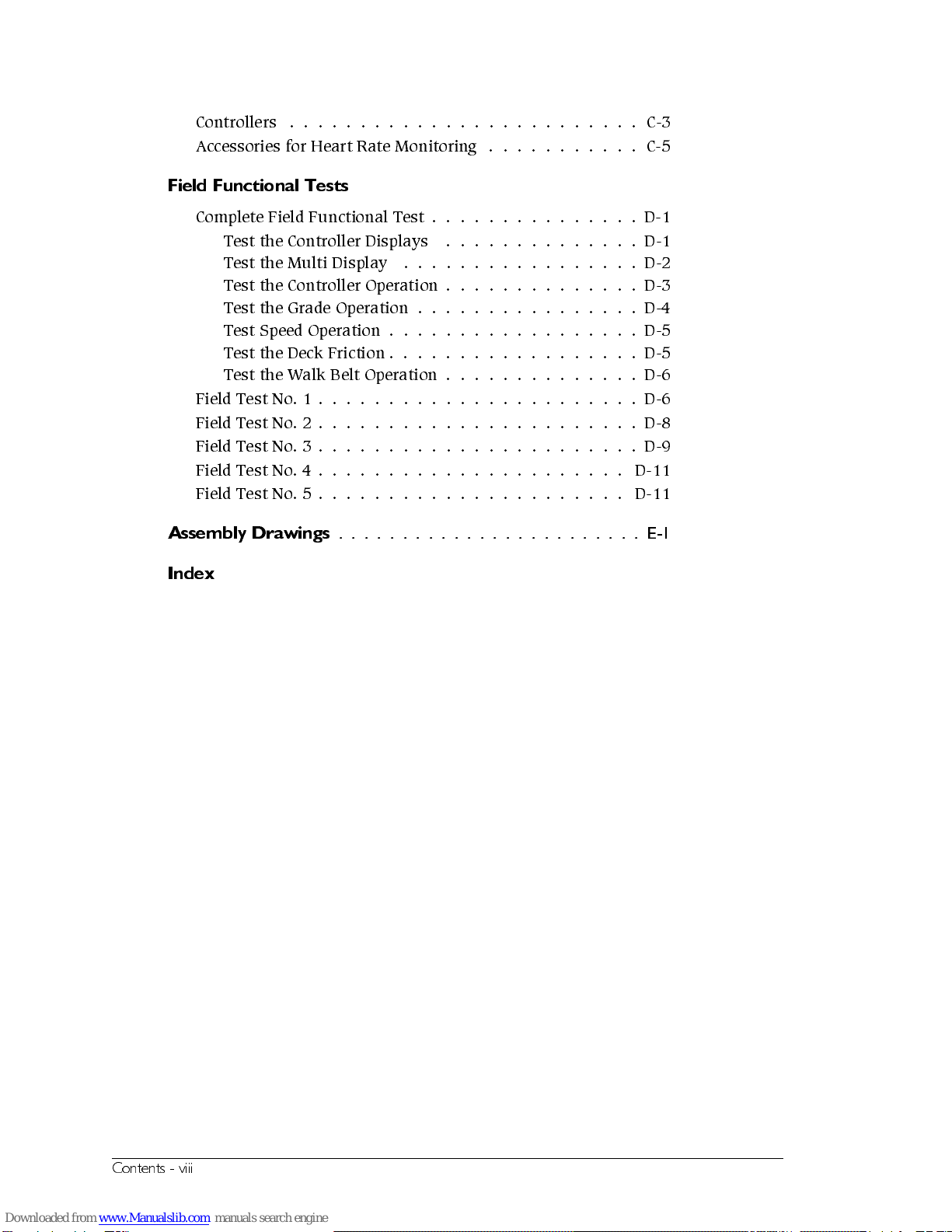

FieldFunctionalTests ...................4-3

RemovingTreadmillHood .................4-3

Re lacing the Configuration Plate . . . . . . . . . . . . . 4-6

RelacingthePowerCord..................4-7

Re lacing the VSD Board/Card Cage Assembly . . . . . . . 4-7

RelacingtheTensioner ..................4-9

RelacingthePoly-VDriveBelt.............. 4-10

Installing the Front Shaft . . . . . . . . . . . . . . . 4-11

RelacingtheDriveMotor ................ 4-11

RelacingtheTransformer................ 4-13

RelacingtheGradeMotor................ 4-14

RelacingtheGradeMotorChain............. 4-15

Re lacing the Grade Potentiometer (POT) . . . . . . . . 4-16

GradePotWires ................... 4-16

RemovingtheRackGears ................ 4-17

ReassemblingtheRackGears .............. 4-18

RelacingaJammedRackGear.............. 4-19

RelacingthePinionShaft................ 4-21

AdjustingtheGradeLimitSwitches ........... 4-22

WalkDeckAssembly................... 4-23

Contents - vi