Preparing the Fuselage

Required Tools and Adhesive

•Xacto Knife, #11 Blade

•Sealing Iron

•Fine line Marker

•Medium CA

Preparing Fuselage

In this step, we are going to remove

covering from the Fuselage which will allow

access for different components in coming

steps.

1. Remove Covering from Fuselage

where wing will be inserted. First

drawing a line about ½” inside the balsa

opening, matching the contour of the

airfoil.

2. Using a Xacto knife with a new #11

blade, cut away covering from both

sides of the Fuselage.

3. Using your Sealing Iron, fold the ½”

covering inward onto balsa wing

opening and seal down in small 1-2”

segments until completed. FIG 1

4. Complete this step if you plan to install

Tuned Pipes/Canisters into your model.

Following procedures from previous

step, simply mark and cut covering ½”

inside the exhaust outlet located on the

bottom of Fuselage. Fold covering

inward and seal to the inside edges of

exhaust opening, you may consider

gluing the edge of covering with a very

small amount of CA to prevent covering

from lifting, due to heat. FIG 2

5. In this step we will cut open the 4

Canopy bolt holes located in the

fuselage (2 per side), using a pointed

#11 blade. First you will need to seal

around each hole then open each hole,

removing covering, with a Xactro knife.

After you have removed the covering

from these holes, re-seal the edges

with your Sealing Iron to prevent

covering from lifting later.

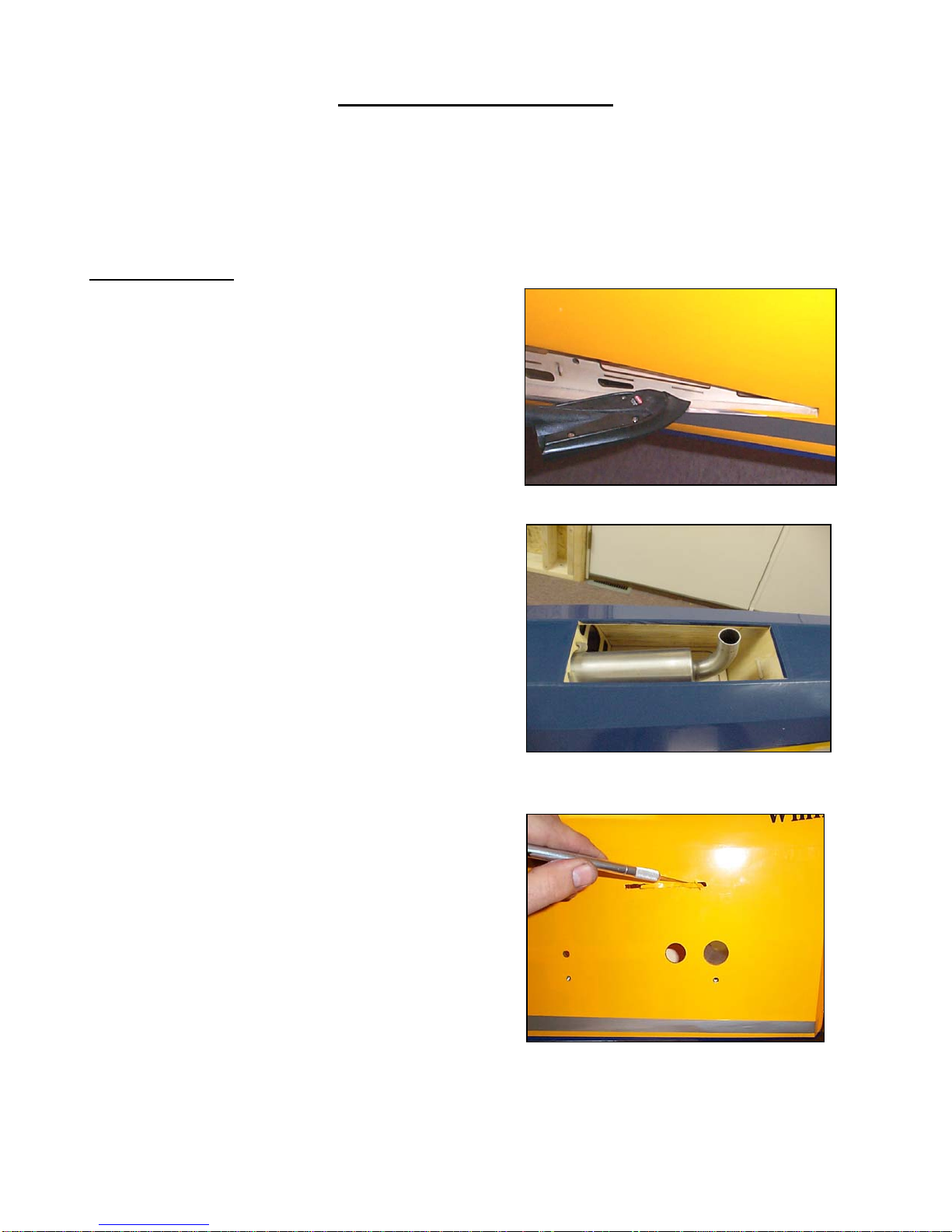

6. In FIG 3, you will need to remove

covering from the following areas on

each side of the Fuselage and seal the

edges with Sealing Iron.

•Rudder pull/pull slots

•Stabilizer tube holes

•Stabilizer bolt holes

•Stabilizer anti rotation pin holes

•Servo lead holes

FIG 1

FIG 3

FIG 2

9