Step 5

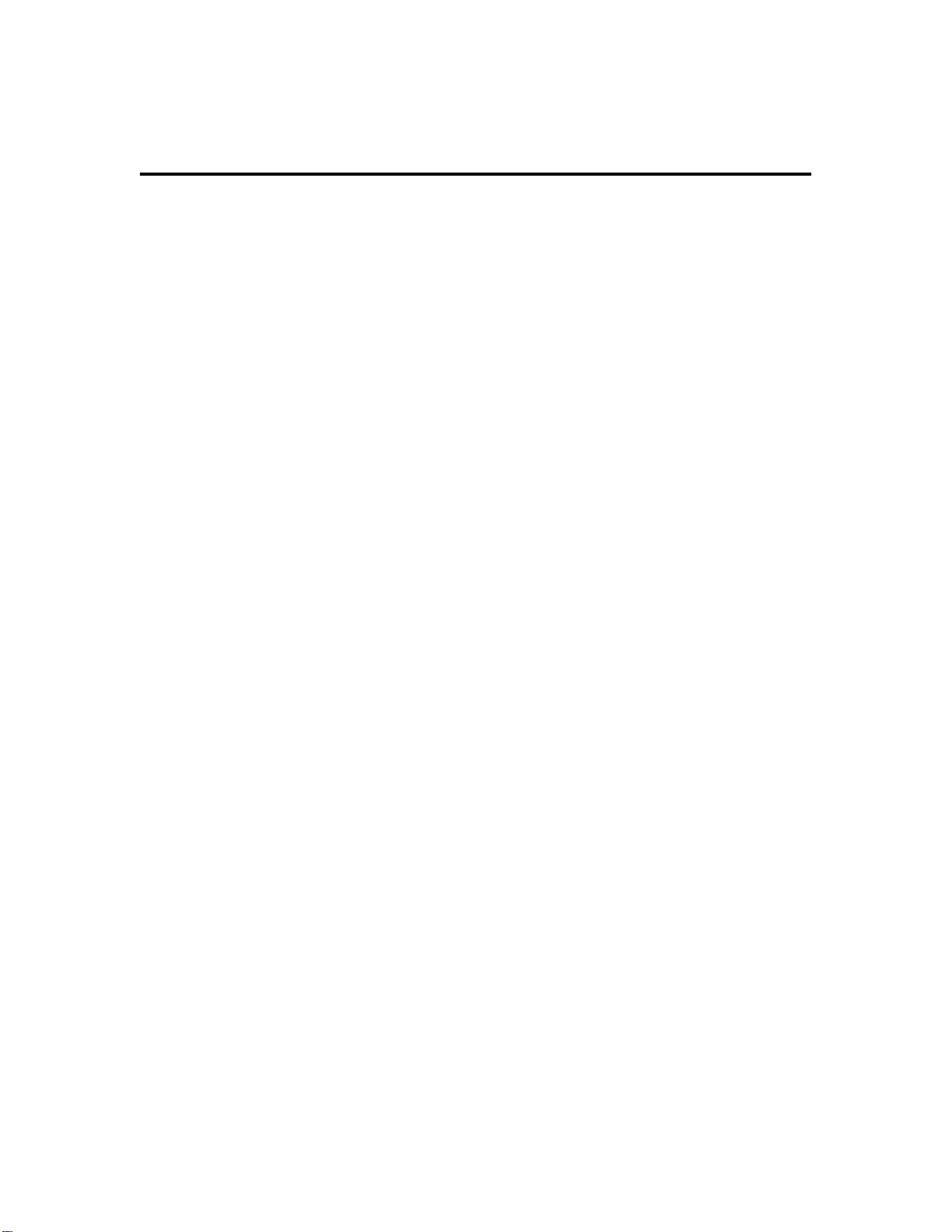

Use a new # 11 blade and gently cut

through the ultra cote. See Figure 5.

There are two layers, cut through the

top layer first and remove it. You

have probably cut through the

second layer. If not you may cut

through the second layer. Be very

careful not to cut into the balsa

sheeting as this will weaken the

structure of the Horizontal Stab as

the skin sheeting is important to its

structural integrity.

Figure 5

Step 6

Use your iron to seal down the Ultra-

cote where you removed the center

section before you make the final

attachment.

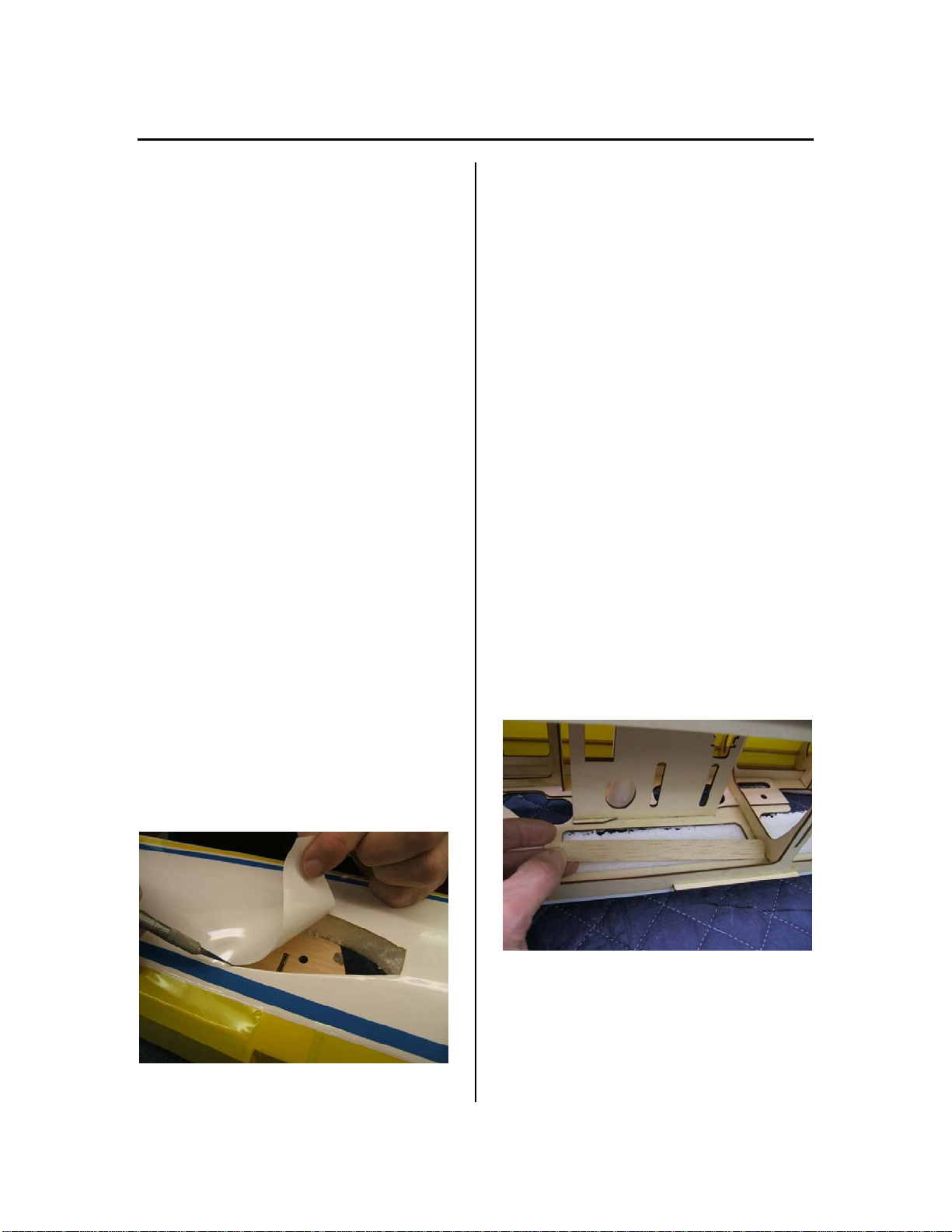

Step 7

Re-insert the H. Stab into the

fuselage. IMPORTANT: Check the

measurements again, see Figure 3 &

Figure 4 to make sure the H. Stab is

square. Before you make the final

attachment of the H. stab to the fuse,

you must check to see that the H.

stab is parallel with the wing.

To do this, you may sight down the

fuselage from the rear.

See Figure 6. Make sure you are

looking straight down the middle of

the fuse.

Figure 6

Step 8

Sight both sides of the H. stab and

compare with both sides of the wing.

If one side is lower and the other

higher, you will need to shim so both

the H. stab and the wing halves are

parallel. Our prototype needed a little

adjustment. We used a round

toothpick to wedge the one side

down a little. It was not enough so

we used another round tooth pick on

the other side of the fuse on the

opposite side to bring the H. stab

parallel with the wing. See Figure 7.

It should not take much shimming to

get it perfect. It is almost impossible

for our OEM to assemble this fuse so

that the H. stab and wing are always

parallel. You can see that the little

wedges with the round toothpicks

can correct this small problem with

very little adjustment. Now you are

ready to glue in place.

10