R.M. Young 61302V User manual

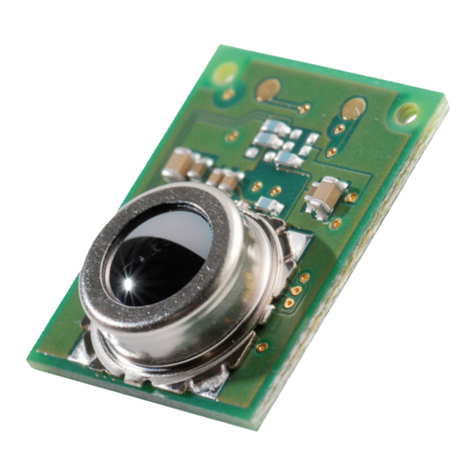

MODEL 61302V

BAROMETRIC PRESSURE SENSOR

INSTRUCTIONS

R.M. YOUNG COMPANY

2801 AERO PARK DRIVE, TRAVERSE CITY, MICHIGAN 49686, USA

TEL: (231) 946-3980 FAX: (231) 946-4772

PN: 61302V-90

REV: I111215

1.0 SPECIFICATIONS

Pressure 500 to 1100 hPa standard range

Digital Accuracy* 0.2 hPa (25°C)

0.3 hPa (-40°C to +60°C)

Analog Accuracy** 0.05% of analog pressure range

Analog Temperature

Dependence** 0.0017% of analo g pressure

range per °C (25°C reference)

Long Term Stability: 0.2% FS per year

*

Dened as ±1 standard deviation from NIST-traceable

pressure reference in clean, dry air. Includes non-

linearity, hysteresis, repeatability, and calibration

uncertainty.

**Defined as ±1 standard deviation from ideal analog

output. Total analog output accuracy is the root sum

square of digital accuracy, analog accuracy, and

analog temperature dependence.

Output Rate 1.8 Hz (max) to 1 per minute

Voltage Output 0 to 5000 mV (standard)

0 to 2500 mV

12-bit resolution (1 in 4000)

Selectable pressure range:

500 to 1100 hPa (standard)

Serial Output Full duplex RS-232

1200 to 38400 baud

Continuous ASCII text

Polled ASCII text

NMEA

0.01 hPa resolution

Supply Voltage 7 to 30 VDC

2.8 mA with Vout (standard)

1.4 uA shutdown (Trig=0V)

7 mA with serial I/O

Case Fiber-reinforced thermoplastic

Weight 44 g (1.5 oz)

Better effective resolution may be achieved by mapping

the voltage output to a narrower range of pressure with

the VOUT HI and VOUT LO parameters. For example, with

VOUT LO set to 950 hPa and VOUT HI set to 1050 hPa and

the VOUT Scale set to 0-5000 mV:

hPa = 0.02 * mV + 950

Effective resolution is about 0.025 hPa

Please see section 4.3 below for details on changing the

VOUT HI and LO parameters.

With jumper P4 configured for voltage output, a special

TRIG input may be used to control barometer power. When

TRIG=0V, all processes cease and power consumption is

reduced to 1.4uA. When the voltage on TRIG > 1.8V (or left

floating), normal operation resumes with a powerup reset.

The TRIG input connection is optional. It may be connected

to +PWR or left floating.

4.2 SERIAL OUTPUT

Jumper settings and software parameters determine

RS-232 serial communication format. The Appendix A Wiring

Diagram shows jumper locations and function.

P1 A/B/C sets output format, baud rate, output rate, and

averaging.The table below summarizes P1 configurations.

P3 A/B sets RS-232 hardware function. AUTO (A) enables

RS-232 hardware when valid standard RS-232 signals

are present at RX and TX. When not present, the RS-232

hardware is disabled to save power. FIXED (B) enables RS-

232 hardware at all times so it can be used with some non-

standard RS-232 signals.

P4 A/B configures the terminal connections for RS-232.

Both jumpers must be in position A for RS-232 serial

communication.

Format Description

Continuous ASCII

Text

(standard)

9600 baud

10 sample average

1.8 Hz output

Polled ASCII Text 9600 baud

10 sample average

Output when polled

Marine NMEA 4800 baud

10 sample average

1Hz output

Software Output parameters determined by

software settings

Note that NMEA output is normally specified to work on RS-

422 and RS-485 networks. The NMEA output here conforms

to the standard data format but the electrical connection

uses RS-232 signal levels.

In POLLED ASCII mode, the unit sends data only after

receiving a poll command. The poll command is Ma! where

‘a’ is the address value. The standard address is ‘0’ (ASCII

48) for a poll command of M0! Please see section 4.3 for

details on changing the poll address.

Standard baud rate is 9600 but any of several available

baud rates between 1200 and 38400 may be used.

2.0 INTRODUCTION

MODEL 61302V Barometric Pressure Sensor is a versatile

electronic barometer featuring high accuracy, low power,

wide operating temperature range, and calibrated voltage

output or RS-232 serial data I/O.

Low power consumption and wide temperature range make

the 61302V ideal for remote applications using battery or

solar power.

Full scale voltage output may be set to span any portion

of the 500 to 1100 hPa operating range. RS-232 serial

I/O options include continuous or polled ASCII text output

or NMEA marine output. The sensor is supplied with the

following standard configuration:

Voltage output

0 to 5000 mV = 500 to 1100 hPa

10 samples averaged

1.8 Hz update rate

3.0 INSTALLATION

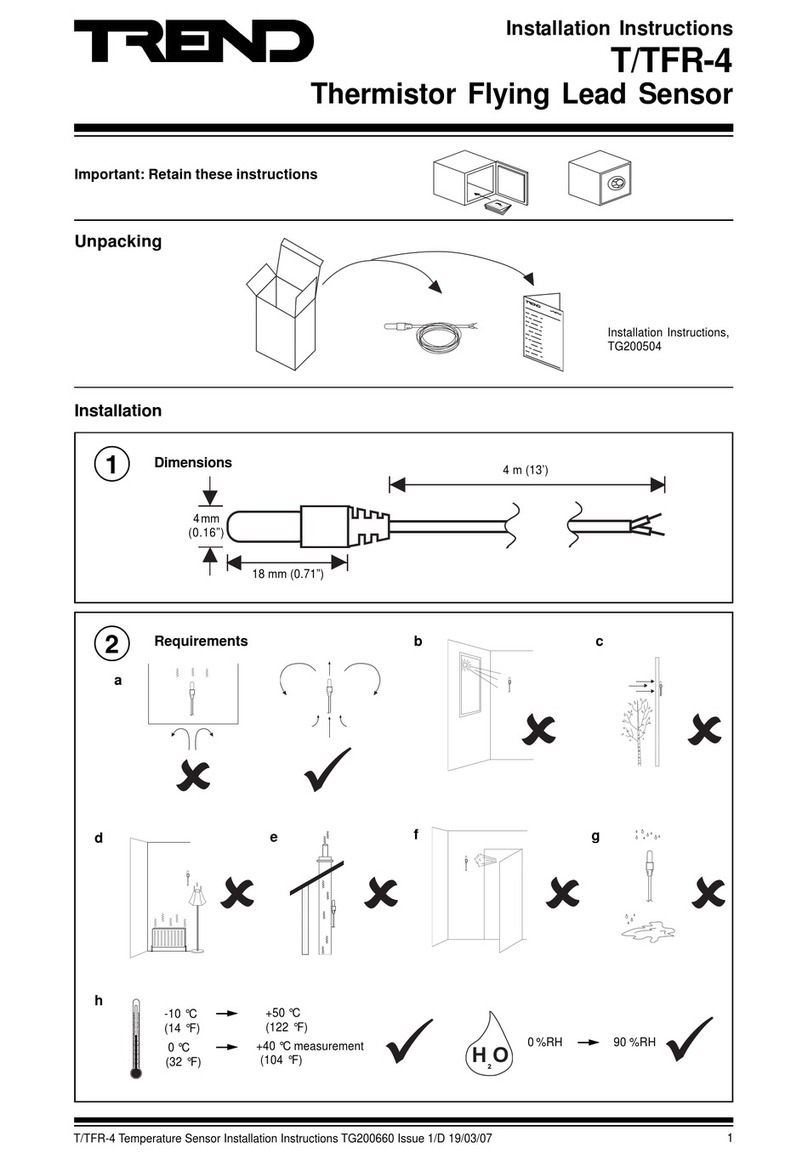

The sensor operates over a temperature range of -40°C to

+60°C and must remain dry.

Electrical connections are made with the 5-position terminal

plug included with the sensor. Jumper settings may be used

to select operating options. Access jumpers by loosening

two screws in the sensor enclosure and removing the cover.

See Appendix A for wiring details and jumper settings.

If changed from the standard configuration, please note that

the software Vout Scale parameter must be set to agree with

the hardware Voltage Output Scale jumper (P3) in order to

achieve calibrated output.

4.0 OPERATION

Operation begins approximately 1 second after power is

applied. Output will appear after a delay determined by

the number of samples averaged and the output rate. With

default values (1.8 Hz output and 10 samples averaged),

outputs will begin after an initial 5 second delay then remain

continuous at the 1.8 Hz rate. Parameters for output rate

and number of samples averaged may be changed using

software commands.

4.1 VOLTAGE OUTPUT

Hardware jumpers and software parameters determine

voltage output operation. Appendix A shows jumper

configurations.

Both P4 jumpers must be in position B for voltage output.

Jumper P 3 sets the Voltage Output Scale to either

0-5000 mV or 0-2500 mV. Please note that jumper P3 must

agree with the software Vout Scale parameter in order to

achieve calibrated output.

The voltage output scale may be mapped to any part of the

500 to 1100 hPa pressure range using the VOUT HI and

VOUT LO software parameters. The standard setting maps

0 to 5000 mV with 500 to 1100 hPa. With this setting:

hPa = 0.12 * mV + 500

Effective resolution is about 0.15 hPa

4.3 SOFTWARE COMMANDS

Software commands sent via serial communication may be

used to set operational parameters. The sensor must be

configured for serial communication and connected to a PC

or other compatible device using a program like HyperTerm.

New settings are stored in temporary memory and

must be burned to flash with command CMD420 to be

retained.

Note that the P 1 jumper must be configured for

SOFTWARE format to alter baud rate, sample average

count, and output rate parameters.

Although the sensor may receive commands at any

time, measurement output may be paused by sending

three ESC (ASCII 27) characters or CMD300 1. While

paused, COMMAND mode is indicated by a “>” prompt.

All commands must be terminated with a carriage return

CR (ASCII 13).

Use “?” to list available commands as shown below.

>?

YOUNG 61300 SERIES BAROMETER V2.03

----------------------------------------

CMD100 n OUTPUT PERIOD (0-60 sec)

CMD105 n AVG SAMPLE COUNT (0-32)

CMD110 n OUTPUT FORMAT

(1=ASCII 2=POLLED 3=NMEA 4=RAW 5=DIAG)

CMD120 n MULTIPLIER (10000 = 1.0000)

CMD125 n OFFSET (hPA x 100)

CMD130 n SEA LEVEL CORRECTION (hPA x 100)

CMD140 n VOUT RANGE HI (500-1100)

CMD142 n VOUT RANGE LO (500-1100)

CMD144 n VOUT SCALE (2=2.5V 5=5V)

CMD150 c POLL ADDR CHAR

CMD160 n BAUD RATE (38400,9600,4800,2400,1200)

CMD300 n 1=STOP, 2=RUN

CMD310 n FORCE VOUT (0-5000 FULL SCALE)

CMD400 n 1=RPT TEXT, 2=RPT CODE ONLY

CMD410 GET CAL TABLE

CMD420 STORE SETUP PARAMETERS

>

CMD100 n sets output period in seconds. When set to zero,

the output rate is about 1.8 per second.

CMD105 n sets the average sample count. Higher sample

count yields more stable readings but will lengthen

the startup delay.

CMD110 n sets output format. RAW and DIAG settings are

for factory use only.

CMD120 n sets the output multiplier. 10000 represents

1.0000

CMD125 n sets the output offset in hPa x 100

CMD130 n sets the sea level correction in hPa x 100

=[Punadjust *( Mult / 10000)] + [(Offset /100) + (Correction Sea Lvl / 100)]

CMD140 n sets the Vout Pressure Range HI

CMD142 n sets the Vout Pressure Range LO

Vout Pressure Range HI must be greater than Vout

Pressure Range LO

CMD144 n sets the Vout Scale. 2 = 0 to 2500 mV. 5 = 0

to 5000 mV. This parameter setting must agree with

the physical P3 jumper position to achieve calibrated

voltage output.

CMD150 c sets the poll address character. Any ASCII

character from ‘0’ (ASCII 48) to ‘z’ (ASCII 122) may

be used.

CMD160 n sets the baud rate. Acceptable values are

38400, 9600, 4800, 2400, and 1200. Note that the

baud rate change occurs immediately after the

command is received. Therefore, in order to continue

communicating, the serial communication program

that issued the command must also change to match.

CMD300 n causes the sensor to pause or resume

measurement. 1 = Stop, 2 = Run.

CMD400 n causes the sensor to issue a report

summarizing parameter settings.

1 = RPT text

2 = RPT code only

CMD410 retrieves the internal calibration table. This is for

factory use only.

CMD420 burns new parameter settings to flash memory.

This step must take place to retain changes otherwise

parameters will revert to the previous values at the

next powerup.

5.0 MAINTENANCE

The MODEL 61302V barometer requires no regular

maintenance. Periodic calibration certification, if required,

is available from the factory.

6.0 WARRANTY

This product is warranted to be free of defects in materials

and construction for a period of 12 months from date of

initial purchase. Liability is limited to repair or replacement

of defective item. A copy of the warranty policy may be

obtained from R. M. Young Company.

7.0 EMC COMPLIANCE

This device complies with Part 15 of the FCC Rules. Operation

is subject to the following two conditions: (1) this device may

not cause harmful interference, and (2) this device must accept

any interference received, including interference that may cause

undesired operation.

This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to part 15 of the

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment

is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be

required to correct the interference at his own expense.

This ISM device complies with Canadian /CES-001.

Cet apparei/ISM est conforme a Ia norme NMB-001 du Canada.

EN55011/CISPR 11, Group 1, Class B device

Class B equipment is suitable for use in domestic establishments

and in establishments directly connected to a low voltage power

supply network which supplies buildings used for domestic

purposes.

8.0 CE COMPLIANCE

This product has been tested and complies with European

CE requirements for the EMC Directive. Please note that

shielded cable must be used.

APPENDIX A

61302V BAROMETER

TYPICAL WIRING CONNECTIONS

Table of contents

Other R.M. Young Accessories manuals