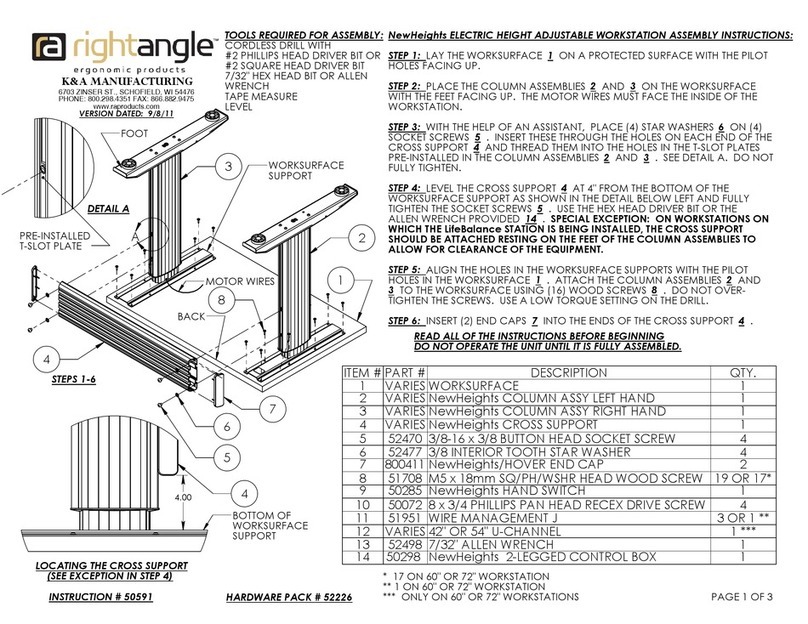

RAISE COLU N

COVER 6"-8"

WELD NUTS SLIDE

INTO THIS GROOVE

ITE # PART # DESCRIPTION QTY.

A 53025 5/16 LOCK WASHER 4

B 53024 5/16-18 x 1/2 BUTTON HEAD SOCKET SCREW 4

C 52963 5/16-18 WELD NUT 4" CL'S 2

D VARIES SERIES 4 CROSS SUPPORT 1

E 800934 CROSS SUPPORT END CAP 2

PAGE 4 OF 4

VERSION DATED 2/20/14

STEP 9: PLUG THE POWER CORD FRO THE CONTROL BOX INTO A STANDARD 110 VOLT RECEPTACLE. A POWER

SURGE PROTECTOR IS RECO ENDED.

STEP 10: THE CROSS SUPPORT D IS AN OPTIONAL ACCESSORY. IF YOUR WORKSTATION INCLUDES A CROSS

SUPPORT, RAISE THE WORKSTATION TO ITS HIGHEST LEVEL. RE OVE THE BLACK PLASTIC CAPS FRO THE

OUTER OST PART OF THE LEG ASSE BLIES AND RAISE THE 6"-8" ABOVE THE TOP OF THE EXTRUSIONS. SEE

DETAIL A.

STEP 11: PLACE (4) LOCK WASHERS A ON (4) SOCKET SCREWS B . THREAD THESE THROUGH THE HOLES AT THE

ENDS OF THE CROSS SUPPORT D AND INTO THE WELD NUTS C . THE PROJECTIONS ON THE WELD NUTS UST

FACE THE BACK OF THE CROSS SUPPORT. DO NOT FULLY TIGHTEN. SEE DETAIL B BELOW. WITH THE HELP OF AN

ASSISTANT, SLIDE THE CROSS SUPPORT ASSE BLY WITH THE WELD NUTS LOOSELY ATTACHED INTO THE GROOVES

AT THE BACK OF THE OUTER COLU NS. SEE DETAIL A.

STEP 12: LOWER THE WORKSTATION TO ITS LOWEST POINT. LEVEL THE CROSS SUPPORT

D AT 4" FRO THE

BOTTO OF THE WORKSURFACE SUPPORT. SEE DETAIL C AT LEFT. FULLY TIGHTEN THE SOCKET SCREWS

B .

STEP 13: INSERT (2) END CAPS E ONTO THE ENDS OF THE CROSS SUPPORT D .

HARDWARE PACK # 53179

DETAIL C

DETAIL A

VERSION DATED 2/20/14

STEP 9: PLUG THE POWER CORD FRO THE CONTROL BOX INTO A STANDARD 110 VOLT RECEPTACLE. A POWER

SURGE PROTECTOR IS RECO ENDED.

STEP 10: THE CROSS SUPPORT D IS AN OPTIONAL ACCESSORY. IF YOUR WORKSTATION INCLUDES A CROSS

SUPPORT, RAISE THE WORKSTATION TO ITS HIGHEST LEVEL. RE OVE THE BLACK PLASTIC CAPS FRO THE

OUTER OST PART OF THE LEG ASSE BLIES AND RAISE THE 6"-8" ABOVE THE TOP OF THE EXTRUSIONS. SEE

DETAIL A.

STEP 11: PLACE (4) LOCK WASHERS A ON (4) SOCKET SCREWS B . THREAD THESE THROUGH THE HOLES AT THE

ENDS OF THE CROSS SUPPORT D AND INTO THE WELD NUTS C . THE PROJECTIONS ON THE WELD NUTS UST

FACE THE BACK OF THE CROSS SUPPORT. DO NOT FULLY TIGHTEN. SEE DETAIL B BELOW. WITH THE HELP OF AN

ASSISTANT, SLIDE THE CROSS SUPPORT ASSE BLY WITH THE WELD NUTS LOOSELY ATTACHED INTO THE GROOVES

AT THE BACK OF THE OUTER COLU NS. SEE DETAIL A.

STEP 12: LOWER THE WORKSTATION TO ITS LOWEST POINT. LEVEL THE CROSS SUPPORT

D AT 4" FRO THE

BOTTO OF THE WORKSURFACE SUPPORT. SEE DETAIL C AT LEFT. FULLY TIGHTEN THE SOCKET SCREWS

B .

STEP 13: INSERT (2) END CAPS E ONTO THE ENDS OF THE CROSS SUPPORT D .

4.000

E

6703 ZINSER ST., SCHOFIELD, WI 54476

PHONE: 800.298.4351 FAX: 866.882.9475

.raproducts.com

K&A MANUFACTURING

NUTS LOOSELY

ATTACH WELD

C

B

DETAIL B

A

D